CHARACTERIZATION OF STRESS CORROSION CRACKING (SCC) IN ULTRA-HIGH STRENGTH STAINLESS STEEL

advertisement

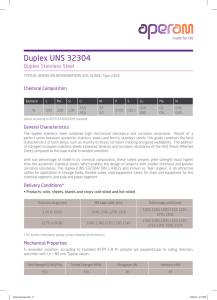

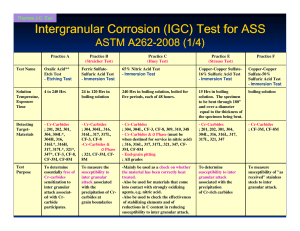

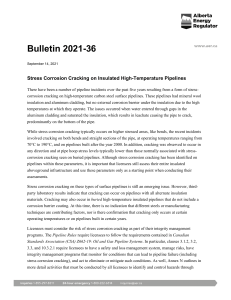

CHARACTERIZATION OF STRESS CORROSION CRACKING (SCC) IN ULTRA-HIGH STRENGTH STAINLESS STEEL Greger L. Pioszak Advisor: Dr. Richard P. Gangloff Department of Materials Science and Engineering University of Virginia, Charlottesville, VA 22904, USA Abstract Ultra-high strength precipitation hardened martensitic stainless steels (UHSSS) are increasingly used in aerospace applications as a replacement for ultra-high strength low alloy steels since stainless character eliminates the need to plate high strength components with toxic cadmium for corrosion resistance. However, modern UHSSS alloys remain susceptible to severe intergranular stress corrosion cracking (IGSCC) and transgranular stress corrosion cracking (TGSCC) when stressed in chloride containing environments. The primary goal of this research is to characterize the stress corrosion crack growth kinetics and fracture morphology for hydrogen environment assisted cracking (HEAC) in UHSSS. Subcritical crack growth experiments have been optimized to provide high resolution measurements of SCC crack growth in Custom®465 and Ferrium®PH48S™ at constant applied potential in aqueous NaCl solution. Results establish that a combination of composition and heat treatment changes applied to Ferrium®PH48S™ have increased the SCC resistance and changed the dominant fracture mechanism from intergranular to transgranular, compared to Custom®465. Metallurgical variables are hypothesized to control the concurrent increase in SCC resistance and change in fracture mechanism and Ferrium®PH48S™. Pioszak 1