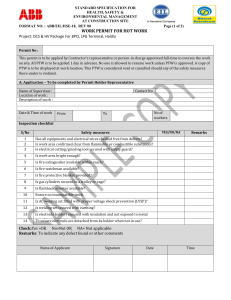

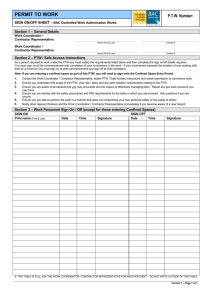

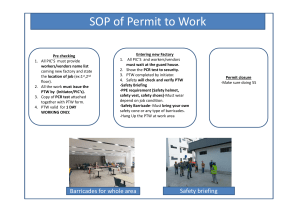

lOMoARcPSD|39376716 Assessment Guide Ece (Jawaharlal Nehru Technological University, Hyderabad) Scan to open on Studocu Studocu is not sponsored or endorsed by any college or university Downloaded by Sam (zaidisaab11@gmail.com) lOMoARcPSD|39376716 1Q. WHAT IS PTW SYSTEM? A: (1) PTW SYSTEM IS AUTHORISED PEOPLE CONDUCT TO SPECIFIC PERSON AT SPECIFIC WORK AND TIME AT SPECIFIC LOCATION. (2) IT IS FORMAL AND LEGAL DOCUMENT (3) ENSURE THAT MAINTAIN COMMUNICATION BETWEEN MANAGEMENT, SUPERVISOR, OPRATORS, WORK CREW. 2Q. WHY PTW SYSTEM? A: PTW SYSTEM IN ENSURE THAT ALL NON-HAZARDIUOS WORKS CAN BE DONE IN SAFE MANNER. 3Q. WHO INVOLVE IN PTW SYSTEM? EXPLAIN AUTHORISATION LEVELS? EXPLAIN PTW LIFE CYCLE? A: PTW APPLIED BY PTW AUTHORISED BY PTW AGREEMENT BY PTW ACCEPT, SUSPENSION, CANCLE, COMPLETE BY PTW VALID, CANCLE BY ISO&DE ISO BY PTW GAS TESTING BY PTW AND ATTACHED DOCUMENTS QWALITY CHECKING - PERMIT APPLICANT - RESPONSIBLE SUPERVISOR - OTHER AFFECTED COSTODION -PERMIT HOLDER -AREA AUTHORITY -AREA AUTHORITY -AUTHORISED GAS TESTER - PTW COORDINATOR 4Q. TYPES OF PERMITS? A: CLASS “A” TYPE PERMIT: (1) 3 COPIES. 1st PINK WITH RED EDGE – WORK SITE GREEN - AREA AUTHORUTY (PERMIT ISSUE POINT) WHITE - RESPOSIBLE SUPERVISOR( FOR INFORMATION PURPOSE) (2) NOTICE PERIOD 72 HOURS (3) VALIDATION PERIOD 12 HOURS (4) AUTHORISATION PERIOAD 14 DAYS (5) ISSUE FOR HIGH RISK WORKS (6) EX: CONFINED SPACE, HOT WORK IN PROCESS FACILITY, CLASS “B” TYPE PERMIT: (1) 3 COPIES. 1ST COPY BLUE COLOUR – WORK SITE GREEN - AREA AUTHORITY WHITE - RESPONSIBLE SUPERVISOR (2) NOTICE PERIOD 24 HOURS (3) VALIDATION PERIOD 12 HOURS (4) AUTHORISATION PERIOAD 28 DAYS (5) ISSUE FOR MIDIUM RISK WORKS 5Q. RESPONSIBILITIES OF PERMIT HOLDER: A: (1)UNDERSTAND THE WORK CONTENT AND REQUERMENTS OF JOB HSE PLAN. (2) TELL TO WORK PARTY ABOUT THE WORK CONTENT AND REQUERMENTS OF JOB HSE PLAN (3) ENSURE THAT ALL CREW MEMBERS UNDERSTAND THE JOB HSE PLAN AND WHAT IS REQUEREMENT (4) ENSURE THAT PERMIT VALIDATION BEFORE STARTING THE WORK DAILY (5) DISPLAY PTW AT SITE (6) PREEPAIR TRIC AND CONDUCT TBT Downloaded by Sam (zaidisaab11@gmail.com) lOMoARcPSD|39376716 (7) TELL TO WORK PARTY ABOUT HARZARD AND CONTROLS OF THE WORK (8) EXPLAIN ERP,ASSEMBLY POINT ,PRECAUTIONS (9) CONDUCT PAUSE AND CHECK (10)CONTINUESLY SUPERVISORING TO WORK CREW RESPONSIBILITIES OF PERMIT APPLICANT: (1) RECEIVE WORK SCOPE FROM THE PROJECT ENGINNER AND PLANNING ENGINEER (2) MAKE A SITE VISIT TO UNDERSTAND THE SCOPE,LOCATION AND WHAT RESOURCES ARE NEEDED (3) PREPARE THE PERMIT, INCLUDE THE JOB HSE PLAN, HRA PERMIT QUALITY, CHECK LIST,DRAWINGS AND REQUIRED CERTIFICATE NEEDED FOR THE JOB (4) AUTHORISE THE PERMIT FROM AREA RESPONSIBLE SUPERVISOR (5) MAKE A STE VISIT ALONG WITH THE PERMIT HOLDER AND EXPLAIN THE CONTENT, HAZARDS ASSOCIATED WITH THE JOB AND THE CONTROLS NEEDED IN PLACE (6) MAKE PERIODIC SITE VISIT TO THE LOCATION WHICH YOU APPLIED A PERMIT FOR (7) YOU OVERALL RESPONSIBLE FOR THE JOB FROM THE START TO END CONDITIONS FOR CHANGE OVER THE PERMIT HOLDER: (1) WHITHIN PROCESS FACILITY BOTH PERMT HOLDER MUST BE OBTAIN THE AREA AUTHORITY OPPROVAL TO CHARGE AND THE OUTGOING PERMIT HOLDER WILL SOGN 10C AND WILL SUSPEND , NEW PERMIT HOLDER WILL SIGN BOX 10B OF BOTH COPIES OF THE PERMIT OF ACCEPTANCE. (2) AR REMOTE LOCATION WHERE HE IS UNABLE TO REACH AREA AUTHORITY SO THEY WILL CONTACT WITH AREA AUTHORITY BY CELL PHONE AND TAKE APPROVAL THAN OUTGOING HOLDER WILL SIGN 10C AND WILL SUSPEND (3) THE OUTGOING PERMIT HOLDER CANT LEAVE THE SITE WHEN EVER HAS FULLY BRIEFED THE CREW PERMIT HOLDER AND THE NEW PERMIT HOLDER HAS SIGNED TO ACCEPT THE PERMIT IN HIS PRESENCE 6Q. PRINCIPLE OF PTW? A: IT IS MANDOTARY DOCUMENT WHICH ALLOWS TO RESPONCIBLE SUPERVISOR, APPLICANT, TO USE OF A FRAME WORK OF QUESTION TO IDENTIFY IF A PTW REQUERED 7Q. FACTORS OF PTW: (1) (2) (3) (4) DETIFINATION OF PTW SCOPE OBJECTIVE PRINCIPLE OF PTW 8Q. WHEN WE SUSPEND PTW? A: (1)VALIDATION PERIOD EXPIRED (2) ANY UNSAFE CONDITION DEVELOPS (3) WORK WITH HIGHER PRIORITY THAN THIS WORK (4) EMERGENCY EVACUATION (5) DELAY WORK MORE TRAHN 4 HOURS 9Q. WHEN WE CANCLE THE PTW? A: (1) AUTHORISATION PERIOD EXPIRED (2) WORK COMPLETE (3) WORK NOT COMPLETE (4) WORK DISCRIPTION DIFFERENT THAN SITE SITUATION Downloaded by Sam (zaidisaab11@gmail.com) lOMoARcPSD|39376716 10Q. DOCUMENTS WITH PTW? A: JOB SAFETY PALN, TRIC, HRA, PTW CHECK LIST, PAUSE AND CHECK, RELATED DRAWINGS 11Q. WHAT WILL YOU CHECK IN PTW? A. PERMIT TYPE,DRAWING, DATES,SIGN,PERMIT NUMBER,LOCATION,WORK DESCRIPTION,ATTACHED CERTIFICATES,JOB HSE PLAN,TRIC CARD,PROCRDURES. 12Q. WHEN PERMIT REQUIRED: (1) (2) (3) (4) (5) (6) WORK WITHIN PROCESS FACILITY WORK WITHIN EPZ ELECTRICAL INSTALLATION WORK WITHIN HYDRO CARBON AREA WORK IS CONFINED SPACE IS ADDITIONAL CERTIFICATES REQUIRED TO WORK 13Q. WHEN PTW NOT REQUIRED? (1) FAMILIER TO WORK FORCE (2) CONFITENTED SUPERVISOR (3) WRITTEN PROCESSOR FOR WORK 1Q. WHAT IS H2S? AND PROPERTIES? A: (1) H2S MEANS HYDROGEN SULPHIDE, IS HIGHLY TOXIC GAS (2) HEVIER THAN AIR (3) EASILY MIX IN WATER (4) CORROSIVE (5) EXPLOSIVE AT 4.3% (6) COLOURLESS (7) ROTTEN EGG SMELL 2Q. HOW WE CAN FIGHT WITH H2S? A: WE CAN NOT FIGHT WITH H2S. BUT WE CAN ONLY ESCAPE FROM THIS GAS. 3Q. TOXIC GASES PROPERTIES: H2S 1.HIGHLY TOXIC 2.COLOUR LESS 3. HEVIER THAN AIR 4.FLAMMEBLE @4.3%-46% 5.ROTTEN EGG SMELL @ 0.13PPM) 6.EASILY MIX IN AIR 7.CORROSIVE 8.SOLUBLE IN WATER EASILY SO2 TOXIC COLOUR LESS HAVIER THAN AIR PONGANT ODOUR (GARLIC/VENIGAR) CORROSIVE - CO TOXIC COLOUR LESS LIGHTER THAN AIR FLAMMABLE @12.5%-74% - CO2 SLIGHTLY TOXIC COLOUR LESS HAVIER THAN AIR - - - Downloaded by Sam (zaidisaab11@gmail.com) lOMoARcPSD|39376716 4Q. TOXIC GASES LIMITS: GAS TVL (8HOURS) H2S SO2 CO CO2 5 PPM 2PPM 35PPM 5000PPM STEL (15MIN) 45MIN BREAK 10PPM 5PPM 50PPM 30000PPM C CEILIONG VALUE IDLH 200PPM - 100PPM 100PPM 12,00PPM 40,000PPM 5Q. EFFECTS LEVELS OF H2S: • • • 0.13 PPM: MINIMUM CONSENTRATION WHICH PRODUCE ODOUR 10 -20 PMM: EYES AND RESPIRATORY ITRACT IRRITATION 20-100 PPM: LOSS OF SENCE OF SMELL, BLISTERRING, INFLAMMATION AND OPACITY OF EYES, HADECHE, NAUCIA, 100-500: RISPIRATORY DIFFICAULTY, RISPIRATORY DEPRESSION, IRRITATION. 500-700: CENTRAL NURVAS SYSTEM EFFECT, WEAKNESS, UNCONCIOUS, TERNOUS, NUMBNESS, CONFUSION. 700-1000: IMMIDIATELY (RAPIDLY) DEATH IF NOT PROMPTLY EMERGENCY ADMINISTRATED. • • • 6Q. OXYGEN IN AIR • • • 21% -OXYGEN 78%- NITROGEN 01%- OTHER GASES 7Q. MULTI GAS DETECTOR: (1) (2) (3) (4) CHECK CALIBRATION DATE VAILATION PHYSICAL DAMAGES BATTERY CHARGE FUNCTIONAL CHECK GASES: (1) H2S (2) CO (3) LEL (4) OXYGE 8Q. TYPES OFALARM SOUND: GAS - BREAKS/ INTERVALS FIRE - CONTINUOUS 9Q. WORKSITE EXAMINATION: PTW Type Examination by Permit Applicant & Responsible Supervisor Examination by Area Authority Process Facility Hydrocarbon Area Before Authorization First Day Every Day First Day Every Day CLASS A YES* YES YES ** YES NO*** CLASS B NO YES NO NO**** NO Downloaded by Sam (zaidisaab11@gmail.com) lOMoARcPSD|39376716 IMPORTANT POINTS: • • • • • • • • • • • • • • • • • • • • • • • PPM: PARTS PER MILLION 1% - 10,000PPM 0.01 – 1 PPM HUMAN DEATH AT 650 PPM HUMAN SAFE UPTO 10PPM JUST HAVING PTW NOT ENGOUGH TOMAKE JOB SAFE, WE MUST COMPLY WITH REQUERMENTS OF THE JOB HSE PLAN. VALIDATION PERIOD OF PERMIT 12 HOURS MUST SUSPEND PTW IF DELAY WORK MORE THAN 4 HOURS RESPONSIBLE SUPERVISOR SEND DETAILS OF PERMITS THOSE PERMITS ONLY AREA AUTHORITY WILL VALIDATE. WHILE WORKING IN SPZ AREA WTU PERSON ARE EFFECTED COSTODIAN PERSON WHILE WORKING IN SPZ ALL CREW DEATAILS SHALL TAKE AREA AUTHORITY NEED MINIMUM 2 SCBA PERSONS WITH 1 CREW (FOR 6 INCLUDE SCBA 2) CAM LOCK/ RIG WALKER SHOULD BE WEAR WHILR WORKING IN SPZ WITH SCBA (2 PERSONS) H2S MONITOR WILL ALERT AT 10 PPM USE FILTER HOOD AT 10 PPM SWITHING OPERATIONS CAN NOT BE CONDUT IN FACILITY AREA, SWITCH OFF FROM OUT SIDE AND ISOLATE THEN TAKE OUT FROM FACILITY AREA, THEN PROCEED WORK AREA AUTHORITY WITH AGT WILL CONDUCT GAS TEST OF FIRST DAY CLASS A PERMIT. ALLOT WORKS TO CREW MEMBERS WHO COMPITENT THERE IN THAT CHECK WORK DESCRIPTION, ACTIVITY NO., HAZARDIOUS AREA WITH DRAWING, FIRE=FUEL+HEAT, IGNITION+OXYGEN WHILE FIRE STOP-DROP-ROLL ABOVE 2M HEIGHT WORK SHOULD WEAR SAFETY HARNESS AND MINIMUM TWO PEOPLE NEED. ELECTRICAL SAFETY DOCUMENTS ARE NOT TRANSFERABLE, SHOULD CANCLE THE SUCH DOCUMENTS AND REISSUE TO THE ANOTHER CEP JOB HSE PLAN -GENERIC TRIC - DYNAMIC SAFETY EQUIPMENTS: FIRE EXTINGUSHER,ESCAPE SET,BREATHING APPARATUS, USING FIRE EXTINGUSHER: • • • • PULL THE PIN AIM THE NOZZLE SQUEEZE THE HANDLE SWEEP FROM SIDE TO SIDE Downloaded by Sam (zaidisaab11@gmail.com) lOMoARcPSD|39376716 1Q. HAZARD? A. ANYTHING WITH POTENTIAL CAUSE HARM OR DAMAGE TO PEOPLE, ASSET, ENVIRONMENT 2Q. RISK? A. ANYTHING WITH POTENTIAL LIKELY TO CAUSE OR DAMAGE. 3Q. CONSEQUENCE? A. AMOUNT OF DAMAGE 4Q. DYNAMIC RISK REVIEW? A. IT IS CONTINUEOS PROCESS FOR IDENTIFIEING HAZARDS AND RISK AND ACTION TAKEN TO BE ELIMINATE AND REDUCE THEM. B. PLANNED AND UNPLANNED C. WHEN NEW PEOPLE ADDED,CONFLICTING ACTIVITY FROM ANOTHER WORK PARTY D. WEATHER CHANGE E. EMERGENCY HAPPENS 5Q. DYNAMIC RISK ASSESSMENT? A. IT IS IDENTIFY THE HAZARD, PUT CONTROL AND ELEMINATE THE RISK. 6Q. JOB SAFETY PLAN (JSP)? A. A DOCUMENT WHICH IS DESCRIBE ABOUT THE HAZARDS AND CONTROLS AND IT IS MANDOTERY DOCUMENT TO ATTACH WITH EVERY PERMIT. 7Q. HEALTH RISK ASSESSMENT? (HRA) A. IT IS PART OF THE HEMP, WHICH EXPLAIN HAZARD, CONTROLS AND RECOVERY MEASSURES RELATED TO THE HEALTH. 8Q. (TRIC) TOOL BOX TALK AND RISK IDENTIFY CARD A. IT IS A SITE RISK ASSESSMENT IN WHICH WE WILL FOCUS ON THE HAZARD AT THE WORK SITE WHEN CARRY OUT THE WORK. 9Q. TYPES OF HAZARDS? (1) UNSAFE ACT (2) UNSAFE CONDITION (3) HAZARD SUBSTANCE (4) SOURCE OF ENERGY (5) PHYSICAL HAZARD 10Q. WHAT IS HEMP? (1) HAZARD EFFECT MANAGEMENT PROCESS (2) IT IS A PROCESS WHICH IS USED TO EXPLAIN ABOUT HAZARDS AND THEIR CONTROLS, RECOVERY MEASURES. I. IDENTIFY: IDENTIFY THE RISK II. ACESS : THEN WE RECOGNIZE THE RISK IS IT AS LOW AS RESONABLY PRACTICABLE? III. CONTROL: MEASURES TAKEN TO ENSURE THAT WORK CAN BE DONE SAFELY IV. RECOVERY: TO BRING SITUAATION TO NORMAL AFTER ANY UNEXPECTED CONSEQUENCES. 11Q. WHAT ARE THE USES OF JOB HSE PLAN? A. B. C. D. E. IDENTIFY THE HAZARDS CONTROLS OF APPLIED IDENTIFY ANY OTHER ACTIVITIES THAT MAY CONFLICT WITH WORK PERSONAL PROTECTIVE EQUIPMENT RECOVERY 12Q. H2S FACILITIES CLASSIFICATION A. SWEET: HAVING LESS THAN<100PMM (0-49PPM) B. SOUR: HAVING MOR THAN >100 PPM WITH 5 BAR PARTIAL PRESSURE (50-499) C. CRITICAL SOUR: HAVING MORE THAN >100 PPM WITH MORE THAN 5 BAR PARTIAL PRESSURE (500+PPM) Downloaded by Sam (zaidisaab11@gmail.com) lOMoARcPSD|39376716 13Q. WHAT DO YOU MEAN MY SIMOPS? A. ANY SITUATION WERE TWO DIFFERENT ACTIVITIES ARE OCCURING CLOSE ENOUGH TO EACH OTHER THAT THERE IS A RISK OF INTERFERENCE, CRASHING OR RISK TRANSFER. SIMOPS INNER ZONE SIMOPS OUTER ZONE ALL WORKERS HAVE RECEIVED APPROVED VALID H2S ALL WORKERS HAVE RECEIVED VALID H2S TRAINING TRAINING CARD CARD SUPPLIED AIR RESPIRATORY EQUIPMENT TO BE CARRIED FILTER ESCAPE HOOD SELF- EXCAVATION TO BE DEMONSTRATED SELF EVACUATION TO BE DEMONSTRATED AGREEMENT WITH SITE ON RESCUE PROVISION EITHR AGREEMENT ON SITE FOR RESCUE PROVISION 14Q. HAZARDIUOS ZONES CLASSIFICATIONS: A. PROCESS FACILITY, HYDROCARBON AREA, NON HYDRO CARBON AREA, RED ZONE, YELLOW ZONE, EPZ, CONFINED SPACE, TEZ, SPZ, ZONES (ZONE-0, ZONE-1, ZONE-2). • PROCESS FACILITY: AN AREA WITHIN THE BOUNDARY FENCE OF ANT PROCESS FACILITY. EX: PUMPING STATIONS, PROCESS UTILITY AREA, GATHERING STATIONS PROCESS SAFETY MANAGEMENT: ALL CONTROL WE ARE APPLYING TO SUSTAIN THE INTEGRETY OF AN ASSETS IS CALLED PROCESS SAFETY MANAGEMENT • HYDROCARBON AREA: AN AREA OUTSIDE OF THE BOUNDARY FENCE OF THE PROCESS FACILITY AREA. (1) 50M FROM BOUNDARY FENCE OF PROCESS FACILITY, WELL PADS (2) 50M FROM EXPOSED SECTION FLOW LINES (3) 100M FROM DRILLING RIG (4) 10M FROM INTERFIELD GAS PIPELINE (5) 25M FROM SOGL • NON-HYDROCARBON AREA: AN AREA WHERE HYDROCARBONS HAVE BEEN PRESENCE AND WE CALLED AS FREEN FIELD AREA. EX: OFFICES, HOSPITALS, RESIDENTIALS, • TEZ (TOTAL EXCLUSION ZONE) : (1) AN AREA WITHIN 400M FROM FLARE TESTING POINT. (2) ENTRY FOR ONLY WTU AUTHORISED PERSONALS. (3) STRICTLY NOT ENTRY FOR CONSTRUCTION AND OPERATIONAL TEAMS (4) ROADS WITHIN THIS ZONE ARE TO BE TEMPORARILY SEALED OFF BY WTU PERSONNEL • SPZ (SPECIAL PRECAUTION ZONE): (1) AN AREA WITHIN 1.4KM FROM FLARE TESTING POINT (2) FOR ENTRY: EPZ WORKING REQUIRENTS + (1) CONTINUES GAS MONITORING (2) POERTABLE WIND SOCK NEAR WORKING AERA (3) COMMUNICATION WITH WTU PERSONS (4) TAKE WTU SING IN PTW AS COSTODIAN HAZRDIUOS ZONES: ZONE-0: AN AREA WHERE EXPLOSIVE AND FLAMMABLE GASES ARE CONTINUOUSLY PRESSNCE FOR LONG PERIODS HOT WORK CAN NOT BE DONE. EX: VISSELS, STORAGE TANKS, FLARE POINT, FLANGE PIT ZONE-1: AN AREA WHERE EXPLOSIVE AND FLAMMABLE GASES ARE LIKELY OCCURE IN NORMAL OPARATIONS Downloaded by Sam (zaidisaab11@gmail.com) lOMoARcPSD|39376716 HOT WORK CAN BE DONE, BUT NEED SPECIAL REQUIRMENTS (CONTINUOUSLY GAS TESING) EX: NEAR COMPRESSORS, FLANGE JOINTS, NEAR VALVES, OUTSIDE THE STORAGE TANKS, VISSELS ZONE-2: AN AREA WHERE EXPLOSIVE AND FLAMMABLE GASES ARE UNLIKELY OCCURE IN NORMAL OPERATION. HOT WORK CAN BE DONE ANYTIME. EX: NEAR PIPELINE WHICH HAVE NO FLANGED JOINTS AREA OUTSIDE. RED ZONE WHERE TOXIC GASES ARE CONTINUOUSLY PRESENCE NEED SPECIAL TRAINING TO ENTER RED ZONE CAN NOT PERFORM WORK INSIDE B.A.SET TO BE WEAR AND HOSE PIPE TO BE CONNECT WITH FIXED AIR BREATHING SYSTEM DURATION OF WORKING. PERMISSIONS AND SPECIAL PRECAUSIONS TO TAKEN TO ENTER, PORTABLE WIND SOCK,CCTV MONITORING,NEAREST ESCAPE GATE EXPECTED MORETHAN 650 PPM YELLOW ZONE WHERE TOXIC GASES ARE LIKELY PRESENCE ANYBODY CAN ENTER WHO HAVING VALID H2S CARD WITH TRAING WORK CAN BE CARRYIED OUT WEAR B.A. SET AND USE TO ESCAPE PURPOSE ONLY CAN ENTER WITH VALID H2S CARD AND INDUCTION TO BRE NEED EXPECTED 100PMM AND ABOVE EPZ (EMEGENCY PLANNING ZONE): GEOGRAPHICAL AREA AROUND THE WELL HEADS, FLOW LINES, FACILITIES CONTAINS HIGH LEVEL OF H2S AND ITS BOUNDARY AREA HAVING 100PPM CONSENTRATION OF H2S IF ANY ACCEDENTICAL LEAK. REQUERMENTS OF EPZ ENTRY: (1) VALID H2S CARD WITH TRAINING - H2S TRAINING (2) H2S MONITOR -DETECTION (3) COMMUNICATION SET (EX. PROF) -COMMUNICATION (4) ESCAPE SET / BREATHING APPARATUS - PROTECTION (5) STAND BY VEHICLE (WITHIN 400M) -EVEACUATION REQUERMENTS FOR WORK IN EPZ: ALL EPZ ENTRY REQUIREMENTS + (6) NEED TO AWARE OF EPZ: (1) CONSIDER CHANGES IN CONDITION (2) TRAINING RESCUE PERSONNEL (3) RISK ASSESSMENT (4) MUSTER AREA OR ASSEMBLY POINT (5) IMMIDIATE ACTION/ EVACUATION/EMERGENCY RSPONCE PROCESSOR RANGE / DISTANCE OF EPZ: AROUND WELL HEAD -1.5KM AROUND LIVE LINE / FLOW LINE -4.4KM HMPS STATION -13KMBIRBA STATION -7KM AL NOOR - 5KM DRILLING RIG -1.5KM ISOLATION BOUNDARY: SIMILAR DEVICES USED TO ESTABLISH AN AREA SAFE FROM HAZARDS FLIUD,THE SET OF VALVES ELECTRICAL SWITH GEARS Downloaded by Sam (zaidisaab11@gmail.com) lOMoARcPSD|39376716 EVACUATION DRILL PROCESS: THE EVACUATION DRILL IS PERFOMED BY STATION OR BUILDING INCHARGE TO CHECK THE READINEDD AND AWARNESS OF PEOPLE ABOUT THE EMERGENCY RESPONSE, ALL SHOULD EVECUATE THE PLACE IMMIDIATLY AFTER HEARING ANY EMEGENCY ALARM AND REACH TO THE DESIGNATED ASSEMBLY POINT. THEY SHOULD NOT RE ENTER THE BUILDING UNTILL ALL CLEAR ANNOUNCEMENT BY THE INCHARGE. CONFINED SPACE: AN AREA WITH LIFE THRETENING CONDITION AND RESTICTED ENTRIES AND EXITS IS CAN BE CALLED AS CONFINED SPACE. HAVING MORE THAN 1.5M DEEP. WHY REQUERED CONFINED SPACE ENTRY CERTIFICATE: IN CONFINED SPACE THERE MAY BE PRESENT TOXIC AND POISONOUS GASES OXYGEN DEFFICIENCY ENVIRONMENT OR PRESENCE OF FLAMMEBLE GASES. PRECAUTIONS TO ENTER AND WORKING IN CONFINED SPACE: • CONTINUOUS GAS TESYTING • VISIBLE SUPERVISION NEEDED • NEED HIAB/ CRANE AT THE TIME OF WORK WITH CONFINED SPACE • MINIMUM 2 VEHICLES FOR ESCAPE • SAFETY HARNESS SHALL BE WEAR • SHOULD APPLY BUDDY SYSTEM • WORK TURN BY TURN AFTER 30MIN, (MAX 30 MIN IN CONFINED SPACE) • WRITE DOWN TIMING ENTRIED AND EXITS. CONFINED SPACE HAZARDS AND CONTROLS: HAZARDS OXYGEN DEFFIANCY POOR COMMUNICATION TOXIC / EXPLOSIVE/FLAMMABLE GASES CONTROLS CONFINED SPACE CERTIFICATE BUDDY SYSTEM FOR CONTINUOUS MONITORING AND COMMUNICATING WITH ANOTHER GAS TESING IN 3 STEPS (TOP- C0/CH4,MIDDLECO2,BUTTOM-H2S,SO2) PROPER PPE SUFFIETIANT LIGHTING MAX 30MIN AFTER CHAGE ANOTHER PERSON PUT SIGN BOARDS WEAR PROPER PPE PREPARE PROPER ENTRIES AND EXITS MAKE AS COMFARTABLE AS POSSIBLE BIOLOGICAL HAZARDS POOR LIGHTING/VISIBILITY TEMPERATURE CHANGES UN EVEN/ SLIPPERY SUFACE, SHARP EDGES UNPROPER ENTRIES AND EXITS CONGESTED PLACE EMERGENCY TYPES: (1) ELECTRICAL EMEGENCY (2) FIRE EMERGENCY (3) H2S LEAK (4) MEDICAL EMERGENCY H2S LEAK EMERGENCY RESPONSE:(ISBL, STATIONS) STEPS: (1) STOP THE WORK (2) HOLD THE BREATH (3) WEAR CAM LOCK/ RIG WALKER (20MIN FOR ESCAPE PURPOSE ONLY) (4) CHECK WIND DIRECTION FOR AROUD THE TSR CREW-(5) MOVE TO TSR-2 ACREOSS THE WIND DIRECTION,(6) REVERSE H2S CARD,(7)COUNT HEADS (8) STAND IN POSITION, (9) AND FOLLOW INSTRUCTIONS FROM MUSTER. Downloaded by Sam (zaidisaab11@gmail.com) lOMoARcPSD|39376716 FOR OTHERS-(5)GO TO NEAREST ASSEMBLY POINT THROUGH ESCAPE GATE (6)COUNT HEADS (7) INFORM TO AREA AUTHORITY (8) FOLLOW MUSTER CHECKER INSTRUCTIONS. H2S LEAK EMERGENCY RESPONSE:(OSBL): (1) STOP THE WORK (2)HOLD BREATH (3) WEAR FILTER HOOD(4) CHECK WIND DIRECTION (5) GO TO FIRST ASSEMBLY POINT ACROSS THE WIND DIRECTION (VEHICLE/OTHER ) (6) COUNT HEADS (7) INFORM TO AREA ATHOURITY(8) MOVE TO SECONDARY ASSEMBLY POINT( T- JUNTION FOOD BALL COURT) LIFE SAVING RULES: (1) VALID PTW, (2) ISOLATION, (3) GAS TESTING, (4) SYSTEM OVEERRIDE, (5) SUSPENDED LOAD, (6) WORK AT HIGHT, (7) BUDDY SYSTEM – CONFINED SPACE, (8) JOURNEY PLAN, (9) SEAT BELT, (10)NO MOBILE USE WHILE DRIVING, (11)DRUGS & ALCHOHOL, (12)OVER SPEED HOUSE SAVING RULES: (1) (2) (3) (4) (5) (6) (7) (2) STOP THE WORK WHEN I FEEL UNSAFE HOLD HANDRAIL WHILE USING THE STAIR DO USE SEAT BELTAND DO NOT USE MOBILE WHILE DRIVING WEAR PROPER PPE KEEP WORKING AREA DRY AND CLEAN, GOOD HOUSE KEEPING UNDERSTAND THE RULES FOR JOB REDUCE THE SOURCES OF WASTE USE THE RIGHT TOOL FOR THE RIGHT JOB ELECTRICAL HARZARDS AND CONTROLS HAZARDS CONTROLS ELECTRICAL SHOCK HIGH VOLTAGE. / LOW VOLTAGE MAINTANANCE EARTHING ENERGY STORED CAPACITORS POOR CABLE CONDITION INSULATION DAMAGE LOOSE TERMINATION OVER LOAD SHORT CIRCUIT DAMAGED POWER TOOLS OHL CONDUCTORS,POLES LIVE LINE WASHING REVERSE POWER CAUTION NOTICE, DANGER BOARD ISOLATION, PPM APPLY CME, AE USE FUSE EXTRACTOR SPARKS MAINTANANCE WITH EQUIPMENTS CEP,FOLLOW ESR,ESOP ISOLATION, DISPLAY MONITORS INSULATION RESISTANCE TEST , KEEP SAFE TIGHTNESS WITH CALIBRATED TORQUE WRENCH LOAD BALANCING CONNECT EARTH AND DISCHARGE BEFORE OPERATE CALIBRATED AND FULL INSULATION TOOLS SAFETY DISTANCE LIMITATION OF ACCESS LOA VOLTAGE TESTER Downloaded by Sam (zaidisaab11@gmail.com) lOMoARcPSD|39376716 Electrical Isolation Keys: A Key Safe shall be employed to control all the Safety Padlock keys used to secure an Isolation. The Key Safe shall be fitted with at least two unique locks with associated keys. Where the electrical isolation requires the use of a Key Safe then the Key Safe keys should be distributed as follows: Key 1 – Permit Holder Key 2 – Senior or Authorized Electrical Person (SAEP or AEP) Key 3 (If fitted) – Area Authority or SAEP/AEP • • • Overhead line clearance: • PR-1242 – Activities in the Vicinity of Overhead Power Lines gives required horizontal & vertical clearances (Typically, 3m both horizontally and vertically) • • A clearance certificate is required to be authorised by the Asset Custodian. An 'Overhead Line Clearance ', is required for passing by or under an overhead line. A PTW is required as this is not an Electrical Safety document. If work is to be conducted under or near an Overhead Line a 'Limitation of Access' with supervision by a Competent Electrical Person may be required. If machinery could possibly come into contact with the Overhead Line, a PTW is required (Activity 9.1). • • Electrical safety rules and PTW interfaces: :Electrical safety documents There are five electrical safety documents: 1. Electrical PTW - For HV work or LV with Circuit Main Earth (CME) 2. Sanction for Test - For HV work 3. Limitation of Access - For HV and LV work 4. Electrical Isolation / De-Isolation Certificate - For HV and LV work 5. Electrical Immobilisation Certificate - LV isolation for Non-Electrical work The Electrical Safety Document highlights the electrical hazards of the relevant electrical work but additionally the work also requires a Class A or B PTW relevant to the activity when the work interfaces with other work/operations. This is to control the additional hazard at the interface. Types of electrical work: Work in electrical areas of a production asset The work shall be authorised by the Area Electrical Supervisor (licensed as a Responsible Supervisor) and agreed by the Production Responsible Supervisor as the Other Affected Custodian and validated by the Electrical Area Authority. If however the work extends or affects equipment outside the substation then a PTW authorised by the Production Responsible Supervisor is required. This includes work in sub-stations and switchyards located in production assets. Electrical work on electrical assets controlled by power systems operations The work shall be authorised by the Infrastructure Electrical Supervisor (licensed as a Responsible Supervisor), no other Affected Custodian and validated by the Electrical Area Authority. Non electrical work on electrical assets controlled by power systems operations The work shall be authorised by the Infrastructure Electrical Supervisor (licensed as a Responsible Supervisor), no other Affected Custodian and validated by the Electrical Area Authority, or he is not available validated by a Production Area Authority who is an Electrically Appointed person. Live line washing Requires only a Limitation of Access (LOA) unless the live lines pass through a hazardous zone (1 or 2) where it needs a Class B PTW. The Electrical Supervisor shall ensure that the auto-reclose facility is disabled. Downloaded by Sam (zaidisaab11@gmail.com) lOMoARcPSD|39376716 Work at remote electrical assets controlled by power systems operations • • • • • • Electrical work will have a suitably qualified electrical person in the work party to validate the PTW. Non-electrical work - e.g. work on gas turbine prime mover is covered by 11.9.2 above, unless circumstances prevent the PDO Electrical Area Authority from validating in which case the PTW can be validated by a suitably qualified Production Area Authority from the local area. This requires agreement from the asset teams and a familiarisation briefing for the Area Authorities. • If the asset team or project team working within an Asset wish to maintain construct or commission plant under custodianship of UIE3 then they need to do so under the PDO PTW system. If asset operations wish to carry out work on utility equipment inside a power station fence the following shall be followed: Operations Responsible Supervisor shall authorise the PTW. The PTW Applicant shall fax a copy of the PTW to the relevant Power System Responsible Supervisor in Yibal, who will sign the faxed copy as Affected Custodian. The PTW shall be faxed back to the PTW Applicant for him to arrange for the Operations Responsible Supervisor to sign the actual PTW in box 5, by writing the words “signed on behalf of” and writing in the name of the Affected Custodian. The signed fax copy should be attached to the worksite copy of the actual PTW as an auditable record of the agreement. When Power Systems wish to carry out any physical work within the fenced area, a PTW should be raised by the Power Systems Responsible Supervisor and countersigned by the Operations Responsible Supervisor as Affected Custodian. For daily validation within an area under the control of Power Systems this can be completed by fax under strict adherence to the following conditions. • • The Power Systems Area Authority shall visit the site for the first validation and at least once per week for ongoing activities where the task or risks have not changed. Subsequent validations can be completed by fax in the following way. o o o o o o 1.1.1 The Permit Holder emails/faxes the PTW to the Area Authority, who signs the scanned copy in box 10, and returns it to the Permit Holder by email or fax. The Permit Holder attaches the signed copy to the worksite copy. On suspension of the activity on a daily basis, the Permit Holder emails/faxes the suspension in box 10 to the Area Authority. The process is repeated when validation is again required. The worksite copy of the PTW will therefore contain a signed copy of box 10 for each day the PTW was validated. On completion or cancellation, the PTW is emailed/faxed to the Area Authority who shall visit the site with the Permit Holder and check the worksite has been left safe and tidy and close/cancel the PTW. Electrical isolation (low voltage) Controls for this work are covered in the Electrical Safety rules. An electrical isolation / de-isolation certificate shall be issued by a responsible member of the custodian department to a third party who is to carry out nonelectrical work on equipment that needs isolating before work commences. 1.2 PTWs for ESP activities This includes work on ESPs, ESPCPs & PCPs and there is a standard approach for requirements for a vendor’s use of our PDO PTW system. Downloaded by Sam (zaidisaab11@gmail.com) lOMoARcPSD|39376716 1.2.1 Pre-requisites for ESP activities The following shall be in place: • • • • • The Contract Holder (CH) shall ensure the competency of vendor engineers assuring their competency credentials and certificates. The Contract Site Rep (CSR) shall ensure that all controls in the HEMP exercise and the Job HSE plan in place. The CH shall ensure every activity has a robust safe execution procedure. The CSR with the Production Coordinator and vendor shall establish Job HSE Plans for every specific activity for ESPs, ESPCPs & PCPs in their area using the Online Job HSE Plan system as baseline. The Job HSE Plans shall be readily available to the CSR, Production Coordinator/Supervisor and vendor. The following steps shall be adhered to for all ESPs, ESPCPs & PCPs activities: 1. The Responsible Supervisor requests the CSR to attend job. 2. The CSR instructs the vendor engineer to carry out the work (this does not have to be face to face) and to refer to relevant Job HSE Plan for the activity and verify all controls are in place. 3. Vendor engineer informs CCR when the job is started. 4. The CCR Operator logs the work details and start time in the “Station Log Book” and reports the status to the Responsible Supervisor. 5. Vendor engineer informs CCR when the job is completed. 6. The CCR Operator logs the work details in the “Station Log Book” including the completion time and reports the status to the Responsible Supervisor. 7. Vendor engineer submits Job HSE Plans for all completed jobs to the CSR for documentation and assurance on return to the base. 1.2.2 PTW requirements for ESP activities *Activities requiring PTW system: Activities requiring only Job HSE plan: Activities requiring Access Authorisation Form: Commissioning of ESP, ESPCP & PCP Working on ESP, ESPCP & PCP panel/Troubleshooting Data Collection including download data from ESP by using DH sensor Fluid Shot Program software (adjustment to controller) if controller is inside the ESP Panel Program software (adjustment to controller) if controller is outside ESP Panel ESP etc powered by Generator Replacing pigtail at Wellhead (Isolated) Assist to restart ESP, ESPCP & PCP after STN S/D. (In this case if vendor engineer is in remote area “Access Permit” can be obtained by any means of communication and sign off the Access Authorisation Form on return for documentation and assurance) Visual Inspection of ESP Panel *Note: The Electrical Supervisor shall sign as the Affected Custodian with direct liaison with the ESP-CSR and the Production Supervisor to sign as the Responsible Supervisor. (8) Downloaded by Sam (zaidisaab11@gmail.com) lOMoARcPSD|39376716 Downloaded by Sam (zaidisaab11@gmail.com) lOMoARcPSD|39376716 NO PERMIT JOB Number: Work Description: Location: A. Questions Regarding Hazardous Areas 1. Is the work within the facilities? YES NO 2. Is the work within a hydrocarbon area? YES NO 3. Is the work in/ on electrical installations? YES NO 4. Is the work in a confined space? YES NO 5. Is a supplementary certificate required for the work? YES NO 6. Is the work within Emergency Planning Zone of a Critical Sour Area YES NO If any of the questions above has a YES answer then a Permit to Work is required B. Questions Regarding Type of Work to be Done 1. Is the work familiar to the work force? YES NO 2. Is the work going to be undertaken by competent staff? YES NO 3. Is there a written procedure for the work? YES NO If any of the questions above has a NO answer then a Permit to Work is required C. No Permit Job Requirements 1. Job HSE Plan been written for the work YES 2. Work Site Supervisor appointed for the work YES Name of appointed Supervisor NO NO If a Job HSE Plan has not been written or a Supervisor is not named, then a Permit to Work is required. Work Site Supervisor Responsible Supervisor Name: Name: Date: Date: Agreed duration and review date Duration: Approved: Approved: Review Date: NO PERMIT JOB can only start when the above have been completed and signed by all parties Downloaded by Sam (zaidisaab11@gmail.com) lOMoARcPSD|39376716 CLASS A PERMIT PETROLEUM DEVELOPMENT OMAN PERMIT No. Work Order Title: 7. VEHICLE ACCESS to restricted Area 1. APPLICATION AND DESCRIPTION (by Applicant) Location: Work Site Vehicle Access Route Plan prepared and approved YES PERMIT No. Permission is given to the Permit Holder to take the following vehicle(s) of the following type(s) to the work site/location: Vehicle types: Location: Vehicle Access is subject to a satisfactory gas test being carried out on each occasion, with the result recorded in Box 8. A A 8. GAS TEST RECORD - results for Confined Space Entry to be recorded on Certificate, NOT HERE. Copies: Pink - Worksite, Green - Permit Control, White - Information Hazardous Area Classification Date Time Result Signature Auth. No. Date Time Result Signature Auth. No. Date Time Result Signature Auth. No. HAZARDOUS ZONE 0 HAZARDOUS ZONE 1 No. in Work Party HAZARDOUS ZONE 2 Work Description NON-HAZARDOUS NORM Contaminated Area YES NO 9. SAFETY COORDINATION Any conflicting work identified will be Suspended or Cancelled before first Validation. Worksite preparations specified in Box 2 may proceed. Mercury Potential YES YES NONO Name : 10a. VALIDATION Expected Max ppm To be signed by the Area Authority at the start of each work period. Vehicle Entry Required? Yes No Hydrocarbon Area Time: Date: 10b. ACCEPTANCE 10c. SUSPENSION To be signed by the oncoming Permit Holder whenever the permit is validated or whenever responsibility passes from one Permit Holder to another. I am satified that the conditions at the worksite are safe I have been fully briefed by the Applicant on the work and necessary precautions. I am satisfied that the for the work specified. I validate the Permit for the worksite is safe for work to start. I will brief the work period stated, provided the work party adhere to the party and supervise the work. I will stop the work if the permit requirements. Work must stop if the permit requirements cannot be met. permit requirments cannot be met. Activity Nos. ( Refer to PTW System Manual Section 3.5.4) Process Facility Signature: H2S Facility Classification HIGH LOW NON Non Hydrocarbon Area To be signed by the offgoing Permit Holder whenever work stops for more than 4 hours. I have examined the worksite. It has been left in a clear and safe condition. Associated Permit Nos. Planner Agrees In Frozen Plan Work Order / EWP No Y 2. CERTIFICATES ATTACHED TO THIS PERMIT √ Certificate Validated Time Time From To N 3. GAS TESTING REQUIREMENTS Certificate Number(s) Gases to be tested for: Gas test to be repeated at intervals of: Electrical Isolation/De-isolation Date Continuous gas monitoring required during execution of the work Name Initials Name PDO Ind/ Contractor Date Signature Time Date Signature Hydrocarbons H2S Oxygen Other Yes No (Specify) hrs 3a. WORKSITE EXAMINATION required by Area Authority Mechanical Isolation Mechanical Isolation Continuation Excavation Overhead Line Clearance Electrical Safety Document Elec. Immobilisation/Mobilisation Radiography Safeguarding Isolation Worksite Examination 1st day Yes No By Validator required Yes No Confined Space Entry √ TRIC Required Everyday 4. APPLICATION BY APPLICANT I have reviewed the task and am satisfied that the information in this Application and in the Job HSE Plan is adequate and correct Name: Position/Ind. Signed: CANCELLATION 11. WORK COMPLETED a. Permit Return by Permit Holder 12. WORK NOT COMPLETED a. Permit Return by Permit Holder Contractor: Tel. No: Date: Work Complete. Worksite and equipment affected left in a safe condition. Work not complete. Worksite and equipment affected left in a safe condition. Duration Requested FROM: Date: Time: TO: Name: Date: Post: Time: *Work is continuing under Permit No: Date: * Delete as appropriate A JOB SAFETY PLAN MUST BE ATTACHED TO THIS PERMIT * Isolations retained under Isolation Certificate No: 5. AGREEMENT by Other Affected Custodian 6. AUTHORISATION by Responsible Supervisor I agree that the work described may be carried out during the proposed period: I have examined the Permit and Job Safety Plan. The work described in this Permit and attached Job safety Plan is authorised for this period: Daily Pre-Validation Allowed? NO YES NO 24 Hour Validation Allowed? YES FROM: Date: Time: TO: Date: Time: Name Signed Ref Ind: Time Date Signed: b. Permit Cancellation by Area Authority Name: Worksite checked, clear and safe (Process Facility only) Signed Ref Ind: 6a Production Co-ordinator Date Time: Signed: b. Permit Cancellation by Area Authority * Delete as appropriate Name Post: *Reinstatements/De-isolations Complete. Isolations retained under Cert No: Date: Worksite checked, clear and safe (Process Facility only) Time Name: Ind: Time: Name: Date: Signed: Name: Signed: Ind: Time: 6b. EXTENSION AUTHORISATION by Responsible Supervisor Name Ref Ind: Extension valid until: Date Signed Date Name: Signed: 13. REGISTRATION OF CANCELLATION Ref Ind: Sign: CLASS B PERMIT PETROLEUM DEVELOPMENT OMAN Time: 1. APPLICATION AND DESCRIPTION (by Applicant) Location: Work Site All necessary documentation collected and retained in PCF PERMIT No. Work Order Title: 7. VEHICLE ACCESS to restricted Area Date: Time: PC Date: Class A Rev 8 SAP 1000066565 Vehicle Access Route Plan prepared and approved YES PERMIT No. Permission is given to the Permit Holder to take the following vehicle(s) of the following type(s) to the work site/location: Vehicle type and Reg'n No: Location: Vehicle Access is subject to a satisfactory gas test being carried out on each occasion, with the result recorded in Box 8. B Copies: Blue - Worksite, Green - Permit Control, White - Information Hazardous Area Classification B 8. GAS TEST RECORD - results for Confined Space Entry to be recorded on Certificate, NOT HERE. Date Time Result Signature Auth. No. Date Time Result Signature Auth. No. Date Time Result Signature Auth. No. HAZARDOUS ZONE 0 HAZARDOUS ZONE 1 No. in Work Party HAZARDOUS ZONE 2 Work Description NON-HAZARDOUS NORM Restricted Area YES NO 9. SAFETY COORDINATION Any conflicting work identified will be Suspended or Cancelled before first Validation. Worksite preparations specified in Box 2 may proceed. Mercury Potential YES YES NONO Name : Date: 10b. ACCEPTANCE 10c. SUSPENSION Expected Max ppm To be signed by the Area Authority at the start of each work period. To be signed by the oncoming Permit Holder whenever the permit is validated or whenever responsibility passes from one Permit Holder to another. I have been fully briefed by the Applicant on the work and necessary precautions. I am satisfied that the worksite is safe for work to start. I will brief the work party and supervise the work. I will stop the work if the permit requirments cannot be met. To be signed by the offgoing Permit Holder whenever work stops for more than 4 hours. Vehicle Entry Required? Yes No Hydrocarbon Area Time: 10a. VALIDATION Activity Nos. ( Refer to PTW System Manual Section 3.5.4) Process Facility Signature: H2S Facility Classification HIGH LOW NON Non Hydrocarbon Area I am satified that the conditions at the worksite are safe for the work specified. I validate the Permit for the period stated, provided the work party adhere to the permit requirements. Work must stop if the permit requirements cannot be met. I have examined the worksite. It has been left in a clear and safe condition. Associated Permit Nos. Planner Agrees In Frozen Plan Work Order / EWP No Y 2. CERTIFICATES ATTACHED TO THIS PERMIT √ Certificate N 3. GAS TESTING REQUIREMENTS Certificate Number(s) Gases to be tested for: Gas test Continuous gas monitoring to be required during execution of repeated the work at intervals of: Electrical Isolation/De-isolation Date Validated Time Time From To Name Initials Name PDO Ind/ Contractor Date Signature Time Date Signature Hydrocarbons H2S Oxygen Other Yes No (Specify) hrs 3a. WORKSITE EXAMINATION required by Area Authority Mechanical Isolation Mechanical Isolation Continuation Excavation Overhead Line Clearance Electrical Safety Document Elec. Immobilisation/Mobilisation Radiography Safeguarding Isolation Worksite Examination 1st day Yes No Yes No Confined Space Entry TRIC Required √ By Validator required Everyday 4. APPLICATION BY APPLICANT I have reviewed the task and am satisfied that the information in this Application and in the Job HSE Plan is adequate and correct Name: Position/Ind. Signed: CANCELLATION 11. WORK COMPLETED a. Permit Return by Permit Holder 12. WORK NOT COMPLETED a. Permit Return by Permit Holder Contractor: Tel. No: Date: Work Complete. Worksite and equipment affected left in a safe condition. Work not complete. Worksite and equipment affected left in a safe condition. Duration Requested FROM: Date: Time: TO: Name: Date: Post: Time: *Work is continuing under Permit No: Date: * Delete as appropriate A JOB SAFETY PLAN MUST BE ATTACHED TO THIS PERMIT * Isolations retained under Isolation Certificate No: 5. AGREEMENT by Other Affected Custodian 6. AUTHORISATION by Responsible Supervisor I agree that the work described may be carried out during the proposed period: I have examined the Permit and Job Safety Plan. The work described in this Permit and attached Job safety Plan is authorised for this period: NO Daily Pre-Validation Allowed? YES 24 Hour Validation Allowed? NO YES FROM: Date: Time: TO: Date: Time: Name Signed Ref Ind: Worksite checked, clear and safe (Process Facility only) Name: Post: Time: *Reinstatements/De-isolations Complete. Signed: b. Permit Cancellation by Area Authority Isolations retained under Cert No: * Delete as appropriate Name Time Signed: b. Permit Cancellation by Area Authority Signed Date: Worksite checked, clear and safe (Process Facility only) Date Ref Ind: 6a Production Co-ordinator (if Required) Date Time Name: Ind: Time: Name: Date: Signed: Name: Signed: Ind: Time: 6b. EXTENSION AUTHORISATION by Responsible Supervisor Name Ref Ind: Extension valid until: Date Signed Date Name: Time: Sign: Ref Ind: Signed: 13. REGISTRATION OF CANCELLATION All necessary documentation collected and retained in PCF Downloaded by Sam (zaidisaab11@gmail.com) Date: Time: PC Date: Class B Rev 8 SAP 1000066566 lOMoARcPSD|39376716 Downloaded by Sam (zaidisaab11@gmail.com) lOMoARcPSD|39376716 Appendix 1 – PTW type and controls for activities in each type of work area Class A PTW required Class B PTW required No permit document (HSE Plan) required Gas Test required before starting work each day and after being away for over an hour Gas Test required every two hours where significant quantities of gas may be present Activity. Location of Work Process Facility Hydrocarbon Area 1. Burning, Welding and Grinding 1.1 Welding (Gas) / Oxy-Acetylene cutting (Hot Work) + Continuous monitoring 1.2 Welding (Arc) (Hot Work) (See 15.6.1) + Continuous monitoring 1.3 Grinding (Hot Work) + Continuous monitoring 2. Confined Space Work 2.1 Confined Space Entry, except for Well Cellars and Casasco pits, and excavations below 1.5m. Note-Gas testing in accordance + with PDO policy is required. (See 3.5.1) Entry into Well Cellars (See 12.6.3) and Casasco Pits (See 12.5.2) and excavations below 1.5m. 2.3 Entry into Well Cellars or Casasco pits by Area Authority to carry out Operational Tasks to an approved procedure. + Continuous Continuous monitoring monitoring + 2.2 3. Electrical Work and Work in Electrical Areas (See Section 15.9) 3.1 Work requiring an electrical safety document as specified in Electrical Safety Rules (ESRs) 3.2 The opening of live electrical junction boxes by Electrical Authorised Persons 4. Handling Hazardous Substances 4.1 Handling substances hazardous to health, e.g. toxic chemicals or asbestos 4.2 Use of Radioactive sources (See 15.6.8) 4.3 Contamination with Naturally Occurring Radiation Material (NORM) 4.4 Working with Pyrophoric Scale (except for scale encountered during pigging operations) 5. Work on Safety Systems (See 15.6.1) 5.1 Work that affects the availability of ESD & F&G Systems 5.2 Work that affects the availability of Process and Machinery Continuous monitoring Downloaded by Sam (zaidisaab11@gmail.com) N/A N/A lOMoARcPSD|39376716 control systems 6. Mechanical Maintenance Activities (See Section 15.6) 6.1 Work that involves cold cutting pipe on systems containing hydrocarbons or hazardous fluids Continuous monitoring + 6.2 Work that involves unbolting flanges on systems containing hydrocarbons or hazardous fluids 6.3 Grit Blasting (Hot Work) 6.4 Power/hand tools (except grinders) that may create a spark between surface and tool 6.5 High Pressure (HP) water jetting 6.6 Painting (hand and spray) (See 15.6.17) 6.7 Engineering and routine/corrective maintenance work which does not involve unbolting flanges or cutting into systems which have contained hydrocarbons or hazardous fluids. 6.8 Work in authorised workshops located in non-hazardous areas. 6.9 Leak clamping of oil/gas flowlines 6.10 Beam pump/PCP maintenance activities (See 15.6.2) 6.11 Polyethylene lining of pipelines and flowlines Continuous monitoring 6.12 Vacuum tanker discharge inside a process area. (See 15.6.6) + Continuous monitoring 6.13 Suction tanker operations inside a process area. (See 15.6.6 + Continuous monitoring 6.14 Engineering and routine/corrective maintenance work which involves the use of lifting equipment 7. Work at Height 7.1 Working where a person may fall more than 2 metres, except on approved walkways and scaffolds 8. Scaffolding Activities 8.1 Erection or dismantling of scaffolding 9. Operations using Cranes and other Heavy Machinery 9.1 Operations where heavy machinery e.g. cranes/crane loads, mechanical excavators, trucks etc. could pass over, or come into contact with, live hydrocarbon, high pressure steam or chemical systems or overhead power lines Gas testing requirements for any diesel engine used is as per 11.1 10. Systems and Equipment Testing and Commissioning / Decommissioning 10.1 Pressure testing of plant and equipment 10.2 Commissioning Systems and Equipment 10.3 11. Decommissioning Use of non-certified equipment in Hazardous Areas 11.1 Use of Temporary Diesel Engines in hazardous areas (including vehicle access, and the use of a mobile crane) (Including refuel operations) + Continuous monitoring 11.2 Use of non-Intrinsically Safe equipment Continuous Downloaded by Sam (zaidisaab11@gmail.com) lOMoARcPSD|39376716 monitoring 11.3 Use of Intrinsically Safe test / portable equipment 11.4 Use of cameras. Providing a gas detector is carried by an individual who has been briefed in its use, and is able to demonstrate an understanding of the detector operation and actions to be taken on alarm activation. Flash requirements to be included on the access authorisation form 11.5 Mobile diesel powered cleaning units used only by Area Authority for external cleaning of water injection plant, equipment and pipework. Continuous monitoring + Continuous monitoring Process Facility 11.6 Use of GPS equipment that is Non I.S. on a well pad. Providing a gas detector is carried by an individual who has been briefed in its use, and is able to demonstrate an understanding of the detector operation and actions to be taken on alarm activation + Continuous monitoring When GPS equipment used in a fenced Process area, 11.2 applies + Continuous monitoring 12. Civil Works 12.1 Excavation. (Hand excavation to 300 mm depth is required in areas where pipes or cables may be present) (See 15.6.7) Hydrocarbon Area 12.2 Rebar cutting, bending and shuttering (form work) and concrete pouring 12.3 Engineering construction activities, not involving welding, burning or grinding (See Section15.2.) 13. Operational Activities 13.1 Production operations including routine checks and visual inspections by the Area Authority which require blowing down or sampling of hydrocarbons (providing an approved Operating Procedure is being followed) 13.2 Routine, documented drilling activities. (See Section15.11) 13.3 Well Services operations at locations where well site custodianship has not been transferred to the Well Services department. (See 15.6.16) 13.4 Drilling Water Services activities listed in Procedure DWSOP No P033 13.5 Pipeline pigging operations covered by authorised procedures & listed in approved programme, including vehicle access to pig trap area. Operation of permanently installed approved equipment which produced an ignition source or open flame when it operates. 13.6 13.7 Seismic exploration activities. (See Section 15.3) N/A Hydrocarbon Area requirements may apply See 3.3.2 Use Pigging Authorisation Form Use Pigging Authorisation Form See Section 15.7 13.8 Terminal Operations. 13.9 Government Gas Operations. See Section 15.8 13.10 Geomatic Survey (See Section 15.4) 13.11 Sampling of Process fluids where the fluids are classed as low, high, or very high risk sour service, or are not yet classified and the sampling is carried out using approved Production Chemistry procedures. + Continuous monitoring Downloaded by Sam (zaidisaab11@gmail.com) + Continuous Monitoring lOMoARcPSD|39376716 13.12 Sampling of Process fluids where the fluids are classed as sweet, and the sampling is carried out using approved Production Chemistry procedures. 13.13 Use of Flushby Unit following dedicated contractors procedures approved by PDO. See Section 15.12 13.14 Use of Flare Ignition Gun by authorised Operations Personnel, providing Operating Procedure PR-1097 is being followed, the user is an AGT, and a gas test is carried out 14. Inspection Work 14.1 Entry to Restricted Areas, for viewing purposes only, by personnel not on the access list for that Area. 15. Roadway Work 15.1 Levelling and grading using machinery 16. Faultfinding 16.1 Minor Fault finding work. This may include the controlled isolation and de-isolation of valves, the removal of instruments for calibration, blowing through of pneumatic relays or other routine minor activities. (See 15.1) 17 + Continuous monitoring + Continuous monitoring No PTW Required. Use Access authorisation Form N/A Hydrocarbon Area requirements may apply See 3.3.2 ESP Activities 17.1 Meggar Testing HV – See E1.1 Hazardous Area (Zone 1 or 2) Non Hazardous Area Intrinsically safe Equipment to be used No PTW Required. Controlled by ESR’s N/A 17.2 Replacing Pig Tail at Wellhead (Isolated) N/A 17.3 Fluid Shot Activity Controlled by ESRs 17.4 Electrical Isolation - HV 17.5 Commissioning ESP, ESPCP & PCP (Will require gas test if breaking hydrocarbon envelope) 17.6 Trouble shooting ESP, ESPCP, & PCP (Controlled under ESRs. See E1.1 No Permit Job to be signed by Electrical Supervisor) No PTW Required. Controlled by ESR’s 17.7 ESP Powered by Generator (Controlled by ESRs See E1.1) Downloaded by Sam (zaidisaab11@gmail.com) No PTW Required. Controlled by ESR’s No PTW Required. Controlled by ESR’s lOMoARcPSD|39376716 Appendix 2 – PTW type and controls for activities in PDO electrical installations Activity. Location of Work Hazardous Area (Zone 1 or 2) E1. Non Hazardous Area Work in Electrical Installations (See Section15.8) E1.1 Work requiring an electrical safety document as specified in Electrical Safety Rules (ESRs) (Activity 3.1) No PTW Required. Controlled by ESR’s E1.2. Periodic Electrical inspections at unmanned substations and power stations as per ESRs and Electrical Safety Operating Procedures (ESOPs), carried out by Power Systems Operations own contractor staff. E1.3. All construction activity such as excavation work, civil and electrical work, lifting operations using crane, shot blasting and painting etc. by third party or PDO supervision. (Use equivalent Activities from No PTW Required. Controlled by ESR’s No PTW Required. Controlled by ESR’s Appendix 1) E1.4. Third party periodic visits to electrical substations and power stations e.g. Telecoms/SCADA, Area Services for routine electrical work. E1.5. Live Line Washing on overhead lines to process field facilities with or without auto-reclosers. No PTW Required. Use Limitation of Access (LOA) E1.6 The Opening of Live Electrical Junction Boxes by Electrical Authorised Persons (Hot Work) (Activity 3.2) No PTW Required. Controlled by ESR’s E1.7. Low Voltage (LV) work requiring an electrical safety document as specified in ESRs No PTW Required. Controlled by ESR’s E1.8 No PTW Required. Use Limitation of Access (LOA) E1.10 Electrical Maintenance Activities at unmanned substations and power stations as per ESRs and ESOPs, carried out by Power Systems Operations own and contractor staff. No PTW Required. Controlled by ESR’s E1.11 Non-routine electrical work in power stations and substations, carried out by Power Systems Operations own contractor staff. Non electrical work in electrical switchrooms, power stations or near overhead lines E1.9 Electrical Switching controlled by ESOPs and ESRs. E1.12 Non electrical work in power stations and substations, carried out by Power Systems Operations own contractor staff. Downloaded by Sam (zaidisaab11@gmail.com)