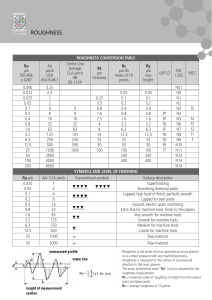

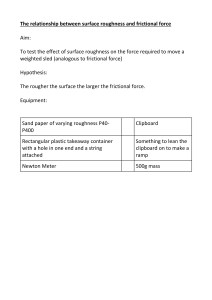

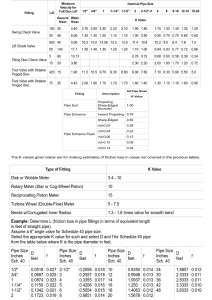

Surface Texture: Surface Roughness, Waviness, and Lay TECH 3421 Video Lecture Importance of Surface Roughness The topography of a surface affects: ● Friction ● Fit ● Aesthetic ● Corrosion resistance ● Optical properties ● Sealing performance ● Fatigue strength Specifying Surface Finish ISO Grade Numbers, N1, N2, etc. Smaller number, smoother finish Triangle Symbols (older designation) More triangles, smoother finish (don’t use) Ra (and other parameters) Smaller number, smoother finish ISO and ASME Standards Other, specialty standards [SPI Mold Finish] Standards for specifying and determining surface texture ASME Y 14.36M - Symbols, ASME B46.1 - Surface Texture ISO 1302 ISO 4287 ISO 4287 Profilometer (one of many types) Background How a record stylus works (worked)... https://www.youtube.com/channel/UCivA7_KLKWo43tFcC kFvydw Measuring the Profile The measured profile Includes roughness, waviness, and errors of form It EXCLUDES: imperfections such as scratches, dents, pits and cracks Roughness, Waviness, Form, and Lay Separating Waviness from Roughness Waviness is filtered out. Notice that our stylus already filtered out some short waves. Cutoff filters out long waves. The cutoff is a length. The measured profile is chopped up into these lengths. Think of cutoff as tuning out the bass of the signal. We just want the treble. Cutoff Separates Waviness from Roughness Evaluation length is generally 5 cutoff lengths A section of the traversed length is discarded at each end. This is not evaluated. The Roughness Profile is Leveled When chopped up, the roughness profile may be rotated away from the nominal (ideal) from. If so, it is rotated to be flat. Roughness Can Now be Evaluated Example: Ra Ra is the average roughness. It is the simplest and one of the most commonly used roughness parameters. Units are length and can be micrometers or microinches Keep in mind: 0.001 mm is 1 micrometer [micron] .001 inches plus one microinch is .001001 There are about 40 inches in a meter There are about 40 microinches In a micrometer 𝝁m 𝝁in Be consistent with the other units of the drawing! Ra Same as CLA - Center Line Average and arithmetic average (AA) Analytical version Ra Notice that Ra DEPENDS On the cutoff! See: https://willrich.c om/wpcontent/upload s/2014/11/Surf ace-TextureMeasurementFundamentals. pdf ASME Y14.36 - Roughness Symbols Symbol rests on surface to be finished. If no roughness is given, a note must be indicate roughness value. Complete Symbol Ra is roughness average (in microinches or micrometers [microns] ). Mu = micro Horizontal line is required when specifying anything to the right of the check Example Surface Texture Symbols Lay Symbols ASME Y14.36M - 2008 Lay Direction Direction is relative to placement on the drawing Surface Roughness Comparator Nice Rule of Thumb: https://michmet.co m/surfaceroughnessanalysis-averageroughnessbasics.htm Typical Ra values by process Keep in mind that there are about 40 inches per meter Surface Roughness Parameters In addition to Ra, there are other parameters that are sometimes measured, for example: Ra; Rc; Ry; Rz; Rq; Rt; Rmax; Rp; Rv; R3z; Rsk; Rku; RPc; RSm; Rz1max; S; HSC; RzJIS; Rppi; R™ a; R™ q; Rlr; Rmr; Rmr(c); R™ c; Rk; Rpk; Rvk; Mr1; Mr2; A1; A2; Vo; Rpm; tp; Htp; R; Rx; AR; These are used to characterize the shape and distribution of the roughness. Is it mostly peaks, mostly valleys, are the peaks spaced out or close together. Rq RMS Value - “Sees” peaks and valleys with more sensitivity than Ra Other Roughness Parameters Other Roughness Parameters Great reference: Link (also in references) And this: Understanding Surface Quality: Beyond Average Roughness (Ra) Case Study Variation in taper surface roughness for a single design effects the wear rate in total hip arthroplasty Robert K. Whittaker Harry S. Hothi Antti Eskelinen Gordon W. Blunn John A. Skinner Alister J. Hart First published: 05 October 2016 https://doi.org/10.1002/jor.23456Citations: 8 Link Measuring Roughness Profilometer Contact Diamond stylus Noncontact Optical (laser triangulation) Electron optical (SEM) Start: 1:38 Example (Surftest J210) Other References See course site. ● Profile Parameters from ISO 4287 ● Mitutoyo Quick Guide to Surface Roughness Measurement