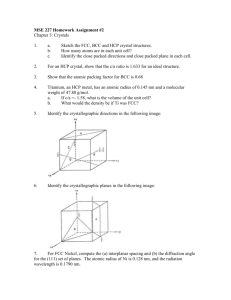

Chapter 3: The Structure of Crystalline Solids ISSUES TO ADDRESS... • How do atoms assemble into solid structures? (for now, focus on metals) • How does the density of a material depend on its structure? • When do material properties vary with the sample (i.e., part) orientation? Chapter 3 - 1 Energy and Packing • __________, ________ packing Energy typical neighbor bond length typical neighbor bond energy • ________, __________ packing r Energy typical neighbor bond length r typical neighbor bond energy ________, _________packed structures tend to have lower energies. Chapter 3 - 2 Materials and Packing ______________ materials... • atoms pack in periodic, 3D arrays • typical of: -metals -many ceramics -some polymers crystalline SiO2 Adapted from Fig. 3.22(a), Callister 7e. __________________ materials... • atoms have no periodic packing • occurs for: -complex structures -rapid cooling ”______________" = Noncrystalline Si Oxygen noncrystalline SiO2 Adapted from Fig. 3.22(b), Callister 7e. Chapter 3 - 3 Section 3.3 – Crystal Systems ___________: smallest repetitive volume which contains the complete lattice pattern of a crystal. crystal systems crystal lattices a, b, and c are the lattice constants Fig. 3.4, Callister 7e. Chapter 3 - 4 Section 3.4 – Metallic Crystal Structures • How can we stack metal atoms to minimize empty space? 2-dimensions vs. Now stack these 2-D layers to make 3-D structures Chapter 3 - 5 Metallic Crystal Structures • Tend to be densely packed. • Reasons for dense packing: - Typically, only one element is present, so all atomic radii are the same. - Metallic bonding is not directional. - Nearest neighbor distances tend to be small in order to lower bond energy. - Electron cloud shields cores from each other • Have the simplest crystal structures. We will examine three such structures... Chapter 3 - 6 Simple Cubic Structure (SC) • Rare due to low packing denisty (only Po has this structure) • Close-packed directions are ____________________. • Coordination # = (# nearest neighbors) (Courtesy P.M. Anderson) Chapter 3 - 7 Atomic Packing Factor (APF) APF = *assume hard spheres • APF for a simple cubic structure = a APF = Adapted from Fig. 3.23, Callister 7e. Chapter 3 - 8 Body Centered Cubic Structure (BCC) • Atoms touch each other __________________________. --Note: All atoms are identical; the center atom is shaded differently only for ease of viewing. ex: Cr, W, Fe (α), Tantalum, Molybdenum • Coordination # = Adapted from Fig. 3.2, Callister 7e. (Courtesy P.M. Anderson) Chapter 3 - 9 Atomic Packing Factor: BCC • APF for a body-centered cubic structure = 3a a 2a Adapted from Fig. 3.2(a), Callister 7e. R a Close-packed directions: length = atoms APF = Chapter 3 - 10 Face Centered Cubic Structure (FCC) • Atoms touch each other along _____________________. --Note: All atoms are identical; the face-centered atoms are shaded differently only for ease of viewing. ex: Al, Cu, Au, Pb, Ni, Pt, Ag • Coordination # = Adapted from Fig. 3.1, Callister 7e. 4 atoms/unit cell: 6 face x 1/2 + 8 corners x 1/8 (Courtesy P.M. Anderson) Chapter 3 - 11 Atomic Packing Factor: FCC • APF for a face-centered cubic structure = maximum achievable APF Close-packed directions: length = 2a Unit cell contains: = a Adapted from Fig. 3.1(a), Callister 7e. atoms unit cell APF = volume atom volume unit cell Chapter 3 - 12 FCC Stacking Sequence • _________________... Stacking Sequence • 2D Projection B A sites B sites A B C B C B B C B B C sites • FCC Unit Cell A B C Chapter 3 - 13 Hexagonal Close-Packed Structure (HCP) • ____________... Stacking Sequence • 3D Projection c a • 2D Projection A sites Top layer B sites Middle layer A sites Bottom layer Adapted from Fig. 3.3(a), Callister 7e. • Coordination # = • APF = • c/a = 1.633 __________________ ex: Cd, Mg, Ti, Zn Chapter 3 - 14 Theoretical Density, ρ Density = ρ = Mass of Atoms in Unit Cell Total Volume of Unit Cell ρ = where n = ___________________ A = ___________________ VC = ___________________ NA = Avogadroʼs number = 6.023 x 1023 atoms/mol Chapter 3 - 15 Theoretical Density, ρ • Ex: A= R= n= R atoms unit cell ρ= a g mol ρtheoretical ρactual volume atoms unit cell mol Chapter 3 - 16 Densities of Material Classes In general ρ_______> ρ_______ > ρ_________ 30 Why? 20 Metals have... • less dense packing • often lighter elements Polymers have... ρ (g/cm3 ) • close-packing 10 (metallic bonding) • often large atomic masses Ceramics have... • low packing density (often amorphous) • lighter elements (C,H,O) Composites have... • intermediate values Metals/ Alloys 5 4 3 2 1 0.5 0.4 0.3 Platinum Gold, W Tantalum Silver, Mo Cu,Ni Steels Tin, Zinc Titanium Aluminum Magnesium Graphite/ Ceramics/ Semicond Composites/ fibers Polymers B ased on data in Table B1, Callister *GFRE, CFRE, & AFRE are Glass, Carbon, & Aramid Fiber-Reinforced Epoxy composites (values based on 60% volume fraction of aligned fibers in an epoxy matrix). Zirconia Al oxide Diamond Si nitride Glass -soda Concrete Silicon G raphite PTFE Silicone PVC PET PC HDPE, PS PP, LDPE Glass fibers GFRE* Carbon fibers CFRE* A ramid fibers AFRE * Wood Data from Table B1, Callister 7e. Chapter 3 - 17 Crystals as Building Blocks • Some engineering applications require single crystals: --diamond single crystals for abrasives (Courtesy Martin Deakins, GE Superabrasives, Worthington, OH. Used with permission.) --turbine blades Fig. 8.33(c), Callister 7e. (Fig. 8.33(c) courtesy of Pratt and Whitney). • Properties of crystalline materials often related to crystal structure. --Ex: Quartz fractures more easily along some crystal planes than others. (Courtesy P.M. Anderson) Chapter 3 - 18 Polycrystals • Most engineering materials are polycrystals. 1 mm • Nb-Hf-W plate with an electron beam weld. • Each "grain" is a single crystal. • If grains are randomly oriented, Anisotropic Adapted from Fig. K, color inset pages of Callister 5e. (Fig. K is courtesy of Paul E. Danielson, Teledyne Wah Chang Albany) Isotropic overall component properties are not directional. • Grain sizes typ. range from 1 nm to 2 cm (i.e., from a few to millions of atomic layers). Chapter 3 - 19 Single vs Polycrystals • Single Crystals E (diagonal) = 273 GPa Data from Table 3.3, Callister 7e. (Source of data is R.W. Hertzberg, Deformation and Fracture Mechanics of Engineering Materials, 3rd ed., John Wiley and Sons, 1989.) -Properties vary with direction: _______________. -Example: the modulus of elasticity (E) in BCC iron: • Polycrystals -Properties may/may not vary with direction. -If grains are randomly oriented: ___________. (Epoly iron = 210 GPa) -If grains are __________, anisotropic. E (edge) = 125 GPa 200 µm Adapted from Fig. 4.14 (b), Callister 7e. (Fig. 4.14(b) is courtesy of L.C. Smith and C. Brady, the National Bureau of Standards, Washington, DC [now the National Institute of Standards and Technology, Gaithersburg, MD].) Chapter 3 - 20 Section 3.6 – Polymorphism • Two or more distinct crystal structures for the same material (allotropy/polymorphism) iron system titanium liquid α, β-Ti 1538ºC δ-Fe BCC carbon 1394ºC diamond, graphite γ-Fe FCC 912ºC BCC α-Fe Chapter 3 - 21 Crystal Structure Review • Unit cell- smallest number of atoms showing atomic arrangement in a crystal • • • • Cubic system: a=b=c, α=β=γ=90o Structure #atoms/uc atom positions APF Coord # a Simple 1 corners 0.52 6 2R BCC 2 corners+middle 0.68 8 4R/ √3 FCC 4 corners+face centers 0.74 12 2√2R Density=(#atoms/uc)(mass/atom)/(volume of unit cell) • • Chapter 3 - 22 Section 3.8 Point Coordinates z Point coordinates for unit cell center are 111 c a/2, b/2, c/2 000 a x y b Point coordinates for unit cell corner are 111 • z ½½½ 2c • • • b y Translation: integer multiple of lattice constants à identical position in another unit cell b Chapter 3 - 23 Point Coordinates-2 Chapter 3 - 24 Crystallographic Points Chapter 3 - 25 Crystallographic Directions Algorithm z y x 1. Read off point coordinates of _____ and _________in terms of unit cell dimensions a, b, and c 2.Calculate vector (____________________) 3. Adjust to __________________________ 4. Enclose in _____________ brackets, no commas _____________________ families of directions _____________ Chapter 3 - 26 Crystallographic Directions Chapter 3 - 27 HCP Crystallographic Directions z Algorithm a2 - a3 a1 1. Vector repositioned (if necessary) to pass through origin. 2. Read off projections in terms of unit cell dimensions a1, a2, a3, or c 3. Adjust to smallest integer values 4. Enclose in square brackets, no commas [uvtw] a 2 ex: ½, ½, -1, 0 -a3 a2 2 Adapted from Fig. 3.8(a), Callister 7e. => [ 1120 ] a3 dashed red lines indicate projections onto a1 and a2 axes a1 2 a1 Chapter 3 - 28 HCP Crystallographic Directions • Hexagonal Crystals – 4 parameter Miller-Bravais lattice coordinates are related to the direction indices (i.e., u'v'w') as follows. z [ u 'v 'w ' ] → [ uvtw ] 1 (2 u ' - v ') 3 1 = v (2 v ' - u ') 3 t = - (u +v ) u= a2 - a3 a1 Fig. 3.8(a), Callister 7e. w = w' Chapter 3 - 29 Crystallographic Planes Adapted from Fig. 3.9, Callister 7e. Chapter 3 - 30 Crystallographic Planes • Miller Indices: Reciprocals of the (three) axial intercepts for a plane, cleared of fractions & common multiples. All parallel planes have same Miller indices. • Algorithm 1. Planes cannot pass _______________________ 2. Planes must _________ or be ___________ to the axes 3. Read off ______________ of plane with axes in terms of a, b, c 4. Take _______________ of intercepts 5. Reduce to ________________values 6. Enclose in _________________, no commas i.e., ___________ Chapter 3 - 31 Crystallographic Planes z example a b c c b a x example a b y z c c a b x Chapter 3 - 32 y Crystallographic Planes z example a b c c • a • • b y x Family of Planes _______ Chapter 3 - 33 Crystallographic Planes (HCP) • In hexagonal unit cells the same idea is used z example a1 a2 a3 c a2 a3 a1 Adapted from Fig. 3.8(a), Callister 7e. Chapter 3 - 34 Crystallographic Planes • • We want to examine the atomic packing of crystallographic planes Iron foil can be used as a catalyst. The atomic packing of the exposed planes is important. a) Draw (100) and (111) crystallographic planes for Fe. b) Calculate the planar density for each of these planes. Chapter 3 - 35 Planar Density of (100) Iron Solution: At T < 912°C iron has the BCC structure. 2D repeat unit (100) Adapted from Fig. 3.2(c), Callister 7e. a= 4 3 R 3 Radius of iron R = 0.1241 nm Chapter 3 - 36 Planar Density of (111) Iron Solution (cont): (111) plane 1 atom in plane/ unit surface cell 2a atoms in plane atoms above plane atoms below plane h= 3 a 2 2 ⎛ 4 3 ⎞ 16 3 2 area = 2 ah = 3 a = 3 ⎜⎜ R ⎟⎟ = R 3 ⎝ 3 ⎠ 2 Chapter 3 - 37 SUMMARY • Atoms may assemble into crystalline or amorphous structures. • Common metallic crystal structures are FCC, BCC, and HCP. Coordination number and atomic packing factor are the same for both FCC and HCP crystal structures. • We can predict the density of a material, provided we know the atomic weight, atomic radius, and crystal geometry (e.g., FCC, BCC, HCP). • Crystallographic points, directions and planes are specified in terms of indexing schemes. Chapter 3 - 38 SUMMARY • Materials can be single crystals or polycrystalline. Material properties generally vary with single crystal orientation (i.e., they are anisotropic), but are generally non-directional (i.e., they are isotropic) in polycrystals with randomly oriented grains. • Some materials can have more than one crystal structure. This is referred to as polymorphism (or allotropy). Chapter 3 - 39