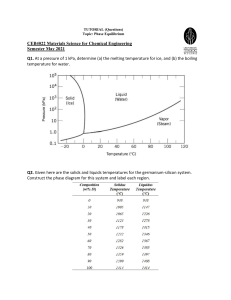

Titanium Alloy Hip Implant - Final Report Joseph, Fabian - fa927539@ucf.edu I am signing to verify that this report was written within academic conduct and without plagiarism. - Fabian Joseph Abstract Throughout the course, we’ve gone through the material selection process for hip implants and replacements. The motivation for the research we’ve conducted for the selection process, is to find the most cost-effective method and material to sell a quality product to consumers. This research was conducted through the process steps of market research, identifying the problem and beginning the search for a solution; design requirement translation, identifying the consumer need and translating material properties to the consumer need; option screening, gathering materials that meet constraints; rating, listing eligible materials from best to worst according to constraints; and documentation for the final choice. There is a rise of additive manufacturing and 3D printing in the creation of implants and prosthetics, it seems to be one of the most cost-effective and efficient methods of production; following the research of the method of production, the perfect material is next to be found. The search was conducted to find the best material that would be suitable for the harsh conditions of the human body with a feasible product life. Through value comparisons and constraint elimination, the choice of material was made; titanium alloy, Titanium-6Aluminum-4Vanadium or Ti-64. This alloy would prove to be the best option to survive the human body environment and provide the best support for the joint and integration into the structure of the body. Table of Contents ● Objective and Requirements ● Material Selection ○ Component Analysis and Loading Condition ○ Material Indices Derivation ○ Material Property Chart ● Manufacturing Process Selection ○ Manufacturing Constraints ○ Justification ○ Cost Information ● Conclusion ○ Summary of Final Selection ○ Confirmation and Comparison ○ Future Prospect ● References Objective and Requirements Prosthetics are made to replace limbs of amputees and help maintain the body’s homeostasis with implants. The goal is to design or allow customization for the consumer’s prosthetic needs through methods like 3D printing and optimization of processing and post-processing to maximize the longevity and biocompatibility of additively manufactured prosthetics. Leveraging novel processes to improve the quality of parts will ensure comfort for those who require prosthetics and mitigate the need for costly replacements and invasive surgeries. Function: material and prosthetic will replace damaged or missing hip joint Constraints: high fatigue strength, compression strength, good biocompatibility and corrosion resistance Free Variables: color, design, aesthetics overall the most biocompatible, corrosion resistant, high fatigue strength, and strong in compression. Material Selection Titanium alloys are grouped with magnesium alloys, and steel alloys for the selection group to be rated overall. Each alloy is some of the best at providing the most strength per its weight. When considering a material index that accounts evenly for toughness, corrosion resistance, and biocompatibility among popular titanium; magnesium; and steel alloys for additive manufacturing, our titanium alloy, Ti64 (Ti-6Al-4V), demonstrates the best combination of these properties. [a] The mechanical properties of Ti64 are important in our search for the best material for our hip implants. The alloy has a low modulus of elasticity, which allows for a great absorption of force; high compressive strength, which is essential as the implant and hip joints mainly experience compression over tension while the body is in action; and good fatigue strength over a multitude of cycles; this fatigue strength is important as it is normal for the human body to experience wavering intensities of cyclic loading [b]. [c] Material property charts can aid in determining initial search areas for potential materials, focusing on mechanical properties and physical characteristics. However, corrosion and biological traits are typically not depicted on these charts due to their contextual nature and challenges in quantification or generalization. As for searching for a material on an Ashby plot, a chart designed to display toughness and density on the axes was chosen. The final selection group of titanium, magnesium, and steel alloys would be concluded with the use of a crafted material index. This index sought to maximize the toughness of the material, while minimizing density and keeping the implants overall weight low; the consumer is not in need of an extra 50 pounds in their body. [K representing material’s toughness and ⲣ representing density …] Opting for a tough material is crucial as it enhances resistance against fatigue fracture, which poses the most significant risk to the implant's durability over time. [d] Manufacturing Process Selection Most metallic alloys do not print well for Laser Powder Bed Fusion (LPBF) due to issues in powder flowability during printing or composition dependent defects such as solidification cracking. This provides an additional constraint for material selection, since in addition to mechanical, corrosive, and biological considerations, the material cannot crack or exhibit excessive porosity due to printing that would severely degrade its performance and lifetime. [e] Utilization of titanium and titanium alloys as biomaterials has increased due to their superior biocompatibility, high corrosion resistance, ability to form a thin surface oxide protective layer, and good mechanical properties. The alloy has a certain elastic modulus and low density that presents itself with a mechanical behavior close to those of bones [f]; this design process that allows Ti-64 to emulate the likeness of our own skeletal structure is called Osseointegration. This oxide layer has a thickness of about 1–5 nm and can prevent the problems caused by the release of metal ions when the surface of titanium and titanium alloys are exposed to the fluids of living organisms for a long time. In a study conducted at the Health Sciences University of Hokkaido in Japan, titanium alloy implants were integrated into the femurs of rats. The titanium alloy implant showed the lowest rate of degradation of material when studied after removal from the lab subject; amongst magnesium alloy, pure magnesium, and polylactic acid. Each implant was left in the rat subject for at least twelve weeks and imaged with SEM (Scanning Electron Microscopy) and X-Ray spectroscopy; at two weeks, the titanium alloy’s images revealed there was fibrous tissue growing on top of the oxide layer of the titanium alloy implant [g]. Compared to another choice of alloy for bone implants, like AZ31 Magnesium alloy, titanium alloy has the lowest risk of degradation inside the host and shows promising signs of osseointegration as the body grows around the implant. Additive manufacturing and LPBF is the most consistent and cost-effective method of producing these implants. Manufacturing cost for the TI64, titanium alloy implant, is hard to find through online sources, but consumer prices are easily accessible. The average implant cost used in total hip arthroplasty (THA) have been reported to range from $2,392 to $12,651 per case and may comprise up to 87% of the total surgical costs [h]. Conclusion The titanium alloy, Titanium-6Aluminum-4Vanadium or Ti-64, is by far the best option for producing metallic hip implants. The alloy has a low modulus of elasticity, high compressive strength, and good fatigue strength over a multitude of cycles; these mechanical properties vouch for the material’s longevity and durability over the other choices of magnesium and steel alloys. The titanium alloy also offers good printability, corrosion resistance, high toughness, and excellent biocompatibility to survive the human body’s harsh chemical conditions. Hip implants today have a variety of combinations of materials that they are manufactured with; most commonly a variety of metal-on-plastic manufacturing combinations. This metal-on-polyethylene implant is the most common type. The femoral head is made of metal, while the socket is made of plastic (polyethylene). The metal components are most commonly made from cobalt-chromium, titanium, zirconium, or nickel; cobalt-chromium is the most common choice of the listed options as of now [i]. Other options may feature a ceramic-on-plastic, ceramic-on-ceramic, or metal-on-metal combinations. [j] Cobalt-chromium alloy can cost between $60–$125 per kilogram, while the TI64 alloy can be from $20-$22 per kilogram. Cobalt-chrome offers some of the same properties as TI64, only at a higher price; in the future, manufacturers may make the switch and see an increase in profits, as the manufacturing costs dip. References [a] - AO Foundation, Positioning of the acetabular component: Intraoperative considerations [b] - Moran TP, Carrion PE, Lee S, Shamsaei N, Phan N, Warner DH. Hot Isostatic Pressing for Fatigue Critical Additively Manufactured Ti-6Al-4V. Materials (Basel). 2022 Mar 10;15(6):2051. doi: 10.3390/ma15062051. PMID: 35329504; PMCID: PMC8952505. [c] - ASM Material Data Sheet, asm.matweb.com/search/SpecificMaterial.asp?bassnum=mtp641. [d] - Meng-Ting Hsieh, Vikram S. Deshpande, Lorenzo Valdevit, A versatile numerical approach for calculating the fracture toughness and R-curves of cellular materials, Journal of the Mechanics and Physics of Solids, Volume 138, 2020 [e] - Yang et al, Six-Sigma Quality Management of Additive Manufacturing (2020). [f] - Ravoiu, A. “IOP Conference Series: Materials Science and Engineering.” IOP Publishing, IOP Science, 2019, https://iopscience.iop.org/article/10.1088/1757-899X/572/1/012006/meta. [g] - Kawamura, Naohiko, et al. 2020, Degradation and Biocompatibility of AZ31 Magnesium Alloy Implants In Vitro and In Vivo: A Micro-Computed Tomography Study in Rats, https://www.mdpi.com/1996-1944/13/2/473. [h] - Robinson JC, Pozen A, Tseng S, Bozic KJ. Variability in costs associated with total hip and knee replacement implants. J Bone Joint Surg Am. 2012;94(18):1693–8. Epub 2012/08/11. doi: 10.2106/JBJS.K.00355 . [i] - Wood, James. “What Are Hip Replacements Made Of?” Practice Plus Group, 14 Dec. 2023, practiceplusgroup.com/knowledge-hub/what-hip-replacements-made-of/#:~:text=The%20main% 20types%20of%20hip,titanium%2C%20zirconium%2C%20or%20nickel. [j] - “Which Materials Are Used for Hip Replacement Implants?” Aditi Corporation, 11 Oct. 2017, www.aditicorporation.in/blog/materials-used-hip-replacement-implants/.