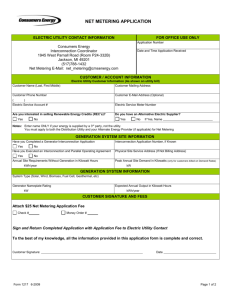

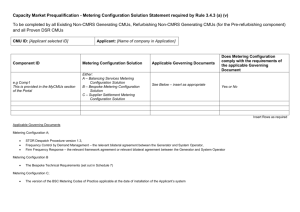

Start Time Topic 8:30am Class Introduction 8:45am Metering Project Justification 9:45am Metering Project Development 10:15am Morning Break 10:30am Metering System Design Noon Lunch Break & Open Discussion 1:00pm Metering System Reporting & Analytics 2:00pm Metering Success Stories & Case Study Reviews 2:30pm Afternoon Break 2:45pm Metering System Effectiveness 3:30pm 10-Question Quiz On Course Material Start Time Topic 8:30am Class Introduction 8:45am Metering Project Justification 9:45am Metering Project Development 10:15am Morning Break 10:30am Metering System Design Noon Lunch Break & Open Discussion 1:00pm Metering System Reporting & Analytics 2:00pm Metering Success Stories & Case Study Reviews 2:30pm Afternoon Break 2:45pm Metering System Effectiveness 3:30pm 10-Question Quiz On Course Material Every dollar not spent on energy is net profit! Example: How much sales does a company running on a 5% return from their net assets need to sell to generate $25,000 in [(Profit/5%)] Profit? $500,000 in sales If your project saves $12,000 annually in energy costs, What is that actual worth to the company bottom line? $240,000 of revenue [(Savings) * (1/% Return)] Key consideration: Energy costs will be consistently rising while management’s goal is to maintain a reasonable level of return on net assets. 5 6 Consumption (kWh) Five 1,000 watt loads Five 1,000 watt loads running for 1 hour = 5kWh of consumption On utility bill this will equal 5kWh * $.XXXX per kWh for consumption charges 1 Hour Demand (kW) The highest peak demand Interval = (5) 1,000 watt loads = 5 kW On utility bill this will equal 5kW * $XX.XX/kW For demand charges 15 Min 15 Min 15 Min 15 Min 15 Min 15 Min 15 Min 15 Min Why does the utility charge for this? Highest 15-Minute Interval During The Month 7 Pop Quiz! Which interval has the higher demand? No matter how usage is distributed during the interval, all usage is averaged. = 5 Min 5 Min 5 Min 5 Min 5 Min 5 Min 15 Minute Interval 15 Minute Interval 3kW Demand 3kW Demand 8 Identify peak usage & process events 9 “Controlling” peak load sounds risky … but it doesn’t have to be • Peak demand savings is about managing all loads efficiently • Energy bill savings can be realized without using less energy or doing less work • Load performance can be protected • Analyzing peak events can provide other operational insights 10 Typical office building demand control strategies • Raise chilled water setpoints • Raise condenser water setpoints to reduce blower fan speeds • Reduce speed setpoints on air supply/return fans • Alternate short-period shutdowns between fan or pump loops that have multiple units operating (exhaust, water loops) • Raise setpoints for meeting rooms and ballrooms held to “standby” temperatures • Shut off common area lighting • Fuel switching – electric to gas or steam • Enable thermal storage systems Must consider manpower, limitations and risks for each load drop 11 Understanding kW Vs KVar Or more simply put …. Glass capacity = Apparent power (kVA) Foam = Reactive power (kVAR) Beer = Real power (kW) Power factor = Beer Level (kW) Mug capacity (kVA) Utilities must generate kVa, but consumers can only use kW kVAR penalties may be charged by the utility Understanding Your Tariff Do you understand how your bill is calculated? • Standard kWh and monthly peak demand • “Time Of Day” rate increases • Ratcheted peak demand charges • Coincidental vs. non-coincidental peaks • Any combination of the above • Other fun & creative ideas by your utility 14 Customer name Account Number Account Number Account Number Customer Name Billing Address Service Address What does not always appear in the bill ? • Rate schedule availability o May be possible to move between different tariffs, or you may be forced to move from one to another if usage changes • Primary/secondary service options (ownership of transformers) • kWh cost changes during time of day, season of year, or hours of demand usage • kW demand charge details o On/off peak demand hours and exception days o Ratchet demands • Power factor penalties • Tariff riders and other “special” conditions 18 Fixed consumption and demand charges throughout the entire year 20 Consumption and demand changes based on daily time periods throughout the month 21 Peak demand is based on the highest kW reading over a number of months 22 Peak demand is based on the highest result of multiple calculations 23 Always look for the term “kW” Savings example for a 250kW reduction: If peak demand = 1,000kW, the cost would be: $.04082 for the first 400,000kWh (400 hours*1,000kW) then $.02553 for all additional kWh If peak demand = 750kW, the cost would be: $.04082 for the first 225,000kWh (300 hours*750kW) then $.02553 for all additional kWh Savings = ($.04082-$.02553) * 100,000kWh = $2,675 24 • Non-coincidental peaks • Sub-station upgrade funds in escrow • All-time high demand 25 Understand the “availability” terms of the tariff, and when it may change! • • Can you select between multiple tariff options? At what point will you no longer be applicable for the existing tariff? How does the change occur? 26 Does you have multiple meters? Understand the account interaction! • Is demand based on non-coincidental peaks? • Are meters on different tariffs? Can they be? • Are there loads on separate accounts that serve common areas? Example: Chillers on different utility accounts connected to a common loop throughout the building. 27 28 29 Rebate Program Best Practices • Engage local program representatives as early as possible • Confirm all available programs and eligibility requirements • Understand program caps and funding cycles • Make an effort to combine measures from multiple projects • Understand baseline measurement methodology • Understand pre-inspection requirements • Document post-project M&V acceptance requirements • Review impact of project on other active incentives and programs 30 31 • • • • • • • • Lighting and on/off controls Advanced lighting controls Comfort cooling HVAC/chiller replacement Motor replacement Building automation controls Motor / variable frequency drive upgrades Computer power management Commercial refrigeration upgrades • • • • • • • Behavioral savings Industrial controls Industrial pump/fan upgrades Injection molding system upgrades Industrial heating & cooling Other industrial process upgrades Compressed air upgrades Other measurable and verifiable upgrades 32 Start Time Topic 8:30am Class Introduction 8:45am Metering Project Justification 9:45am Metering Project Development 10:15am Morning Break 10:30am Metering System Design Noon Lunch Break & Open Discussion 1:00pm Metering System Reporting & Analytics 2:00pm Metering Success Stories & Case Study Reviews 2:30pm Afternoon Break 2:45pm Metering System Effectiveness 3:30pm 10-Question Quiz On Course Material Justification of energy metering & analytics Energy Awareness - Sharing of energy data across the entire organization Usage Allocation - Improved visibility and accountability of energy usage Utility Bill Verification – Validate usage and costs on monthly utility bills Operations – Impact of operational changes on energy usage Equipment Performance - Real-time feedback on energy usage levels Asset Utilization – Tracking of run-hours and capacity Continuous Commissioning M&V – Identification of new opportunities “If we have data, let’s look at data. If all we have are opinions, let’s go with mine.” – Jim Barksdale, former Netscape CEO 34 Metering & analytic data can be used by many levels of internal and external users • Internal Resources - Maintenance - Engineering - Accounting (Crystal ball!) - Facility Management - Corporate Management • External Resources - Utilities & Energy Suppliers Energy Efficiency Companies Engineering Firms & Contractors Customers, ISO 50001 Energy Management 35 Research possible tax exemptions 36 Return On Investment • Energy cost reductions • • • • • Usage allocation & billing Energy efficiency M&V Peak load management Equipment performance Asset utilization • Metering hardware • • • • • Installation costs System integration Software licensing & config End-user training Data analytics & reporting Does your project ROI statement fully capture all short and long-term costs, savings, benefits and risks? 37 Projects require constant selling ….. • • • • • • • • Project development Project timelines In-house trades & resources Prioritization of tasks Milestone reviews Change requests Additional funds & resources End-user acceptance “Mediocre ideas that generate enthusiasm will go further than great ideas that inspire no one.” - Mary Kay Ash 38 Do your homework ….. • Company strategic objectives • Define problems to be solved • Resources required • Personalities, politics and policies • Decision influencers • Your credibility with management • Source of possible objections • Who will receive the benefits • Risk of not doing the project ….. then develop a sales (persuasion) plan 39 Ask leading questions … Employee Performance • Which department or facility operates most efficiently? • Which maintenance team is best at executing PM routines? • Which department is best at performing shutdown procedures? Facility Management • Which area is at most risk for equipment failure? • Which area has the least amount of downtime? Operations • What operational changes require increased energy usage? • Which facility does the best job performing setpoint adjustments? “I don’t know” is a win! 40 Budget for both the direct and indirect Costs Direct Costs: • Temporary & permanent metering hardware • Electrical installation labor & materials • Controls system integration • Software configuration & licensing • End-user training Indirect Costs: • • • • Development of a bulletproof baseline Resources required to analyze data Report development & delivery Documentation of savings for management 41 The Triple Constraint: “Fast”, “Good” or “Cheap”? Pick any 2 • To develop quickly with high quality will be very costly • To develop quickly with low cost will provide low quality • To develop with high quality and low cost will take lots of time 3 comparisons: “Buy it”, “Build it” or “Integrated” Buy It - Off The Shelf Build It - Homegrown Integrated - Best Of Breed Q1 Q2 Q3 Q4 Y2 Y3 Y4 Y5 $25,000 $15,000 $10,000 $5,000 $12,500 $10,000 $2,000 $12,500 $10,000 $2,000 $7,500 $5,000 $3,600 $1,500 $3,500 $4,500 $1,500 $3,500 $5,625 $1,500 $3,500 $7,031 $1,500 $3,500 $30,000 $25,000 $20,000 Buy It $15,000 Build It $10,000 Integrated $5,000 $0 Q1 Q2 Q3 Q4 Y2 Y3 Y4 Y5 42 Focus on qualitative instead of quantitative Drive project advocacy - Identify all areas that will benefit Investment, not operational cost – Present as a business investment Address the fact there may be no clear ROI – Savings may be based on developing and unexpected insights Set savings expectations - worst case, best case with probabilities Calculate the break-even point - document the expected timeline Document Indirect benefits - List benefits beyond cost savings 43 Provide a specific table of value drivers that would normally provide the line item savings for ROI calculations Business Value Increase Revenue Lower Costs Improve Asset Utilization Manage Manufacturing Costs Identify energy costs per product Match utility generation to actual usage Monitor equipment energy usage Operational Efficiency Reduce downtime & scrap count Monitor shutdown procedures Identify set-point issues & reduce runtimes Energy Reporting More timely reporting and quicker response to issues Automated energy data collection Reallocate individuals managing energy usage data 44 Reference results of other projects & studies (DOE, Vendors) Installation of meters 0 – 2% Initial impact Utility Bill Allocation 2.5 – 5% Improved awareness Optimization & load management 5 – 15% Improved awareness, Operations and maintenance, demand management Ongoing commissioning 15 – 45% Ongoing identification of operations and maintenance improvements Energy management with real-time metering system 11-20% - Reduction in the energy consumption Equipment malfunctions and upgrades 12-20% - Reduced energy use 45 Communicating The Benefit Simplified Overview – Clearly and credibly define the opportunity Value Statement – Explain direct & indirect project value Risk Statement – Present steps to be taken to ensure success Use Visuals – Show savings opportunities in a simplified format Sell It – Let your passion and enthusiasm show “I don't start with a design objective, I start with a communication objective. I feel my project is successful if it communicates what it is supposed to communicate.” - Mike Davidson, InVision 46 Start Time Topic 8:30am Class Introduction 8:45am Metering Project Justification 9:45am Metering Project Development 10:15am Morning Break 10:30am Metering System Design Noon Lunch Break & Open Discussion 1:00pm Metering System Reporting & Analytics 2:00pm Metering Success Stories & Case Study Reviews 2:30pm Afternoon Break 2:45pm Metering System Effectiveness 3:30pm 10-Question Quiz On Course Material WATER AIR GAS ELECTRIC STEAM CHILLED WATER Typical metering loads for industrial energy management • Water, natural gas, and electric utilities • Plant Generated Utilities – Boilers, chillers, air compressors – Operational set-points, capacity constraints and preventive maintenance • Plant Distribution - Compressed air and steam leaks, flow issues, pressure drops • Equipment performance – Faulty bearings, loss of lubrication, flow issues, improper set-points, unbalanced loads • Peak Load Management – Peak avoidance, Start-up, load sequencing • Operational Issues - Failure to follow defined shut-down procedures 48 Temporary • Used for temporary & baseline data collection • Quick install for utility incentive baselines • Data usually resides locally as USB stored data Permanent With On-Site Data • Requires formal electrical installation • Data resides in data acquisition server or existing automation platform that can distribute data Permanent With Web-Hosted Data • Metering data transferred to web host through local hardware • Metering data available for integration with local control & manufacturing systems • Data available to customer on web-based tools 49 • An economical first step • • • Typically can store months of data User configurable logging rates: seconds, minutes, hours Data downloaded from device to a laptop PC 50 Multiple loads with various technologies providing data to multiple users LOCAL DATABASE & CLIENTS DATA ACQUISITION SERVER REMOTE DATA SERVER CELLULAR NETWORK CELL MODEM WIRELESS NETWORK METERING DATA CONCENTRATOR DIGITAL I/O PULSE OUTPUTS COMM NETWORK ANALOG I/O REMOTE TRANSMITTER FLOW & PRESSURE CONTROL SYSTEM BTU METERS REMOTE REPORTING CLIENTS 51 Main Electric Utility Meter Utility Meter Pulse Wiring Notes: • Utility or customer will provide junction box with fuses • Utility meter may be located on inacessable utility property • Typically a low voltage (+24VDC) circuit but can be 120VAC • Utility meter pulse may already be in use – requires a “pulse splitter” • Utility meters are rarely in locations that are easy to run conduit to 52 Typical Electric Sub-Metering Installation Dedicated breaker for metering voltage taps Data Acquisition Hardware 53 Current Transformers $ Solid Core – Used mainly for smaller circuits. Requires wires to be disconnected. $$ Split Core – Most common. Can be opened to install without disconnecting wires. $$$ Rogowski Coil – For larger/ multi conductor applications. Requires an integrator circuit and DC power supply. 54 Electric Sub-Meters Electric Sub-Meter Installation Notes: • Most have similar wiring requirements o Voltage Taps, CT Wiring, Pulse or communication outputs • Voltage taps should be fused when possible o Using a spare breaker is best • Phases of voltage taps and CTs MUST be matched • Meter output usually pulse (kWh/pulse) or Modbus (Communications) • Some allow remote connection over IP address for configuration and data access 55 Data Acquisition Units • Have local I/O capacity • Capable of communication to other devices using 3rd party protocols • May have limited storage capacity to buffer data if communications to the outside world are disrupted • Some have long term storage capacity • Remote configuration and data collection 56 Gas Meters • Utility gas meters typically require wiring to an enclosure mounted XX Ft away from the meter (ask utility) and will have a pulse output • Some meters will have an option for “Pulse-To-Flow” analog converters • Insertion type gas meters require a welded fitting on the gas pipe. This will require a pipeline gas purge and pressure test process 57 Refrigeration Chillers BTU Meter Modbus communications To metering data acquisition unit Wattnode Meter & CTs Chiller Power Enclosure Service Disconnect 58 Compressed Air Systems Metering Enclosure (Logger & Cell Modem) Electric Meters & CTs Air Compressors Flow Sensor Air Storage Tank Filter Compressed Air Dryer To Plant Pressure Sensor 59 • • • Flow is proportional to motor speed Pressure is proportional to motor speed squared Power is proportional to motor speed cubed Key point: Reducing fan motor speed by 50% will reduce power consumption by 87.5% This may need to be carefully explained to others!!! Complete the “VFD Savings Worksheet” for the following conditions: Existing Fan Motor Data Motor HP = 25HP Daily Run Hours = 24 Run Days Per Week = 5 Run Weeks Per Year = 52 kWh Cost = $.075 VFD Setpoints: Runtime 1 = 20% Runtime 2 = 60% Runtime 3 = 20% Speed Setpoint 1 = 100% Speed Setpoint 2 = 80% Speed Setpoint 3 = 60% Not always a good fit … Installing VFDs and Running them at Constant Speed • If the motor runs at full speed, a VFD may not save energy. • If the VFD will run at a fixed speed below 100% , there will be energy savings but it may be less expensive to just modify motor pulley/gears. High Static Pressure Installations • Boiler feed water pumps and pumps that push water above ground level require high static pressure. The more static head a system has, the smaller the range a VFD can modulate and the lower savings will be. Installing a VFD to Reduce Demand • A VFD will not reduce demand charges by soft-starting motors. Motors have a significant in-rush for a short period, but Demand is calculated as the average usage over the interval, so the in-rush is averaged out. How can metering help identify these issues? Communication Network Wiring - Modbus Modbus Installation Notes: • Multi-drop serial network, 4000 Ft max, 32 nodes • Each end of line should have termination resistors (120 ohm) • Connect the cable shield or Modbus common (if there is no shield) to earth ground at only the Modbus master end of the cable. Grounding both ends can cause ground loops 63 Wireless I/O Typical Topologies Point To-Point Bus • Budget research & engineering time required Ring • Always perform a wireless site-audit • Understand device battery life Tree • Consider any possible area physical changes (vehicles, trees) Mesh • Understand topology options, limitations & benefits • Justify by comparing to cost of a hardwired solution o Wire & cable costs, conduit runs, wall penetrations Star 64 “Temporary solutions often become permanent problems” Always treat temporary installations as if they will be permanent! • • • • • • • Enclosure mounting Power Feeds Temporary hardware inside enclosures Wires passing through enclosure doors Labels & wire numbers Temporary connections - voltage taps, wire nuts & butt splices Communication cable runs 65 The cost of leaking distribution systems Compressed air systems: • If not been well maintained will have a leak rate equal to10%-30% of the total production capacity. Steam Systems: • If no steam trap survey has been done, upwards of 50% of steam traps can be failed • If a trap survey is performed annually, this figure drops to 25%. • A bi-annual trap survey will reduce this to less than 12% An effective metering program will detect changes in production that help identify leak issues Documenting Air Leaks With a PRESSURE leak, the Turbulence is on the outside and can be detected with an ultrasonic probe, as measured in decibels (dB) Estimating Air Leaks Savings Convert dB readings to CFM Perform air leak audit ESTIMATED CFM DB 150 PSI 125 PSI 100 PSI 75 PSI 50 PSI 10 0.70 0.60 0.5 0.3 0.15 20 1.40 1.20 0.8 0.9 0.5 30 1.85 1.65 1.4 1.1 0.8 40 2.40 1.90 1.7 1.4 1.1 50 3.90 3.40 2 2.8 2.2 60 4.50 4.10 3.6 3 2.8 70 6.80 6.40 5.2 4.9 3.9 80 10.20 9.10 7.7 6.8 5.6 90 11.00 10.30 8.4 7.7 7.1 100 12.90 12.50 10.6 10 9.6 Develop air leak worksheet with energy losses, savings and repair costs LEAK TAG # DEPARTMENT 1001 Line 14 Prod 1002 Line 14 EQUIPMENT Hose Reel Surge Bin 1 LEAK TYPE Nozzle Fitting Fitting DB READ 46 52 EST PRESS (PSI) 100 80 EST CFM (CHART) RUN TIME (%) EST LEAK COST EST REPAIR COST 3.00 100% $337.54 $7.50 2.87 50% $161.45 $0.75 1004 Line 3 1/2 Mezz Story Control Panel 52 100 3.35 100% $376.92 $12.50 1041 Comp Room Vacuum Loader Pump #2 46 100 2.90 100% $326.28 $45.00 $1,800.19 $75.00 $326.28 $365.66 $125.00 $45.00 $3,694 $311 1042 Line 4 End Of Line X 5 Leaks 44 100 16.00 100% 1043 Line 4 1045 Comp Room End Of Line Vacuum Loader Drive Roll Manifold Pump #1 47 47 100 100 2.90 3.25 100% 100% TOTALS: 34.27 Typical Savings Opportunity – Zero Loss Drains • Replace timer based systems that purge on a timed basis - even if there is no need to operate Typical Savings Opportunity – Engineered Nozzles Typical Savings Opportunity – Pressure Setback Value of a 7 PSI pressure setback: Savings Opportunity – Air Compressor VSD Documenting Steam Leaks Monetizing Steam Leaks Energy Loss Can Be Destructive } } } } } } Leaking steam can damage piping valves, traps and insulation Leaking or blocked pressure relief valves can damage the systems hey are protecting Dripping condensate can damage equipment Electric corona, tracking and arcing can result in excessive heat and damaged connections Air leaks can be a noise hazard and also result in equipment damage Gas leaks – An extremely dangerous environment Energy Loss Can Impact Product Quality • • • Changes in work area temperature and humidity can cause quality issues and impact product shelf life Air and vacuum leaks can impact the operation of production and test equipment Steam distribution issues can impact process heat Start Time Topic 8:30am Class Introduction 8:45am Metering Project Justification 9:45am Metering Project Development 10:15am Morning Break 10:30am Metering System Design Noon Lunch Break & Open Discussion 1:00pm Metering System Reporting & Analytics 2:00pm Metering Success Stories & Case Study Reviews 2:30pm Afternoon Break 2:45pm Metering System Effectiveness 3:30pm 10-Question Quiz On Course Material Data Types Metering Data & Visualization Metering Data Analytics 78 Consider how to best transform data into information Example: Air Compressor Performance Data for compressed air system showing Flow (CFM) and compressor energy (kW) Same view of data shown as “CFM/kW” 79 Getting the right information to the right people Example: Data mapping worksheets COMPRESSED AIR SYSTEM METER DATA SOURCE RATE UNITS Air Compressor #1kWh WattNode 1 Min kWh Air Compressor #2 kWh WattNode 1 Min kWh Air Compressor #1kW WattNode 1 Min kW ENGINEERING Real-time and historical X access. X X 5 second resolution. Air Compressor #2 kW WattNode 1 Min kW X Compressed Air Pressure Analog 1 Min PSI Compressed Air Flow Pulse Count 1 Min CFM Summary for today, X yesterday and last 7 X days. CFM Per kW Calculated 1 Min Ratio X MANAGEMENT KPI Shift reports. ENERGY SCORECARD Include electric utility costs. Weekly summary with comparison to previous week. X PLANT STEAM METER DATA SOURCE RATE UNITS Boiler Feed Gas Flow Analog 15 Min CFM Boiler 1 Steam Flow Analog 15 Min Lbs/Hr Boiler 2 Steam Flow Analog 15 Min Lbs/Hr ENGINEERING Real-time and historical X access. X X 1 minute resolution. Boiler 1 Firing Rate Modbus 1 Min % X Boiler 2 Firing Rate Modbus 1 Min % Plant Header Steam Flow Analog 15 Min Lbs/Hr Summary for hourly, X today, yesterday and X last 7 days. Plant Header Steam Pressure Analog 15 Min PSI X Gas Cost Calculated 15 Min $ Steam Cost Calculated 15 Min $ Midnight report required. X MANAGEMENT KPI Shift reports. ENERGY SCORECARD Include gas utility costs and outside air temperature. Weekly summary with comparison to previous week. Include Line 2,3,5 & 12 total run hours. Include Line 2, 3, 5 & 12 X production schedules X X X X 80 Temporary Metering Grocery Store Rooftop Condenser Data Analytics – Hospitality Permanent Metering Industrial Site Vendor specific Data 81 Why Analytics? Apophenia - Seeing meaningful patterns or connections in random or meaningless data. • • • • Analysis of real-time and historical usage data Graphic reporting with a simplified views of complex issues Automated identification of events hidden within large amounts of relational data ü Usage patterns ü Deviations & Failures ü Opportunities for operational improvement Standardized reporting, KPI’s and scorecarding across all areas 82 Benefits Of Analytics • Automated identification of issues within data sets • Graphic reporting provides simplified views of a complex issues 83 Relational Data • Understand relationships between main utility meter readings and equipment usage 84 Key Performance Indicators • Develop KPI dashboards to view comparing data from multiple sites 85 Analytic rules can be based on load specific characteristics Main electric utility meter Chillers • • • • • kWh limit exceeded o Shift, Daily, Weekly, Monthly Peak demand (kW) limit exceeded Weekend shutdown kW not below target level Compressed air • • • • • kWh limit exceeded o Shift, Daily, Weekly, Monthly Short cycling Multiple units running for excessive time High/low PSI limit exceeded High/low flow limit exceeded • kWh limit exceeded o Shift, Daily, Weekly, Monthly Short cycling Multiple units running for excessive time Steam • • • Total Lbs/Hr limit exceeded o Shift, Daily, Weekly, Monthly High/low PSI of flow limits exceeded Shutdown PSI not below target level Boilers • • • Firing rate level exceeds time limit Short cycling Multiple units firing too long 86 Knowing the score is good, understanding how we got there is great! Summarize, simplify and share your progress with others • Define energy savings goals and targets • Provide simple set of key performance indicators (KPI’s) for management • Show progress from month-to-month • Compare data between facilities SCORECARDING FACILITY STATUS KEY ASSET PERFORMANCE FACILITY COMPARISONS 87 Start Time Topic 8:30am Class Introduction 8:45am Metering Project Justification 9:45am Metering Project Development 10:15am Morning Break 10:30am Metering System Design Noon Lunch Break & Open Discussion 1:00pm Metering System Reporting & Analytics 2:00pm Metering Success Stories & Case Study Reviews 2:30pm Afternoon Break 2:45pm Metering System Effectiveness 3:30pm 10-Question Quiz On Course Material Variable Frequency Drive (VFD) Installation PROJECT • Metal finishing room with air make-up units, exhaust fans and RTUs • Motors were operating at full speed, 24 hours a day • Installed 7 VFDs and adjusted set-points based on actual demand • Local utility provided financial incentives RESULTS • Reduced over 187,000 kWh annually • Total Cost: $59,110 • Utility Incentive: $14,800 • Site Cost: $44,310 • Annual Electric Savings: $27,830 Unanticipated Peak Readings • Facility had instances of excessive flow during metering M&V in January 2017 • Contacted plant and learned issue was due to a faulty photo eye on blow-off system that was allowing compressed air to continuously flow for extended periods 90 Set-point Changes • Facility had contractor working on weekend who required 90PSI for pneumatic gun • Entire plant system was raised to a higher set-point and not returned to normal 91 Weekend Shutdown Monitoring • Monitor weekend baselines and confirm shutdown procedures are followed • Combine with a weekend shutdown program that includes audits Tue Wed Thr Fri Mo n Weekend Periods 92 Excessive Load Cycling • Plant with 2 air compressors running in “Lead/Lag” Operation • Identified set-point issue where the 2nd compressor responding to flow issues • Compressed air header piping modified and set-point adjustments made • Flow is stabilized and 2nd compressor now runs less frequently • Estimated annual electric savings of $21,202 • Reduction of frequent cycling also reduced amount of maintenance required 93 Lead/Lag Load Monitoring • Compare energy usage of equipment operating in pairs and identify differences • In the example below, one unit (red line) can handle more of the load than the other unit (blue line). Should the one unit always be the lead to reduce costs? 94 Lighting Installation Validation • • Pre-Post energy samples taken for utility rebate M&V Occupancy sensor tuning completed as a 2nd stage of the installation 95 Setpoint Reductions 96 Boiler Setpoint Monitoring • Confirm when Operators modify system setpoints • The example below shows boiler pressure setpoints (green and blue lines) being switched at 4:30am • This results in the lead boiler assignment being changed from Boiler 2 to Boiler 1 (boiler firing rates are shown in black and red lines) Lead/Lag Transition Boiler 2 Is Lead Boiler 2 Is Lead 97 • • Graphs below show boiler firing rates for 2 units running in a lag/lag operation Pressure setpoints were adjusted for more efficient operation December 2017 March 2018 Lead Boiler Lag Boiler Lead Boiler Boiler Running Boiler Running > 50% Boiler Running @ 100% 95% 30% 10% 23% 3% 1% 61% 19% 12% Change From Dec 2017 -34% -11% 2% Lag Boiler 5% 1% 0% Change From Dec 2017 -18% -2% -1% 98 Leak Reductions • • • • Repaired plant air leaks and replaced open air blows with engineered nozzles Reduced flow allowed reduction in pressure setpoint, and compressor electric usage Average compressor electric demand reduced from 83.26kW to 56.74kW (31%) Average plant air flow reduced from 445 CFM to 329 CFM (26% reduction) Before Avg: 83.26kW Before Avg: 445 CFM After Avg: 56.74kW After Avg: 329 CFM Missing kW data during cutover to new compressor 99 Start Time Topic 8:30am Class Introduction 8:45am Metering Project Justification 9:45am Metering Project Development 10:15am Morning Break 10:30am Metering System Design Noon Lunch Break & Open Discussion 1:00pm Metering System Reporting & Analytics 2:00pm Metering Success Stories & Case Study Reviews 2:30pm Afternoon Break 2:45pm Metering System Effectiveness 3:30pm 10-Question Quiz On Course Material 3 Common Causes Energy Analytics is about understanding energy, not analytics • Users may not be technical and will need systems that they can easily use and understand People may need more than just the bottom line • Don’t provide only graphics and hope users will understand the insights and savings opportunity • Create narratives explaining why data indicates an opportunity for energy savings Management is not making data-driven decisions • Provide a dashboard and automate e-mail distribution of weekly/monthly usage & event reports to key users. 101 Someone with the skills, time and Patience required to …. • Evaluate what value the system is providing • Review M&V data and document actual savings • Review dashboards and reports to confirm they can be easily understood by end users • Work with management to promote usage of data as part of their decision making processes You can have more than 1 champion! 102 Developing an energy management toolkit should be part of every metering project • Confirm suspected losses • Baseline energy measurements as part of PM 104 Industrial Sites: Non-Woven Fabric Manufacturer Compressed Air Systems • TN, USA : Found 310 air leaks worth of $112k • SJP, Brazil : Found 42 air leaks worth of $40k • Approx. 20-30% of all compressed air was being lost due to air leaks Steam Systems • OHK, USA : Found 210 steam leaks worth of $186k • Bailleul, France : Leaking steam traps caused $134k of steam-blow-off from condensate return • Approx. 15-30% of steam was being lost due to leaks and poor system optimization 106 Start Time Topic 8:30am Class Introduction 8:45am Metering Project Justification 9:45am Metering Project Development 10:15am Morning Break 10:30am Metering System Design Noon Lunch Break & Open Discussion 1:00pm Metering System Reporting & Analytics 2:00pm Metering Success Stories & Case Study Reviews 2:30pm Afternoon Break 2:45pm Metering System Effectiveness 3:30pm 10-Question Quiz On Course Material 1) The kWh values shown on a monthly utility bill are a measure of: A) Peak demand B) Energy consumption C) Power factor D) Reactive power 2) A good time to contact your utility company about possible project incentives is: A) As soon as possible B) After project approval C) Before install ing D) After completion 3) If you are comparing power delivered to a glass of beer, kW is the: A) Glass capacity B) Amount of beer C) Amount of foam D) Brand of beer C) Current D) Diameter of wire 4) Current transformers are used to measure: A) Voltage B) Watts 5) A Variable Frequency Drive (VFD) may NOT be a good fit for pump motors that: A) Run at max speed B) Run at a fixed speed C) Pump vertically D) All of the above 108 6) The kW values shown on a monthly utility bill are a measure of: A) Peak demand B) Energy consumption C) Power factor D) Reactive power 7) A typical use of an analytics package is to show: A) Usage patterns B) Relational data C) Key performance data D) All of the above 8) Metering data is typically used by which internal group: A) Maintenance B) Management C) Finance D) All of the above 9) A good “low-cost” first step to understand how specific loads operate is: A) Engineering study B) Temporary meters C) Fund raising party D) All of the above 10) Most electric utility meters transmit usage to customers systems using: A) Analog signals B) Meter pulses C) Streaming data D) E-mail 109 JAMES MAJSAK, C.E.M. Director, Load Management 860-628-1008 (Direct) jmajsak@groomenergy.com www.groomenergy.com GROOM ENERGY - GROUPE EDF Commercial and Industrial Energy Solutions 110