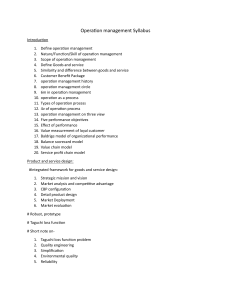

REDUCTION OF SHORT SHOTS BY OPTIMIZING INJECTION MOLDING PROCESS PARAMETERS

advertisement

International Journal of Mechanical Engineering and Technology ENGINEERING (IJMET), ISSN 0976 – INTERNATIONAL JOURNAL OF MECHANICAL 6340(Print), ISSN 0976 – 6359(Online) Volume 3, Issue 3, SepDec (2012) © IAEME AND TECHNOLOGY (IJMET) ISSN 0976 – 6340 (Print) ISSN 0976 – 6359 (Online) Volume 3, Issue 3, September - December (2012), pp. 285-293 © IAEME: www.iaeme.com/ijmet.asp Journal Impact Factor (2012): 3.8071 (Calculated by GISI) www.jifactor.com IJMET ©IAEME REDUCTION OF SHORT SHOTS BY OPTIMIZING INJECTION MOLDING PROCESS PARAMETERS Mr. M.G. Rathi Assistant Professor, Department of Mechanical Engineering, Government College of Engineering Aurangabad, (MS), India. Email – mgrathi_kumar@yahoo.co.in Mr. Manoj D. Salunke Student, Department of Mechanical Engineering, Government College of Engineering Aurangabad, (MS), India. Email – manojsalunke2012@gmail.com ABSTRACT Injection molding process dominated over plastic industry by approximately consuming 32wt% of all plastics. It became world’s favorite plastic processing method due to its high production rate, low cost and capability to produce intricate Parts with high precision. It is much difficult to set optimal process parameter levels which may cause defects in articles, such as SHORT SHOT. This paper deals with optimal injection molding process parameters for minimum SHORT SHOT. In this paper, optimal injection molding conditions for minimum SHORT SHOT were determined by the Taguchi Method and the analysis of variance (ANOVA) methods and mathematical model for process behavior is found by regression analysis. For this study total 32 trials are taken. Determination of the optimal process parameters were based on S/N ratios. According to the results, Barrel Temperature and mold closing speed are the most important parameters. Mold pressure and back pressure had no significant effect on the weight of the component Keywords: Injection Molding, S/N Ratio, ANOVA, Regression Analysis I. INTRODUCTION John Wesley is a pioneer scientist who invented injection molding first time by injecting celluloid into a mold which resulted in billiard balls which were used as a replacement for ivory which was based on the pressure die casting technique for metals. [1] Plastic injection molding 285 International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 – 6340(Print), ISSN 0976 – 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) © IAEME uses plastic in the form of pellets or granules as a raw material. It is then heated until a melt is obtained. Then the melt is injected into a mould where it is allowed to solidify to obtain the desired shape. [2] Short Shot is the defect occurs due to insufficient material injection in the mold cavity during the fill process which results in dimensional shortages. Process parameter settings which are responsible for short shots are Low injection pressure, Low injection speed, Low holding pressure, Packing switching early, Low melting stock temperature, Low mould temperature, Short holding pressure time. [3] If factors responsible for short shots are optimized we can improve the process by reducing short shots. The Taguchi method is a well-known technique that provides a systematic and efficient methodology for process optimization. It has been widely used for product design and process optimization worldwide. [4] This is due to the advantages of the design of experiment using Taguchi’s technique, which includes simplification of experimental plan and feasibility of study of interaction between different parameters. Lesser number of experiments is required in this method. As a consequence, time as well as cost is reduced considerably. Taguchi proposes experimental plan in terms of orthogonal array that gives different combinations of parameters and their levels for each experiment. According to this technique, the entire parameter space is studied with minimal number of necessary experiments only. [5, 6] Based on the average output value of the quality characteristic at each parameter level, main effect analysis is performed. Analysis of variance (ANOVA) is then used to determine which process parameter is statistically significant and the contribution of each process parameter towards the output characteristic. With the main effect and ANOVA analyses, possible combination of optimum parameters can be predicted. Finally, a confirmation experiment is conducted to verify the optimal process parameters obtained from the process parameter design. The following study was carried out at a plastic injection molding process department in Supreme Industries Ltd. Jalgaon. One of the several pipe fittings components is 3/4th Inch PVC pipe T which is the main focus in this study. Since this is largest producing component of the industry high process defects of this component from the injection molding process is the company’s main concern. The data collection was limited to 2 months November2011 and December 2011. The combined 2-month average of the short-shot defects were about 47 % of the total types of defects in the 3/4 Th Inch PVC pipe T. II. TAGUCHI TECHNIQUE Taguchi and Konishi had developed Taguchi techniques. [7] These techniques have been utilized widely in engineering analysis to optimize the performance characteristics within the combination of design parameters. Taguchi technique is also power tool for the design of high quality systems. It introduces an integrated approach that is simple and efficient to find the best range of designs for quality, performance, and computational cost. [8] In this study, parameter design is coupled to achieve the optimum levels of process parameters leading to minimum Short Shots during the manufacturing of plastic parts 286 International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 – 6340(Print), ISSN 0976 – 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) © IAEME Taguchi Parameter Design Fallows chronological sequence as • • • • • Selection Of Quality Characteristics Selection of Control Factors and Noise Factors Selection of Orthogonal Arrays Analysis of Results Confirmation of results A. SELECTION OF QUALITY CHARACTERISTICS From the discussion with company peoples strongly felt that weight of production part bears a direct relationship with occurrence SHORT-SHOTS. Recent production parts measurement revealed that average weights of qualified parts fell on the higher side of the distribution while those with SHORT-SHOTS were on the lower end so that weight of the part in grams is taken as quality characteristics. In Taguchi Method Desirable Performance is classified in three categories such as thesmaller-the-better, the-larger the-better, and the-nominal-the-best. Signal to Noise analysis is designed to measure quality characteristic. It is given by S/N = -10 log10(MSD) (1) Where MSD= Mean Squared Division For the smaller the better characteristic, (2) Larger the better characteristic, (3) Nominal the best characteristic, MSD = [(Y1 – m)2 + (Y1 – m)2 + (Y1 – m)2+ ·······)]/n (4) Where Y1, Y2, Y3 are the responses and n is the number of tests in a trial and m is the target value of the result. [9] Larger Weight values represent better or improved minimum short shot. Therefore, a Larger -the-better quality characteristic was implemented and introduced in this study. B. SELECTION OF CONTROL FACTORS AND NOISE FACTORS In this study we have consider 6 factors which affect majorly on quality characteristic such as (A) Injection Pressure, (B) Mold Closing Speed, (C) Mold Pressure, (D) Backpressure, (E) Screw Speed, (F) Barrel Temperature. One of the advantages of Taguchi parameter design is it can also consider uncontrollable factors (Noise Factors) but in this study we have considered only controllable factors. 287 International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 – 6340(Print), ISSN 0976 – 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) © IAEME C. SELECTION OF ORTHOGONAL ARRAY Since 6 controllable factors and two levels of each factor were considered L8 (2**6) Orthogonal Array was selected for this study. D. ANALYSIS OF RESULTS Result Analysis was carried out by making ANOVA to determine percentage effect of each parameter on the quality characteristic. E. CONFORMATION OF RESULTS The confirmation experiment is very important in parameter design, particularly when small fractional factorial experiments are utilized. Confirmation of results was done by taking confirmation test with optimum settings. III. EXPERIMENTAL STUDY A. INJECTION MOLDING PROCESS Trials are taken on Milacron 110 Injection Molding Machine by injecting Chlorinated Poly Vinyl Chloride (CPVC) material in 3/4th inch Tee mold. The specimen is shown in Figure 3.1 Figure 3.1 3/4th inch Tee B. EXPERIMENTAL DESIGN In order to determine the optimal process conditions and the effect of the processing parameters on the quality Characteristic i.e. weight of CPCV 3/4th inch TEE, the Taguchi method, experimental design was utilized. The controllable factors selected were the (A) Injection Pressure, (B) Mold Closing Speed, (C) Mold Pressure, (D) Backpressure, (E) Screw Speed, (F) Barrel Temperature. Table 3.1 gives the variable factors and their levels. Six controllable factors with two levels were studied, as shown in Table 3.1; therefore, the L8 orthogonal array (OA) was selected for this study therefore there were 8 trial conditions, four trials with each trial condition was taken. The signal- to-noise ratios (S/N) for each experiment were determined by using larger is the better characteristic. 288 International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 – 6340(Print), ISSN 0976 – 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) © IAEME Table 3.1: Controllable factors and levels NOTATION FACTOR DESCRIPTION LEVEL 1 LEVEL 2 A Injection Pressure (Bar) 85 125 B Mold Closing Speed (mm/s) 90 200 C Mold Pressure (Bar) 80 90 D Back Pressure (Bar) 15 40 E Screw Speed (rpm) 55 70 F Barrel Temperature (0c) 138 170 IV. RESULT ANALYSIS A. TRIAL CONDITIONS AND RESULTS According to L8 layout there are eight trial conditions as shown in Table 4.1 Table 4.1 Layout for Experimental Design according to L8 Array Exp. No. A Injection Pressure (Bar) 1 C Mould Pressure (Bar) D Back Pressure (Bar) E Screw Speed (rpm) F Barrel Temperature (0c) 85 B Mould Closing Speed ( mm/s) 90 80 15 55 138 2 85 90 90 40 70 170 3 85 200 80 15 70 170 4 85 200 90 40 55 138 5 125 90 80 40 55 170 6 125 90 90 15 70 138 7 125 200 80 40 70 138 8 125 200 90 15 55 170 Four trials with each trial condition were taken there S/N ratios with Larger is the better quality characteristic were calculated and summarized in Table 4.2 289 International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 – 6340(Print), ISSN 0976 – 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) © IAEME Table 4.2 Summary Report for Different trials conducted during Experiments Trial No. Weight In Grams S/N Ratio Sample 1 Sample 2 Sample 3 Sample 4 1 99 84.5 69 86.5 38.343 2 180 174 150 164 44.391 3 195 199 200 199 45.943 4 105 105 106 103 40.401 5 199 139 133 134 43.25 6 128 132 119 99.5 41.395 7 117 146 91 154 41.504 8 200 201 201 201 46.053 Grand Average 42.66 Above test results were studied and effect of each parameter on S/N ratio was calculated and plotted as shown in Figure 4.1 Main Effects Plot for SN ratios Data Means 43.6 INJEC TIO N PRESSURE (Bar) MO ULD C LO SING SPEED (mm/s) MO LD PRESSURE (Bar) 43.2 Meanof SNratios 42.8 42.4 42.0 85 43.6 125 BA C K PRESSURE (Bar) 90 200 SC REW SPEED (rpm) 80 90 BA RREL TEMPRA TURE (0c) 43.2 42.8 42.4 42.0 15 40 55 70 138 170 Signal-to-noise: Larger is better Figure 4.1 Effect of Process parameters on S/N Ratio B. ANATYSIS OF VARIANCE BY QT-4 SOFTWARE ANOVA was performed by using a software qualitek-4 which gives significance of each factor in terms of Percent in the last column of the Table 4.3 290 International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 – 6340(Print), ISSN 0976 – 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) © IAEME Table 4.3 ANOVA Table DOF Factors Sums Of Squares Variance Pure Sum F-Ratio Percent 1 A: Injection Pressure 1 1.219 1.219 18.779 1.154 2.207 2 B: Mould Closing Speed 1 5.314 5.314 81.831 5.249 10.036 3 C:Mould Pressure 1 1.278 1.278 19.685 1.213 2.320 4 D: Back Pressure 1 0.597 0.597 9.196 0.532 1.017 5 E: Screw Speed 1 3.361 3.361 51.754 3.296 6.302 6 F: Barrel Temperature 1 40.468 40.468 623.099 40.403 77.246 Other/Error 1 0.064 Total: 7 0.064 0.872 52.304 100.000% From ANOVA it is clear that Mold closing speed and Barrel Temperature is the most significant factors. The Optimum conditions and the optimum results are calculated with the help of ANOVA and given in Table 4.4 Table 4.4 Optimum Condition and performance Sr. No. Factors Level Description Level Contribution 1 A:Injection Pressure 125 2 0.390 2 B: Mould Closing 200 2 0.815 4 C: Mould Pressure 90 2 0.400 5 D: Back Pressure 15 1 0.273 6 E: Screw Speed 70 2 0.648 7 F: Barrel temperature 170 2 2.249 Total Contribution From All Factors... 4.774 Current Grand Average Of Performance... 42.660 Expected Result At Optimum Condition... 47.162 291 International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 – 6340(Print), ISSN 0976 – 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) © IAEME C. REGRESSION ANALYSIS Regression Analysis of the Test Data gives the relationship of controllable parameters with average output in the form of linear equation given below Y = -382.720+ 0.274*A + 0.246*B + 0.772*C -0.534*D + 1.173*E + 2.196*F (5) Where Y = Response i.e. Weight of the component in Grams A = Injection Pressure in Bar , B = Mould Closing Speed in mm/s, C = Mould Pressure in Bar, D = Back Pressure in Bar, E = Screw Speed in rpm, F = Barrel temperature in 0c If we put optimum parameters which are drawn by ANOVA in equation 5 it will give optimum value of quality characteristic which will minimize short shots Yopt = -382.720+ 0.274* A2 + 0.246* B2+ 0.772* C2 -0.534* D1 + 1.173* E2+ 2.196* F2 Yopt = -382.720+ 0.274* 125 + 0.246* 200+ 0.772* 90 -0.534* 15 + 1.173* 70+ 2.196* 170 Yopt = 217.63gm ( Predicted by Regression Equation) D. Confirmation Experiment In Order to test the predicted result, confirmation experiment has been conducted by running another four trials at the optimal settings of the process parameters determined from the Analysis i.e. A2B2C2D1E2F2 Observation Trial 1 Trial 2 Trial 3 Trial 4 Average Weight S/N Ratio 1 217.5gm 217gm 216gm 217gm 46.72 217.5gm The results are shown in above table and it is observed that the average weight i.e. 217gm and average S/N Ratio 46.72 which falls within predicted 80% Confidence Interval. V. CONCLUSIONS The Taguchi method was applied to find an optimal setting of the injection molding process. The result from the Taguchi method chooses an optimal solution from combinations of factors if it gives maximized normalized combined S/N ratio of targeted outputs. The L-8 OA was used to accommodate six control factors and each with 2 levels for experimental plan selected process parameters are Injection Pressure (85, 125 bar ) , Mold Closing Speed ( 90, 200, mm/s) ,Mold Pressure ( 80,90 bar), Backpressure (15,40 bar), Screw Speed ( 55,70 rpm), Barrel Temperature ( 138,170 0c). The results are summarized as follows: 292 International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 – 6340(Print), ISSN 0976 – 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) © IAEME • • • • • Among the six process parameters Barrel Temperature, Mold Closing Speed, Screw Speed is having more significant effect on Quality Characteristic. The Optimal level of process parameter were found to be A2B2C2D1E2F2 The prediction made by Taguchi parameter design technique is in good agreement with confirmation results. The result of present investigation are valid within specified range of process parameters Also the prediction made by Regression Analysis is in good agreement with confirmation results. The Optimal level process parameter are found to be A2B2C2D1E2F2 corresponding to Injection Pressure of 125 bar, Mold Closing Speed of 200, mm/s, Mold Pressure of 90 bar, Backpressure of 15bar, Screw Speed of 70 rpm, Barrel Temperature of 170 0c and also the process parameters which affecting weight variations are focused and controlled. REFERENCES [1] Crawford, R, 1998, “Plastic Engineering”. 3rd ed. Oxford: Butterworth – Heine-mann. [2] Chen, R.S., Lee, H.H., and Yu, C.Y., 1997, “Application of Taguchi’s Method on the optimal process design of an injection molded PC/PBT automobile bumper”. Composite Structures, 39, pp. 209-214 [3] “Short Shot Defect Analysis” http://www.dakumar.com/blog/short-shot-defect- analysis410.html [4] Wang, W.H., and Tarng, Y.S., 1998, “Design Optimization of cutting parameters for turning operations based on the Taguchi method”. Journal of Materials Processing Technology, 84, pp. 122-129. [5] Phadke, M.S., 1989, “Quality Engineering Using Robust Design”. Prentice Hall International Inc., New York. [6] Roy, R.K., 1990, “A primer on the Taguchi method”. Competitive Manufacturing Series, Van Nostrand Reinhold, New York. [7] Taguchi G, Konishi S. Taguchi methods, orthogonal arrays and linear graphs, tools for quality American supplier institute. American Supplier Institute; 1987 [p. 8–35]. [8] Taguchi G. Introduction to quality engineering. New York: Mc Graw-Hill; 1990. [9] Roy, R. A Primer on the Taguchi Method. New York: Van Nostrand Reinhold; 1990 293