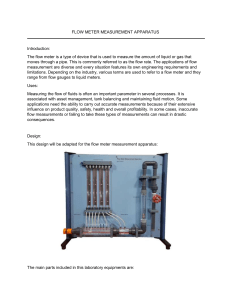

TECHNOLOGICAL INSTITUTE OF THE PHILIPPINES 1338 ARLEGUI ST., QUIAPO, MANILA COLLEGE OF ENGINEERING AND ARCHITECTURE CIVIL ENGINEERING DEPARTMENT HYDRAULICS ENGINEERING CE 319 – CE31S14 EXPERIMENTAL RESEARCH MANUSCRIPT “Optimizing Flow Measurement: A Comparative Analysis of Venturi Meters and Orifice Flow Meters for Accurate Hydraulic Flow Monitoring” SUBMITTED BY: Bonus, Juliana H. Buerano, Rod Cedric A. Caratao, Andrei E. Combinido, Jan Chian Y. Factor, Emmanuel SUBMITTED TO: Engr. Gabriel Galvez DECEMBER 2023 Table of Contents ABSTRACT................................................................................................................................................ 3 1. INTRODUCTION ................................................................................................................................. 4 1.1 Background of the study ................................................................................................................... 4 1.2 Statement of the Problem .................................................................................................................. 5 1.3 Objectives .......................................................................................................................................... 5 1.4 Significance of the Study .................................................................................................................. 5 1.5 Scope and Limitations .................................................................................................................. 6 2. REVIEW OF RELATED LITERATURE .............................................................................................. 6 2.1&2 Reynolds Number and Differential Producer Discharge Coefficient ........................................... 6 2.3 Innovative Flow Measurement Techniques using a Venturi and an Integrated Artificial Neural Network (ANN)....................................................................................................................................... 7 2.4 Addressed numerical challenges in hydraulic orifice flow modeling ............................................... 7 3. METHODOLOGY .............................................................................................................................. 8 3.1 Overall Methodology Framework ..................................................................................................... 8 3.2 Materials/Equipment Used ................................................................................................................ 9 3.3 Experiment Procedures ................................................................................................................... 10 3.4 Statistical Treatments ...................................................................................................................... 12 4. RESULTS AND DISCUSSION ........................................................................................................ 12 4.1 Preparation of Figures and Tables ................................................................................................... 12 5. CONCLUSIONS AND RECOMMENDATIONS............................................................................. 17 6. References ...............……………………………………………………………………………. 17 7. Appendices ……………………………………………………………………………………... 18 OPTIMIZING FLOW MEASUREMENT: A COMPARATIVE ANALYSIS OF VENTURI METERS AND ORIFICE FLOW METERS FOR ACCURATE HYDRAULIC FLOW MONITORING ABSTRACT The research presented here gives a thorough comparison of Venturi meters and orifice flow meters with the goal of optimizing flow measurement in hydraulic systems. The research conducts a thorough examination of the accuracy, dependability, and practical factors connected with these commonly used flow measurement devices under variable operation instances. According to data from orifice meters, there is reportedly not much energy loss when flow rates rise at the orifice's plate. Nonetheless, a sizable amount of the excess energy is lost when the flow accelerates and decelerates, suggesting possible constraints in sustaining energy efficiency for the duration of the orifice meter's flow path. The coefficient of discharge of the orifice meter indicates how well it enables fluid to travel through, which is an important factor to take into account. Inversely, the venturi meter exhibits a better result, with the measured values nearly matching the actual. The venturi meter's efficient structure and its bending and spreading sections, which lessen boundary-layer separation, increase its efficiency. The diverging part of the meter makes it easier to recover some of the pressure loss that occurred in the converging area. This illustrates the venturi meter's advantageous coefficient of discharge in addition to its overall energy efficiency. The study analyzes the advantages and restrictions of each instrument. Venturi meters, with their improved energy efficiency and precision, are chosen in scenarios demanding accurate flow measurement; orifice meters are used in applications that support quick installation and dependability. The intent of this research is to provide industry professionals with the necessary knowledge to choose and apply flow measurement instruments with assurance, due to comprehensive comparisons and strong results from three trials. It addresses factors including cost-effectiveness and convenience of installation, as well as providing advice to help engineers, taking into account the particular needs of their hydraulic systems. Keywords: Flow Rates, Venturi meter, Orifice Flow meters, Coefficient of Discharge, Hydraulic System 1. INTRODUCTION 1.1 Background of the study Hydraulic flow meters are known as gauges, indicators, and liquid meters depending on where they are being used and the industry. They are normally made from resilient material with the ability to withstand the stress and pressure associated with liquid pressure. The common types of metals utilized are brass, aluminum, or stainless steel. A hydraulic flow meter can be positioned in any part of a hydraulic line to identify the flow rate. Since not every hydraulic system is the same, there are flow meters with varying port sizes to fit different systems. The meter itself has three main parts, which are the device, a transducer, and transmitter. Orifice meters and venturi meters are devices used for measuring liquid flow, each with its own approach. Orifice meters create constriction by directing liquid through a small opening, resulting in a higher pressure drop. In contrast, venturi meters use a specialized Venturi tube with a unique shape, causing less pressure drop and offering improved accuracy. Despite their simplicity and widespread use, orifice meters may lead to higher pressure drop, while venturi meters are favored for applications requiring minimized pressure loss and precise flow measurements. Comparing orifice meters and venturi meters for liquid flow measurement offers valuable insights. Orifice meters, though simpler, may result in higher pressure drops, suitable for specific applications. In contrast, venturi meters provide lower pressure drops, improving energy efficiency and accuracy, making them ideal for precise measurements with minimal pressure loss. This comparison informs decision-making for engineers and practitioners, refining methodologies for flow measurement in diverse industries. The study envisions a future where informed selection of flow measurement methods enhances precision and sustainability in hydraulic systems. 1.2 Statement of the Problem This study aimed to compare the hydraulic flow between Venturi Meters and Orifice Flow Meters. The following questions should be answered as the researchers conduct the experimentations and analyses of the proposed topic. The following are the questions answered in this study: 1. How does the Venturi Meters and Orifice Flow Meters differ in terms of these variables: 1.1. Discharge Coefficient 1.2. Flow Rate 2. Which hydraulic flow monitoring device is more efficient: Venturi Meters or Orifice Flow Meters? 1.3 Objectives This study aimed to compare the hydraulic flow between Venturi Meters and Orifice Flow Meters. In particular, the investigation intends to achieve the following: 1. To determine the difference between Venturi Meters and Orifice Flow Meters in terms of these variables: 1.1. Discharge Coefficient 1.2. Flow Rate 2. To identify the efficient hydraulic flow monitoring device between Venturi Meters and Orifice Flow Meters. 1.4 Significance of the Study The result of this study will be beneficial to the following: The Researchers: The proven result of the study would greatly benefit the researchers to have a comparative analysis about the hydraulic flow monitoring devices. Future Researchers: A great basis of relative research can help strengthen the work of future researchers, and in the development of ideas about accurate hydraulic flow monitoring devices. Hydraulics Students: This study will serve as a help for the students in choosing an accurate hydraulic flow monitoring device in their laboratory experiment. 1.5 Scope and Limitations The study focused on the comparative analyses between Venturi Meters and Orifice Flow Meters. The researchers aimed to discover the most efficient and accurate hydraulic flow monitoring device. Researchers were able to gather data and compare the results among the two devices with the use of a hydraulic bench. The researchers are limited to these variables: Discharge Coefficient and Flow Rate. The trials will be limited to three (3) trials only. 2. REVIEW OF RELATED LITERATURE 2.1&2 Reynolds Number and Differential Producer Discharge Coefficient Hollingshead et al. (2011) investigated the relationship between Reynolds number and differential producer discharge coefficient by solving steady, Reynolds-averaged Navier–Stokes equations. Both numerical solutions and experimental data were employed to validate the findings. The primary focus was on low Reynolds numbers typical in the transportation of viscous fluids through pipelines, though high Reynolds numbers were also considered. The study revealed that at low Reynolds numbers, Venturi, V-cone, and wedge flow meters exhibited a rapid decrease in discharge coefficients with declining Reynolds numbers. In contrast, the orifice plate meter displayed an unconventional trend, with the discharge coefficient initially increasing to a maximum before sharply declining as Reynolds numbers decreased further. These results enhance comprehension of differential flow meters operating at low Reynolds numbers and underscore the predictive capability of computational fluid dynamics in estimating discharge coefficient trends, particularly at very low Reynolds numbers. The study emphasized the behavior of several flow meters, highlighting low Reynolds numbers that are common in pipeline transportation of viscous fluids. Aichouni et al. (2001) used solutions to the stable, Reynolds-averaged Navier-Stokes equations to investigate the relationship between Reynolds number and differential producer discharge coefficient. The results were validated using both experimental data and numerical simulations. While the orifice plate meter showed an unusual tendency of first increasing its discharge coefficient to a maximum and then drastically decreasing at further decreased Reynolds numbers, the venturi, V-cone, and wedge flow meters showed a noticeable decrease in discharge coefficients at low Reynolds numbers. These results highlight the predictive power of computational fluid dynamics in forecasting discharge coefficient trends, especially at very low Reynolds numbers, and they help to clarify differential flow meters, especially at low Reynolds numbers. 2.3 Innovative Flow Measurement Techniques using a Venturi and an Integrated Artificial Neural Network (ANN) Santhosh et al. (2012) have developed an intelligent flow measuring instrument that utilizes a venturi to measure flow, converting the output to voltage through a data conversion unit. An artificial neural network (ANN) is integrated into the system, contributing to overall linearization and independence from factors like venturi-to-pipe diameter ratio, liquid density, and temperature. This design eliminates the need for repeated calibration when changing liquids or parameters. Flow control is crucial in industries, influencing parameters such as temperature and pressure. The commonly used Venturi, known for its sensitivity and ruggedness, faces challenges such as offset and non-linear responses. To overcome these issues, the proposed instrument incorporates an ANN, training the system to extend linearity and produce outputs independent of critical factors like diameter ratio, liquid density, and temperature. This smart flow measurement technique offers a solution to the challenges associated with traditional venturi-based flow measurement, providing accuracy, reliability, and adaptability in various industrial applications. 2.4 Addressed numerical challenges in hydraulic orifice flow modeling W. Borutzky et al. (2002) described the flow through hydraulic orifices is known to pose numerical challenges due to the derivative of flow with respect to pressure drop approaching infinity as the pressure drop nears zero. The paper addresses this issue by starting with an approximation of the discharge coefficient's characteristic, as proposed by Merritt, and introduces a single empirical flow formula. This formula establishes a linear relationship for small pressure differences and reverts to the conventional square root law under turbulent conditions, ensuring a smooth transition from laminar to turbulent regions. The avoidance of numerical difficulties is facilitated by the finite slope of the characteristic at zero pressure difference. The formula incorporates physically meaningful terms and utilizes parameters with clear physical interpretations. Implemented successfully in a bond graph model of a hydraulic sample circuit, the proposed orifice model demonstrates accurate simulation results. 3. METHODOLOGY This part contains different methodologies both scientific and descriptive which include data gathering, qualitative and quantitative approach, experimental, observational, and statistical treatment. Methods already published should be indicated by a reference; only relevant methods should be included. 3.1 Overall Methodology Framework Create a flowchart showing the methodology to be implemented in this study. Make sure that the texts are readable in the flowchart and use colors and shapes purposively. Source Sampling Sample Processing Lab Experimentation Data interpretation Source Sampling All the required materials will be obtained during the first phase. It entails acquiring the need Hydraulic bench’s (HM 150), nozzle with different size (channel 12mm, cone 12mm, rounded 12mm) and Orifice Discharge Apparatus (HM 150.12) Sample Processing The procedure involves preparing the acquired resources for a laboratory experiment. Various nozzles with different specifications, such as a Channel 12mm, Inlet Cone 12mm, and Inlet Rounded 12mm, are utilized. These nozzles are employed to determine the orifice discharge, and the same ones are used in a venturi meter. Additionally, a grammar checker is employed to ensure linguistic accuracy in the experimental documentation. Laboratory Experimentation The objective of this comparative analysis is to assess the performance, accuracy, and efficiency of the two distinct flow measurement devices. in the current phase relies on the unconfined compression test. This test is pivotal as the data needed for analysis is derived directly from its results, making it a crucial component of the experiment. Data interpretation This occurrence can be explained by the heightened flow rate at the orifice plate's aperture, leading to minimal energy dissipation. Nonetheless, as the fluid progresses through the orifice and slows down, a substantial amount of surplus energy is dispersed. 3.2 Materials/Equipment Used 1. Venturi meter • The Venturi meter is a vital tool for calculating the flow rate by comparing the pressure difference between two points in a constricted pipe. 2. Orifice Flow Meter • An orifice flow meter measures fluid flow through a pipe by creating a restriction and measuring pressure difference across the plate, correlated with flow rate, making it a cost-effective and simple tool. 3. Hydraulic bench's • The hydraulic bench, equipped with flow meters, is a crucial tool in fluid mechanics laboratories, enabling researchers to study fluid behavior and hydraulic concepts in a controlled environment. 4. Different types of nozzles • Channel 12mm A hydraulic channel, a specific component of a hydraulic system, is a narrow conduit or tubing with a diameter or width of 12mm, crucial for controlling fluid flow rates and pressures. • Inlet cone 12mm The size of an inlet cone, typically a cone-shaped inlet with a diameter of 12mm, is crucial in hydraulic systems for controlling fluid intake, ensuring proper flow rates, and optimizing performance. • Inlet rounded 12mm An "inlet rounded 12mm" is a rounded or circular inlet with a diameter of 12mm, used in hydraulic systems for smooth, controlled fluid entry, minimizing turbulence and pressure losses, and impacting flow rate and efficiency. 3.3 Experiment Procedures The intent of this experimental study is to compare Venturi meters and Orifice flow meters for accurate hydraulic flow monitoring. To determine which flow measurement instrument is the most efficient to utilize. The following procedures are for determining the comparison concepts of the two flow measurements. I. Venturi Meter Velocity from Measured Energy Head 1. Connect Bernoulli's Demonstrator (HM 150.07) from the hydraulic bench using the hose. 2. Assure that the setup is leveled, then open the inlet and outlet valves of Bernoulli's Demonstrator (HM 150.07). 3. Turn on the hydraulic bench's pump, then gradually open the control valve. 4. Turn on the water pressure gauge's vent valves. 5. Once there is no reading on the 6-fold water pressure gauge, adjust the input and output. 6. Take a reading at each of the six tubes' measuring points for the pressure head (hp) and write it down on the sheet. 7. To determine their total heads, adjust the probe at each measuring point. 8. Calculate the pressure, dynamic, and total heads and plot them compared to the venturi nozzle section's length. Velocity Computed from Discharge 9. Calculate the volumetric discharge (Q) by timing how long it takes to fill ten liters of water (t). the HM 150's volumetric tank. Determine Q's value in m3/s. 10. Divide the discharge by the area at the measurement points (provided in Table 1) to find the velocity at each point. The computed velocity will be this: 11. At each measurement point, plot the results of the computed and measured velocities. II. Orifice Flow Meter 1. In the tank's base, place the chosen nozzle and sealing ring. 2. For the water supply to drain and the overflow to be transmitted to the hydraulic bench's outlet, the hose needs to be attached to it. 3. Close the hydraulic bench's main valve after opening the drain. 4. Upon activating the pump, cautiously open the main valve and control the discharge. There should be less water than overflow. 5. In order to prevent the inflow's applied force effect, adjust the input basket so that it is not submerged in water. 6. Record the pressure reading obtained from the left pressure gauge in your data sheet. The theoretical head will be this. 7. Using the appropriate pressure gauge, take a reading while positioning the pitot tube in the center of the jet. The actual head will be this. 8. Determine the velocity's theoretical and actual values by applying Torricelli's equation. 9. When the spindle tip comes into contact with the jet flow, adjust it. Take note of the measurement on the micrometer. Next, use the following formula to determine the jet's radius: The results are expressed in millimeters. 10. After closing the drain, measure the time it takes to go from the initial volume to the final volume by assigning two values for the water volume. 11. Using the following formula, determine the contraction and velocity coefficients. 12. Compute the discharge coefficient following the determination of the two coefficients. 3.4 Statistical Treatments The obtained data from the testing procedures were analyzed with the use of one-way ANOVA treatment. The researchers utilized one-way ANOVA treatment to interpret significant differences of the discharge coefficient and flow rate between the measuring devices. The measuring devices underwent three (3) trials for the validity of the gathered output variables and were compared. 4. RESULTS AND DISCUSSION The intent of this study was to analyze the efficiency of orifice and venturi flow meters, with an emphasis on important variables including energy efficiency, flow rates, and coefficient of discharge (Cd). The outcomes showed notable variations between the two meters, offering insightful information about how to use them in engineering settings. 4.1 Preparation of Figures and Tables The concept of operation for this orifice flow meter is that a pressure drop in proportion to the square of the flow rate is caused by a carefully drilled hole, or orifice, within a thin plate. Its main job is to measure fluid flow rates in pipes accurately. A vital component of process control, the orifice flow meter helps businesses run their operations more safely and efficiently. The apparatus plays a crucial role in water treatment plants by regulating fluid distribution and guaranteeing the equilibrium required for efficient water treatment procedures. Table 1: Velocity Coefficient in Orifice flow meter VELOCITY COEEFICIENT THEORETICAL TRIAL ENERGY NO. HEAD (mm) 1 9 2 10.2 3 16 THEORETICAL VELOCITY (mm/s) 13.288 14.147 17.718 ACTUAL ENERGY HEAD (mm) 5 4.8 15.4 ACTUAL VELOCITY (mm/s) 9.904544 9.704432 17.3824 VELOCITY COEEFICIENT 0.74536 0.68599 0.98107 This study places a great deal of weight on the orifice velocity coefficient (Cv). As a reflection of the orifice's capacity to transform potential energy into kinetic energy, the orifice velocity coefficient is inextricably related to its form and design. Performance optimization of the system is aided by the prediction and control of fluid flow characteristics through orifices made possible by an understanding of CV. Table 2: Contraction Coefficient in Orifice flow meter CONTRACTION COEEFICIENT RDG ON TRIAL MICROMETER NO. (mm) 1 4.072 2 4.073 3 4.074 Rjet (mm) 8.928 8.927 8.926 DIAMETER JET (mm) 18.856 18.858 18.852 INLET DIAMETER 12 12 12 CONTRACTION COEEFICIENT 2.46909 2.46961 2.46804 A key tool in the study of fluid flow is the coefficient of contraction, which measures how much a fluid stream's cross-sectional area shrinks when it approaches a constriction. It is essential for correctly estimating and comprehending fluid behavior in a variety of settings, such as flow measurements through nozzles and orifices. Table 3: Relationship of the coefficients. CONTRACTION COEFICIENT TRIAL CONTRACTION NO. COEFICIENT 1 2.469088444 2 2.46961225 3 2.468041 VELOCITY COEFICIENT 0.7454 0.686 0.9811 DISCHARGE COEFFICIENT 1.84035 1.69414 2.42132 The experimental trial data on the orifice flow meter provides a baseline dataset for a later comparison with data from Venturi meters. The purpose of this comparative study is to evaluate these two different flow measurement devices in terms of performance, accuracy, and efficiency. For assessing the usefulness and accuracy of flow measurements, the data from orifice flow meters, which includes volumetric flow rates, pressure differentials, and related hydraulic coefficients, is an essential point of reference. Table 4: Flow Rate in Venturi meter TIME(s) 42.71 START VOLUME(L) 0 END VOLUME(L) 10 DISCHARGE (L/S) 0.234137204 DISCHARGE (𝑚3 /𝑠) 0.000234137 The venturi meter showed a clear benefit in terms of flow rate characteristics: it consistently demonstrated greater flow rates. A smoother and more effective flow was produced by the venturi tube's slow change in fluid velocity, which reduced turbulence. Given its practical consequences, the venturi meter is a better choice in situations requiring precision and low energy loss because it is not only more accurate but also more energy efficient. Table 5: Calibration of the Venturi meter POINT AREA 𝑚2 1 2 3 4 5 6 0.000338 0.000233 0.0000846 0.00017 0.000255 0.000338 PRESSURE HEAD(hp) m 0.262 0.215 0.025 0.142 0.156 0.16 VELOCITY HEAD(hv) m 0.024457297 0.051467137 0.390392197 0.096681641 0.042969618 0.024457297 TOTAL HEAD(ht) m 0.286457297 0.266467137 0.415392197 0.238681641 0.198969618 0.184457297 COMPUTED VELOCITY m/s 0.692713622 1.004880706 2.767579248 1.377277673 0.918185115 0.692713622 The fluid in a venturi meter experiences pressure variations as it moves through the converging and diverging parts of the venturi tube. According to Bernoulli's principle, the fluid velocity first increases in the converging part, which causes the pressure to decrease. The venturi's throat is where the pressure loss is least significant. The fluid subsequently enters the diverging portion, where its velocity drops and pressure rise as a result. As a whole, energy losses are reduced and there is some pressure recovery. The venturi meter's reputation for greater energy recovery and efficiency is largely due to its effective pressure fluctuation. Figure 1: Variation of heads along Venturi Meter Variation of heads along Venturi Meter 0.5 Head(m) 0.4 0.3 0.2 0.1 0 0 1 2 3 4 5 6 7 PIEZOMETER TUBE NO. Pressure Head Velocity Head Total Head A venturi meter’s CD usually exceeds 0.95, which means it is highly efficient and loses minimal energy. If there are no appreciable disruptions or pressure losses, a high CD indicates that the venturi meter is successfully catching the fluid flow. The internal surface condition of the meter, the fluid flow's Reynolds number, and the venturi tube's form and design are all factors that affect the meter's coefficient of discharge. A carefully constructed venturi tube and sleek, smooth interior surfaces add to the greater Cd. Table 6: Finding the Coefficient of discharge in Venturi meter START END PRESSURE THROAT VOLUME(L) VOLUME(L) TIME(s) HEAD(hp) (Head) 0 10 42.71 0.262 0.025 0 10 76.28 0.198 0.057 0 10 84.09 0.185 0.089 √ℎ𝑝 − ℎ 0.486826458 0.375499667 0.309838668 C-AVERAGE 𝐶= 𝑄 𝛽√ℎ𝑝 − ℎ 1.285496405 0.933156252 1.025875462 1.081509373 DISCHARGE 0.000234137 0.000131096 0.00011892 2𝑔 𝛽 = 𝑎𝑡√ 𝑎𝑡 1 − 𝑎𝑖 0.000374132 (hp-h) 0.237 0.141 0.096 An important part of the study involves comparing the Venturi and orifice flow meters in order to identify the unique performance features of each of these two flows measuring devices. Using information from extensive experimental trials, the study gives priority to important factors like accuracy, flow condition sensitivity, energy efficiency, practical consequences, reliability, and cost-effectiveness. Figure 2: Coefficient of discharge of the flow meter 4 3.5 3 2.5 COEFFICIENT DISCHARGE 2 VENTURI METER 1.5 ORIFICE METER 1 0.5 0 1 2 3 TRIAL NO. In a study comparing Venturi and Orifice flow meters for hydraulic flow monitoring, the Venturi meter showed better flexibility right out of the gate and had the potential to achieve high discharge coefficients. Because of the steady increase in fluid velocity that minimizes turbulence and guarantees smoother flow, the Venturi meter continuously demonstrated higher flow rates. Because of its design, the Venturi meter is better suited for applications that need accuracy and little energy loss. However, the orifice meter, which had a sudden constriction, displayed a lower coefficient of discharge, which was a sign of higher turbulence and a noticeable pressure drop. The initial energy loss was negligible as the flow rate increased at the orifice plate opening, but the large loss of extra energy upon deceleration suggests that there may be constraints in energy efficiency along the entire flow path. The study focused on the accommodations that must be made when choosing between the two meters: the orifice meter offered a more affordable option but made compromises in accuracy and energy efficiency, while the Venturi meter excelled in both areas. All things considered, the results help make well-informed decisions when choosing the right flow meter depending on the demands and priorities of a given application. 5. CONCLUSIONS AND RECOMMENDATIONS Conclusion In this experiment, we utilized two types of differential flow meters, namely the orifice meter and the venturi meter. The measuring technique involved assessing the operation and characteristics of these meters by comparing the pressure drop, which is indicative of the fluid velocity in the pipe and calculating the coefficient of discharge. The data analysis revealed that for the orifice meter, a high-pressure drop was observed and remained unrecovered. This phenomenon can be attributed to the increased flow rate at the orifice plate's opening, resulting in minimal energy loss. However, as the fluid continues through the orifice and decelerates, a significant portion of excess energy is dissipated. In contrast, the venturi meter exhibited values that were closely aligned with the actual measurements. This accuracy can be attributed to the streamlined shape of the venturi meter, which minimizes pressure drop by almost eliminating boundary-layer separation and assuming negligible form drag. The venturi meter comprises converging and diverging sections, with some pressure loss occurring in the converging part, but a well-designed venturi meter can recover a percentage of this pressure loss in the diverging section. Overall, the venturi meter proved to be more accurate than the orifice meter, offering advantages such as high-pressure tolerance and energy recovery. Recommendations There are a couple of recommendations that may be used in this experiment to obtain better data and findings, allowing the experiment to be done properly and systematically. To obtain reliable results, the experiment must be done at least twice, and the average computed. We must also check that there are no air bubbles for improved accuracy and to avoid reading errors. We can depress the staddle valve on the upper right side of the manometer board with a pen. Allow liquids and trapped air to escape by softly depressing the staddle valve. enable enough time for bleeding to enable all bubbles to escape. We must also keep an eye on the water level in the manometer board. If the water level in the manometer board rises to the point where it is no longer visible, we must adjust it using the staddle valve. Keep the maximum manometer values with the maximum measurable flow rate. References Aichouni, M. (2003). Experimental Investigation Of The Installation Effects On Venturi And Orifice Flow Meters. https://aichouni.tripod.com/Papers/CIMetrologie2001.pdf?fbclid=IwAR3-BpV9qaT4pJMaJDWjj-kYf5wnMbtiGVEEFFhI2aHnO-H4Q3g9A1F3lU Clark, W.J. (2016). Flow Measurement. Flow Measurement: By Square-Edged Orifice Plate Using Corner Tapping's. https://books.google.com.ph/books?hl=en&lr&id=_sUgBQAAQBAJ&oi=fnd&pg=PP1&dq=info% 3AX8gJ_n_ry8gJ%3Ascholar.google.com%2F&ots=KnOmdKSTnk&sig=oRDBK3qHMRbJPd4bQ G2TBmbkGDs&redir_esc=y&fbclid=IwAR1OG89uGa0_shIrrfOINKqOkYBmqNDSUmmiGDjl_ DbxQfatsmn2lwoEzHE#v=onepag Editorial staff. (2023). Comparison of Venturi and Orifice flow meter. https://instrumentationtools.com/comparison-venturi-orifice-flowmeter/?fbclid=IwAR34GqOENKOMtSzNppId1FedPIRyNPrbU_ch8WAuXkojh6uBbAV6HnrVDP M Hollingshead, C. L., & Johnson, M. C. (2011). Discharge coefficient performance of Venturi, standard concentric orifice plate, V-cone and wedge flow meters at low Reynolds numbers. Science Direct. https://www.sciencedirect.com/science/article/pii/S0920410511001987 An Introduction to Flow Meters. (2023). OMEGA. https://www.omega.com/en-us/resources/flowmeters?fbclid=IwAR07-B9AmYTAYf7QMoeOkGAUyNQYCXzLPi2wBLXcTaQzctHpmTYGIr0TcQ Santhosh, K. (2012). An Intelligent Flow Measuring Technique Using Venturi. https://www.iaeng.org/publication/IMECS2012/IMECS2012_pp902907.pdf?fbclid=IwAR1J6B_Nx_cBDv78MUN80Hps3jtGfCyDd4HQK-3i6RVjXugo7ypiLKabNB4 Shaaban, S. (2014). Chemical Engineering Research and Design. Optimization of orifice meter's energy consumption. https://www.sciencedirect.com/science/article/abs/pii/S0263876213003511?via%3Dihub W., B. (2002). Simulation Modelling Practice and Theory. An orifice flow model for laminar and turbulent conditions. https://www.sciencedirect.com/science/article/abs/pii/S1569190X02000928?fbclid=IwAR081jNYj8 aYf0pVWM1hFkifJqIWJeKwZRmeC3qdw2qT4D34713uQuYqXOY Appendices Orifice Flow Meter Picture 1: Setting up the orifice flow meter. Picture 2: Undergoing experimentation on orifice flow meter. Picture 3: Data recording of the experiment on orifice flow meter. Venturi Meter Picture 4: Setting up the venturi meter. Picture 5: Undergoing experimentation on venturi meter. Picture 6: Data recording of the experiment on venturi meter. RUBRICS FOR PERFORMING EXPERIMENTS SO (6): Develop and conduct appropriate experimentation, analyze, and interpret data, and use engineering judgment to draw conclusions. Criteria 1 2 3 4 5 6 Develop The students are The students are The students are The students are The students are able The students are able to Appropriate unable to develop a able to partially able to develop able to develop a to develop develop a lab Experimentation basic component of develop component of a basic component of components of experiment/activity a laboratory components of laboratory a laboratory laboratory experiment appropriate to the experiment laboratory experiment but has experiment appropriate to the chosen topic and experiment no presentations of appropriate to the chosen topic and aligned to the analysis of data yet chosen topic aligned to engineering engineering principles has presented principles learned in learned in the previous conclusion or the previous experiments. recommendation Experiments Conduct The students are The students The students The students The students are able The students are able to Appropriate unable to conduct a inappropriately conduct some conduct laboratory to conduct appropriate conduct a precise Experimentation laboratory conduct the laboratory experiment/activity laboratory laboratory experiment/ experiment / laboratory experiments / with correct experiment/activity activity with excellent activity experiment / activities but did not methods/procedures with sufficient results results and conclusions. activity arrive at the correct but insufficient and able draw a valid results results to draw conclusion conclusion Score Ability to The students are The students The students The students use The students use The students use Analyze and unable to provide provide irrelevant provide limited appropriate data adequate data analysis multiple data analysis Interpret Data analysis and and inaccurate analysis of data analysis techniques. techniques techniques appropriate interpretation of analysis and with no Data analysis appropriate for data for data collected, data interpretation of interpretation is reported with collected, informative with insufficient informative with respect to the interpretation respect to the experimentation / experimentation/ activity being activity being conducted. Data conducted. analysis is reported data with comprehensive interpretation Use Engineering The student failed The student was The student was The student was The student was able The student was able to Judgment to to use engineering able to use able to use able to to use Engineering use engineering Draw judgement to draw engineering Engineering use engineering judgement more than judgement more than Conclusions conclusions judgement but judgement judgement sufficient to draw sufficient to draw inappropriate for but insufficient to sufficient to correct conclusions correct conclusions and the topic and failed draw correct draw correct was able to provide to draw correct conclusions conclusions new insights conclusions Comments/Observations: Total Score: