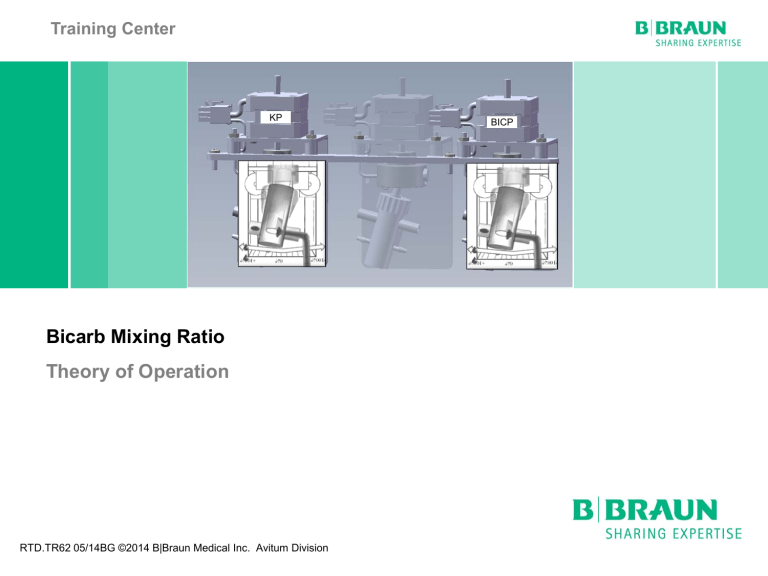

Training Center KP Bicarb Mixing Ratio Theory of Operation RTD.TR62 05/14BG ©2014 B|Braun Medical Inc. Avitum Division BICP Training Center Mixing Ratio Theory of Operation The Dialog+® Hemodialysis System monitors the speed of the Bicarb and Acid pumps together with their relationship to the Dialysate flow rate. The speed of the pumps are increased or decreased based upon the conductivity setting programmed into the machine. RTD.TR62 05/14BG ©2014 B|Braun Medical Inc. Avitum Division Training Center During preparation or treatment, if either of the pumps’ speed is outside of the working range to achieve conductivity, a mixing ratio error message will be displayed. Example: 14.3 3.5 Flow Rates BICLF ENDLF 300 - 800 45X Solution Working Range Working Range RTD.TR62 05/14BG ©2014 B|Braun Medical Inc. Avitum Division Bicarb Conductivity Range Final Conductivity Range 2.0 – 4.0 mS/cm 12.5 – 16.0 mS/cm Training Center The working range values for mixing ratio are set during the installation of the machine in Calibration 2.10 and may be adjusted for the customer’s brand of concentrates. Set Working Value Range RTD.TR62 05/14BG ©2014 B|Braun Medical Inc. Avitum Division Training Center Ratio Working Range Monitor the mixing ratio using the overview screen Monitoring the speed of the Bicarb pump is an important part of troubleshooting a Bicarb mixing ratio alarm. RTD.TR62 05/14BG ©2014 B|Braun Medical Inc. Avitum Division Training Center Mixing Ratio Relationship to Pump Speed The speed of the pump can vary depending on the calibrated stroke value, the prescribed Bicarb conductivity and flow rates. 18 Bicarb Mixing Ratio +/- 7 Alarm 25 Set Value Alarm 32 Working range RTD.TR62 05/14BG ©2014 B|Braun Medical Inc. Avitum Division Training Center Calculating the Bicarb Mixing Ratio Dialysate Flow ml/min Bicarb Mixing Ratio = = Bicarb Delivery ml/min Bicarb Delivery ml/min Bicarb Delivery = ml/min Bicarb Delivery = ml/min Stroke Value x .226 ml Bicarb Pump Speed 600 ml/min Mixing Ratio = 28.25 ml/min Mixing Ratio = 21.23 x 125 rpm 28.25 ml/min RTD.TR62 05/14BG ©2014 B|Braun Medical Inc. Avitum Division In this equation, the Dialysate flow rate and stroke value highlighted in yellow are constant. Training Center Bicarb Mixing Ratio Alarms Actions: Observe the BIC-RATIO and BICP pump speed and BICLF values using the overview screen Observation Example Set value 3.5 142 142 17.98 17.98 RTD.TR62 05/14BG ©2014 B|Braun Medical Inc. Avitum Division A mixing ratio of ≥ 18 and a higher than expected BICP rpm is an indication the Bicarb pump is running faster to achieve the level of Bicarb required for the prescribed conductivity level. Training Center KP Bicarb Mixing Ratio Alarms Possible Causes RTD.TR63 05/14BG ©2014 B|Braun Medical Inc. Avitum Division BICP Training Center Bicarb Mixing Ratio Alarms Possible causes: 1. Solcart cartridge placement 2. Cartridge Holder O-Rings 3. Central Bicarb Suction Coupling integrity 4. Bicarb wand and PE tube integrity 5. Air in machine 6. TSBIC 7. BICLF 8. BICP 9. BICPOS 10. Faulty Power Board Motor 11. Faulty Digital Board 12. Faulty Analog Board For additional information review troubleshooting modules RTD.TR63 05/14BG ©2014 B|Braun Medical Inc. Avitum Division Training Center Bicarb Mixing Ratio Alarms Possible Causes Air in Machine TSBIC 1- 4 5 6 BICLF BICP Electronic Circuits 7 8-9 10-12 Basic Checks and Actions RTD.TR63 05/14BG ©2014 B|Braun Medical Inc. Avitum Division Training Center KP Bicarb Mixing Ratio Alarms Basic Checks and Actions RTD.TR64 05/14BG ©2014 B|Braun Medical Inc. Avitum Division BICP Training Center Basic Checks and Actions Possible causes with a low mixing ration value and higher then expected BICP value. Observation Example Set value 3.5 ► Solcart cartridge placement ► Cartridge Holder O-Rings ► Central Bicarb Suction Coupling integrity ► Bicarb wand and PE tube integrity 142 142 17.98 17.98 Actual values may vary RTD.TR64 05/14BG ©2014 B|Braun Medical Inc. Avitum Division Training Center Basic Checks and Actions Actions: ► Reposition the Solcart Cartridge ► Replace cartridge holder o-rings off line. Disinfect the machine after replacement. RTD.TR64 05/14BG ©2014 B|Braun Medical Inc. Avitum Division Training Center Basic Checks and Actions Actions: ► Check for the presence of air in blue tubing when the BICP pump is on and the coupling connected to the central wall connector. Check Central Bicarb Suction Coupling connector and O-ring for integrity. Clean or replace the connector or o-ring if necessary ► Check for air in the Bicarb concentrate tubing. Check Bicarb wand and PE tube for integrity RTD.TR64 05/14BG ©2014 B|Braun Medical Inc. Avitum Division Check for residual Bicarb Check for cracks in tubing and connector Training Center KP Bicarb Mixing Ratio Alarms Air in Machine RTD.TR65 05/14BG ©2014 B|Braun Medical Inc. Avitum Division BICP Training Center Bicarb Mixing Ratio Alarms caused by air in machine Actions: ► Check for the presence of air in the tubing at the marked points. If air is present troubleshoot independently utilizing Air in Machine Module. Air at this point suggests a fault in the Water Sub-Rack RTD.TR65 05/14BG ©2014 B|Braun Medical Inc. Avitum Division Air at this point suggests a fault in the DF Sub-Rack Training Center KP Bicarb Mixing Ratio Alarms TSBIC Check RTD.TR66 05/14BG ©2014 B|Braun Medical Inc. Avitum Division BICP Training Center Relationship of Temperature and Conductivity Conductivity is a measurement of the movement of free electrons in a conductor. When measuring Dialysate, electrons move easier when the temperature increases resulting in a higher conductivity reading without changing the content of the mixture. A temperature deviation at TSBIC of 1°C can equate to ≈0.3 mS/cm difference at BICLF A faulty or mis-calibrated TSBIC can cause deviations in the BICLF reading thereby causing Bicarb Mixing Ratio alarms. RTD.TR66 05/14BG ©2014 B|Braun Medical Inc. Avitum Division Training Center Bicarb Mixing Ratio Alarms caused by TSBIC Actions: ► Check the accuracy of TSBIC with a calibrated external meter in TSM Test 1.11 If TSBIC checks within specifications proceed to additional troubleshooting modules ► If necessary, calibrate using the instructions in the Service Manual. (tolerance +/- .5°C ) Values for pumps and heater are for reference only. Actual values may vary. RTD.TR66 05/14BG ©2014 B|Braun Medical Inc. Avitum Division Training Center KP Bicarb Mixing Ratio Alarms BICLF Check RTD.TR67 05/14BG ©2014 B|Braun Medical Inc. Avitum Division BICP Training Center Bicarb Mixing Ratio Alarms caused by BICLF Actions: ► Check the accuracy of BICLF with a calibrated external meter in TSM Test 1.12 using diluted concentrate solution as per service manual If BICLF checks within specifications proceed to additional troubleshooting modules ► Calibrate according to the instructions in the Service Manual only if necessary. (tolerance +/- .2mS/cm ) Values for pumps and heater are for reference only. Actual values may differ. RTD.TR67 05/14BG ©2014 B|Braun Medical Inc. Avitum Division Training Center KP Bicarb Mixing Ratio Alarms Bicarb Pump RTD.TR68 05/14BG ©2014 B|Braun Medical Inc. Avitum Division BICP Training Center Bicarb Mixing Ratio Alarms caused by the Bicarb Pump components Actions: ► Check for the BICP_S signal using the overview screen. ► The BICP_S signal must be within 10 rpm to the BICP SIGNAL 142 6 17.98 17.98 Possible causes of failure: ► Stuck pump ► Faulty Hall Sensor BICPPOS ► Faulty wire connections ► Faulty Power Board Motors ► Faulty Digital Board The values shown are samples only. Actual values may vary. RTD.TR68 05/14BG ©2014 B|Braun Medical Inc. Avitum Division BICPPOS Training Center Bicarb Pump Breakdown 1. Motor Speed controlled by the LLC to run at a speed that will deliver the required solution amount to the BICLF conductivity sensor 1 2. Bell-housing 5 Contains the magnets that trigger the BICPOS sensor #4 3. Pump Body 4 2 Pumps Bicarb from supply into machine 4. Supervisor sensor BICPOS Monitors the speed of the pump sends signal to the LLS 5. Assembly Jig Used during the pump assembly ensuring proper placement between the motor-head and bell-housing RTD.TR68 05/14BG ©2014 B|Braun Medical Inc. Avitum Division 3 Training Center Bicarb Mixing Ratio Alarms The Bicarb Pump Body may be worn causing the flow of Bicarb to the BICLF(Bicarb conductivity cell) to be intermittent. TESTS: Check the pump delivery using Test 1.12 by looking for fluctuations of the conductivity value at BICLF Explanation: 1 If BICLF 1 continuously fluctuates with a constant speed at the Bicarb pump 2 and FPE 3 the Bicarb pump body may be worn 3 2 Corrective Actions: ► Replace the Piston Pump and calibrate using Calibration 2.8 and in accordance with the Service Manual RTD.TR68 05/14BG ©2014 B|Braun Medical Inc. Avitum Division Training Center KP Bicarb Mixing Ratio Alarms Electrical Connections RTD.TR69 05/14BG ©2014 B|Braun Medical Inc. Avitum Division BICP Training Center Block Diagram of circuits associated with Bicarb Mixing Ratio Alarms ► Review basic modules before considering electronic components RTD.TR69 05/14BG ©2014 B|Braun Medical Inc. Avitum Division Training Center Check Basic Board Connections for the appropriate circuits that may be faulty ► Disconnect and reconnect ribbons and harnesses 1 BICLF 1. 2 BICP 2. 2 3 TSBIC 3. 6 4. 4 Power Board Motors 4 5 Digital Board 5. 6 Power Supply Hall Sensors 6. 5 6 3 RTD.TR69 05/14BG ©2014 B|Braun Medical Inc. Avitum Division 1 Training Center KP Bicarb Mixing Ratio Alarms BICP Low RPM RTD.TR70 05/14BG ©2014 B|Braun Medical Inc. Avitum Division BICP Training Center Bicarb Mixing Ratio Alarms Possible causes with a High mixing ration value and lower than expected BICP rpm. Observation Example Set value 3.5 ► 65 65 ► 33.10 33.10 ► ► ► Incorrect concentrate TSBIC deviates from actual value BICLF deviates from actual value Worn Piston Pump Faulty DBK The values shown are samples only. Actual values may vary RTD.TR70 05/14BG ©2014 B|Braun Medical Inc. Avitum Division Training Center Corrective Actions and Checks Incorrect concentrate mixture ► Check Bicarb concentrate solution for proper mixture. Improperly mixed solution may be too concentrated causing the machine to run the BICP pump at a slower rpm to achieve the desired amount of conductivity. TSBIC deviates from actual value ► Check TSBIC temperature using Test 1.11 (see TSBIC Module) BICLF deviates from actual value ► Check BICLF conductivity using Test 1.12 (see BICLF Module) RTD.TR70 05/14BG ©2014 B|Braun Medical Inc. Avitum Division Training Center Corrective Actions and Checks Worn Piston Pump The piston pump can wear over time allowing solution from a high pressure central supply to leak through the pump causing the BICLF conductivity sensor to react by slowing down the BICP pump thereby causing a Bicarb mixing ratio alarm. ► ► ► Calibrate Bicarb pump BICP using Calibration 2.8 Check the stroke value after the calibration (range 199-245 ul/head rot.) Replace BICP pump body if the stroke value is out of range (follow the repair matrix) Concentrate Supply 0-1bar RTD.TR70 05/14BG ©2014 B|Braun Medical Inc. Avitum Division Training Center Corrective Actions and Checks DBK Spring ( Solcart B ® option only) The DBK spring could be weak allowing Bicarb to seep into the degassed and heated side of the upline tank causing the fresh water being pulled into the DF block to be slightly conductive. The BICLF conductivity sensor will react by slowing down the BICP pump thereby causing a mixing ratio alarm. RTD.TR70 05/14BG ©2014 B|Braun Medical Inc. Avitum Division Training Center Corrective Actions and Checks 1. Connect a calibrated conductivity meter to the input of the DF block and measure the conductivity. 2. The reading on the meter should be 0.00 mS/cm or the value of the RO water source. 3. Replace the DBK spring if a conductivity level is greater than the value of the RO water source. RTD.TR70 05/14BG ©2014 B|Braun Medical Inc. Avitum Division