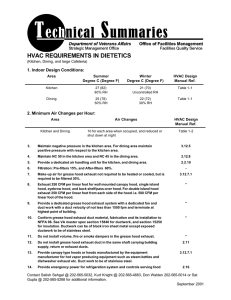

PRESENTATION OF COMMERCIAL KITCHEN VENTILATION, COMFORT, FIRE FIGHTING & ENERGY SAVING Lebanon Chapter A. PURPOSE B. EXHAUST C. MAKE UP AIR D. FIRE FIGHTING ASHRAE Life Member E. ENERGY SAVING Elie@embassociates.com Prepared by: Elie M Baradhy EMB & Associates April 2019 COMMERCIAL KITCHEN PLACES OF APPLICATION 1. Restaurants 2. Hotels 3. Hospitals 4. Malls 5. Clubs 6. Catering Outlets 7. Sea Resorts 8. Mountain Resorts 9. Prisons 10.Canteens • Factory • School & University • Army • Construction Site A. PURPOSE • Create Healthy, Environmental, Hygienic and Safe working Place. B. EXHAUST • Catch, Contain all fumes, Odors, Grease, Heat and exhaust them to the atmosphere, outside premises, with considering acceptable environmental conditions in the neighborhood in terms of fume, odor, grease and noise abatement. C. MAKE UP AIR • Replace exhausted air by clean, hygienic, tampered and treated fresh air. D. FIRE FIGHTING • Monitor and Suppress any eventual fire break out from the cooking area and into the exhaust duct, Including combustible sources shut off and isolation. (Gas, Fuel, Electricity, etc.) E. ENERGY SAVING • Energy Saving methods application is mainly to reduce the operating cost and ease down the energy bill on the operator within the HVAC application on the commercial kitchen. Beside that, is to reduce the global warming effect and pull down the CO² tonnage emitted in the atmosphere, thus participating in saving the earth. GREEN EARTH philosophy. A. PURPOSE HEALTHY 1. Capture and Exhaust all cooking process pollutants( Fume, Odor, Grease, Heat) from kitchen working place. 2. Safeguard chefs and cooks from direct exposure to health risk cooking vapors. (Grease laden vapors and fumes proved to be carcinogen). 3. Apply Air Quality Standards such as ISO, EN, ASHRAE for makeup air ASHRAE Standard 55-1, Class I or Minimum Class II Class I: Air with low contamination and inoffensive odor. Class II: Air with moderate contamination and mildly offensive odor. ISO and/or EN Standards: Like EN 13779 and EN 15251 INTRODUCTION. 1. ENGINEERING ISSUES 2. SYSTEMS DISCUSSION A.EXHAUST 1. HOODS. Types and Sizing. 2. FILTERS. 3. DUCT. 4. FANS 5. POLLUTION CONTROL. 6. EXHAUST AIR CALCULATION METHODS. COMMERCIAL KITCHEN VENTILATION ENGINEERING ISSUES: The commercial kitchen ventilation design and application engineering is considered according to relative international authorities a challenging engineering practice that is required to apply for the proper design and application of an efficient, comfortable, safe and hygienic working place that fully comply to related international standards and codes by applying the following rules and practice: 1. Design and apply proper full and effective capture, containment, exhaust and pollution control of all produced effluent arising from cooking process done under a hood. 2. Design and apply the necessary thermal, humidity, air quality and acoustical environment and comfort in the kitchen working place. 3. Design and apply, where necessary all the pollution control of cooking exhaust by abatement of all emitted fumes, odor and grease particulate. 4. Design and apply all the necessary safe environment by fire protecting, detecting, fighting and prevention to safeguard the humans and property. 5. Design and apply where necessary the right energy saving methods in order to lower the operating cost and reducing the global warming by reducing the CO² tonnage rate emission. 6. By considering all the above, the engineer shall fully comply to the international standards, satisfy the requirement of the client and eliminate any objectionable complain for the kitchen operators and the community using or adjacent to the premises. 7. Failing to do so, the engineer will entrain the non satisfaction of the client along with the lack of comfortable, safe and healthy working and living conditions of all kitchen operators and humans living in the neighborhood. It is rather a complex and necessary engineering issue to consider and apply, and which needs good know how, and professional background. INTERNATIONAL STANDARDS AND CODES REFERENCES REFERENCES IMC UMC ASHRAE HANDBOOK ASHRAE STD. 154 EN 16282 & VDI 2052 HVCA DW172 NFPA STD 96 FR. Reglementation: Ventilation en cuisines PRO HOOD MANUFACTURERS DESIGN MANUALS ADDING TO THIS MANY RESEARCH AND STUDY PAPERS AND DOCUMENT SUCH AS: 1. ASHRAE RP 1469, 2. FISHNICK, 3. FSTC 4. ETC… Kitchen Effluent - What Is It? • Kitchen Effluent – is the by-product of commercial cooking processes that must be captured, contained, and removed from the space by the kitchen ventilation system. • Kitchen Effluent – consists of heat and contaminants – very small grease particles – grease vapor (just like humidity in the air) – moisture – odor – VOC’s (volatile organic compounds). US DEFINITIONUS • Fire Safety measures and fighting methods to safeguard humans and property • Pollution Control through special equipment and devices. Clean Environment. • Energy Saving methods application to reduce operating and Life cycle Cost along with safeguarding the earth. MAIN TARGET OF HOOD EXHAUST CAPTURE AND CONTAINMENT (C & C) The most efficient hood operation is to capture and contain all cooking effluent emitted from the cooking appliances under the hood without any over spilling. HOOD TYPES TYPICAL CANOPY SIZING Note Overhang, Side and Frontal Total of 300 mm. DISHWASHER OVERHANG SIZING ASHRAE Designation of Filter Application and efficiency Filter Efficiency @ 140 cfm/ft 100 90 80 Efficiency, % 70 60 50 40 30 20 10 0 1 2 3 4 5 6 7 8 9 10 particle size, micron Cyclonic Filter Baffle I Baffle II 8 Filter efficiency as function of the airflow (cyclonic filter) 100 90 80 Efficiency, % 70 60 50 40 30 20 10 0 1 2 3 4 5 6 7 particle size, micron 140 cfm/ft 200 cfm/ft 270 cfm/ft 8 9 10 Emissions from cooking process grease composition 100 90 80 70 60 50 40 30 % Vapor 20 % Particulate 10 0 ASHRAE RP-745 Emissions from cooking process Emissions lb/1000lb of product cooked Vapor PM < 2.5 PM > 10 PM > 10 Emissions from cooking process grease composition 100 90 80 70 60 50 40 30 % Vapor 20 % Particulate 10 0 ASHRAE RP-745 IMC DUCT SYSTEM DESCRIPTION 506.3.1 Duct materials. Ducts serving Type I hoods shall be constructed of materials in accordance with Sections 506.3.1.1 and 506.3.1.2. 506.3.1.1 Grease duct materials. Grease ducts serving Type I hoods shall be constructed of steel having a minimum thickness of 0.0575 inch (1.463 mm) (No. 16 gage) or stainless steel not less than 0.0450 inch (1.14 mm)(No. 18 gage) in thickness. Exception: Factory-built commercial kitchen grease ducts listed and labeled in accordance with UL 1978 and installed in accordance with Section 304.1. 506.3.1.2 Makeup air ducts. Makeup air ducts connecting to or within 18 inches (457 mm) of a Type I hood shall be constructed and installed in accordance with Sections 603.1, 603.3, 603.4, 603.9, 603.10 and 603.12. Duct insulation installed within 18 inches (457 mm) of a Type I hood shall be noncombustible or shall be listed for the application. 506.3.2 Joints, seams and penetrations of grease ducts. Joints, seams and penetrations of grease ducts shall be made with a continuous liquid-tight weld or braze made on the external surface of the duct system. NFPA 96, DUCT SYSTEM DESCRIPTION 7.5.1* Materials. 7.5.1.1 Ducts shall be constructed of and supported by carbon steel not less than 1.52 mm (0.060 in.) (No. 16 MSG) in thickness or stainless steel not less than 1.21 mm (0.048 in.) (No. 18 MSG) in thickness. 7.5.1.2 Factory-built grease ducts listed in accordance with ANSI/UL 1978 shall be permitted to use materials in accordance with their listing. 7.5.2 Installation. 7.5.2.1 All seams, joints, penetrations, and duct-to-hood collar connections shall have a liquidtight continuous external weld. 7.5.2.1.1 Factory-built grease ducts listed in accordance with ANSI/UL 1978 shall be permitted to incorporate nonwelded joint construction in accordance with their listings. ALSO LOOK INTO: 1.ASHRAE STANDARD 154, Chapter 6 2. NFPA 96 3. DW 172, Section 15 4.EN 16282-5 5. EN 13779, Tightness Class C Bell duct joint Male end I.D. [mm (in.)] Exhaust duct Weld around I.D. [mm + 6.4 mm (in. + ¹⁄₄ in.)] (max.) Female end I.D. [mm (in.)] 50.8 mm (2 in.) (max.) 16 gauge [1.52 mm (0.060 in.)] black iron Notes: 1. Duct size stays the same throughout the duct system. 2. Smaller (inside) male duct end is always above or uphill (on sloped duct), to be self-draining into larger (outside) female duct end. FIGURE 7.5.5.1(b) Bell-Type Duct Connection. Telescoping duct joint Inside section I.D. [mm (in.)] Exhaust duct Weld around 50.8 mm (2 in.) (max.) Outside section FIGURE 7.5.5.1(c) Flange with Edge Weld. I.D. [mm + 6.4 mm Flange with Filled Weld. 16 gauge [1.52 mm (0.060 in.)] black iron Notes: 1. Duct size decreases (going upward) with each telescope. 2. Smaller (inside) duct section is always above or uphill (on sloped duct), to be self-draining into larger (outside) duct. FIGURE 7.5.5.1(a) FIGURE 7.5.5.1(d) (in. + ¹⁄₄ in.)] (max.) Telescoping-Type Duct Connection. 8.1.6 Openings for Cleaning, Servicing, and Inspection. 8.1.6.1 Openings for cleaning, servicing, and inspection shall conform to the requirements of 7.3.7. 8.1.6.2 Clearances shall conform to the requirements of Section 4.2 or, if installed within an enclosure, to the requirements of 7.7.2.2. B.6.5.1 Horizontal Ducts. B.6.5.1.1 On horizontal ducts, at least one 508 mm × 508 mm (20 in. × 20 in.) opening shall be provided for personnel entry. B.6.5.1.2 Where an opening of the size specified in B.6.5.1.1 is not possible, openings large enough to permit thorough cleaning shall be provided at 3.7 m (12 ft) intervals. B.6.5.2 Vertical Ducts. B.6.5.2.1 On vertical ductwork where personnel entry is possible, access shall be provided at the top of the vertical riser to accommodate descent. B.6.5.2.2 Where personnel entry is not possible, adequate access for cleaning shall be provided on each floor. B.6.5.2.3 On nonlisted ductwork, the edge of the opening shall be not less than 38.1 mm (1 1∕2 in.) from all outside edges of the duct or welded seams. INLINE FAN UTILITY FAN Note: All Electric Motors shall be out of Air Stream ROOF UBLAST FAN MAIN ELEMENTS: 1. MULTIPLE STAGES OF FILTERS; PRE FILTER, BAG FILTER, HEPA FILTER, CARBON FILTER 2. ELECTROSTATIC PRECIPITATOR OR UV LAMP BATTERY 3. EXHAUST FAN PCU with UV module Fan section Disposable panel filters section UV lamps section Disposable bag filters section Absolute [HEPA] filters section Activated carbon filters section FILTERS STANDARDS RATING COMPARISON ASHRAE 52.2 1. MERV 6 2. MERV 7 3. MERV 8 4. MERV 9 5. MERV 10 6. MERV 11 7. MERV 12 8. MERV 13 9. MERV 14 EN 779 Dust Spot Efficiency 25-30% “ “ “ 30-35% “ “ “ 35-40% “ “ “ 40-45% “ “ “ 50-55% “ “ “ 60-65% “ “ “ 70-75% “ “ “ 80-90% “ “ “ 90_95% G4 G4 G4 F5 F6 F7 F8 F8 F9 ULTRA VIOLET LIGHT TREATMENT UV-C Most of the grease exhausted from the hood can be classified as fatty acids; an example being oleic acid, which is the primary fat in ground beef. These substances consist of long chains of molecules connected by double bonds, which are chemically reactive. One chemical reaction that occurs is called Photolysis and takes place when UV-light hits the long molecular chains and breaks the double bonds resulting in smaller molecular chains of grease. The second chemical reaction is called Ozonolysis in which the ozone generated by the lamps continues to react with the smaller chains of grease and grease vapors to chemically alter them. The resulting substance will not stick to the ductwork or fans (as grease does) which helps eliminate a serious fire risk. UV SYSTEM EXPLAINED ■ ASTM has adopted a grease filter efficiency standard: F2519-05. ■ New technologies, such as UV light, can provide enhanced grease abatement. What is ultraviolet light and how does it work? UV stands for ultraviolet light, which is most commonly produced by the sun and delivered to the Earth's atmosphere. UV light has three different bands: UVA, UVB, and UVC. UVA has the longest wavelength, UVB is medium and UVC has the shortest wavelength. UVC is the type used for germicidal applications and is commonly seen in both water and air sterilization applications. UVC producing lamps come in two varieties: ozone producing and non-ozone producing. For the galley hood application, the added ozone production has proven to be beneficial in destroying grease. In ships' galleys most of the grease exhausted from the hood can be classified as fatty acids; an example being oleic acid, which is the primary fat in ground beef. These substances consist of long chains of molecules connected by double bonds, which are chemically reactive. One chemical reaction that occurs is called Photolysis and takes place when UV-light hits the long molecular chains and breaks the double bonds resulting in smaller molecular chains of grease. The second chemical reaction is called Ozonolysis in which the ozone generated by the lamps continues to react with the smaller chains of grease and grease vapors to chemically alter them. The resulting substance will not stick to the ductwork or fans (as grease does) which helps eliminate a serious fire risk. UV Light Can… ■ Minimize the buildup of grease in ductwork leading to: ■ Reduced frequency of cleaning ■ Increased fire protection safety ■ Eliminates grease buildup on roofs and enhances the life of exhaust fans. UV Light Technology ■ UVC lights placed in the exhaust plenum of kitchen hoods. ■ The UV light breaks the longer chains of grease molecules. ■ Ozone oxidizes the smaller particulate matter and vapor components. ■ Most effective on smaller particulate and vapor ■ Efficient filtration still needed prior to the UV lights. 21 ULTRA VIOLET LAMPS IN HOOD Other Alternative; UV LAMPS IN PTU. For most efficient system of UV both reactions is to create enough time span between ozonolysis and photolysis, (2 seconds minimum, ± 15 to 20 meter duct run between hood and exhaust outlet). Electro-static air filtration Example: Charcoal Grilling EXHAUST FLOW RATES !. ASHRAE METHOD ASHRAE STD 154 SUGGESTS MORE PRECISE METHOD AS FOLLOW (Derived from VDI 2052) IMC METHOD 507.5.4 Light-duty cooking appliances. The minimum net airflow for hoods, as determined by Section 507.1, used for light- duty cooking appliances and food service preparation shall be determined as follows: Type of Hood CFM per linear foot of hood Backshelf/pass-over 250 Double island canopy (per side) 250 Eyebrow 250 Single island canopy 400 Wall-mounted canopy 200 For SI: 1 cfm per linear foot = 1.55 L/s per linear meter. 507.5.5 Dishwashing appliances. The minimum net airflow for Type II hoods used for dishwashing appliances shall be 100 cfm per linear foot (155 L/s per linear meter) of hood length. 507.5.3 Medium-duty cooking appliances. The minimum net airflow for hoods, as determined by Section 507.1, used for medium-duty cooking appliances shall be determined as follows: Type of Hood CFM per linear foot of hood Backshelf/pass-over 300 Double island canopy (per side) 300 Eyebrow 250 Single island canopy 500 Wall-mounted canopy 300 For SI: 1 cfm per linear foot = 1.55 L/s per linear meter. 507.5.2 Heavy-duty cooking appliances. The minimum net airflow for hoods, as determined by Section 507.1, used for heavy-duty cooking appliances shall be determined as follows: Type of Hood CFM per linear foot of hood Backshelf/pass-over 400 Double island canopy (per side) 400 Eyebrow Not allowed Single island canopy 600 Wall-mounted canopy 400 For SI: 1 cfm per linear foot = 1.55 L/s per linear meter. 2, INTERNATIONAL MECHANICAL CODE FLOW RATES METHOD 507.5.1 Extra-heavy-duty cooking appliances. The minimum net airflow for hoods, as determined by Section 507.1, used for extra-heavy duty cooking appliances shall be determined as follows: Type of Hood CFM per linear foot of hood Backshelf/pass-over Not allowed Double island canopy (per side) 550 Eyebrow Not allowed Single island canopy 700 Wall-mounted canopy 550 For SI: 1 cfm per linear foot = 1.55 L/s per linear meter. THE BRITISH METHOD: BESA DW 172 Method 1: THERMAL CONVECTION METHOD • Using Appliance Coefficient, (Gas or Electric),temperature and size as listed in Table 2 • Using Canopy Factor as listed in Table 3: Low Level, Passover, Overhad Wall, Overhead Wall, Island Mounted, Island, • Example Method 2: FACE VELOCITY METHOD The volume of air to be extracted may be determined by selecting a velocity across the face area of the canopy that is appropriate for the type of appliances expected to be used. The capture velocity is multiplied by the canopy area to determine the volume of air to be extracted. The capture velocity should be selected to ensure an even distribution of air across the canopy face, this velocity will vary according to the cooking application and whether the canopy is either wall or island mounted. • Light loading - 0.25 mIs. Applies to steaming ovens, boiling pans, bains marie and stock-pot stoves. • Medium loading - 0.35 mIs. Applies to deep fat fryers, bratt pans, solid and open top ranges and griddles. • Heavy Loading - 0.5 mIs. Applies to chargrills, mesquite and specialist broiler units. Method 3: APPLIANCE POWER INPUT (This is a provisional method when there is insufficient information available regarding the cooking Equipment) When details of the cooking equipment to be used is limited to the amount of power required rather than the physical size of the appliance, then the power input method may be used. Each type of appliance is allocated a recommended flow rate in m3/s which is then multiplied by the power input in kW to determine the flow rate required for each appliance. The total air required is then determined by adding together the recommended extract rate for each item of equipment. Method 4: AIR CHANGES Depending on the size of the kitchen, type of cooking, number of people and not very recommended 40 Air Changes per Hour should be regarded as a minimum for comfort Method 5: LINEAR EXTRACT Table 5: Flow rates (m3/s per linear metre of canopy) Type of Canopy Wall_Mounted Light Duty Medium Duty Heavy Duty 0.23-031 0.31 - 0.46 0.31 - 0.62 Single Island 0.39 - 0.46 0.46 - 0.62 0.46 - 0.93 Double Island 0.23 - 0.31 0.31 - 0.46 0.39 - 0.62 Eyebrow 0.23 - 0.39 0.23 - 0.39 — Passover/Backshelf 0.15 - 0.31 0.31 - 0.46 0.46 - 0.62 Extra Heavy Duty 0.54+ 0.85 + 0.77 + — not recommended NB - Extract rates for double island canopies are for active filter length, i.e. double the rate for an equivalent length wall Canopy EN 16282-1 2017 and VDI 2052 VDI OLD METHOD VDI 2052 Calculation following Sensible Heat of equipment unit. A. Qs (m³/h) = Ps * K1 * K2 Φ *Cp * (Ta-Ti) VDI 2052 Calculation following Latent Heat pf equipment unit B. Ql (m³/h) = Pl * K1 * K2 Φ * L * (xa * xi) Total Flow rate is the summation of all calculated units FINAL FLOW RATE IS THE HIGHER OF ANY OF THE ABOVE A OR B Note: Unit Sensible and Latent heat emission is usually found in old VDI 2052 Relative tables. The extraction flow to take into account will be the highest between Qs and Ql. QS = extraction flow (m3/h) following sensible heat Ql = extraction flow (m3/h) following the latent heat ϕ = air density: 1.2 kg/m3 Ps = sensible heat from cooker (kW) Pl = latent heat released by the appliance (kW) K1 = Coefficient of simultaneous taking into account the non functioning of all devices of cooking at full power, varies between 0.7 and 1. K2 = Coefficient of efficiency of capture: 0.8 for a hood - 1 for ceilings filtrants Cp = specific heat capacity of air: 0.35kW / kg ° C L = latent heat from the air: 0.7kW / kg Ta-Ti = difference in temperature between the ambient air and air introduced: 8 ° C Xa-Xi = mass of water difference between ambient air and air introduced: 5 g/kg dry air NEW EN 16282-1 and VDI 2052 STANDARD EXHAUST FLOW RATES METHOD Very Complex but most accurate calculation using mainly the cooking equipment sensible and latent heat emission converted to air flow volume Based on the following formulas and other derivatives found in the standards The NEW EN STANDARD 16282-1 2017 is the latest and very similar to VDI 2052 if not equal Here, We mostly focus on it. The Calculation Method uses mainly the EFFLUENT PLUME EFFECT EN STANDARD 16282-1 and VDI 2052 NEW 2017 METHOD Symbols: P = Power KW, Qs = Sensible Heat W. CONCLUSION OF EN 16282-1 (VDI 2052) METHODS: FOLOW ALL CALCULAION DETAILS AND TABLES DESCRIBED IN STANDARD. IN SHORT: 1. Total appliances Sensible Load Calculated Air Flow, m²/hr (Formula 3) 2. Total appliances Latent Load Calculated Air Flow, m²/hr (Formula 11) 3. Choose Highest Value between Sensible and Latent and Apply 4. Add to it the Compensation Air Flow that could be ± 10 of the total exhaust air, refer to table. END RESULT: Final Total Extraction is the air flow that should be specified for the exhaust fan and should equal or little above to the THERMAL PLUME CALCULATION AIR FLOW LIST OF DESIGN MANUALS ISSUED BY SOME MANUFACTURERS 1. HALTON 2. GREENHECK 3. BRITANNIA 4. GAYLORD 5. CAPTIVEAIRE 6. OTHERS FR. REGLENTATION DES CUISINES PRO FR. REGLEMENTATION DES GRANDES CUISINES PRO DETERMINATION DES DEBITS D’EXTRACTION La détermination des débits d’extraction dans les cuisines professionnelles doit répondre à deux critères spécifiques afin de respecter les conditions d’hygiène et de confort : •L’évacuation vers l’extérieur de la chaleur sensible et la- tente dégagée par les appareils de cuisson. •L’évacuation vers l’extérieur des polluants dégagés par la cuisson après captation et filtration. Les cuisines étant des locaux à “pollution spécifique”, elles doivent être en dépression par rapport aux locaux adjacents (dépression de 10% minimum) et l’air extrait doit impérati- vement être rejeté vers l’extérieur et à huit mètres de tout ouvrant ou de prise d’air neuf (voir article 63.1 de la circulaire du 09 août 1978 modifiée page 245). Il existe trois méthodes pour la détermination des débits d’ex- traction, mais en France une seule est officielle : Méthode suivant la réglementation RSD 64-2 révisée le 20/01/83 (méthode officielle) : /h /Repas L’arrêté du 20/01/1983 demandemde déterminer un minimum de renouvellement d’air neuf dans les cuisines suivant le nombre de repas servis simultanément. CUISINES COLLECTIVES 3 Relais 15 Moins de 150 repas servis simultanément 25 De 150 à 500 repas servis simultanément (1) 20 De 501 à 1 500 repas servis simultanément (2) 15 Plus de 1 500 repas servis simultanément (3) 10 Cette méthode de calcul, bien qu’étant la seule officielle, ne peut être utilisée qu’en avant projet car elle ne prend pas en compte : Le type d’appareils de cuisson. Le mode de ventilation utilisé. Les différentes zones de cuisson. SIMPLE FRENCH METHOD IN CASE NO IDENTIFICATION OF APPLIANCES Méthode suivant la vitesse de passage d’air : Cette méthode consiste à déterminer un débit d’extraction en fonction d’une vitesse de passage d’air dans la surface libre (frontale et latérale) entre le bas de la hotte et le haut du plan de cuisson. Suivant le type d’appareil de cuisson, la vitesse de passage d’air doit être comprise entre 0.2 et 0.5m/s. Plus les polluants à extraire seront lourds, plus la vitesse de passage d’air devra être élevée. Exemple : Piano à fort dégagement de vapeur (marmite, four va- peur...) : Vitesse de passage d’air entre 0.2 et 0.3m/s. Piano à fort dégagement de graisse (friteuse, grill...) : Vitesse de passage d’air entre 0.4 et 0.5m/s. Cette méthode de calcul assure un confort de travail et d’hygiène acceptable dans les cuisines. Elle ne peut être appli- quée qu’à un système d’extraction par hottes traditionnelles. Elle ne prend pas en compte la chaleur dissipée (sensible et latente) par les appareils de cuissons. Débit d’extraction (m3/h) = Surface libre (m2) x Vitesse de passage (m/s) x 3600 99.2 Supply air systems The task of supply air systems is to replace the extract air and create conditions for the remov9.2 Supply air systems The task of supply air systems is to replace the extract air and create conditions for the removal of heat and humidity. Sup9.2 Supply air systems The task of supply air systems is to replace the extract air and create conditions for the removal of heat and humidity. Supply air systems shall be designed in such a way that the air extraction, conditioning, delivery or distribution does not adversely affect the hygiene situation within the kitchen area. ly air systems shall be designed in such a way that the air extraction, conditioning, delivery or distribution does not adversely affect the hygiene situation within the kitchen area. al of heat and humidity. Supply air systems shall be designed in such a way that the air extraction, conditioning, delivery or distribution does not adversely affect the hygiene situation within the kitchen area. 9.2 Supply air systems PLUS The task of supply air systems is to replace the extract air and create conditions for the removal of heat and humidity. PROVIDE GOOD QUALITY FRESH in AIR ANDa COMFORT CONDITIONS FOR conditioning, OPERATORS delivery or Supply air systems shall be designed such way that the air extraction, distribution does not adversely affect the hygiene situation within the kitchen area. .2 Supply air systems The task of supply air systems is to replace the extract air and create conditions for the removal of heat and humidity. Supply air systems shall be designed in such a way that the air extraction, conditioning, delivery or distribution does not adversely affect the hygiene situation within the kitchen area. ENVIRONMENAL & COMFORT Required Dry Temperature Range: 20°C - 26°C with IDA 1 IAQ Or Ashrae Class I Required Relative Humidity Range: 60 - 70% Ideally: 1. Cooking Area ± 25-26° C 2. Preparation Area ± 23-24°C 3. Pastry Area ± 20-22°C Category Description Typical environment ODA 1 Outdoor air, which may be only temporarily dust y Applies where the World Health Organisation WHO (2005) guidelines are fulfilled (annual mean for PM2.5 ≤ 10 μg/m3 and PM10 ≤ 20 μg/m3). ODA 2 Outdoor air with high concentrations of particulate matter Applies where P M concentrations exceed the WHO guidelines by a factor of up to 1,5 (annual mean for PM2.5 ≤ 15 μg/m3 and PM10 ≤ 30 μg/m3). ODA 3 Outdoor air with very high concentrations of particulate matter Applies where P M concentrations exceed the WHO guidelines by a factor of greater than 1,5 (annual mean for PM2.5 > 15 μg/m3 and PM10 > 30 μg/m3). Efficiency Size range, µm ePM10 0,3 ≤ × ≤10 ePM2,5 0,3 ≤ × ≤2,5 ePM1 0,3 ≤ × ≤1 Table 1 — Optical particle diameter size ranges for the definition of the efficiencies, ePMx Classification of indoor air quality Category Description CO2 –level above level of outdoor air (ppm) Typical range Rate of outdoor air (m3/h/person) Typical range, non-smoking area IDA 1 IDA 2 High IAQ Medium IAQ ≤ 400 400 – 600 >54 36 – 54 IDA 3 Moderate IAQ 600 –1000 22 – 36 > 1000 < 22 IDA 4 Low IAQ 3 Filter Recommendations according to EN 13779 Table referring in The European Standard EN 13779. IAQ Indoor Air Quality Outdoor Air Quality Pollution level IDA 1 (High) ODA 1 ODA 2 ODA 3 IDA 2 (Medium) IDA 3 (Moderate) IDA 4 (Low) F9 F8 F7 F5 F7 + F9 F6 + F8 F5 + F7 F5 + F6 F5 + F7 F5 + F6 F7 + GF + F9 F7 + GF + F9 Thermal comfort, tolerance For the following it is assumed that kitchen personnel wear clothing with an average clothing insulation corresponding to 0,6 clo. This value shall be used for the relevant comfort parameters in accordance with EN ISO 7730 (humidity, air movement, radiant heat, temperature). The ventilation system shall maintain the air quality within range 1 specified in Figure 1. Air temperature and humidity are measured at a height of 1,10 m above the floor at a distance of 0,50 m from the appliances. Key X wet bulb temperature in °C Y air temperature in °C a relative humidity in % 1. comfort range at the workplace 2. tolerable range at the workplace Temperature of room air The temperature of the room air in kitchens and dishwashing area shall be at least 18 °C and shall not exceed 26 °C unless unavoidable due to the processes. This does not include seasonal, excess temperatures or areas in which higher or lower temperatures are unavoidable due to their function. Suggested Thermal Comfort Zone for Commercial Kitchens 20°C 25°C 30°C VARIOUS TYPES OF MAKE UP AIR DISCHARGE IN KITCHEN To Add to it Displacement ventilation CAPTURE AND CONTAINMENT APPLICATION: 1. Proper exhaust flow rate calculation referring to international standards and codes methods. 2. Hood Proper dimensions, mainly the requested sizes of side and frontal overhangs. 3. Elimination of air flow turbulence and or draft outside and adjacent to the hood faces: (low velocity fresh air, avoiding 4 way diffusers adjacent to the hood, etc.. HERE ARE SOME PICTURES AND VIDEOS ON HOOD BEHAVIOR IN DIFFERENT OPERATION CONDITIONS Figure 21. Schlieren Image Showing Thermal Plume Being Pulled Outside Hood by Air Curtain Figure 22. Schlieren Image Showing Thermal Plume Being Captured with Back-Wall Supply Figure 23. Schlieren Image Showing Thermal Plume Being Pulled Outside Hood by Front Face Figure 26. Schlieren Image Showing Thermal Plume Being Pulled Outside Hood by Air Discharged from Four-Way Diffuser Figure 24. Schlieren Image Showing Thermal Plume Being Displaced by Short-Circuit Supply, Causing Hood to Spill Figure 25. Schlieren Image Showing Effective Plume Capture with Replacement Air Supplied Through 400 mm Wide Perforated Perimeter Supply, Shown with Additional Front Overhang Figure 27. Schlieren Image Showing Plume Being Effectively Captured when Replacement Air Is Supplied at Low Velocity from Displacement Diffusers FIGURE A-2 Best practices restaurant air balance example. FIGURE A-2 Best practices restaurant air balance example. OPTIMUM DESIGN: Fresh Air 85 to 90% of Exhaust Air. Negative Pressure up to 5 PA between Kitchen and Adjacent spaces Vk : vitesse d'air à la sortie du diffuseur Vr : vitesse résiduelle dans la zone d'occupation Ti : taux d'induction Hr : hygrométrie dans l'ambiance Tamb : température dans l'ambiance Vmoy : vitesse d'aspiration périphérique moyenne 20/KDG/1500/0107/EN Picture 22. Open ceiling Ventilated Ceilings 25 CLOSED CEILING REFER TO: 1.NFPA 96 2.IFC. 3.DW 172 SECTION 20 4.EN-16282-7 SAFETY Mainly Fire Protection and Fighting: 1. First Apply related codes and standards, Like NFPA 101, 1, 5000, 96, IMC, IFC, EN and Local AHJ. 2. Apply Automatic Sprinklers where mandatory in the working place. NFPA 13 3. Add portable extinguishers where required. 4. Apply Automatic Fire Alarm System 5. Apply Automatic suppression system over the hoods and exhaust ducts HOOD FIRE SUPPRESSION SYSTEM BASIC LAYOUT WHERE IS ENERGY SAVING IN KITCHEN VENTILATION? In Kitchen Ventilation the consumed energy is mainly of Electrical nature. • Fan Motors • Refrigeration. Cooling of Fresh Air • Heating. Heating of Fresh Air. To Tackle with these energy consuming sources. We need to do the following: • Choose high efficiency motors. • Ease down on air flow quantity with proper and only needed flow, no more no less. • Design and select ducts, filters and terminals with low pressure drop. And Mainly consider and apply a proper demand ventilation control system between exhaust air and make up one. DCV. Finally study and design proper cooling and heating system responding only to the demand of the space and its operating condition and the related outdoor ambient conditions based on the actual geographical location of the outlet. IS ENERGY SAVING IN KITCHEN VENTILATION DEMAND CONTROL VENTILATION It is a designed and engineered system to interact operation modes between cooking activity (Firing or non firing of cooking appliances under the hood) and to control and manage the air flow (Exhaust and Make Up) according to this activity and its cooking process and the thermal plume generation and intensity. This is achieved by implementing a field sensing system to monitor and measure this activity and send commands to the fan motors, cooling and heating devices to reduce their speed (Through well managed VFD systems) and their cooling/heating flows by reducing the consumption of KW in electrical load and cooling and heating loads SUCH AS: 1. HALTON MARVEL System 2. INTELLI-HOOD, Melink Corp. MAINLY DESCRIBED AND REQUIRED IN ASHRAE 90.1 STANDARD AND ANY OTHER ENERGY SAVING STANDARDS IN THE INTERNATIONAL COMMUNITY EXHAUST ENERGY RECOVERY UNIT ONLY FOR HEAT RECOVERY FROM EXHAUST HOOD RULE OF THUMB ENERGY SAVING CALCULATION & AND RETURN ON INVESTMENT A kitchen with 2300 l/s (5000 CFM) Fresh Air to be cooled from 30°C DB / 65% RH TO 18°C DB/96% RH Requires 85.8 KW Of Cooling (25 TR) At 1200 Watt /TR Energy Consumption = 30 KWH 8 Hours of Daily Operation = 240 KWH Daily Consumption Operating Summer/Winter 365 Days/Year = 240 KWH * 365 = 87600 KWH/Year At 15 Cents KWH = 13140 $ YEAR Average Saving Per YEAR 30 % of 13140 * 0.30= 3942 $ Year SAY ± 4000 $/YEAR of Saving DCKV Average Cost ± 4000$ , Add to it The Exhaust fan Energy Saving too = 4000$ PLUS THE RETURN ON INVESYMENT IS ONLY FOR ONE YEAR OR LESS. NEXT COMING PRESENTATION IN THE NEAR FUTURE VFD APPLICATION & NETWORK HARMONICS Elie M. Baradhy www.embassociates.com elie@embassosiates.com