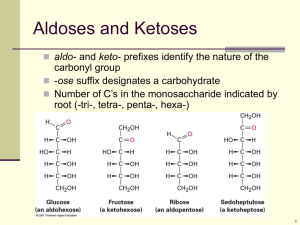

PRACTICAL BIOTECHNOLOGY Glucoamylase production by yeast ORDINARY brewer’s yeast (Saccharomyces cerevisiae) is able to utilise a variety of carbohydrates as an energy source. These include glucose, sucrose and maltose. While sucrose is readily available (as cane or beet sugar) glucose and the other sugars must be prepared by enzymic or chemical hydrolysis of starch. This is the main puropse of malting in traditional beer brewing. All these sugar feedstocks are relatively expensive. Unlike S. cerevisiae, the yeast S. diastaticus is able to grow on starch and dextrins. This is because it makes an extra-cellular enzyme, glucoamylase, which catalyses the hydrolysis of -1,4 glycosidic bonds in starch. It does this by progressively chopping off single glucose molecules from the ends of amylose chains. (Some glucoamylases can also attack the branching -1,6 bonds of amylopectin, but at a much slower rate than -1,4 bonds.) Great interest has focussed in recent years on transferring the gene for glucoamylase into S. cerevisiae by sexual hybridization with S. diastaticus. Such hybrids can grow on cheaper substrates and better utilize the carbon present in conventional feedstocks. This increases the yield of ethanol and allows the yeast to out-compete any bacterial contaminants which might lead to off-flavours in alcoholic drinks. (S. diastaticus can not be used directly for brewing, as it produces a compound which gives beer a spicy phenolic flavour.) This investigation of glucoamylase production by S. diastaticus uses an NCBE Bioreactor, although it may easily be adapted for use with other fermenters. Alternatively, the yeast can be used for a simple investigation of amylase production on a starch agar plate. Materials Culture of Saccharomyces diastaticus (available from the NCBE) Broth containing 1% starch, 1% yeast extract and 1% peptone, 500 cm3 (put 20 cm3 of the broth into a McCartney bottle, for use as an inoculum; put 450 cm3 into the Bioreactor). NCBE Bioreactor (+ air pump and water bath) For the glucoamylase assay method Centrifuge Starch solution, 1% Semi-quantitative glucose test strips e.g. Boehringer Mannheim Diabur-Test® 5000 (available from high street chemists) Waste container of disinfectant diastaticus in a McCartney bottle containing 20 cm3 of starch yeast broth. Incubate at 28–30C. Day 2 3. Running the Bioreactor 4. 1. 2. Set up and autoclave the NCBE Bioreactor as described in the User Guide, using 450 cm3 of starch yeast broth. After autoclaving, allow the vessel to cool, and attach sterile syringes etc. as instructed in ther Bioreactor manual. Prepare an inoculum of Saccharomyces Bubble air through the culture medium to ensure that the conditions within remain aerobic. Add antifoam as required to prevent undue frothing. Take care to ensure that the air filters do not become blocked with liquid. Monitoring starch breakdown 5. 6. 7. 8. 9. Take small samples of broth from the Bioreactor at regular intervals, using the method described in the Bioreactor manual. Put the sample into a centrifuge tube, cover with Cling film to prevent the formation and escape of aerosols. Spin down the yeast cells in a properly-balanced centrifuge. Take some of the cell-free supernatant to test for glucoamylase activity. Add an equal volume of 1% starch solution to the cell-free broth. Incubate at 30C for 6 hours or overnight if more convenient. Use a semi-quantitative glucose test strip to measure the concentration of glucose in the reacted mixture. Dispose of used test samples and glucose test strips into disinfectant. Safety Standard microbiological safety procedures, including aseptic techniques, must be observed by teachers, technicians and students when carrying out this work. Teachers are referred to: ‘Microbiology. An HMI guide for schools and further education’ (1990) HMSO as well as any safety guidelines produced by their LEA and / or school governing body. Particular care should also be taken when using the centrifuge, and steps such as those described above should be taken to prevent the formation of aerosols. Further activities 1. If a colorimeter or spectrometer is available, measure the turbidity of the culture sample before testing it for enzyme activity. This will give an indication of the growth of the yeast. 2. Before testing the culture samples for enzyme activity, measure the concentration of glucose in each, using a glucose test strip. 3. Investigate the effect of growing S. diastaticus on substrates other than starch. Does it still produce glucoamylase in these conditions? Practic al details Advance preparation Day 1 Place the Bioreactor in a water bath at 28C. Allow the broth inside to warm to this temperature, then inoculate the Bioreactor using the culture prepared in (2) above. Glucoamylase production Set up and inoculate the Bioreactor as described in the User Guide and the accompanying notes. Use starch broth in the flask and Saccharomyces diastaticus as the inoculum. The yeast secretes an enzyme, glucoamylase, into the culture medium. This breaks down the starch to glucose. Try to predict — what will happen to the number of yeast cells during the fermentation — what will happen to the enzyme concentration — what will happen to the glucose concentration Enzyme assay Record the glucose concentration, then put the used test strips into disinfectant Mix equal volumes of 1% starch solution and cellfree broth Spin down the yeast cells, then take some of the cell-free supernatant Incubate at 30C, then test with a glucose test strip glucose units joined in an amylose chain glucoamylase hydrolyses -1,4 bonds, splitting glucose units from the end of the chain CH 2 OH CH 2OH O HO O OH CH 2 OH O -1,4- glycosidic bond OH CH 2 OH O O OH OH glucose molecule split from chain Present your findings as a graph O O OH OH O OH OH How the amylose chains in starch are broken down by glucoamylase © National Centre for Biotechnology Education, 1995