Improve Processes with Engineered Purging Compound for Blow Molding

advertisement

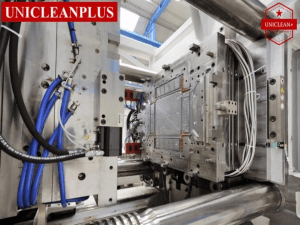

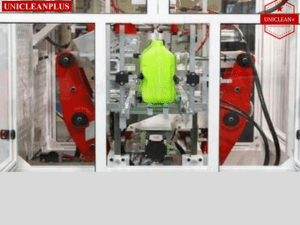

Improve Processes with Engineered Purging Compound for Blow Molding ‘Blow Molding’ is a versatile process developed to create thermoplastic products. This process serves a variety of purposes. This thermoplastic manufacturing process is trusted to be the most suitable process for the capability to create lightweight, hollow, durable plastic items for different purposes—from households to food sites to pharmaceuticals to more. There is a lot of growth for this process. Understanding them would help your site get valuable insights for the process. Blow Molding is a Reliable Process for the Following Factors – Versatility: the capacity to create a great range of products, from bottles to tanks to drums to a lot more. This process is preferred as various shapes of products are easy to craft. Durable Products: The best thing about this thermoplastic process is the lightweight products that are created that are durable. Cost-effective: This process helps to produce products rapidly with low waste, thus lowering costs. Thus, Blow Molding is a very trusted process for a lot of industries, as they are best suited to produce products of different shapes, sizes, weights, etc. rapidly to meet the manufacturing requirements of the thermoplastic industries, producing lightweight, durable, bestperforming thermoplastic products. Purging Compound for Blow Molding: To ensure the blow moulding process is optimal, ensure proper cleaning of the equipment required for the process. So, how to do that? Your answer is with ‘UNICLEANPLUS’, the very trusted Purging Material Supplier. The Purging Compound for Blow Molding by UNICLEANPLUS is carefully developed by experts to fit the requirements of various machines, materials, processes, etc. of thermoplastic firms. The technology opted for by our company is the best to rely for as this splits the molecular bonds that damage the equipment. Therefore, our products are said to be safe, toxic-free, easy to use, high-quality. Our goal is to help firms reduce the molding material wastage, to improve the quality of products, save costs, make processes faster, etc. We prioritize offering products tailored to clients’ requirements; therefore, UNICLEANPLUS is the most trusted supplier to order Purging Products for Blow Molding. Safeguard the quality of products with the right Purging Material. These materials are best to ensure proper cleaning of the equipment, reduce wastage, improve the quality of the results. The Purging Materials for Blow Molding are preferred to improve the quality of the products to fit customer requirements, reduce the possibility of defective products, reduce excess product waste to help lower costs, etc. The Best Practices for Purging Materials are: Read or be clear about the purging product you are about to order. Order Purging Materials that are suitable for the process Follow the right procedure to get the right results from the Purging Material Ensure checks for the equipment to avoid the buildup of products. Keep records of the processes to check for results easily We have experts to help you with the right knowledge about the Purging Material for your requirements. Our team would be happy to help you with your queries. Our experts are professionals of Purging Materials; they would help you quickly with your Purging Material order to help you get the right results with the Purging Material of UNICLEANPLUS. To Read Our Published Blog: https://unicleanplus.wordpress.com/2024/08/16/improve-processes-withengineered-purging-compound-for-blow-molding/ Thank You! UNICLEANPLUS Address : Bharatipolychem Pvt Ltd, Plot No-451 City: Lesliganj State: Jharkhand Zip: 822118 Country: India Phone: +91 9021232809 Website: https://www.unicleanplus.com/ Email: sales@bharatipolychem.com