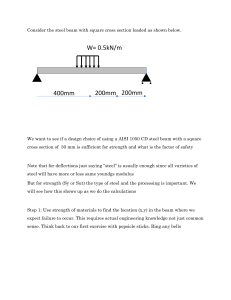

› www.thestructuralengineer.org Note 1 Level 2 Technical Technical Guidance Note TheStructuralEngineer January 2013 25 Designing a steel beam ICON LEGEND Introduction This Technical Guidance Note is the first of the Level 2 guides. Guides in this next level build on what has been described previously in the Level 1 series. The topics covered at Level 2 are of a more complex nature as they typically deal with the design of elements as opposed to core concepts such as loading and stability. As such, the amount of prior knowledge the reader is assumed to have is at the very least the contents of relevant Level 1 Technical Guidance Notes. • Principles of steel beam design • Applied practice • Worked example The subject of this guide is the design of non-composite steel beams to BS EN 1993-1-1 – Eurocode 3: Design of Steel Structures – Part 1-1: General Rules for Buildings. It covers both restrained and unrestrained rolled steel ‘I’ and ‘H’ beam sections. It does not encompass the design of ‘T’ sections, hollow sections, castellated beams, angles and welded sections. The key to understanding the design of steel beams is to determine whether or not the beam is restrained against lateral torsional buckling. This subject is covered in the Level 1 (No. 16) Technical Guidance Note: Lateral torsional buckling. If a beam is restrained, all that needs to be checked is the bending moment and shear resistance of the beam as well as serviceability limits against the applied load/actions. All of which are based on the beam’s core properties. If the beam is unrestrained along any part of its length however, then there is a risk it will fail due to lateral torsional buckling. To address this, Eurocode 3 establishes a reduction factor that is applied to the bending moment resistance of the beam. Calculating this factor is the cornerstone of unrestrained steel beam design within Eurocode 3. Steel material properties The density of steel is 7850 kg/m3 and the Young’s Modulus (E) is 210,000 N/mm2. S275 and S355 are the two strength This version 1.1 published October 2016. • Web resources Description Principles of steel beam design Frequent references will be made on the section variables throughout this guide. You are advised therefore to examine Figure 1 for the definition and nomenclature of these variables. • Further reading Variable b Width of flange h Depth of beam z-z Minor axis y-y Major axis d Depth of web tw Thickness of web tf Thickness of flange r Radius of root fillet between web and flange Wpl,y Plastic section modulus about the y-y axis Wel,y Elastic section modulus about the y-y axis iz Radius of gyration about the z-z axis A Cross sectional area of the beam Iyy Second moment of area about the y-y axis • Figure 1 Beam section notation used in Eurocode 3 grades of steel most commonly used in the construction industry within the UK. S275’s nominal yield strength is 275 N/mm2 and Grade S355’s nominal yield strength is 355 N/mm2. The actual yield strength is dependent on the maximum thickness of an element within a steel section, as the thicker the element the lower the yield strength. Table 1 defines what the yield strength should be for the most common ranges of thicknesses found in open rolled steel sections. These figures are based on the values given in BS EN 10025 Hot Rolled Products of Structural Steels, which is the product standard for rolled steel sections of various sub-grades. › Note 1 Level 2 26 Technical Technical Guidance Note TheStructuralEngineer January 2013 Table 1: Yield strength fy vs. element thickness Grade Yield strength fy for element thickness < 16mm (N/mm2) Yield strength fy for element Yield strength fy for element thickness > 16mm thickness > 40mm and < 40mm (N/mm2) and < 63mm (N/mm2) S275 275 265 255 S355 355 345 335 Classification of beam sections Clause 5.5.2 in BS EN 1993-1-1 groups steel beams into four classifications. These classifications are based on a steel beam section’s resistance to suffering from a local failure due to buckling: Class 1/‘Plastic’ These sections can form a plastic hinge when a bending moment is applied to them without suffering from local buckling failure. Class 2/‘Compact’ These sections cannot properly develop a plastic hinge as their ability to rotate is limited before local buckling failure occurs. Class 3/‘Semi-Compact’ These are sections that can withstand elastic stresses, specifically at the extreme fibres of the section, but cannot form a plastic hinge. This has the effect of negating their plastic bending moment capacity. Class 4/‘Slender’ Sections that will fail due to local buckling prior to the point of yield stress. Their plastic bending capacity therefore is non-existent. When determining the classification of a section, typically two parts of a rolled steel beam section are considered. For a simply supported beam, these are the edge of the top flange and the web, both of which are subjected to compression stress due to bending. Figure 2 indicates where these elements lie within a rolled steel beam section. Table 5.2 in Clause 5.5 of BS EN 1993-1-1 defines the limits within which the geometry • Figure 2 Elements of a rolled steel beam that determine its classification of the elements must lie. These limits are further modified based on the yield strength of the material; this is defined via coefficient ε thus: 235 N/mm fy f = 2 Where: ε is the coefficient for section classification fy is the yield strength of the steel, based on element thickness Table 2 indicates the limiting values for various classes of section for both of the elements identified in Figure 2. If any of the ratios go beyond those stated in Table 2 the section is considered to be in the Class 4 category. Table 2: Limiting values of geometries for section classes 1-3 Class Web Flange 1 c/t ≤ 72ε c/t ≤ 9ε 2 c/t ≤ 83ε c/t ≤ 10ε 3 c/t ≤ 124ε c/t ≤ 14ε Shear capacity Typically the component of the beam that takes the majority of the applied shear force is its web. There are instances where stiffeners are installed in order to support high shear loads, but this is very much the exception rather than the rule. "Guides in this next level build on what has been described previously in the Level 1 series" www.thestructuralengineer.org 27 All steel beams must satisfy the following expression: V Ed # 1 V c, Rd Where: VEd is the applied shear force Vc,Rd is the design shear resistance In the case of Class 1 and 2 rolled steel beams, the design shear resistance is designated as Vpl,RD and is defined in Clause 6.2.6, equation 6.18 of BS EN 1993-1-1 as: V pl,Rd = A v (f y / 3) c M0 M c,Rd = W y fy c M0 Where: Wy is the major axis section modulus of the beam based on its classification: Wy = Wpl,y (Plastic section modulus) for Class 1 or 2 Wy = Wel,y (Elastic section modulus) for Class 3 Wy = Weff,y (Minimum effective section modulus) for Class 4 fy is the yield strength of the steel, based on element thickness γM0 is the partial factor for the resistance of cross-sections, which in the UK is set at 1.0 Where: Av is the cross section area of the part of the beam that is resisting shear. For ‘I’ and ‘H’ sections this can conservatively be taken to be htw, which is the cross sectional area of the web and the thickness of the flange (Figure 3). For all other classes of beam sections, you are referred to Clause 6.2.6 (4) of BS EN 1993-1-1 for determining their design shear resistance. The bending moment resistance should be reduced if the applied shear force is more than half of the plastic shear resistance of the beam. Where it exceeds this value, Clause 6.2.8 of BS EN 1993-1-1 applies. This places a modification factor against the yield strength. The reduced bending capacity of the beam only applies to where the high shear force is applied to the beam and not its overall length. This leads to only continuous beams being sensitive to this reduced bending capacity, as the hogging moment over the support needs to be resisted as well as the shear due to the presence of the support. Clause 6.2.6 of BS EN 1993-1-1 has a more accurate equation that takes into account the radii of the root fillet to the web-toflange interface of the ‘H’ and ‘I’ sections. These can be used if you are finding it difficult to satisfy the shear resistance requirements. Bending moment resistance of steel beams BS EN 1993-1-1 defines the bending moment resistance of restrained steel beams (Mc,Rd) in clause 6.2.5(2) as: Clause 6.3.2.3 of BS EN 1993-1-1 describes how the value of χLT is related to the slenderness of the beam. This is related to the distance between restraints to the element of the beam that is subject to compression. For simply supported beams it is its upper-most flange. This is known as the non-dimensional slenderness ( m LT ) and is defined thus: m LT = W y fy M cr Where: Wy and fy are as per previous definitions Mcr is the elastic critical moment for lateral torsional buckling, which is based on the slenderness of the beam Mcr is not defined within Eurocode 3, which Modified yield strength = (1-ρ)fy Where: Slenderness ` 2V - 1j 2 Ed V pl,Rd This modified yield strength is then inserted into the calculation that determines bending moment resistance. • Lateral torsional buckling offers no guidance in calculating its value. There are however, many direct methods for calculating slenderness, the most simple of which is described in this guide. t = Figure 3 Approximate extent of web resisting shear in a steel beam beam based on its classification and is the same for restrained beams fy is the yield strength of the steel, based on element thickness γM1 is the partial factor for resistance of members subject to instability, which in the UK is set at 1.0 χLT is the reduction factor that takes into account lateral torsional buckling For Class 4 sections you are required to follow the guidance given in BS EN 1993-15 – Eurocode 3: Design of Steel Structures – Part 1-5: Plated Structural Elements. Class 4 sections are not found in rolled ‘I’ and ‘H’ elements and are therefore beyond the scope of this guide. For ‘H’ and ‘I’ sections it is possible to use simplified methods to calculate the relative slenderness of the beam. The most conservative method is defined in Table 1.1 of NCCI: Determination of non-dimensional slenderness of I and H sections SN002aEN-EU. It is based on applying the following equations that vary depending on the grade of steel being used: For S275 Grade steel: m LT = :L D iz 96 For S355 Grade steel: In the case of an unrestrained portion of a beam, a factor is applied to the bending moment resistance (Mb,Rd) that takes into account the risk of lateral torsional buckling. This is described Clause 6.3.2.1 (3) of BS EN 1993-1-1, in equation 6.55 as: M b, Rd = | LT W y fy c M1 Where: Wy is the major axis section modulus of the m LT = :L D iz 85 Where: L is the distance between restraints to the compression flange of the beam iz is the radius of gyration about the minor axis of the beam While valid, this method is very conservative › Note 1 Level 2 28 Technical Technical Guidance Note TheStructuralEngineer January 2013 as it ignores the bending moment diagram of the beam and can therefore result in oversized members. There is however, a more accurate yet complex method that does take into account the bending moment diagram and is described in NCCI: Determination of non-dimensional slenderness of I and H sections SN002aEN-EU. It is strongly recommended that you examine this method in order to design more efficiently sized steel beams. 0.4 and 0.75 respectively, as described in Clause NA.2.17 of NA to BS EN 1993-1-1. αLT is the imperfection factor and is found in Table 6.3 of BS EN 1993-1-1, which reads against the steel beam’s buckling curve. The buckling curves are labelled ‘a’ to ‘d’ and can be found in Clause NA.2.17 of NA to BS EN 1993-1-1. The buckling curve is dependent upon the h/b ratio of the beam section. Serviceability The vertical deflection limits for steel beams can be found in the Clause NA.2.23 of the UK National Annexe to BS EN 1993-1-1. Table 3 is based on these stated limits, which are for the deflection due to unfactored imposed loads/variable actions only. In addition to deflection, it is prudent to check the vibration of the beam i.e. its dynamic response. Technical Guidance Note No. 11, Level 1 explains how to do this. There are further methods in determining Mcr described in the Non-Contradictory Complimentary Information website for structural steelwork. Once the non-dimensional slenderness is established, the value of χLT is determined using equation 6.57 of Clause 6.3.2.3 of BS EN 1993-1-1 thus: | LT = 1 U LT + Table 3: Vertical deflection to steel beams Beam type/structure Deflection limit Cantilever Length/180 Beams supporting brittle finishes Span/360 All other conditions Span/200 Purlins and cladding rails To suit cladding system 2 2 U LT - b m LT U LT = 0.5 61 + a LT ( m LT - m LT, 0) + b m LT@ 2 Where: The values of β and m LT,0 are defined as Eurocode 0. Applied practice The applicable codes of practice for designing steel beams are as follows: BS EN 1993-1-1 Eurocode 3: Design of Steel Structures – Part 1-1: General Rules for Buildings BS EN 1993-1-1 UK National Annex to Eurocode 3: Design of Steel Structures – Part 1-1: General Rules for Buildings Worked example A simply supported, unrestrained steel beam spanning 8m is supporting another steel beam in the middle of its span. The ultimate load from this beam is 500 kN, while the serviceability load due to variable actions is 200 kN. The floor structure consists of one way spanning precast concrete planks with a screed and tiled finish. These planks span parallel to the steel beam and hence do not provide lateral restraint. Determine what size of beam is required to support this load, assuming the steel grade to be S355. www.thestructuralengineer.org 29 Glossary and further reading Reduction factor – A variable applied to the bending moment resistance of a beam due to the fact that it is unrestrained and hence subject to lateral torsional buckling. Rolled steel section – A steel element that is cast to a pre-set size and not built up from separate plate elements. Section classification – A categorisation of steel elements that is based on the element’s ability to develop a plastic hinge when placed under load. Further Reading The Institution of Structural Engineers (2010) Manual for the Design of Steelwork Building Structures to Eurocode 3 London: The Institution of Structural Engineers Steel Construction Institute (2009) Steel Building Design. Worked Examples for Students (P387) Ascot, Berkshire: SCI The Institution of Structural Engineers (2012) ‘Principles of design’ The Structural Engineer Vol. 90 (1) pp. 40-41 The Institution of Structural Engineers (2012) ‘Derivation of dead loads’ The Structural Engineer Vol. 90 (1) pp. 43-45 The Institution of Structural Engineers (2012) ‘Derivation of imposed loads’ The Structural Engineer Vol. 90 (2) pp. 46-48 The Institution of Structural Engineers (2012) ‘Derivation of wind load’ The Structural Engineer Vol. 90 (2) pp. 49-52 The Institution of Structural Engineers (2012) ‘Derivation of snow load’ The Structural Engineer Vol. 90 (3) pp. 22-24 The Institution of Structural Engineers (2012) ‘Lateral torsional buckling’ The Structural Engineer Vol. 90 (16) pp. 28-30 Eurocode 0. Web resources Tata Steel Interactive ‘Blue Book’: www.tatasteelconstruction.com/en/design_ guidance/the_blue_book/ Non-Contradictory Complimentary Information website for structural steelwork: www.steel-ncci.co.uk/