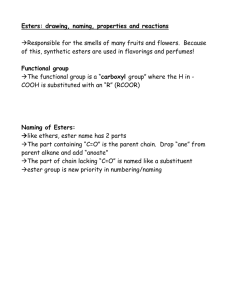

2022 Electrical Insulation Conference (EIC), Knoxville, TN, USA, 19-23 June 2022 2022 IEEE Electrical Insulation Conference (EIC) | 978-1-6654-8023-9/22/$31.00 ©2022 IEEE | DOI: 10.1109/EIC51169.2022.9833175 Vegetable fluids: the reason of the new trend Fabio Scatiggio Giorgio Campi A&A Fratelli Parodi A&A Fratelli Parodi Genoa, Italy fscatiggio@fratelliparodi.it Genoa, Italy gcampi@fratelliparodi.it Abstract—: In recent time the use of natural esters (NE), as well synthetic esters (SE), are growing up much faster than expected. Despite some little drawbacks (oxidation stability, viscosity) the advantages in terms of transformer life extension, reduced risk of fire, biodegradability and sustainability have resulted in esters being applied in all types of electrical equipment. Even without mention the conventional and historical application for distribution, large power transformers with no limit in terms of voltage or power have been installed in many countries, railway traction transformers and offshore wind turbine are today filled with NE or SE only, SF6 in instrument transformer is progressively replaced by NE. Focus of this paper is to understand the reason of the current market new “green” orientation. Performances like oxidation stability, gassing, water tolerance, self-extinguishing and smoke emission in case of fire. Keywords—natural esters, high-oleic sunflower, fire risk, sustainability, life extension, paper, stray gassing, transformers. formulations of new esters and careful evaluations of new liquids in new transformer applications results in a wider acceptance of ester liquids in power transformers. There were individual pilot projects presented by the industry in the past, including prototype transformers for transmission grid in power ratings up to 300 MVA and with voltage rating up to 400 kV [1]. Based on such successful pilot projects, the transmission companies or other users of large power transformers consider project specifications with broader use of natural ester liquids. For example, the national Italian Transmission System Operator has already installed dozens of autotransformers 250 MVA, 380 kV immersed in natural esters and is currently refurbishing its fleet where certain proportion of the transformers rated for 250 MVA, 380 kV (1050 kV BIL) will use the natural ester liquid [2, 3]. The transformers would benefit not only from the improved fire safety performance and reduced environmental footprint but additionally, would have improved overloadability. I. INTRODUCTION – NATURAL ESTERS Mineral oil has been considered as the most preferred liquid insulation over the past 140 years for power transformers. With its strong credentials as an efficient dielectric and cooling medium coupled with low cost, it sounded unlikely that any alternative liquid could significantly replace the mineral oil, at least in the short time. Anyway, a totally different scenario appeared, at the beginning in developed countries and later worldwide, where the growing interest in fire safe, eco-friendly, and sustainable materials could fast tip the balance in favour of vegetable esters. Additionally, the current electrical market due to the intermittency of the renewable energies (photovoltaic and wind energy) and due to the high fluctuating energy demand (as during the Covid pandemic) requires more flexible and resilient transformers able to be overloaded occasionally, but also permanently. The use of natural esters coupled with solid insulating materials of higher performance (like aramid Nomex® insulation) provides the best solution for overcoming such complexity. This could be achieved by the combination of the natural ester liquid with higher class insulation system in transformer windings Additionally, more recently, natural ester has been also applied to instrument transformers with the aim of creating a totally “green” substation [5]. II. BENEFITS OF THE NATURAL ESTERS Natural esters can be obtained from dozens of different vegetable crops but the most largely used are soybean, rapeseed, and high-oleic sunflower. Natural esters for electrical application results as a mixture of some different long chain fatty acids; the latter ones can be fully saturated (no carbon-carbon doble-bonds), some of them are mono-unsaturated (one carboncarbon doble bond), and some others are poly-unsaturated (multiple carbon-carbon double bonds) which encompass also the so-called Ω-3. The balance between the different fatty acids affects the final properties of electric natural esters, mainly oxidation stability, viscosity, and stray gassing. In Figure 1 the fatty acid composition of Paryol Electra 7426 based on high oleic sunflower is shown, where the towering contribution of oleic acid, which is monounsaturated (C18:1) and the limited contribution of linolenic acid, which is poly-unsaturated (C18:3) can be perceived. In this sense, many renewable energy production plants require transformers that use biodegradable and sustainable liquids. They are also becoming more and more popular solution in urban substations due to the safety of these liquids in case of fire, as compared to traditional mineral oils. The use of natural esters has grown exponentially even if initially it was limited to small distribution and industrial transformers only. The continuous improvements in 978-1-6654-8023-9/22/$31.00 ©2022 IEEE 339 Authorized licensed use limited to: Universidad del Valle. Downloaded on September 19,2023 at 17:33:35 UTC from IEEE Xplore. Restrictions apply. Technical Brochure 296 [8]. Figure 3 shows the results of stray gassing test at 120°C: 100 Fatty acid composition (%) 82,16 • after 16 hours which simulates the ramp up, • after 164 hours simulating the plateau, • after 164 + degassing + 16 hours demonstrating the recrudescence after degassing. 80 % 60 40 0,03 4,67 0,15 0,25 20 0,05 0,04 Stray Gassing 0,05 0,03 2,96 0,90 8,07 0,04 1400 0 1200 C2H6 ppm 1000 0 III. CHEMICAL EVALUATION: OXIDATION STABILITY AND STRAY GASSING 200 Oxidation Stability by Rapid-Oxy 160°C 150 100 50 0 20 Soybean 1 20,1 Soybean 2 31 Rapeseed PARYOL ELECTRA 7426 (high-oleic sunflower NE) 90 67 5 20 Paryol Paryol Paryol Soya 16 Soya 164 Soya Rapeseed Rapeseed Rapeseed Electra 16 Electra Electra 164+D+16 16 164 164+D+ 164 164+D+16 16 There are three suggested factors that improve cellulose life when immersed in natural esters. 187,2 1. The high-level water tolerance of esters which is one or two orders of magnitude greater than that of mineral oils. But this pathway by itself cannot explain how the paper insulation gets dry, because the cellulose has much greater affinity for moisture than insulating liquids. 2. The hydrolytic protection because water reacts with the natural ester forming long-chain fatty acids, harmless to paper, producing a continuous dehydration process of the cellulose. 3. The cellulose trans-esterification, otherwise, the longchain fatty acids react with hydroxyls (-OH) termination of cellulose promoting the paper hydrophobicity [10]. 103,2 37,8 2 263 IV. SOLID INSUALTION PROTECTION AND TRANSFORMER LIFE EXTENSION 53,3 53,3 2 93 As it is well known, the stray gassing may be also influenced by the presence of the additives especially the metal passivators [9]. 140°C 95,8 114 34 388 332 Figure 3: Hydrogen (H2) and ethane (C2H6) generated during the stray gassing tests at 120°C As a matter of fact, the peculiar composition of high oleic sunflower natural ester improves its oxidation stability, which results in being superior of soybean and rapeseed and almost comparable with the uninhibited mineral oils, as demonstrated by the accelerated tests conducted by the Rapid-Oxy technique. The test procedure was chosen for reducing the test time rather than IEC 61225-C modified by IEC 62770, which takes 48 hours. The used instrument was a Rapid-Oxy 100 manufactured by Anton Paar. A small sample of liquid (5 ml) was arranged in a special closed vessel made by stainless steel. The vessel was closed and pressurized with pure oxygen at 700 kPa and heated at 140°C. The stop criterion was the time until pressure drop of 10% from Pmax. The test was repeated at 160°C, too. Results shown in Figure 2 are the average values, in minutes, of three replications. 866 630 600 200 Figure 1: Fatty acid composition (%) of high-oleic sunflower Paryol Electra 7426. 803 800 400 minutes H2 1200 0,29 0,24 0,05 30,7 Uninhibited mineral oil These three factors are the base for a common assumption that ester liquids improve long-term thermal performance of cellulose papers. Various studies on this topic are summarized in Informative Annex C of IEC 60076-14 [11]. However, those studies are mainly based on one specific natural ester liquid from one supplier and may not be representative for all different liquids available today for the industry. For that reason, there are more and more studies available that analyze insulation systems with different liquids of different origin and compositions [12]. Figure 2: Oxidation stability by Rapid-Oxy100 tests at 140°C (orange) and 160°C (blue) There are many demonstrations of the direct correlation between the Ω-3 acids content and the ethane generation (C2H6) at relatively low temperature in absence of electrical field (the so-called stray gassing) [6, 7]. To confirm such studies, we carried out some stray gassing tests, in according with CIGRE The measured improvement of cellulose thermal performance presented in those studies is not always the same. This may result in standardization committee removing soon the 340 Authorized licensed use limited to: Universidad del Valle. Downloaded on September 19,2023 at 17:33:35 UTC from IEEE Xplore. Restrictions apply. typical guidance on cellulose in ester performance from the industry standards. Instead, the evaluation of insulation systems that combine given liquids with given solid insulation materials may be suggested. This assumption has been confirmed by real fire experiment on field [14] were the time to ignition of a distribution transformer filled with mineral oil and with natural ester was respectively 12 and 27 minutes as reported in Figure 4. Extensive studies following the procedure defined in IEEE Std. C57.100 [13] combining aramid DuPont™ Nomex® 910 immersed in high-oleic sunflower natural ester A&A Parodi Paryol Electra 7426 are in progress and will be available soon. Temperature (°C) 500 V. SELF-EXTINGUISHING LIQUIDS AND FIRE RISK Fires caused by insulating liquid combustion in case of transformer breakdown have ever been considered as a primary source of risk in electrical installations, especially for urban distribution lines, where the consequences of catastrophic events (fire and explosion) could involve the operators and even the population. NE Paryol Electra 7426 10 20 Heating time (min) VI. CONCLUSION After more than 20 years (Figure 5) of experience nowadays natural esters cannot be considered as an alternative to mineral oils only. NEs belong to new paradigm of insulating fluids with superior performances in terms of biodegradability, lowflammability, self-extinguishing behaviour, low gassing, and life extension. Energy to raise F.P. Estimation of transformers filled with NE 0.92 165 355 °C 75 265 KJ/Kg·K 1.860 2.080 KJ/l 2.500.000 250.000 Units per Year 0.88 °C 30 Figure 4: Time to ignition of transformer filled with Parodi Paryol Electra 7426 (NE) and mineral oil. 300.000 Kg/l MO Mineral Oil 123 507 2.000.000 200.000 1.500.000 150.000 1.000.000 100.000 Cumulative Units Fluid Type Specific heat capacity at 80°C 200 0 TABLE I: FIRE PROPERIES OF LIQUIDS Temperature gap from 90°C 300 0 The today unanimously recognized best solution for fire prevention is the replacement of mineral oil with natural or synthetic ester. These fluids in addition to their high fire-points are not harmful for humans, flora, fauna and waterborne. Fire point 400 100 Askarel (PCB diluted in trichlorobenzene) has been used for some decades as “ultimate” solution, a sort of universal panacea, for fully eradicate the fire risk. As well-known this fluid is not an option today because, due to its carcinogenicity, it is worldwide banned. Density Fire ignition 500.000 50.000 0 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017 2018 2019 2020 0 By itself, as reported in Table , the specific heat capacity is higher for the natural ester than the mineral oil, that means one needs to provide more heat to increase the temperature by 1 Kelvin degree for the natural ester than for the mineral oil. Additionally, one needs to provide more heat to the natural ester compared to the mineral oil to take the fluid to its fire point, since the gap from the max top oil temperature (90°C) is greater. For instance, the natural ester needs a heat energy of 507 KJ/l whereas mineral oil needs just 123 KJ/l to take the fluid to its fire point. This essentially means that the time to ignition will be longer for the natural ester compared to a conventional mineral oil. Units per year Cumulative Figure 5: Global market trend for transformers fille with NE Currently the value of environmental sustainability is and must become even more a duty for all industrial applications including the electrical one. This is a sector of industry that, more than many others, has always been ready to acknowledge and adopt technical innovations while respecting social ethics. It is desirable that all local fire safety legislations will soon incorporate the obvious advantages offered by natural esters, translating them into regulatory simplifications, such as the reduction of distances, the elimination of fire-barriers and of the deluge systems in case of spillage. Moreover, in case of fire, the natural ester generates less heat compared to the mineral oil during combustion, respectively 39 MJ/kg and 46 MJ/kg. As a result of lower heat of combustion, the natural ester will not support the fire to the same extent as the mineral oil. All of which would speed up green transition of the electrical industry. 341 Authorized licensed use limited to: Universidad del Valle. Downloaded on September 19,2023 at 17:33:35 UTC from IEEE Xplore. Restrictions apply. [7] ACKNOWLEDGMENT The authors sincerely thank the DuPont team for the support and the contribution in the preparation of this paper. [8] [9] REFERENCES [1] [2] [3] [4] [5] [6] R. Fritsche, U. Rimmele and F. Trautmann “Prototype 420 kV power transformer using natural ester dielectric fluid” – Proceedings of TechCon, February 2014, Phoenix. F. Scatiggio and M. Pompili “Evaluation of vegetable ester for filling large power transformers” - Proceedings of the 1st International Conference on Dielectrics – Montpellier (FR) – 2016, Page 1052 F. Scatiggio, F. Pepe, S. Sacco, and C. Serafino “Increased Loadability of Transformers Immersed in Natural Ester”, Proceedings of the 2019 IEEE 20th International Conference on Dielectric Liquids – Rome (IT) 2019. F. Scatiggio and S. Sacco “Power Transforems in Natural Esters: from Prototype to Standard Production - Trasformatori di potenza in estere naturale: dal prototipo alla produzione di serie” – L’Energia Elettrica 40 – July/August 2020. F. Negri, L. Giovanelli, M. Yazdani, and K. Kaineder “Green Substation: Dream or Reality?” - 2021 Electrical Insulation Conference (EIC), Virtual Event, June 7 – June 28, 2021 G. K. Nanaiah and J. A. Anderson “Electrolyte Leakage and Evolution of Ethylene and Ethane from Pepper Leaf Disks Following Temperature Stress and Fatty Acid Infiltration” - J. AMER SOC. HORT. SCI. 117(5):846-851. - 1992. [10] [11] [12] [13] [14] A. Rajab “Early Deterioration and its Detection of Natural Monoesters Type Insulation Oil Used for Transformers” - Philosophy Doctoral Degree (Ph.D.) in Electrical Engineering Dissertation - Kyushu Institute of Technology - February 2017. Cigre Task Force D1.01/A2.11 “Recent Developments in DGA Interpretation” – Cigre Technical Brochure 296 – Paris – 2006. F. Scatiggio, M. Pompili and R. Bartnikas “Effects of Metal Deactivator Concentration upon the Gassing Characteristics of Transformer Oils” IEEE Transactions on Dielectrics and Electrical Insulation Vol. 18, No. 3; June 2011. K. Rapp, C. P. McShane, and J. Luksich “Interaction Mechanisms of Natural Ester Dielectric Fluid and Kraft Paper” – Proceedings of IEEE International Conference on Dielectric Liquids, 2005. ICDL 2005. IEC 60076-14:2013 “Power Transformers - Part 14: Design and application of liquid-immersed transformers using high-temperature insulation materials”. J. Contreras, J. Rodriguez, C. Gaytan, B. Greaves and T. Prevost “Thermal Aging Performance of Cellulose Insulation in Natural Ester Liquid”, IEEE Transactions on Dielectrics and Electrical Insulation, Vol. 28, No. 4; August 2021. IEEE Std. C57.100™ “IEEE Standard Test Procedure for Thermal Evaluation of Insulation Systems for Liquid Immersed Power and Distribution Transformers”, 2011. M. Mazzarro, F. Scatiggio et al. “Fire simulation tests of mineral oil and natural esters transformers” - 20th IEEE International Conference on Dielectric Liquids (ICDL), Rome, Italy 342 Authorized licensed use limited to: Universidad del Valle. Downloaded on September 19,2023 at 17:33:35 UTC from IEEE Xplore. Restrictions apply.