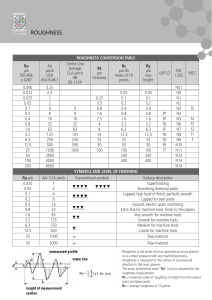

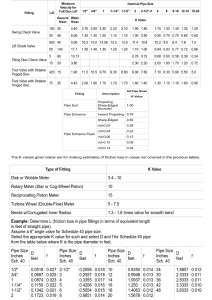

MESUREMENT TECHNIQUES Lecture 13 OVERVIEW Surface metrology examines the deviation between one point (or points) on a surface and another points (other points) on the same surface Surface metrology is a concern of many branches of science and widely involved in the world of commerce and manufacturing Surface metrology Surface metrology or surface topology refers to the geometry and texture of surfaces The condition of surface is defined by its characteristics: Surface texture (finish) Roundness (a function of geometry) Material Hardness Surface metallurgy Surface metrology (cont’) Three forms of asperity 1. 2. 3. Roughness Waviness Error of form Vary according to the length of spacing or wavelength The fourth asperity is not distinguish by wavelength; it is flaw Lay is the direction of the asperities which in most cases means that roughness and waviness are perpendicular to each other Surface assessment Roughness – the finest of the asperities Waviness - concern the more widely spaced ones Flaw – surface defect Lay – The direction of the asperities * Asperity is defined as unevenness of surface, roughness Various lay configuration This chart categorizes the various lay configurations and shows the standardizes symbols used on drawing MAIN MEASUREMENT METHOD OF SURFACE ROUGHNESS Inspection and assessment of surface roughness of machined workpieces can be carried out by means of different measurement techniques. These methods can be ranked into the following classes: 1. 2. 3. 4. Direct measurement methods Comparison based techniques Non contact methods On-process measurement Direct Measurement Method Direct methods assess surface finish by means of stylus type devices. Measurements are obtained using a stylus drawn along the surface to be measured: the stylus motion perpendicular to the surface is registered. This registered profile is then used to calculate the roughness parameters. Disadvantage- This method requires interruption of the machine process, and the sharp diamond stylus may make micro-scratches on surfaces. Comparison Based Technique Comparison techniques use specimens of surface roughness produced by the same process, material and machining parameters as the surface to be compared. Visual and tactile senses are used to compare a specimen with a surface of known surface finish. Because of the subjective judgment involved, this method is useful for surface roughness Rq>1.6 micron Non-contact Method There have been some work done to attempt to measure surface roughness using non contact technique. Here is an electronic speckle correlation method given as an example (figure 8.1). When coherent light illuminates a rough surface, the diffracted waves from each point of the surface mutually interfere to form a pattern which appears as a grain pattern of bright and dark regions. The spatial statistical properties of this speckle image can be related to the surface characteristics. The degree of correlation of two speckle patterns produced from the same surface by two different illumination beams can be used as a roughness parameter. Figure 8.1 On-process Measurement Many methods have been used to measure surface roughness in process. For example: Machine vision. In this technique, a light source is used to illuminate the surface with a digital system to viewing the surface and the data being sent to a computer to be analyzed. The digitized data is then used with a correlation chart to get actual roughness values. Inductance method. An inductance pickup is used to measure the distance between the surface and the pickup. This measurement gives a parametric value that may be used to give a comparative roughness. However, this method is limited to measuring magnetic materials. Ultrasound. A spherically focused ultrasonic sensor is positioned with a non normal incidence angle above the surface. The sensor sends out an ultrasonic pulse to the a personal computer for analysis and calculation of roughness parameters. SURFACE EVALUATION Surface roughness comparator Microscope Stylus method Surface roughness comparator The most common way to evaluate surface finish is to compare it visually and by feel with roughness comparison specimens having various surface finishes It consist of composite set of surface roughness specimen standard Surface roughness comparator (cont’) Microscope Examination of surfaces by microscope can be informative But it does not usually allow the heights of the asperities to be determined without destroying the test part by cutting a taper through the surface Stylus Instrument Why we use stylus method?? It is the most familiar method for practical shop work It the best demonstrate the fundamental principles of surface metrology Standard is based on the stylus method STYLUS INSTRUMENT Stylus instrument The stylus instrument widely used technique for measuring a surface profile This technique uses a fine diamond stylus with tip size approximately 0.1 to 10 µm to transverse the surface As the stylus tracks the surface peaks and valleys, its vertical motion is converted to a time varying electrical signal that represent surface profile Stylus instruments operate like a phonograph pickup: the stylus is drawn across the surface and generates electrical signals that are proportional to the changes in the surface The changes in height can be read directly with a meter or on a printed chart Two types of stylus instrument 1. 2. True- datum or skidless instruments Surface- datum or skid type instrument True- datum instrument With this instrument, we draw across the surface in a very precise, mechanically controlled movement Advantages The resulting graph is nearly a true representation of the surface along that one line showing roughness, waviness, errors of form and flaws Disadvantages Very difficult to set the instrument up; must precisely align the surface being assessed with the path of the instrument Figure 8.2 True-datum stylus instruments move the stylus across the part along a reference datum established by the instrument Surface datum instrument Can easily set up because they use the surface being assessed as the datum A supporting slide (skid, a rounded member fixed to the head, a shoe, a flat pad) mounted in the head rests on the surface and slides the stylus pickup along Skids may be located, in front of, behind, or on the opposite side of the stylus Figure 8.3 Surface datum instruments create their own reference datum. This is done by supporting the stylus, T, by a member S, that is sufficiently wide to slide along the surface. NUMERICAL VALUES FOR ASSESSMENT Arithmetic roughness average This method is also known as roughness average and by two earlier term; arithmetic average (AA) and center-line average (CLA) The roughness average is the arithmetic average of the absolute values of the deviation from the profile height measured from the centerline along a specified sampling length Two method for determining the value i. ii. Graphical method Electrical averaging NUMERICAL VALUES FOR ASSESSMENT (cont’) Other standardized assessment methods 1. Root-Means-Square roughness (Ra or RMS) 2. Maximum Peak-Valley Roughness (Rmax or Rt) 3. Closely related to the roughness average (Ra) Square the distances, average them, and determine the square root of the result The resulting value is the index for surface texture comparison Usually 11% higher than the Ra value Determine the distance between the lines that contact the extreme outer and inner point of the profile Second most popular method in industry See figure A Ten-Point Height (Rz) Averages the distance between the five peaks and five deepest valleys within the sampling length See figure B Other standardized assessment methods (cont’) 4. Average Peak-to-Valley Roughness (R or H or Hpl) 5. Average Spacing of Roughness Peaks (Ar or AR) 6. Average the individual peak-to-valley heights See figure C Use the height between adjacent peaks and valleys, not measure from a center line to peak valleys Average the distance between the peaks without regard to their height See figure D Swedish Height of Irregularities (R or H) Also known as Profiljup methos Only standard in Sweden (H) and Denmark (R) It assume that, in wear situation, the peaks are affected by wear, but the valleys are not. Other standardized assessment methods (cont’) 7. Bearing Length Ration (Tp and others) 8. Leveling Depth (Rp and others) 9. Create a reference line through some of the peaks This line is at a predetermined height from the mean line, and you have then divide the subtended length through the peaks by sampling length to arrive at the assessment value See figure F Measure the height between the highest peak and the mean line See figure G Waviness Height (W) Assess the waviness without regard to roughness by determining the peak-to-valley distance of the total profile within the sampling length Example