EDO-PPP-GEN-GNR-INT-XXX-013-095-96-Rev-D -Edopec General Presantation for tank accesories

advertisement

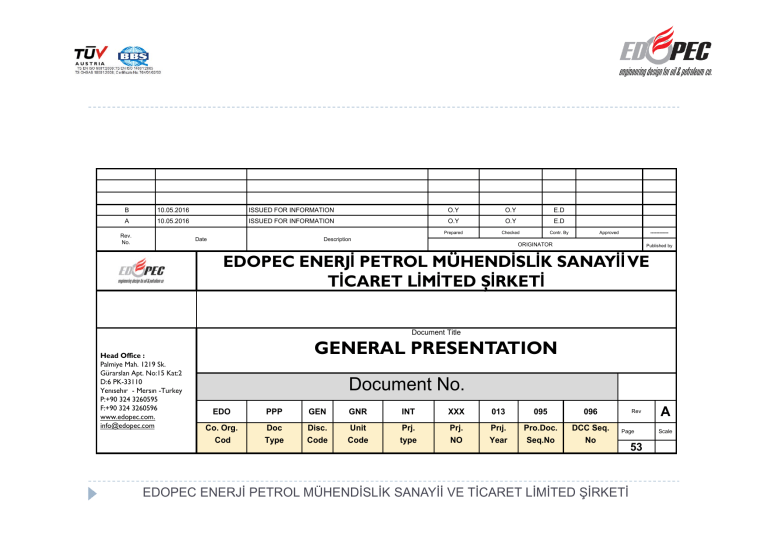

B 10 05 2016 10.05.2016 ISSUED FOR INFORMATION OY O.Y OY O.Y A 10.05.2016 ISSUED FOR INFORMATION O.Y O.Y E.D Prepared Checked Contr. By Rev. No. Date Description ED E.D Approved ------------ ORIGINATOR Published by EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ȘİRKETİ Document Title Head Office : Palmiye Mah. 1219 Sk. Gürarslan Apt. No:15 Kat:2 D:6 PK-33110 Yenısehır - Mersın -Turkeyy P:+90 324 3260595 F:+90 324 3260596 www.edopec.com. info@edopec.com GENERAL PRESENTATION Document No. EDO PPP GEN GNR INT XXX 013 095 096 Co. Org. Doc Disc. Unit Prj. Prj. Prıj. Pro.Doc. DCC Seq. Cod Type Code Code type NO Year Seq.No No Rev Page EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ 53 A Scale EDOPEC CONSTRUCTION Edopec Construction Storage Tank Facilities Designing and Engineering Materials Supply Consultant Construction Pipeline Hydrotesting Construction/(Digging, Welding) Cathodic Protection Engineering www.edopec.com EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ KÜÇÜKTEKNİK MAKİNA -PETRAC MANUFACTURE OF FUEL TANK ACCESSORIES Pressure Vacuum Vent (TSEK-06/3014 ) Flame Arrester ( TSE 35-6-EX.K./024 ) Gauge Hatch aa-)) Unlocking type b-) Locking Type c-) Non-atmospheric Gauge Hatch Floating Suction Pipe Blende Type Interrupter Tank Level Indicator Floating Roof Sealing System Floating Roof According to API 650 MANUFACTURE OF FIRE PROTECTION ACCESSORIES Foam Expulsing Systems. Foam Expulsing Ball Fire Foam Nozzles, Fire Fuse Foam Skimmers, Mixing Apparatus www kucukteknik www.kucukteknik 3 EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ EDOPEC KÜÇÜKTEKNİK MAKİNA -PETRAC Pig R Pi Receiver i Pig Launcher Strainer Fuel Filtering Vessels Pipeline Flow Indicator Isolated Coupling C Blown Down Silencer Pressure Vessels Heat Exchangers 4 EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ EDOPEC CORROSION CONTROL CORROSION and CATHODIC PROTECTION of MARINE STRUCTURES Platform & Corrosion Monitoring of Pipelines Corrosion Monitoring, Projection, Installation, Undertaking and Controlling of Cathodic Protection of Jetty and Marine Pile Structures CATHODIC PROTECTION SYSTEM of WATER & SEWERAGE WATER Cathodic Protection Systems of Water Pipelines Cathodic Protection Systems of Water Tanks Cathodic Protection Systems of Water Works CATHODIC PROTECTION of PETROLEUM PLANTS Cathodic Protection System of Fuel Oil Pipeline Cathodic Protection System of Underground and Storage Tanks CATHODIC PROTECTION of NATURALGAS PLANTS C th di P Cathodic Protection t ti Systems S t off Natural N t l gas Pipelines Pi li STEEL STRUCTURES IN CONCRETE Cathodic Protection System of Reinforced Cored Steel Cathodic Protection System of Dam Pipes Chloride Extraction of Concrete Re-alkalization System ENGINEERING SERVICES CATHODIC PROTECTION Design Service Prodesign Tasks Design Calculations List of Conditions and Specifications Detailing Tests of Current Requirement Solutions of Problems Maintenance and Repair Mounting Field Experiments and Consult Services Undertaking 5 EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ TANK DESIGN AND SITE ERECTION Engineering E i i capacity i and dT Tools l EDOPEC , can do design works shown below for aboveground storage g tanks in acc. with API 650 DRG BASIC TANK FOUNDATION DETAIL DRG TANK BOTTOM PLATE MONTAGE DETAIL DRG ANCHOR DETAILS DRG TANK SHELL PLATE GENERAL LAYOUT DRG TANK SHELL STAIRS AND BALUSTRADE DETAIL EXTERNAL EARTHING DETAILS DRG ROOF STAIR SHELL DETAIL DRG TANK LIGHTING DETAIL DRG ROOF STAIR SLEDGE DETAIL DRG TANK BOTTOM EXTERNAL CATHODIC PROTECTION SYSTEM LAYOUT DETAIL DRG NOZZLE ORIENTATION DRG TR UNIT -TITANIUM ANOD DETAILS DRG ROOF DRAIN NOZZLES DETAIL GEN SHIPMENT AND PACKAGING DETAILS DRG SHELL MANHOLE DETAIL DRG DOME ACCESSUAR DETAIL DRG FIRE FIGHTING GENERAL LAY OUT DRG FOAM CHAMBER INSTALLATION DETAIL DRG INTERNAL CATHODIC PROTECTION SYSTEM GENERAL LAYOUT DETAIL DRG EDOPEC ,acquires all the tank storage design standards.API , ASTM , ASME ,ASCE,NACE. ASCE NACE 6 EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ TANK DESIGN AND SITE ERECTION 7 EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ TANK DESIGN 8 EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ PETROLEUM DIVISION 9 EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ ENGINEERING CAPACITY AND TOOLS DOCUMENT NAME STANDART Edittion TANK SHELL CALCULATIONS API STANDARD 650 -Welded Steel Tanks for Oil Storage, Variable Point Calculation TENTH EDITION, NOVEMBER 1998,ADDENDUM 4, DECEMBER 2005 SELF SUPPORTED CONE ROOF CALCULATIONS API STANDARD 650 -Welded Steel Tanks forOil Storage, Variable Point Calculation TENTH EDITION, NOVEMBER 1998,ADDENDUM 4, DECEMBER 2006 FIRE FIGHTING CALCULATIONS NFPA 15 Standard for Water Spray Fixed Systems for Fire Protection 1998 Edition SOIL AND EARTHQUAKE INVESTIGATION API STANDARD 650 -Welded Steel Tanks forOil Storage, SCE 7-98 - Minimum Design Loads For Building and Other Structures TENTH EDITION, NOVEMBER 1998,ADDENDUM 4, DECEMBER 2005 INTERNAL CATHODIC PROTECTION CALCULATIONS NACE RP 0285 – Corrosion Control of Underground Storage Tank Systems by Cathodic Protection NACE RP 0193 –External External Cathodic Protection of On On-Grade Grade Metallic Storage Tank Bottom EXTERNAL CATHODIC PROTECTION CALCULATIONS NACE RP 0285 – Corrosion Control of Underground Storage Tank Systems by Cathodic Protection NACE RP 0193 –External Cathodic Protection of On-Grade Metallic Storage Tank Bottom EARTHING CALCULATIONS Marcus o. Durham , Ph.D., P.E.Fellow ,IEEE TheWay Corp.” Interaction and Design of Grounded System For Tanks And Vessels” NACE RP 2003 –“Protection Againts Ignitions Arrising Aot of Static,Lightning,and St Currens Stray C Si th Edition Sixth Editi ,September S t b 1998 ANCHORE CALCULATİON API STANDARD 650 -Welded Steel Tanks forOil Storage, Variable Point Calculation ANNULAR PLATE CALCULATION API STANDARD 650 -Welded Steel Tanks forOil Storage, Variable Point Calculation VENTİNG CALCULATION API -2000 Venting Atmospheric andLow-Pressure Storage Tanks -Nonrefrigerated and Refrigerated API STANDARD 2000FIFTH EDITION, APRIL 1998 WELD MAP INSPECTION PLAN WPS PQR LIST OF MATERIAL (STEEL LATE,BOLT,PIPE) 10 EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ STORAGE TANK DESIGN ENGINEERING AND DOCUMENTS 11 EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ PREFABRICIATION CAPABILITIES EDOPEC -In In Mersin İskenderun , Tank accessories are manufactured in mersin. In Mersin-İskenderun 500 m22 closed l d area Nozzle manufacturing, sandblasting,painting 1000 m2 open area Plate cutting,bending,profil 12 EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ SHOP FABRICATION Semi-manufactures which are used in Tank manufacturing; Nozzles Ladder for loading platform Balustrades Manhole etc., etc are manufactured in EDOPEC subcontractors 13 EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ SITE ERECTION (WMS;EQUIPMENT) EDOPEC’s Manufacturings on field 1 st Method 1. Ready Basement: 1. 2. 3. 4 4. 5. 6. 7. 8. 9. 10 10. 11. 12. 13. 14 14. Fixing the Main Body Manufacturing limit and setting the crane Distribution,assembling and spot welding of base plates. Stopper welding to the Base plate.Assembling of 1st course plates,opening of mainbody manholes. Assembling of 2nd and 3rd course plates.First plates First vertical and then the horizontal weldings of 1st course.(Between 1st and 2nd course,not a base) Assembling of 4th course and then vertical and horizantal welding between 2nd and 3rd courses.This will continue like this till to the last course Assembling of 4th course. According to the adverse weather conditions wind ggirder can be pput on the middle course duringg the manufacturing. g Assembling of the last course’s upper wind girder Remove the crane.Assembling of vertical columns.After finishing the welding of ceiling girders,ceiling plates are mounted as clinker-built Welding of Base plates.Assembling of Cathodic Protection anode supports Welding between the base and the 1st course. course All manufacturing processes according to the nozzle orientation Filling the water and hydrotesting Loading the water out and drying.sandblasting and painting Assembling of Tank accessories and commissioning 14 EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ SITE ERECTION (WMS;EQUIPMENT) EDOPEC’ manufacturings EDOPEC’s f i on Field Fi ld 2 nd Method(Using Mobile Crane) 1. Ready Basement: 1. Fixing the main body manufacturing limit 2 2. Distribution,assembling and spot welding of base plates. plates 3. Stopper welding to the Base plate.Assembling of 1st course plates,opening of mainbody manholes 4. Assembling of 2nd and 3rd course plates.First vertical and then the horizontal weldings of 1st course.(Between 1st and 2nd course,not a base) 5. Buildingg ladder to the inner p part beginning g g from the 2nd course 6. Assembling of 4th course and then vertical and horizantal welding between 2nd and 3rd courses.This will continue like this till to the last course. 7. According to the adverse weather conditions wind girder can be put on the middle course during the manufacturing. 8. Assemblingg of the last course’s upper pp wind ggirder. 9. Assembling of vertical columns.After finishing the welding of ceiling girders,ceiling plates are mounted as clinker-built 10. Welding of Base plates.Assembling of Cathodic Protection anode supports 11. Welding between the base and the 1st course. 12. All manufacturing processes according to the nozzle orientation 13. Filling the water and hydrotesting 14. Loading the water out and drying.sandblasting and painting 15. Assembling of Tank accessories and commissioning 15 EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ PROCUREMENT AND SUBCONTRACTING EDOPEC’s procurement process is relative to ISO 9001:2000 Quality System procedures.Should the occasion arises,we can define substantive procurement operations for each projects. projects Vendor selections are relative to as its defined in,ISO 9001:2000 quality system.Should the occasion arise we determine vendors only for that project. List of the vendors,which are approved at the end of the year or on certain stages,are issued as approved vendors list to send out to the project directors. 16 EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ QA/QC EDOPEC ,has ISO quality management systems.All the controls are done periodically in every 6 months at our head office,manufacturing facilities and construction sites. Setting QA/QC systems in project terms is a regular application for our company.Considering the project requirements,we can take an adventage of new employee(s) for QA/QC Sh ld the Should h occasion arise,EDOPEC EDOPEC can bbenefit f ffrom Th Third dP Party Inspectors I for QA/QC. EDOPEC accepts the QA/QC applications as an peremptory necessity for it projects. its j t 17 EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ TRANSPORT FACILITES EDOPEC employs vendors for the transportation of manufactured materials and products. Local transportation is committed with EDOPEC’s vehicles. During the manufacturing and loading EDOPEC uses its own equipments.. 18 EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ AVAILIBILITY OF BASE MATERIALS EDOPEC supplys the Tank plates from approved vendors. 19 EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ SITE PICTURE 20 EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ SITE PICTURE 21 EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ SAMPLE TANK FARM DESIGN EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ 22 STORAGE TANK ACCESORIES FA +GH+PVV GAUGE HATCH NON- ATMOSPHERİC SAMPLİNG HATCH FLAME ARRESTER WITH PRESSURE VACUUM VENT 23 EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ EMERGENCY VENT FOR STORAGE TANK 24 EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ FLOATING SUCTION ARM AND SWIVEL JOINT 25 EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ CLEANOUT DOOR CLEAN OUT DOOR 26 HEAT TEARETMENT REPORT EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ CLEANOUT DOOR 27 EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET İ İ İ İ PIG EQUIPMENT PIG SIGNAL PIG R/L - CLOSURE 28 EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ PIPE LINE PIG RECEIVER AND LAUNCHER 29 EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ COMPANY INFORMATION Head Office : Palmiye Mah. 1219 Sk. Gürarslan Apt. (Kapı No:15) K t2D Kat:2 D:6 6 PK PK-33110 33110 Yenısehır -Mersın -Turkey P:+90 324 3260595 F +90 324 3260596 F:+90 www.edopec.com. info@edopec.com 30 EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET LİMİTED ŞİRKETİ