Code Enforcement Land Use and Environmental Services Agency

advertisement

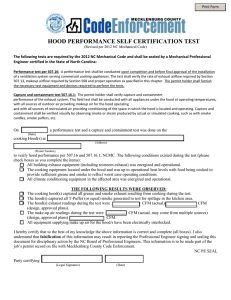

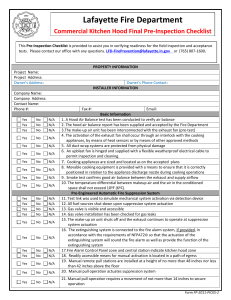

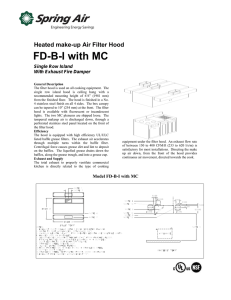

CODE INTERPRETATION Land Use and Environmental Services Agency Code Enforcement Code Volume Reference: NC Mechanical Code 2006 Code Chapter Reference: 507.16, 507.16.1, 507.16.2 Subject: Performance Test Detail Effective Date: 1/1/2003 Prepared/Revision Date: October 2008 CODE: 507.16 Performance test. A performance test shall be conducted upon completion and before final approval of the installation of a ventilation system serving commercial cooking appliances. The test shall verify the rate of exhaust airflow required by Section 507.13, makeup airflow required by Section 508, and proper operation as specified in this chapter. The permit holder (or testing firm) shall furnish the necessary test equipment and devices required to perform the tests. 507.16.1 Capture and containment test. The permit holder shall verify capture and containment performance of the exhaust system. This field test shall be conducted with all appliances under the hood at operating temperatures. Capture and containment shall be verified visually by observing smoke or steam produced by actual or simulated cooking, such as with smoke candles, smoke puffers, etc. 507.16.2 Certification. These tests shall be witnessed by the code official, or at the code official’s option, by a professional engineer. INTERPRETATION: The hood/s (Type I only) test shall verify the rate of airflow and proper operation with these additional requirements: 1. 2. 3. 4. 5. 6. 7. All building exhausting equipment (i.e. misc. kitchen exhaust fans, bath fans, etc.) shall be energized and in operation during the performance test. The cooking equipment under the hood/s shall be in place, up to operational heat levels and sufficient smoke/ grease generating foods to simulate the desired cooking process. The hood shall capture all exhaust. T-T Puffers (or equal) shall be used during the test to check for spillage of exhaust to the kitchen area. The test shall also include the verifying of actual flow rates versus design flow rates. The Designer or installer shall provide documentation detailing and certification of all test results including the status of the structures systems during the tests (i.e. temperatures, food cooked, fans, etc.) Testing/verification shall be performed by a P.E or person/s certified through AABC, TABB, NEBB or NBC, who shall provide documentation of performance to the code official. The electrical interlocking of any system providing make up air to the hood. AABC (Associated Air Balance Council) TABB (Testing & Balancing Bureau) NEBB (National Environmental Balancing Bureau) NBI (National Balancing Council) Prepared by: Consistency Team Approved by: Philip B. Edwards, M/P Code Administrator