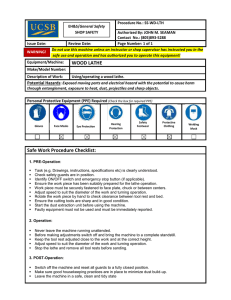

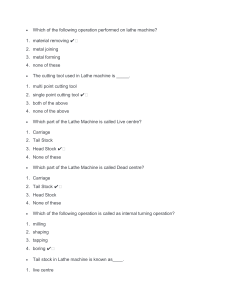

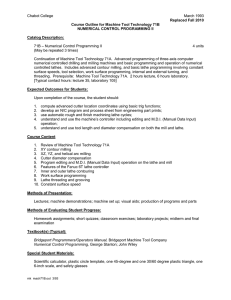

04-02 Turning and Related Operations azharhussain@uettaxila. edu.pk 3 Material Removal Processes • The starting material is solid metal • Excess material is removed from the starting metal that the resulting part has the desired geometry so • Most common in this category are machining operations such as turning, drilling and milling, accomplished using cutting tools that are harder and stronger than the work metal • In grinding abrasive grinding wheel is used to remove material azharhussain@uettaxila. edu.pk 4 What is a Machine Tool? • A machine tool is a non-portable, power operated device or system of devices in which energy is expended to produce jobs of desired size, shape and surface finish by removing excess material from the preformed blanks in the form of chips with the help of cutting tools moved past the work surface(s). azharhussain@uettaxila. edu.pk 5 Lathe Cutting Operations Miscellaneous cutting operations that can be performed on a lathe. Note that all parts are circular – a property known as axisymmetry. azharhussain@uettaxila. edu.pk 52 What is Common in Machine Tools? • • • • • • • Electric Motor Transmission Mechanism Spindle Base or Bed Slides or Ways Cutting Tool Mechanisms for different movements • Different Levers, Handwheels & Gauges • Workpiece holding device • Accessories • Cutting Speed • Feed Rate azharhussain@uettaxila. edu.pk 6 The Lathe • The forerunner or mother of all machine tools • The work is held and rotated on its axis while the cutting tool is advanced along the lines of a desired cut main purpose of a lathe is to machine round work • The engine lathe is the most common lathe found in a machine shop azharhussain@uettaxila. edu.pk 7 Parts of the Lathe • The main parts of the lathe are – The bed (and ways) – Headstock – Quick-change gear box – Carriage – Tailstock Bed: • The bed is a heavy casting made to support the working parts of the lathe • On its top section are machined ways that guide and align the major parts of the lathe azharhussain@uettaxila. edu.pk 8 Parts of the Lathe… Headstock: • The headstock is clamped on the left-hand side of the bed • The headstock spindle, a hollow cylindrical shaft provides a drive through gears from motor to work-holding devices • A live center, a faceplate, or a chuck can be fitted to the spindle nose to hold and drive the work • The live center has a 60° point that provides a bearing for the work to turn between centers azharhussain@uettaxila. edu.pk 9 Parts of the Lathe… Quick-change Gearbox: • The quick-change gearbox, containing a number of different-size gears, provides the feed rod and lead screw with various speeds for turning and thread cutting operations • The feed rod advances the carriage for turning operations when the automatic feed lever is engaged • The lead screw advances the carriage for thread cutting when the split-nut lever is engaged azharhussain@uettaxila. edu.pk 10 Parts of the Lathe… Carriage: • Used to move the cutting tool along the lathe bed • The saddle, an H-shaped casting mounted on the top of the lathe ways, provides a means of mounting the cross-slide and the apron • The cross-slide, mounted on the top of the saddle, provides a manual or an automatic cross movement for the cutting tool azharhussain@uettaxila. edu.pk 11 Parts of the Lathe… • The compound rest, fitted on top of the cross-slide, is used to support the cutting tool • It can be swiveled to any angle for taper-turning operations • The cross-slide and compound rest both have graduated collars • The apron, fastened to the saddle, houses the gears and the mechanism required to move the carriage or crossslide automatically azharhussain@uettaxila. edu.pk 12 Parts of the Lathe… • The apron handwheel can be turned manually to move the carriage along the bed • This handwheel is connected to a gear that meshes in a rack fastened to the lathe bed • The automatic feed lever engages a clutch that provides automatic feed to the carriage azharhussain@uettaxila. edu.pk 13 Parts of the Lathe… • The feed-change lever can be set for longitudinal feed or for crossfeed • When in neutral position , the feed-change lever permits the split-nut lever to be engaged for thread cutting • For thread cutting, the carriage is moved automatically when the split-nut lever is engaged • This causes the threads of the split-nut to engage into the threads of the revolving lead screw and move the carriage at a predetermined rate. azharhussain@uettaxila. edu.pk 14 Parts of the Lathe… Tailstock: • The tailstock can be adjusted for taper or parallel turning by two screws set in the base • The tailstock spindle has an internal taper to receive the dead center, which provides support for the right-hand end of the work • Other standard tapered-shank tools, such as reamers and drills, can be held in the tailstock spindle • A spindle clamp is used to hold the tailstock spindle in a • fixed position The tailstock handwheel moves the tailstock spindle in or out of the tailstock azharhussain@uettaxila. casting 15 edu.pk Schematic view of a center lathe azharhussain@uettaxila. edu.pk 16 General view of a typical lathe, showing various components azharhussain@uettaxila. edu.pk 18 Movement of different parts of Lathe in different axes The Carriage azharhussain@uettaxila. edu.pk 20 Turret Lathe Schematic illustration of the components of a turret lathe. Note the two turrets: square and hexagonal (main). azharhussain@uettaxila. edu.pk 22 Turret Lathe in Action Video azharhussain@uettaxila. edu.pk 23 Numerical Control Lathe and Turret (a) A computer numerical-control lathe. Note the two turrets on this machine. These machines have higher power and spindle speed than other lathes in order to take advantage of new cutting tools with enhanced properties. (b) A typical turret equipped with ten tools, some of which are powered. azharhussain@uettaxila.e du.pk 24 Boring and Boring Mill (a) Schematic illustration of a steel boring bar with a carbide insert. Note the passageway in the bar for (b) cutting fluid application. Schematic illustration of a boring bar with tungsten-alloy “inertia disks” sealed in the bar to counteract vibration and chatter during boring. This system is effective for boring bar length-todiameter ratios of up to 6. Schematic illustration of a vertical boring mill. Such a machine can accommodate workpiece sizes as large as 2.5m (98 in.) in diameter. azharhussain@uettaxila. edu.pk 25 Lathe Workholding Devices Lathe Centers: • Most turning operations can be performed between centers on a lathe • Work to be turned between centers must have a center hole drilled in each end to provide a bearing surface • A lathe dog, fitted into a driving plate, provides a drive for the work • The lathe dog has an opening to receive the work and a setscrew to fasten the dog to the work • The tail of the dog fits into a slot on the driveplate and provides a drive to the workpiece azharhussain@uettaxila. edu.pk 26 Lathe centers and lathe dogs azharhussain@uettaxila.edu.pk 27 Lathe centers and lathe dogs azharhussain@uettaxila.edu.pk 28 Lathe Workholding Devices Chucks: The most common are three-jaw universal, four-jaw independent, and collet chuck The three-jaw universal chuck: • Holds round and hexagonal work • Three jaws move simultaneously when adjusted by the chuck wrench • Usually provided with two sets of jaws, one for outside chucking and the other for inside chucking azharhussain@uettaxila. edu.pk 29 Three-jaw universal chuck azharhussain@uettaxila. edu.pk 30 Lathe Workholding Devices Four-jaw Independent Chucks: • 4-jaw chucks are usually non-self-centering • Each jaw can be moved independently • Ideal for gripping round, square, hexagonal and irregularly shaped workpieces • The jaws can be reversed to hold work by inside diameter • Multi-jaw chucks (6 or 8 jaws) for special purpose and high standards of accuracy azharhussain@uettaxila. edu.pk 31 Four-jaw and six-jaw chucks azharhussain@uettaxila.ed u.pk 32 Lathe Workholding Devices Magnetic Chuck: • It has the advantage of holding iron or steel parts • The parts that are too thin or that may be damaged if held in a conventional chuck • Suitable only for light operations • A magnetic chuck consists of an accurately centered permanent magnet face azharhussain@uettaxila. edu.pk 33 Magnetic chuck azharhussain@uettaxila. edu.pk 34 Lathe Workholding Devices Faceplates: • Circular metal plate fixed to the end of spindle • Used to hold work that is too large or of such a shape that it cannot be held in a chuck or between centers • It has slots or threaded holes • W.piece is clamped using T-bolts in the slots or threaded holes azharhussain@uettaxila. edu.pk 35 Faceplate and T-bolts azharhussain@uettaxila.ed u.pk 36 Lathe Workholding Devices Collet Chucks: • Used for small parts that cannot be held in a jawchuck azharhussain@uettaxila. edu.pk 37 Lathe Workholding Devices Collet Chucks: Workpiece held in collet chuck azharhussain@uettaxila.edu.pk 38 Lathe Workholding Devices Mandrels: • Mandrels are shafts specially made to hold work to be machined concentrically around a previously bored or drilled hole • There are two general types, plain and expanding • Plain mandrels have a 0.006-in. taper per foot • There must be a mandrel for each hole size azharhussain@uettaxila. edu.pk 39 Lathe Workholding Devices Plain Mandrels: azharhussain@uettaxila. edu.pk 40 Lathe Workholding Devices Sleeve-type Expanding Mandrels: azharhussain@uettaxila. edu.pk 41 Lathe Workholding Devices Steadyrest: • Used to support long or slender work held in a chuck or between lathe centers • It is located on, and aligned by, the ways of the lathe • It may be positioned at any point along the lathe bed, provided it clears the carriage travel • Its three jaws my be adjusted to support any work diameter within the steadyrest capacity • It also supports the center of long work to prevent springing when the work is machined between centers azharhussain@uettaxila. edu.pk 42 Steadyrest azharhussain@uettaxila. edu.pk 43 Lathe Workholding Devices Follower Rest: • Often used to support a long, slender workpiece during machining • Mounted on the saddle, travels with the carriage to prevent work from springing up and away from the cutting tool • The cutting tool is generally positioned just ahead of the follower rest to provide a smooth bearing surface for the two jaws of the follower rest azharhussain@uettaxila. edu.pk 44 Follower Rest azharhussain@uettaxila. edu.pk 45 Lathe Machine Types Multispindle Lathe Machine https://www.youtube.com/watch?v=y2dd_G_v jGE CNC Lathe, Conventional Lathe, Lathe Accessories azharhussain@uettaxila. edu.pk 46 Cutting Speed, Feed and Depth of Cut • Lathe work cutting speed (CS) : the rate at which a point on the work circumference travels past the cutting tool • Expressed as ft / min or m / min • r / min = CS x 12 / π D ≈ CS x 4 / D • Example: Calculate the r/min required to turn a 2-in. diameter piece of machine steel (CS 90). • For metric calculations: r/min = CS (m) x 1000/π x D (mm) ≈ CS (m) x 320/D (mm) azharhussain@uettaxila. edu.pk 47 Cutting Speed, Feed and Depth of Cut • The feed of a lathe may be defined as the distance the cutting tool advances along the length of the work for every revolution of the spindle • For example, if the lathe is set for a 0.015-in. feed, the cutting tool will travel along the length of the work 0.015 in. for every complete turn of the workpiece • The depth of cut is the depth of the chip taken by the cutting tool and is one-half the total amount removed from the workpiece in one cut azharhussain@uettaxila. edu.pk 48 Lathe cutting speeds in feet and meters per minute using a high-speed steel toolbit (rough cut turning and boring) Material ft/min m/min Machine steel 90 27 Tool steel 70 21 Cast iron 60 18 Bronze 90 27 Aluminum 200 61 azharhussain@uettaxila. edu.pk 49 Feed for various materials using high-speed steel cutting tool (rough cut turning and boring) Material in. mm Machine steel 0.010-0.020 0.25-0.50 Tool steel 0.010-0.020 0.25-0.50 Cast iron 0.015-0.025 0.4-0.65 Bronze 0.015-0.025 0.4-0.65 Aluminum 0.015-0.030 0.4-0.75 azharhussain@uettaxila. edu.pk 50 Lathe Cutting Tools azharhussain@uettaxila. edu.pk 51 Taper Turning Methods 1. 2. 3. 4. 5. Offsetting the tailstock Swiveling the compound slide Using form tool Using taper turning attachment Giving longitudinal and cross feed simultaneously – Very rare and risky azharhussain@uettaxila. edu.pk 53 Brief Review on Lathe Intro to Lathe Operations Video Lathe Workholding Video Lathe Cutting Tools Video Lathe Controls Video azharhussain@uettaxila. edu.pk 54 Center Lathe Specifications • Maximum diameter and length of job that can be accommodated • Power of the main drive (motor) • Range of spindle speeds • Range of feeds • Space occupied by the machine azharhussain@uettaxila. edu.pk 55 Questions?? azharhussain@uettaxila. edu.pk 56 N = v/(πD) Homework Problem related to turning from 22.1-22.5 References • Technology of Machine Tools, 6th Ed. by S. F. Krar, A. R. Gill, P. Smid; McGraw Hill Higher Education • Degarmo’s Materials And Processes In Manufacturing, 10th Ed. By J.T Black, R. A. Kohser; John Wiley And Sons • Manufacturing Engineering And Technology, 5th Ed. By S. Kalpakjian, S. R. Schmid; Pearson Education azharhussain@uettaxila. edu.pk 57