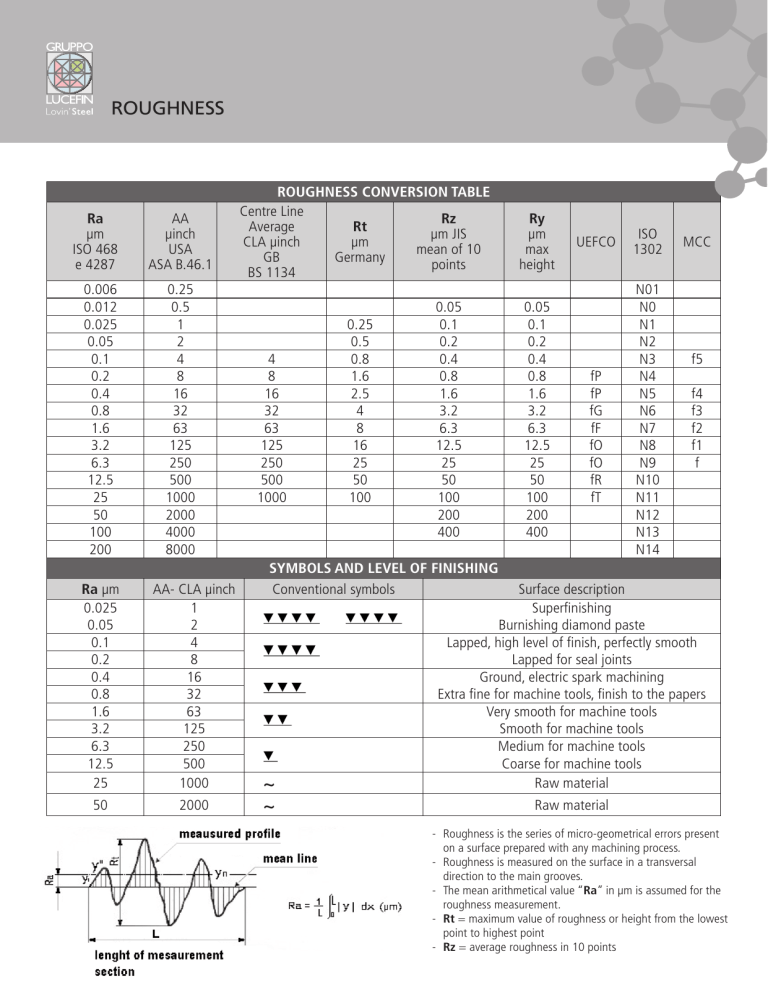

Roughness Ra μm ISO 468 e 4287 0.006 0.012 0.025 0.05 0.1 0.2 0.4 0.8 1.6 3.2 6.3 12.5 25 50 100 200 AA μinch USA ASA B.46.1 0.25 0.5 1 2 4 8 16 32 63 125 250 500 1000 2000 4000 8000 Ra μm 0.025 0.05 0.1 0.2 0.4 0.8 1.6 3.2 6.3 12.5 25 AA- CLA μinch 1 2 4 8 16 32 63 125 250 500 1000 50 2000 Roughness conversion table Centre Line Rz Rt Average μm JIS μm CLA μinch mean of 10 Germany GB points BS 1134 4 8 16 32 63 125 250 500 1000 0.25 0.5 0.8 1.6 2.5 4 8 16 25 50 100 0.05 0.1 0.2 0.4 0.8 1.6 3.2 6.3 12.5 25 50 100 200 400 Ry μm max height 0.05 0.1 0.2 0.4 0.8 1.6 3.2 6.3 12.5 25 50 100 200 400 UEFCO fP fP fG fF fO fO fR fT ISO 1302 N01 N0 N1 N2 N3 N4 N5 N6 N7 N8 N9 N10 N11 N12 N13 N14 MCC f5 f4 f3 f2 f1 f Symbols and level of finishing Conventional symbols ~ ~ Surface description Superfinishing Burnishing diamond paste Lapped, high level of finish, perfectly smooth Lapped for seal joints Ground, electric spark machining Extra fine for machine tools, finish to the papers Very smooth for machine tools Smooth for machine tools Medium for machine tools Coarse for machine tools Raw material Raw material - Roughness is the series of micro-geometrical errors present on a surface prepared with any machining process. - Roughness is measured on the surface in a transversal direction to the main grooves. - The mean arithmetical value “Ra” in μm is assumed for the roughness measurement. - Rt = maximum value of roughness or height from the lowest point to highest point - Rz = average roughness in 10 points