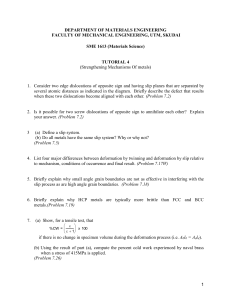

Notes-Unit-1 Part-2 UNIT-I Syllabus : Plastic Deformation: Introduction to engineering materials, Imperfections in crystals, Dislocation in crystals, Types of dislocations, Effect of slip and twinning on plastic deformation, Strain hardening, Cold and hot working, Bauschinger effect, Recovery, Recrystallization, Grain growth and its effect on mechanical properties of metals. Fracture: Types of fracture in metals, Ductile and brittle fracture, Griffith theory of brittle fracture, Crack propagation and ductile to brittle transition temperature. Part-2: Effect of slip and twinning on plastic deformation, Strain hardening, Cold and hot working, Bauschinger effect, Recovery, Recrystallization, Grain growth and its effect on mechanical properties of metals. Plastic deformation: plastic deformation process is the one in which an object undergoes an irreversible change in size or shape due to the application of force. According to the theory of material science, plastic deformation occurs when a metal is subjected to enough stress to result in persistent deformation. Additionally, plastic deformation refers to the breakdown of a small number of atomic bonds caused by the movement of dislocations. Mechanism of Plastic deformation – Slip & Twinning In metals, there are two main mechanisms for plastic deformation: o o Slip Twinning The primary process of deformation in metals is slip. A slip is the sliding of crystal blocks over one another along various crystallographic planes referred to as slip planes. In twinning, a portion of the crystals adopts an orientation that is clearly and symmetrically connected to the direction of the remaining untwined lattice. Slip When the applied stress is greater than the material’s critically resolved shear stress, atoms slide over one another within the crystal structure. Slip happens when edge dislocations travel along densely packed planes and directions, where there are the most atoms per unit length. The set of slip planes and directions where the dislocation movement needs the least amount of energy is referred to as the slip system. Due to the presence of dislocations, the resolved shear stress calculated theoretically significantly exceeds experimental findings. Slip allows for the promotion of plastic deformation by causing an existing dislocation to move along the slip line rather than creating new ones. If a structure contains enough closely packed slip systems, slip is typically the basic process of plastic deformation. Twinning Twinning occurs because of screw dislocation. Although slip movement typically causes plastic distortion, twinning can occasionally replace slip systems in situations where there are few slip systems to begin with. When atomic bonds are distorted, a process known as twinning occurs that causes the atoms’ orientation to shift. As a result, local atoms rearrange across a twinning plane as mirror copies of one another. Twining occurs across specific crystallographic planes and directions known as twin planes and twin directions, much like slide does. Atoms parallel to the twin plane travel along the lattice during twinning, causing the lattice within the twinned region to distort. Each atomic plane’s separation from the twin plane directly relates to the quantity of movement. Twining causes planes to slip more by affecting the plane’s orientation, which adds to plastic deformation. Strain hardening: Strain Hardening is phenomenon in which when a metal is deformed beyond the yield point, an increasing stress is required to produce additional plastic deformation and the metal apparently becomes stronger and more difficult to deform. Let a material is deformed beyond yield point and the load is removed. Then the material returns to a state of zero stress along a path parallel to the elastic loading line when the material is reloaded, it follows the same path up to the original stress-strain curve. The new yield strength is now substantially higher than the old yield strength. But, the total elongation available has now diminished. When a material is permanently deformed, the dislocations move until they are stopped by grain boundaries or intersection by other dislocations. The dislocations pile up against each other, and can become intertwined. Thus the dislocations pile up at the grain boundaries or entangled with each other. This prevents any further permanent deformation of that particular grain, without the use significantly greater energy. This greatly increases the strength of the material under any subsequent loading. Bauschinger effect The Bauschinger Effect is defined as a decrease in the yield strength of the material in compression as a result of prior deformation in tension. It is a general phenomenon found in most polycrystalline metals. Based on the cold work structure, two types of mechanisms are generally used to explain the Bauschinger effect: Local back stresses may be present in the material, which assist the movement of dislocations in the reverse direction. The pile-up of dislocations at grain boundaries and around strong precipitates are two main sources of these back stresses. When the strain direction is reversed, dislocations of the opposite sign can be produced from the same source that produced the slip-causing dislocations in the initial direction. Dislocations with opposite signs can attract and annihilate each other. Since strain hardening is related to an increased dislocation density, reducing the number of dislocations reduces strength. Recovery, Recrystallization, Grain growth Plastic deformation of metal distorts the crystal lattice. It breaks up the blocks of initial equiaxed grains to produce fibrous structure and increases the energy level of metal. Deformed metal, during comparison with its un-deformed state, is in nonequilibrium, thermodynamically unstable state. Therefore, spontaneous processes occur in strain-hardened metal. When the temperature of metal is increased, the metal attempts to approach equilibrium through three processes: (i) Recovery, (ii) Recrystallization, and (iii) Grain growth. (i) Recovery: Recovery is the initial stage of heat treatment, where dislocations within the crystal lattice begin to rearrange and eliminate some of the internal strain energy, often through the motion of dislocations and the annihilation of point defects.When a strain-hardened metal is heated to a low temperature, the elastic distortions of the crystal lattice are reduced due to the increase in amplitude of thermal oscillation of the atoms. This heating will decrease the strength of the strain-hardened metal but there is an increase in the toughness and ductility of metal, though they will not reach the values possessed by the initial material before strain-hardening. No changes in microstructure of metal are observed in this period. (ii)Recrystallisation: Formation of new equiaxed grains in the heating process of metal, instead of the oriented fibrous structure of the deformed metal, is called recrystallisation. The first effect of heating of metal is to form new minute grains and these rapidly enlarge until further growth is restricted by grain meeting another. The original system of grains go out of the picture and the new crystallized structure is formed in the metal. Recrystallisation does not produce new structures however it produces new grains or crystals of the same structure in the metal. It consists in having the atoms of the deformed metal overcome the bonds of the distorted lattice, the formation of nuclei of equiaxed grains and subsequent growth of these grains due to transfer of atoms from deformed to un-deformed crystallites. Recrystallisation temperature is also defined as that temperature at which half of the cold worked material will recrystallise in 60 minutes. (iii) Grain Growth: After recrystallization, further heat treatment or time at elevated temperatures can lead to grain growth, where existing grains increase in size. On recrystallisation of metal, the grains are smaller and somewhat regular in shape. The grains in metal will grow if the temperature is high enough or if the temperature is allowed to exceed the minimum required for recrystallisation. For any temperature above the recrystallization temperature, normally there is practical maximum size at which the grains will reach equilibrium and cease to grow significantly. The mechanical properties of metals are influenced by various microstructural changes that occur during different heat treatment processes, including recovery, recrystallization, and grain growth. Let's discuss each of these processes and their effects on the mechanical properties of metals: Effect of Recovery, Recrystallization, Grain growth on Mechanical Properties of the metals Recovery reduces the dislocation density, which results in a decrease in the metal's hardness and an increase in its ductility. This is because the metal becomes more malleable as internal stresses are relieved. Yield strength and tensile strength may decrease slightly during recovery, but the overall impact is often minor. Recrystallization leads to the formation of new, equiaxed grains that are generally smaller than the original grains. This process improves the metal's ductility, toughness, and formability. Grain boundaries play a crucial role in the mechanical properties, and the formation of new grains with clean, low-angle boundaries can lead to improved mechanical properties. As a result of recrystallization, the yield strength and hardness decrease, but the material becomes more ductile and less susceptible to cracking. As grain size increases, the material's strength and hardness tend to decrease, while its ductility increases. Larger grains are less resistant to plastic deformation. Finegrained materials are generally stronger and harder but may be less ductile. Coarsegrained materials are often more ductile but have reduced strength and hardness. Grain growth can also impact other properties, such as creep resistance and thermal conductivity. In a nutshell, Recovery reduces internal stresses and dislocation density, leading to decreased hardness and increased ductility. Recrystallization forms new grains with clean grain boundaries, enhancing ductility and formability while reducing strength and hardness. Grain growth, if allowed to progress, can lead to larger grains, reducing strength and hardness while increasing ductility. Cold and hot working Hot working and cold working are two distinct processes used to shape and deform metals, and they are typically employed based on the temperature at which they are performed. Hot Working: Hot working is a metalworking process that is carried out at elevated temperatures, generally above the recrystallization temperature of the material. The recrystallization temperature is typically between 30% to 50% of the metal's melting point. During hot working, the metal is in a ductile and malleable state, allowing it to be easily deformed and shaped without the risk of fracture. Hot working processes include techniques such as forging, rolling, extrusion, and hot stamping. The high temperature softens the metal and reduces its resistance to plastic deformation, making it suitable for forming complex shapes and structures. Cold Working : Cold working, also known as cold forming, is a metalworking process that is performed below the recrystallization temperature of the material. In cold working, metals are less ductile and more resistant to deformation at these lower temperatures. As a result, cold working processes require higher forces to induce plastic deformation. Examples of cold working techniques include cold rolling, cold forging, wire drawing, and bending of sheet metal. Cold working is often used when precision shaping, tight tolerances, and high dimensional accuracy are required. However, it causes work hardening, which increases the material's strength and hardness but reduces its ductility. In both hot working and cold working processes, the choice of temperature and technique depends on the specific requirements of the application, the desired properties of the final product, and the characteristics of the metal being worked. Differences between Hot Working and Cold Working S.No. 1 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. Cold working Hot working It is done at a temperature below Hot working is done at a temperature the recrystallization temperature. above recrystallization temperature. It is done below recrystallization Hardening due to plastic deformation is temperature so it is accomplished completely eliminated. by strain hardening. Cold working decreases It increases mechanical properties. mechanical properties of metal like elongation, reduction of area and impact values. Re-crystallization does not take Re-crystallization takes place. place. Material is not uniform after this Material is uniform thought. working. There is more risk of cracks. There is less risk of cracks. Cold working increases ultimate In hot working, ultimate tensile strength, tensile strength, yield pointyield point, corrosion resistance are hardness and fatigue strength butunaffected. decreases resistance to corrosion. Internal and residual stresses are Internal and residual stresses are not produced. produced. Cold working required more energy It requires less energy for plastic for plastic deformation. deformation because at higher temperature metal become more ductile and soft. More stress is required. Less stress required. It does not require pickling because Heavy oxidation occurs during hot no oxidation of metal takes place. working so pickling is required to remove oxide. Embrittlement does not occur in There is chance of embrittlement by cold working due to no reaction oxygen in hot working hence metal with oxygen at lower temperature. working is done at inert atmosphere for reactive metals.