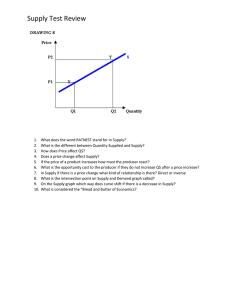

PRODUCER GAS GENERATION PROCESS 1.0 PRODUCER GAS Producer gas, rich in CO and H2 is manufactured by using solid fuel like coal or coke. The manufacture of this gas combines the merits of easily available solid fuel as primary source and clean rich gaseous fuel as final product for use. The producer gas is manufactured by blowing air with or without steam through a thick bed of hot solid fuel (coal/coke). The air blown causes carbon in coal/coke to get converted into CO and CO2 gas. The introduction of steam gives hydrogen as a result of reaction with carbon. The volatile matter present in the upper layer of coal/coke bed evolves due to heat and joins the out going gases. 1.1 Properties of Producer Gas The typical producer gas analysis, generated by using coal as fuel and air as blowing media, is given in Table 1. The producer gas rich in hydrocarbons is obtained while using coal as fuel due to high volatile matter content present in coal. The introduction of steam increases hydrogen content of the gas. The calorific value of producer gas ranges from 1200 to 1500 kcal/m3 depending on the fuel and blow media. The flame propagation rate is slow due to the presence of large (60 - 65%) volume of inert constituents like N2 and CO2. The producer gas burns with luminous flame when produced from coal due to the presence of hydrocarbons. The flame is non-luminous when made from coke or anthracite due to absence of hydrocarbons in the gas. The specific gravity of producer gas is high (0.85 - 0.9) which is helpful in directing the flame in the desired direction. The producer gas can be preheated to get high flame temperature as it is free or contains very low in hydrocarbon. Table 1 Properties of Producer Gas 1.2 Manufacturing Process of Producer Gas The producer gas manufactured by using a reactor is shown in Figure – 1 schematically. It is a shaft type cylindrical reactor having three major sections, the charging system located at the top, shaft reactor forming the middle section and air blowing with ash disposal system located at the bottom. The diameter of the reactor depends on the desired rate of gas generation. The reactor shell is made of steel which is lined with fireclay bricks. The gas off take is located at the top. The holes are provided on the top and side wall to poke the coal bed in case it gets Page 1 of 4 PRODUCER GAS GENERATION PROCESS fused. The shaft reactor rests on the bowl shape trough on the ground level. This trough is filled with water which acts as bottom gas seal. The air distributor hood is located above the water level. The air hood is designed in a way to allow air to move up, but the ash descending down does not block the air hood. Figure – 1 Producer gas unit (schematic) The top feeding system is a rotating chamber attached to hopper which prevents the gases leaking out while the charging is made continuously. The cylindrical reactor is tall enough to accommodate coal charge to give specified gas rate. This reactor may be assumed to have the following five zones: (i) Free space zone The first top zone is a free space for the gas and it extends from top to a level below the gas off take point. (ii) Distillation zone The second zone, extending below free space to about 300 - 350 mm, serves as a distillation zone. This zone has temperature 400 - 600°C to cause the removal of moisture and volatile matter. Page 2 of 4 PRODUCER GAS GENERATION PROCESS (iii) Secondary reduction zone The third zone (~ 900 - 1100°C) extending 450 - 500 mm below the distillation zone is called secondary reduction zone. In this zone, the hydrogen gas is formed due to following reaction: CO + H2O → CO2 + H2 (Shift reaction - Exothermic) (iv) Primary reduction zone This is a high temperature (1200 - 1300°C) gasification zone extending to a depth of about 300 - 350 mm between secondary reduction zone and combustion zone. The generation of H2 and CO occurs as a result of the following reactions: C + H2O → CO + H2 (Carbon gasification - Endothermic) C + CO2 → 2CO (Baudouard reaction—Endothermic) (v) Combustion zone This combustion zone, extending about 150 mm above the ash zone, is the highest temperature zone (1300 - 1500°C) where the carbon in the feed is burned to give heat and CO2 gas: C + O2 → CO2 (Combustion reaction - exothermic) The steam is injected in regulated quantity to give granulated ash for easy disposal. The ash zone below the combustion zone is located in the bottom trough filled with water to act as gas seal. The ash is periodically removed out from the trough for disposal. The good operating conditions are indicated by cherry red top surface with off gases leaving at 600°C. This hot gas is useful if it is used without cooling. When cool gas is needed the off gas temperature is kept low (~ 400°C) rendering top surface looking black. The very high temperature of exit gas is indicative of thin fuel bed and very low off gas is indicative of too thick coal bed or moist coal feed. 1.3 Flexibility of Use of Fuel for Generating Producer Gas The producer gas can be generated from a variety of solid fuels (Table – 2) like anthracite coal, bituminous non-coking coal and low grades of coke. The coal used for producer gas should not be caking in nature and must not swell on heating. The low ash in coal is preferable, but not a necessity. The coal size ranging 20 - 30 mm are common. The bigger size coal (30 - 50 mm) is preferred by large plants. The refractory ash (fusion temperature ~ 1400°C) is preferred as it helps in smooth operation of the plant. Table – 2 Producer Gas Composition with Different Fuel and Blow Media (1 kcal/m3 = 0.0042 MJ/m3) Page 3 of 4 PRODUCER GAS GENERATION PROCESS 1.4 Applications The raw hot producer gas was used as fuel in the past for open hearth steel making process in non-integrated steel plants. Even now, at some places the open hearth furnaces are useful for generating liquid melt for big steel castings. Such open hearth furnaces have choice to adopt producer gas over liquid fuel. At present, the producer gas is commonly used in non-integrated steel plants for soaking pits and reheating furnaces due to its flexibility of adopting different types of solid fuel. Further, the heavy gas with long luminous flame is highly desired for reheating long billets. The conventional integrated steel plants use producer gas plant as stand-by system if there is a problem in coke oven or blast furnace to meet the gas supply for other units under special circumstances. This is very useful during blast furnace relining period to meet the plant gas supply. The producer gas plants are easy to install with wide range capacity in short time which make it highly flexible for use. Page 4 of 4