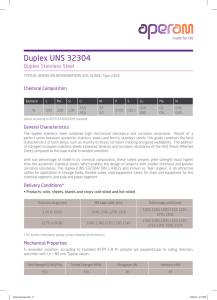

Damage Mechanisms as per API 571 Training for Colleagues Presented by: Mohammed Ashik Kp General and Localized Corrosion • Description: • General corrosion is a uniform attack across the surface of a material. Localized corrosion includes pitting, crevice corrosion, and filiform corrosion. • Affected Materials: • Most metals, including carbon steel, stainless steel, and aluminum. Galvanic Corrosion • Description: • Occurs when two dissimilar metals are electrically connected in a corrosive electrolyte, leading to accelerated corrosion of the anodic metal. • Affected Materials: • Dissimilar metal pairs such as aluminum and steel, copper and aluminum. Erosion and Erosion-Corrosion • Description: • Erosion is the removal of material due to mechanical action of fluid or solid particles. Erosion-corrosion is the combined effect of erosion and corrosion. • Affected Materials: • Carbon steel, stainless steel, and other alloys. Cavitation • Description: • Cavitation occurs when vapor bubbles form and collapse in a liquid, causing surface damage. • Affected Materials: • Most metals, particularly in pumps and propellers. Fretting • Description: • Fretting occurs at contact areas subjected to repeated small amplitude oscillatory motion, leading to surface damage and wear. • Affected Materials: • Most metals, especially at bolted joints and contact points. High-Temperature Corrosion • Description: • Occurs due to the reaction of metals with hot gases, typically at temperatures above 400°C. • Affected Materials: • Carbon steels, stainless steels, nickel alloys. • Common Environments: • Furnaces, boilers, gas turbines. Sulfidation • Description: • Corrosion of materials by sulfur compounds, particularly at high temperatures. • Affected Materials: • Carbon steel, stainless steels, low alloy steels. • Common Environments: • Petroleum refining, chemical processing. Chloride Stress Corrosion Cracking (Cl-SCC) • Description: • Cracking of austenitic stainless steels and other alloys due to tensile stress and chloride ions. • Affected Materials: • Austenitic stainless steels, nickel-based alloys. • Common Environments: Caustic Stress Corrosion Cracking (Caustic Embrittlement) • Description: • Cracking of carbon steels and low alloy steels due to tensile stress and caustic environments. • Affected Materials: • Carbon steels, low alloy steels. • Common Environments: