9,

75

62

9,

75

62

ith

N

ith

N

in

,

in

,

/2

7/

26

/2

7/

26

3

02

3

02

15

1:

15

1:

:3

7

:3

7

M

A

M

A

9,

75

62

9,

75

62

23

20

6/

/2

,7

in

ith

N

23

20

6/

/2

,7

in

ith

N

7

:3

15

1:

7

:3

15

1:

M

A

M

A

62

75

9,

N

62

75

9,

N

it h

in

,7

/2

6/

20

23

it h

in

,7

/2

6/

20

23

1:

15

:3

7

1:

15

:3

7

A

A

M

M

M

A

M

A

1:

15

:3

7

ii

HVAC ENGINEERS’ HANDBOOK COMMITTEE

it h

in

,7

/2

6/

20

23

1:

15

:3

7

|

it h

in

,7

/2

6/

20

23

ISHRAE HVAC DATABOOK

ISHRAE

The following members of ISHRAE are the Committee Members for the

First Edition of the HVAC Databook 2017.

Mr. R. S. Kulkarni

-

Mr. R. P. Paranjpe

-

Consultant, Pune

Mr. Shantanoo Laghate

Technical Advisor MEP Projects

Mumbai

Chairperson

Member

62

75

9,

N

62

75

9,

N

HVACR Consultant

Pune

Mr. G. M. Lele

-

Member

-

Member

M

M

Consultant

Bhubaneshwar

A

7

:3

Member

Mr. T. Hari Rao

-

Member

Mr. P. V. Balasubramanian

-

Member

20

6/

/2

ith

in

,7

ith

in

15

-

1:

Mr. G. V. Rao

23

Member

20

-

6/

Mr. R. V. Simha

/2

Editor

,7

-

1:

Mr. N. Raghuram

23

15

:3

7

A

The First Edition of the HVAC Handbook was also prepared and published by the

ISHRAE Bangalore Chapter in 1996 with the following Committee Members.

9,

N

-

Member

Mr. P. V. Subramanian

-

Member

Mr. R. Anish Simha

-

Member

Mr. C. Subramaniam

-

Member

Mr. G. Ramesh Kumar

-

Member

Mr. S.N. Raju

-

Member

-

Member

A

A

15

1:

23

/2

0

/2

6

,7

in

N

ith

9,

75

62

62

75

9,

N

ith

in

,7

/2

6

/2

0

23

1:

15

:3

7

Mr. S.N. Murthy

M

Mr. P. V. Balasubramanian

M

Chairperson

75

-

:3

7

62

75

Mr. B. Manjunatha Swamy

62

9,

N

The Second Edition was prepared by ISHRAE Bangalore Chapter in 2014 with the

following Committee Members.

M

iii

The HVAC industry is growing at a considerable rate due to technological

developments and to meet the consumer expectations. The growing trend of

smart buildings and homes, development of energy efficient systems, regulated

by MEPS, and higher market penetration supported by green technologies

are some of the factors contributing towards the growth of the HVAC market

in the coming years. India is no exception and the growth is expected to be

higher than the rest of the world, as 70 % of the buildings are yet to be built

backed by the robust GDP growth. The Indian HVAC market is around 4 Bn $

M

A

A

M

which is 3 % of the world market. In last few years the technology gap between

ISHRAE

1:

15

:3

7

it h

in

,7

/2

6/

20

23

FORWARD

62

75

9,

N

62

75

9,

N

A

M

A

1:

15

:3

7

|

it h

in

,7

/2

6/

20

23

ISHRAE HVAC DATABOOK

7

:3

:3

7

the developed countries and India has reduced and will be at par with the

15

1:

1:

15

developed world in the coming years.

23

23

The HVAC industry which was limited to the metros has now penetrated to the

20

6/

/2

/2

6/

20

tier two and three cities and the small towns.

,7

in

to publish Guide books, standards, and Data books to address various HVAC

ith

ith

in

,7

ISHRAE, as a part of its objective to disseminate knowledge, has taken initiatives

N

N

requirements specifically in the Indian context. This HVAC data book is one of

9,

75

75

9,

the many initiatives undertaken. This is the third edition and has incorporated the

62

62

up-dated Indian weather data, emerging refrigerants and other developments.

This data book will be of immense help to the upcoming designers, contractors

and engineers in the HVAC field.

The data book is outcome of the dedication and passion of the ISHRAE ITC

M

M

sub-committee chaired by R S Kulkarni. The other members who contributed

A

:3

7

:3

7

A

are R P Paranjpe, Shantanoo Laghate and G M Lele

15

1:

23

23

1:

15

Jitendra Bhambure

/2

0

/2

6

,7

in

N

ith

9,

75

62

62

75

9,

N

ith

in

,7

/2

6

/2

0

Chair ISHRAE Technical Committee

M

A

M

A

iv

1:

15

:3

7

1:

15

:3

7

|

it h

in

,7

/2

6/

20

23

PREFACE

it h

in

,7

/2

6/

20

23

ISHRAE HVAC DATABOOK

ISHRAE

ISHRAE Bangalore Chapter brought out the first HVAC Handbook in 1996, for use, as a

reference for HVAC professionals. This brought together, all the data necessary to conduct

Heat Load Calculations.

62

75

9,

N

62

75

9,

N

In the year 2014, Bangalore ISHRAE Chapter, undertook to make this Handbook more

comprehensive, with a lot of additional data, in the I-P System. In this revision, information has

been added to make this Handbook relevant, and in line with the latest trends, especially the

efficiency standards for HVAC Equipment, VRF / VRV systems and green building norms .

As ISHRAE is now publishing a number of other Handbooks, some of the repetetions, with

the Refrigeration and Ventilation Handbook have been deleted, to make the Databook more

suitable for HVAC alone.

In this Databook, the weather Data is udated as per latest ISHRAE Indian weather Data

Handbook.

A

A

M

An addition of the CLTD Method of Heat Load Calculation has been made, to make available

more precise Heat Load Calculations, linked to Indian weather data.

M

The I-P System is retained in this version also.

7

:3

15

15

:3

7

We hope to make Heat load Calculations less cumbersome and more precise, so that all

ISHRAE members can use it.

1:

1:

Based on the feedback received earlier, links to Psychrometric Calculator are incorporated.

23

20

20

23

This effort could not have been possible without the guidance and contributions from

Mr. R. P. Paranjpey, Mr. Shantanoo Laghate and Mr. Govind Lele.

6/

/2

ith

N

9,

75

9,

N

ith

in

,7

/2

6

/2

0

23

1:

15

:3

7

A

M

62

75

62

62

75

9,

N

ith

in

,7

/2

6

/2

0

23

1:

15

:3

7

A

M

62

75

9,

N

ith

in

,7

Chairman HVAC Databook Committee.

in

,7

/2

6/

I must thank them profusely.

M

M

A

7

:3

15

1:

23

20

6/

/2

,7

in

ith

N

9,

M

A

:3

7

15

1:

2. Dr. R Saravanan

8.

Mr. N.S. Chandrasekar

3. Dr. Shishir Chandra Bhaduri

9.

Mr. Susobhan Bhattacharya

4. Dr. Sanjeev Jain

10. Mr. Vishal Kapur

5. Mr. Abid Husain

11. Mr. Sachin Maheshwari

N

9,

75

62

02

/2

7/

26

in

,

ith

02

7/

26

in

,

ith

62

75

9,

N

6. Mr. Nitin M Deodhar

3

Mr. Ravindra S Kulkarni

3

7.

/2

1:

15

:3

7

A

M

62

75

9,

N

ith

in

,7

/2

6/

20

23

1:

15

:3

7

A

M

62

75

9,

N

it h

in

,7

/2

6/

20

23

1:

15

:3

7

A

M

A

1:

15

:3

7

it h

in

,7

/2

6/

20

23

62

75

9,

N

75

62

1. Mr. Jitendra M Bhambure

M

A

M

A

1:

15

:3

7

62

75

9,

N

ISHRAE

62

75

9,

N

vi

it h

in

,7

/2

6/

20

23

1:

15

:3

7

|

it h

in

,7

/2

6/

20

23

ISHRAE HVAC DATABOOK

DISCLAIMER

Unless otherwise specifically stated, the information contained herein is

made available to the public by the Indian Society of Heating, Refrigerating

and Air-conditioning Engineers henceforth called as ISHRAE in this

document.

M

A

7

:3

1:

23

20

6/

/2

,7

in

in

,7

/2

6/

20

23

1:

15

The committee and ISHRAE have strived hard to be as accurate and

complete as possible, however the committee or ISHRAE or any other

entities thereof do not warrant or represent at any time that the contents

within are accurate. While all attempts have been made to verify information

provided in the Handbook, the committee or ISHRAE assumes no

responsibility for any errors, omissions, contradictory information, contrary

interpretations, relevance of standards for the present scenario, latest

updates of the information / data / chart of the subject matter herein.

15

:3

7

A

M

Neither ISHRAE nor ISHRAE Handbook Committee or any other committee

formed under ISHRAE or any other agency or entities thereof assumes any

legal liability or responsibility for the accuracy, completeness, usefulness

or interpretations of any information, contents, data, diagrams, charts and

figures in this Handbook.

ith

N

9,

75

62

62

75

9,

N

ith

This Handbook is not intended for use as a source of business,

advertising, recommendations or for any other purpose than the intended

use. Adherence to absolutely all applicable laws, rules and regulations,

statutory guidelines / requirement is the sole responsibility of the purchaser

or reader of this Handbook. This Handbook is only a collection of data

from various sources and not a statutory document for any approvals,

recommendations, proof, reference, etc.

M

A

A

M

Reference herein to any specific commercial product, process, and

service by trade name, trademark, manufacturer or otherwise, does not

constitute or imply its endorsement, recommendations or favouring by

ISHRAE or any entities thereof.

:3

7

15

23

/2

0

/2

6

N

ith

9,

75

62

62

75

9,

N

ith

in

,7

HVAC Engineers’ Databook Committee.

in

,7

/2

6

/2

0

23

1:

It is also expressed by the committe that while specifying Insulating

Materials, due considerations should be given to the “Smoke Generation”.

References to ISO-5659-2 (1994), NFPA 270, ASTMD5424 and

BS-6853:1999 should be made.

1:

15

:3

7

The views and opinions of the originator expressed therein do not

necessarily state or reflect those of ISHRAE or any entities thereof.

M

A

M

A

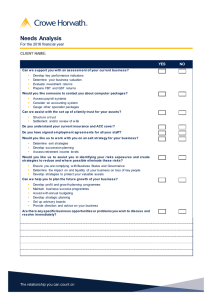

Design Data, Psychrometric, IAQ and Comfort

Section-2

Air Distribution, Ducts, Design and Materials

Section-3

Water/Steam Piping Design and Materials

Section-4

Refrigerant Piping

Section-5

Refrigerant, Properties and Lubricants

Section-6

Thermal Insulation of Ducts and Pipes

Section-7

Noise and Vibration

Section-8

Electrical Motors, Starters, Cables and Measurement Sensors

Section-9

Green Buildings

Section-10

Units and Conversions

Section-11

IS Codes & Standards

Section-12

International Codes & Standards

Section-13

Safety for Air-conditioning and Refrigeration Engineers

Section-14

Glossary

Section-15

About ISHRAE

Section-16

Annexure - Procedure to used cltd progremme

M

A

7

:3

15

1:

23

20

6/

/2

,7

in

ith

N

9,

75

M

A

:3

7

15

1:

23

/2

0

/2

6

,7

in

N

ith

9,

62

75

9,

N

ith

in

,7

/2

6

/2

0

23

1:

15

:3

7

A

M

62

75

9,

N

ith

in

,7

/2

6/

20

23

1:

15

:3

7

A

M

62

75

9,

N

Section-1

62

75

9,

N

1:

15

:3

7

SUMMARY OF THE CONTENTS

62

75

62

vii

it h

in

,7

/2

6/

20

23

1:

15

:3

7

|

it h

in

,7

/2

6/

20

23

ISHRAE HVAC DATABOOK

M

A

M

A

viii

1:

15

:3

7

1:

15

:3

7

|

it h

in

,7

/2

6/

20

23

CONTENTS

it h

in

,7

/2

6/

20

23

ISHRAE HVAC DATABOOK

SECTION - 1 : DESIGN DATA, PSYCHROMETRICS, IAQ AND COMFORT

62

75

9,

N

1.1

1.4

1.5

1.6

1.27

1.28

1.29

1.29

1.30

1.30

A

in

,7

/2

6/

20

23

1:

15

:3

7

A

7

:3

15

1:

23

N

ith

1.41

M

:3

7

1.44

1.44

1.45

1.45

1.46

1.46

1.46

1.46

15

1:

23

/2

0

/2

6

,7

in

N

ith

9,

62

75

9,

N

ith

in

,7

/2

6

/2

0

23

1:

15

:3

7

A

M

62

75

9,

1.42

1.42

1.43

1.43

1.43

1.44

A

20

6/

/2

,7

in

ith

N

9,

75

62

75

62

1.34

1.34

1.35

1.36

1.37

1.37

1.37

1.37

1.38

M

1.31

1.32

1.33

M

62

75

9,

N

Introduction

Table 1.1 :

Classification of Climate

Table 1.2 :

Design Ambient Dry Bulb Temperature & Coincident Wet Bulb Temperature 0F

Table 1.3 :

Monthwise Maximum, Minimum Temperatures and Daily Range

Table 1.4 :

Typical Inside Design Conditions - Industrial

Table 1.5 :

Typical Inside Design Conditions - Industrial

Table 1.6 :

Corrections in Outdoor Design Temperatures for Time of Day

Table 1.7 :

Corrections in Outdoor Design Temperatures for Month of Year

Table 1.8 :

Overall Factors for Solar Heat Gain through Glass with or Without Shading Devlces

Table 1.9 :

Transmission Coefficient U for Windows, Skylights, Doors & Glass Block Walls

(Btu / (hr) (sq. ft.) (Deg. F Temp Diff)

Table 1.10 : Solar Heat Gain through Ordinary Glass Btu / (Hr.) (Sq. Ft. Sash Area)

Table 1.11 : Solar Heat Gain through Ordinary Glass Btu / (Hr.) (Sq. Ft. Sash Area)

Table 1.12 : Solar Heat Gain through Ordinary Glass Btu / (Hr.) (Sq. Ft. Sash Area)

Table 1.13 : Total Solar Radiation (Direct plus Diffused) Incident on Various Surfaces of

building in Btu/ Sqft / day for Summer and Winter Seasons

Table 1.14 : Solar Altitudes (to the Nearest Degree) for Indian Latitudes

Table 1.15 : U-Factors for Various Fenestration Products in Btu/h-ft - F

Table 1.16 : U-Factors for Various Fenestration Products in Btu/h-ft - F

Table 1.16 : Solar Heat Gain Co-efficient for Domed Horizontal Skylights

Table 1.17 : Design U-Factors of Swinging Doors In Btu/H-Ft2 °F

Table 1.18 : Design U-Factors for Revolving Doors in Btu/h-ft2 -°F

Table 1.19 : Design U-Factors for Double Skin Steel Emergency Exit Doors in Btu/h - ft2 - °F

Table 1.20 : Thermal Resistance R - Building and insulating Materials

(Deg. F per Btu) / (hr) (Sq. ft)

Table 1.21 : Equivalent Temperature Difference (Deg. F)

For Dark Colored †, Sunlit and Shaded Walls’*

Table 1.22 : Equivalent Temperature Difference (Deg. F)

Table 1.23 : Corrections to Equivalent Temperatures (Deg. F)

Table 1.24 : Heat gain from people

Table 1.25 : Typical Bypass Factors

Table 1.26 : Typical Bypass Factors

Table 1.27 : Recommended Rates of Radiant and Convectlve Heat Gain from Warewashing

Equipment during idle (standby) or washing conditions

Table 1.28 : Recommended Heat Gain from Typical Medical Equipment

Table 1.29 : Recommended Heat Gain from Typical Laboratory Equipment

Table 1.30 : Recommended Heat Gain from Typical Computer Equipment

Table 1.31 : Recommended Heat Gain from Typical Laser Printers and Copier

Table 1.32 : Recommended Heat Gain from Miscellaneous Office Equipment

Table 1.34 : Recommended Load Factors for Various Types of Offices

Table 1.33 : Gain Load Estimates for Various Office Load Densities

Table 1.35 : Minimum Nominal Full-Load

Efficiency for V60H NEMA General Purpose

Electric Motor* (Subtype 1) Rated 600 Volts or Less (Random Wound)*

Table 1.36A : Minimum 50 Hz efficiency values defined in IEC/EN 60034-30-1:2014

(based on test methods specified in IEC 60034-2-1:2014)

Table 1.36B : Recommended Rates of Radiant Heat Gain from Hooded Gas Appliances

during Idle (Ready-to-Cook) Conditions

Table 1.37 : Recommended Rates of Radiant Heat Gain from Hooded Solid Fuel Appliances

During Idle (Ready-to-Cook) Conditions

1.47

1.49

1.49

M

A

M

A

ix

1:

15

:3

7

7

A

1.59

1.62

1.63

1.66

1.68

1.68

M

1.50

1.51

1.52

1.53

1.54

1.54

1.54

1.55

1.55

1.56

1.57

1.57

1.57

1.58

1.58

A

1.69

1.69

1.70

1.70

1.70

1.71

1.73

1.73

1.73

1.74

1.75

1.76

1.77

1.77

1.77

1.78

1.79

1.79

1.80

1.81

1.83

15

1:

23

/2

0

/2

6

,7

in

N

ith

9,

M

1.68

:3

7

9,

N

ith

in

,7

/2

6/

20

23

1:

15

:3

62

75

9,

N

75

62

75

62

62

75

9,

N

ith

in

,7

/2

6

/2

0

23

1:

15

:3

7

A

M

62

75

9,

N

ith

in

,7

/2

6/

20

23

1:

15

:3

7

A

M

62

75

9,

N

it h

in

,7

/2

6/

20

23

Lighting Power Densities Using Space-by-Space Method

Apparatus Dew points

Apparatus Dew points

Apparatus Dew points

Relative Density of Air at various temperatures

Relative Density of Air at various Altitudes

Standard Atmosphere Data for Altitudes to 60,000 Ft.

Dew Points in °F

Relative Humidity in percent

Equivalent Wind Chill Temperature of Cold Environments

Desirable Wind Speeds (m/s) for Thermal Comfort Conditions

Minimum Wind Speed (m/s) for just Acceptable Warm Conditions

Garment Insulation Values

Guidelines for Concentration Limits of Selected Air Contamination of Indoor Origin

Sources, Possible Concentrations, and Indoor to Outdoor Concentration

Ratios of some Indoor Pollutants

Table 1.53 : Minimum Ventilation Rates In Breathing Zone for Air-Conditioned Spaces

Table 1.54 : Minimum Exhaust Rates

Table 1.55 : Concentration of Interest for Selected Contaminants

Table 1.56 : Concentrations of Interest for Selected Volatile Organic Compounds

Table 1.57 : Recommended Values of Air changes (for ventilation only)

Table 1.58 : Maximum Permissible Wet Bulb Temperature for Given Dry Bulb Temperatures

(Industrial Ventilation Application)

Table 1.59 : Maximum allowable contaminant concentrations in Ventilation Air

Annual Average (Arithmetic Mean)

Table 1.60 : Temperature and Time Requirements For Killing Month in Stored Clothing

Table 1.61 : Refrigerating Effect (RE) Produced by Open Refrigerated Display Fixtures

Table 1.62 : Typical Recommended Design Criteria for Ventilation and Filtration for Office Buildings

Table 1.63 : Typical Recommended Indoor Temperature and Humidity in Office Buildings

Table 1.6 4 : Hotel Design Criteria

Table 1.65 : General Design Criteria temperature RH and Air Movement

Table 1.66 : Design Criteria for Hotel Back-of-House Areasa T & RH

Table 1.67 : Recommended Winter and Summer Design Dry-Bulb Temperatures for Various Spaces in Schoolsa

Table 1.68 : Filter Efficiencies for Central Ventilation and Air-Conditioning Systems in General Hospitalsc

Table 1.69 : Design Parameters for Areas Affecting Patient Care in Hospitals and Outpatient Facilities

Table 1.70 : Design Parameters for Areas Affecting Patient Care in Hospitals and Outpatient Facilities

Table 1.71 : Comparison of Regulations and Guidelines Pertinent to Indoor Environments

Table 1.72 : Pressure Relationships and Ventilation of Criteria Areas of Nursing Homes

Table 1.73 : Recommended Dry-Bulb Temperatures for Common Laboratory Animals

Table 1.74 : Heat Generated by Laboratory Animals

Table 1.75 : Exhaust Quantities for Test Cells

Table 1.76 : Typical Noise Levels in Test Cells

Table 1.77 : Sample Diesel Locomotive Engine Emission Dataa

Table 1.78 : Comparison of Construction Alternatives - Tall Buildings

Table 1.79 : Airborne Particle Concentration Limits from ISO Standard 14644-1

Table 1.80 : Air changes per Hour Versus Vertical Airflow Velocities, Room Heights

and Cleanliness Classes for HIGH BAY areas

Table 1.81 : Class 1, Class 2 and Selected NEBS Design Conditions

Table 1.82 : Types of air filters and its applications

Table 1.83 : Comparison of Standard of Filtration efficiency classification

Table 1.84 : The Beaufort Scale of Wind Force with Specifications and Velocity Equivalents

Table 1.85 : Generation of Gaseous Contaminants by Building Materials

Table 1.86 : Generation of Gaseous Contaminants by Building Materials

Table 1.87 : Total Body Emission of Some Gaseous Contaminants by Humans

it h

in

,7

/2

6/

20

23

Table 1.38 :

Table 1.39 :

Table 1.40 :

Table 1.41 :

Table 1.42 :

Table 1.43 :

Table 1.44 :

Table 1.45 :

Table 1.46 :

Table 1.47 :

Table 1.48 :

Table 1.49 :

Table 1.50 :

Table 1.51 :

Table 1.52 :

|

1:

15

:3

7

ISHRAE HVAC DATABOOK

1.84

1.85

1.86

1.86

1.87

1.87

1.87

M

A

M

A

1:

15

:3

7

Figures

Figure 1.1 :

Figure 1.2 :

Figure 1.3 :

Figure 1.4 :

Figure 1.5 :

Figure 1.6 :

Figure 1.7 :

Figure 1.8 :

Figure 1.9 :

Figure 1.10 :

Figure 1.11 :

Figure 1.12 :

Figure 1.13 :

1.4

1.37

1.49

1.56

1.69

1.78

1.81

1.82

1.83

1.84

1.85

1.95

1.96

1.91

1.92

A

7

:3

15

1:

23

20

6/

/2

in

9,

N

ith

2.2

2.3

2.5

2.5

2.5

2.5

2.6

2.8

2.9

2.11

2.12

2.12

2.13

A

:3

7

2.13

2.14

2.15

2.18

2.18

2.18

2.18

2.19

2.19

2.19

2.20

2.20

15

1:

23

/2

0

/2

6

,7

in

N

ith

9,

62

75

9,

N

ith

in

,7

/2

6

/2

0

23

1:

15

:3

7

A

M

62

75

9,

N

ith

in

SECTION - 2 : AIR DISTRIBUTION, DUCTS, DESIGN AND MATERIALS

Introduction

Table 2.1 :

Fan Laws

Table 2.2 :

Recommended Maximum Duct Velocities for Low Velocity Systems (FPM)

Table 2.3 :

Occupied Zone Room Air Velocities (3 ft. above floor level) in FPM

Table 2. 4 : Typical Design Velocities For HVAC Components

Table 2. 5 : Typical Terminal Velocities

Table 2.6 :

Duct Roughness Factor

Table 2.7 :

Recommended Maximum System Leakage (Percentage)

Table 2.8 :

Leakage as Percentage of Airflowa’b

Table 2.9 :

Equivalent Rectangular Duct Dimensions

Table 2.10 : Equivalent Flat Oval Duct Dimensions

Table 2.11: Unsealed Longitudinal Seam Leakage, Metal Ducts

Table 2.12 : Percent Section Area in Branches for Maintaining Equal Friction

Table 2.13 : Maximum Difference between Supply Air Temperature and

Room Dewpoint without Condensing Moisture on Duct (F)

Table 2.14 : Friction of Round Elbows

Table 2.15 : Friction of Rectangular Elbows

Table 2.16 : Galvanized Sheet Thickness

Table 2.17 : Stainless Steel Sheet Thickness

Table 2.18 : Uncoated Steel Sheet Thickness

Table 2.19 : Steel Angle Weight per Unit Length (Approximate)

Table 2.20 : Pressure Classification for Ductwork

Table 2.21 : Static Pressure in Ducts Classification

Table 2.22 : Recommended Return Inlet Face Velocities

Table 2.23 : Zinc Coating on Sheets

Table 2.24 : Mass of Coating (Total both sides)

M

,7

,7

/2

6/

20

23

1:

15

:3

7

A

M

Climate Zone Map of India

Double Glazing Unit Construction Detail

Office Equipment Load Factor Comparison (Wilkins and Me Gaffin 1994)

ASHRAE Summer and Winter Comfort Zones

Refrigerated Case Load Variation with Store Air Humidity

Size of Indoor Particles

Flow rate through leakage area under pressure Differential

Clean room air lock type

Energy Efficiency of Air Recirculation System

Recommended Data Center Class 1, Class 2 and NEBS Operating oF.

Class 1, Class 2 and NEBS Allowable Temperature Range Versus Altitude

Psychrometric Chart - Normal Temperature °F Design pressure : 760 mm hg

Psychrometric Chart - Low Temperature °F Design pressure : 760 mm hg

1.88

1.89

M

62

75

9,

N

it h

in

,7

/2

6/

20

23

1.92

1.93

1.93

1.93

1.94

62

75

9,

N

75

62

75

62

x

Filter Efficiencies

Electrically Operated Unitary Air-conditioners and Condensing

Units-Minimum Efficiency Requirements

Table 1.90 : Water - Chilling Packages - Efficiency Requirements a,b,c,

Table 1.91 : Electrically Operated Packaged Terminal Air-Conditioners,Single-Package

Vertical Air-Conditioner, Room Air-Conditioners, and Room Air-Conditioner Heat Pumps Minimum Efficiency Requirements

Table 1.92 : Performance Requirements for the Heat Rejection Equipment

Table 1.93 : Heat Transfer Equipment

Table 1.93A : Electricity Operated Variable-Refrigerant-Flow Air-Conditioners Minimum Efficiency Requirements

Table 1.94 : Air-Conditioners and Condensing Units Serving Computer Rooms

Table 1.95 : Cooling and Dehumidifying Heat Load Estimate Form

it h

in

,7

/2

6/

20

23

Table 1.88 :

Table 1.89 :

|

1:

15

:3

7

ISHRAE HVAC DATABOOK

M

A

M

A

1:

15

:3

7

62

75

9,

N

in

M

,7

/2

6/

20

23

1:

15

:3

7

A

M

15

:3

7

A

2.32

2.32

2.34

2.34

2.39

2.40

2.41

2.41

2.42

2.42

2.43

2.43

75

9,

N

ith

in

,7

M

A

:3

7

2.8

2.9

2.10

2.14

2.17

2.17

2.23

2.26

2.27

2.28

2.30

2.31

2.33

2.33

2.33

2.34

2.35

2.35

15

/2

6

/2

0

23

1:

15

:3

7

A

M

62

75

9,

N

ith

2.4

2.4

2.4

2.4

2.4

2.6

2.7

1:

23

/2

0

62

62

75

9,

N

ith

in

,7

Figure 2.8 :

Figure 2.9 :

Figure 2.10 :

Figure 2.11:

Figure 2.12:

Figure 2.13 :

Figure 2.14 :

Figure 2.15 :

Figure 2.16 :

Figure 2.17 :

Figure 2.18:

Figure 2.19 :

Figure 2.20 :

Figure 2.21 :

Figure 2.22 :

Figure 2.23 :

Figure 2.24 :

Figure 2.25 :

Fan Law For Speed Curves

Fan Law Air Flow

Fan Law Pressure

Fan Law Break Hoursepower

Centrifugal Fan Performance Curve

Criteria for Louver Sizing

Rigid Duct Design - Friction Chart

Friction chart for Round Duct, Air Density = 0.075 Ib/ft3 and x =0 0.003 ft

Round Flexible Duct

Duct Leakage

Air density correction factors

Duct Heat Gain VS Aspect Ratio

Losses for Round Fittings

Vane Location for Rectangular Elbow

Rectangular Duct / Transverse Joints

Rectangular External Reinforcement

Configuration of Seam in Duct IS : 655 / 2006

Structure of Joint by Angle Flange Technique - (IS : 655 / 2006)

Example of Configuration of Joint by same sheet flange technique (ISS 655 -2006)

Example of Configuration of Joint by slide on flange technique (IS : 655 / 2006)

Example of ‘N’ Seal Position (IS: 655 / 2006)

Example of ‘A’ Seal Position (IS: 655 / 2006)

Example of ‘B’ Seal Position (IS: 655 / 2006)

Example of ‘C’ Seal Position (IS: 655 / 2006)

Inside Standing Seam - Longitudinal 2 in Wg

Unreinforced Duct - SMACNA

/2

6

62

75

9,

N

ith

in

FIGURES

Figure 2.1 :

Figure 2.2 :

Figure 2.3 :

Figure 2.4 :

Figure 2.5 :

Figure 2.6 :

Figure 2.7 :

2.22

2.22

2.29

2.30

2.32

2.32

1:

23

20

,7

Table 2.38 :

Table 2.39 :

Table 2.40 :

Table 2.41 :

Tabte 2.42 :

Table 2.43 :

Table 2.44 :

Table 2.45 :

Table 2.46 :

Table 2.47 :

Table 2.48 :

6/

Table 2.37 :

/2

62

75

9,

N

Table 2.31 :

Table 2.32 :

Table 2.33 :

Table 2.34 :

Table 2.35 :

Table 2.36 :

xi

2.21

2.21

2.22

2.22

2.22

2.22

it h

in

,7

/2

6/

20

23

Classification by Internal Pressure of Duct and Pressure Range (IS 635-2006)

Tolerance on External Diameters of Circular Duct, Circular Spiral Duct and Socket Joint

Thickness of Sheet for Galvanized Steel Sheet Duct - (IS : 655 / 2006)

Thickness of Sheet for Stainless Steel Sheet Duct - (IS : 655 / 2006)

Thickness of Sheet for Rigid Polyvinyl Chloride Duct - (IS : 655 / 2006)

Thickness of Sheet for Galvanized Steel Sheet Duct and

Stainless Steel Sheet Duct Round - (IS : 655 / 2006)

Thickness of Sheet for Circular Spiral Galvanized Steel Sheet Duct - (IS : 655 / 2006)

Thickness of Sheet for Circular Spiral Stainless Steel Sheet Duct (IS : 655 / 2006)

Material for Joint of Low Pressure Duct by Angle Flange Technique (IS : 655 / 2006)

Material for Joint by Same Sheet Flange Technique IS : 655 / 2006

Joint Flange of Slide on Flange Technique (IS: 655 / 2006)

Minimum Values of Thickness of Sheet for Corner Metal Fittings and

Diameter of Bolt (IS : 655 / 2006)

Fixing Spacing and Number of Flange Pressure Metal Fittings

(with Bolt) Size of Joint Flange (IS 655 / 2006)

Longitudinal Reinforcement between Joints of Rectangular Duct (IS : 655 / 2006)

Unreinforced Duct (Wall Thickness) as per SMACNA

Minimum Thickness of Slip / Drive

Allowable Loads in Pounds for Trapeze Hangars

Duct Surface area in Square Feet per Linear Foot

Rectangular Duct Hangers, Minimum Size

Velocity Pressures

Minimum Duct Seal Levels

Aluminium Sheet (Weight and Thickness)

Chemical Composition of CRCA Sheets (IS 513 : 2008)

Louver Dampers Design

it h

in

,7

/2

6/

20

23

Table 2.25 :

Table 2.26 :

Table 2.27 :

Table 2.28 :

Table 2.29 :

Table 2.30 :

|

1:

15

:3

7

ISHRAE HVAC DATABOOK

M

A

M

A

1:

15

:3

7

A

7

:3

15

1:

23

20

6/

/2

,7

in

ith

N

9,

M

A

:3

7

A

1:

23

/2

0

/2

6

,7

in

N

ith

9,

75

62

in

N

ith

9,

75

62

3.3

3.4

3.5

3.5

3.5

3.6

3.7

3.21

3.21

3.21

3.21

15

:3

7

/2

6

/2

0

23

1:

15

Friction Loss for Closed piping Systems (Water)

Friction Loss for Open piping Systems (Water)

Friction loss for Water in Commercial Steel Pipe (Schedule - 40)

Friction loss for Water in Copper Pipe (Types K.L.M.)

Friction loss for Water in Plastic Pipe (Types Schematic )

Elbow equivalent of T’s at various flow conditions

Net Positive Suction Head Available

Cooling Tower Piping System

Schematic Piping Layout Showing Static and Suction Head

Variable Flow Chilled-water System (Primary / Secondary)

Variable Flow Chilled Water System

,7

FIGURES

Figure 3.1 :

Figure 3.2 :

Figure 3.3 :

Figure 3.4 :

Figure 3.5 :

Figure 3.6 :

Figure 3.7 :

Figure 3.8 :

Figure 3.9 :

Figure 3.9a :

Figure 3.10 :

M

62

75

9,

N

3.2

3.6

3.8

3.9

3.10

3.11

3.11

3.12

3.12

3.13

3.13

3.14

3.14

3.15

3.16

3.16

3.16

3.17

3.17

3.18

3.18

3.19

3.19

3.20

3.20

3.30

3.30

3.31

3.33

3.33

3.34

3.34

M

62

75

9,

N

ith

in

,7

/2

6/

20

23

1:

15

:3

7

A

M

62

75

9,

N

SECTION - 3 : WATER/STEAM PIPING DESIGN AND MATERIALS

INTRODUCTION

Table 3.1 :

Equivalent Length in Feet of Pipe for 90° elbows

Table 3.2 :

Flow of Water in Steel Pipe of Larger diameters

Table 3.3 :

Flow of Water in Steel Pipe of Larger diameters

Table 3.4 :

Flow of Water in Steel Pipe of Larger Diameters

Table 3.5 :

Friction Losses for Copper Pipe and Tubing

Table 3.6 :

Friction Losses for Copper Pipe and Tubing

Table 3.7 :

Friction Losses for Copper Pipe and Tubing

Table 3.8 :

Friction Losses for Copper Pipe and Tubing

Table 3.9 :

Friction Losses for Copper Tube and Piping

Table 3.10 : Friction Losses for Copper Tube and Piping

Table 3.11 : Friction Losses fsor Copper Piping and Tubing

Table 3.12 : Iron and Copper Elbow Equivalents*

Table 3.13 : Specification for Mild Steel Tubes, Tubular and Other Wrought Iron Fittings

Table 3.14 : Application of Pipe, Fittings, and Valves for Heating and Air-conditioning

Table 3.15 : Larger Diameter pipes as per IS : 3589 Physical Data

Table 3.16 : Compatibility of Plastic Materials

Table 3.17 : Fitting Losses in Equivalent Metres of Pipe

Table 3.18 : Special Fitting Losses in Equivalent Metres of Pipe

Table 3.19 : Proper Flow and Pressure Required During Flow For Different Fixtures

Table 3.20 : Pressure drops used for sizing steam pipe*

Table 3.21 : Suggested Hanger Spacing and Rod Size for Straight Horizontal Pipe Runs

Table 3.22 : Valve Losses in Equivalent Meters of Pipe

Table 3.23 : Fouling Factors

Table 3.24 : Heat Transfer Surface Required to Offset Fouling

Table 3.25 : Low Pressure Steam Pipe Capacities Pounds Per Hour

Table 3.26: Medium Pressure Steam Pipe Capacities (30 psig)

Table 3.27 : Important Properties of Gasket Materials

Table 3.28 : Peak Day Full-Storage TES storage Sizing Calculation (Typical)

Table 3.29 : Chilled Water Density

Table 3.30 : Peak Day Partial-Storage TES Sizing Calculations (Typical)

Table 3.31 : Design Day Chiller and Storage Load Contributions and

Leaving Coolant Temperatures (LCT) (Typical)

75

62

xii

2.36

2.36

2.37

2.38

2.38

2.44

it h

in

,7

/2

6/

20

23

Duct Reinforced on all sides - SMACNA

Corner Closures - Slips and Drives - SMACNA

Corner Closures - Flanges - SMACNA

Corner Closures - Flanges - SMACNA

Corner Closures - Flanges - SMACNA

Leakage Test Meter Apparatus - Flange Taps (SMACNA)

it h

in

,7

/2

6/

20

23

Figure 2.26 :

Figure 2.27 :

Figure 2.28 :

Figure 2.29 :

Figure 2.30 :

Figure 2.31 :

|

1:

15

:3

7

ISHRAE HVAC DATABOOK

M

A

M

A

A

7

:3

15

1:

23

20

6/

A

:3

7

15

1:

23

/2

0

4.2

4.3

4.3

4.4

4.5

4.6

4.7

4.8

4.9

4.9

4.10

4.10

4.11

4.11

4.12

4.12

4.13

4.14

4.15

4.16

4.17

4.18

4.19

4.20

4.21

4.21

M

/2

,7

/2

6

in

N

ith

9,

75

62

in

N

ith

9,

75

62

,7

/2

6

/2

0

23

1:

15

:3

7

A

M

62

75

9,

N

ith

in

,7

SECTION - 4 : REFRIGERANT PIPING

Compressor capacity Vs Line Pressure Drop at 42° F Evaporator Temperature R-134a, and R-502

Equivalent Length for Fittings (feet)

Equivalent Length for Valves and Refrigeration Devices (feet)

R-22 Refrigerant Line Sizing Table (Tons)

R-134 a Refrigerant Line Size Table (Tons)

R404A Refrigerant Line Size table (Tons)

R-410 A Refrigerant Line Size Table (Tons)

R-407 C Refrigerant Line Size Table (Tons)

R-22 Minimum Capacity For Suction Riser (Tons)

R-134a Minimum Capacity For Suction Riser (Tons)

R 410A Minimum Capacity for Suction Riser (Tons)

R-407C Minimum Capacity for Suction Riser (Tons)

R-22 Minimum Capacity for Discharge Riser (Tons)

R-134a Minimum Capacity for Discharge Riser (Tons)

R-410A Minimum Capacity For Discharge Riser (Tons)

R-407C Minimum Capacity For Discharge Riser (Tons)

R-22 Suction Gas Velocity Correction Factors

R-134a Suction Gas Velocity Correction Factors

R- 410A Suction Gas Velocity Correction Factors

R-407C Suction Gas Velocity Correction Factors

R-22 Discharge Gas Velocity Correction Factors

R-134a Discharge Gas Velocity Correction Factors

R-410a Discharge Gas Velocity Correction Factors

R-407C Discharge Gas Velocity Correction Factors

R-22 Refrigerant Charge (Ibs. Per 100 Feet of Pipe)

R-134a Refrigerant Charge (Ibs. Per 100 Feet of Pipe)

,7

62

75

9,

N

ith

in

Table 4.1:

Table 4.2 :

Table 4.3 :

Table 4.4 :

Table 4.5 :

Table 4.6 :

Table 4.7 :

Table 4.8 :

Table 4.9 :

Table 4.10 :

Table 4.11 :

Table 4.12 :

Table 4.13 :

Table 4.14 :

Table 4.15 :

Table 4.16 :

Table 4.17 :

Table 4.18 :

Table 4.19 :

Table 4.20 :

Table 4.21 :

Table 4.22 :

Table 4.23 :

Table 4.24 :

Table 4.25 :

Table 4.26 :

3.21

3.22

3.23

3.23

3.23

3.24

3.24

3.25

3.26

3.27

3.27

3.28

3.28

3.29

3.33

3.33

3.33

3.34

3.34

3.34

3.35

3.35

3.35

3.35

3.35

3.35

M

it h

in

,7

/2

6/

20

23

62

75

9,

N

/2

6/

20

23

1:

15

:3

7

A

M

62

75

9,

N

it h

in

,7

/2

6/

20

23

Figure 3.11 : Cooling Water

Figure 3.12 : Energy use in HVAC Pumping

Figure 3.13 : Vertical Building Chilled Water Piping

Figure 3.14 : Reverse return for low control valve differential

Figure 3.15 : Secondary Chilled water system with coil circulator (Example)

Figure 3.16 : Classification of HVAC pumps

Figure 3.17 : Distributed pumping with small circulators in chilled plant

Figure 3.18 : HVAC pumps and their Performance

Figure 3.19 a : Steam Pipe Sizing

Figure 3.19 b : Steam Pipe Sizing

Figure 3.19 c : Steam Pipe Sizing

Figure 3.19 d : Steam Pipe Sizing

Figure 3.19 e : Steam Pipe Sizing

Figure 3.20 : Velocity Multiplier

Figure 3.21 : Typical Temperature Stratification Profile in Storage Tank

Figure 3.22 : Typical Chilled Water Storage Profiles

Figure 3.23 : Full Storage TES Tank Peak Day Operation Facility Cooling Load versus chiller output

Figure 3.24 : Typical Sensible Storage Connection Scheme

Figure 3.25 : Charge mode status of direct Transfer Pumping Interface

Figure 3.26 : Direct Transfer Pumping Interface

Figure 3.27 : Indirect Transfer Pumping Interface

Figure 3.28 : Parallel Flow for Chiller and Storage

Figure 3.29 : Series Flow, Chiller Upstream

Figure 3.30 : Charge Mode status of Indirect Transfer Pumping Interface

Figure 3.31 : Series Flow, Chiller Downstream

Figure 3.32 : Primary / Secondary Chilled Water Plant with Stratified storage tank as decoupler

xiii

1:

15

:3

7

|

1:

15

:3

7

ISHRAE HVAC DATABOOK

M

A

M

A

R-22 Suction Gas Velocity

R-134a Suction Gas Velocity

R-410A Suction Gas Velocity

R-407C Suction Gas Velocity

R-22 Discharge Gas Velocity

R-134a Discharge Gas Velocity

R-410a Discharge Gas Velocity

R-407C Discharge Gas Velocity

62

75

9,

N

M

5.2

5.5

5.7

5.9

5.11

5.13

5.14

5.14

5.14

5.14

5.15

5.15

FIGURES

Figure 5.1 :

Figure 5.2 :

Figure 5.3 :

Figure 5.4 :

Figure 5.5 :

Pressure Enthalpy Diagram R-22

Pressure Enthaply Diagram R-134a

Pressure Enthaply Diagram R-404A

Pressure Enthaply Diagram R-407C

Thermophysical Properties of Refrigerants R-410A

:3

15

1:

23

20

6/

,7

62

75

9,

N

ith

in

,7

/2

6

/2

0

23

1:

15

:3

7

A

M

in

ith

N

9,

75

62

M

A

:3

7

15

1:

23

/2

0

9,

N

ith

in

,7

/2

6

9,

N

ith

in

,7

/2

6/

20

23

1:

15

:3

7

SECTION - 5 : REFRIGERANT, SECONDARY COOLANTS AND LUBRICANTS

Refrigerants Pressure Temperature

Thermophysical Properties of Refrigerants R-22

Thermophysical Properties of Refrigerants

Thermophysical Properties of Refrigerants

Thermophysical Properties of Refrigerants

Thermophysical Properties of Refrigerants

Recommended viscosity ranges for lubricants in small and commercial systems

Typical Properties of Refrigerant Lubricants - Industrial Refrigeration

Mutual Solubility of Refrigerant and Mineral Oil

Typical Properties of Refrigerant Lubricants

Physical Properties - SUN ISO - Oils - Data

Physical Properties - SUN ISO - Oils - Data

7

/2

A

M

4.27

4.27

4.27

4.27

4.27

4.27

4.27

Table 5.1 :

Table 5.2 :

Table 5.3 :

Table 5.4 :

Table 5.5 :

Table 5.6 :

Table 5.7 :

Table 5.8 :

Table 5.9 :

Table 5.10 :

Table 5.11 :

Table 5.12:

75

62

4.24

4.25

4.26

4.26

4.13

4.14

4.15

4.16

4.17

4.18

4.19

4.20

75

62

4.23

A

62

75

9,

N

Table 4.31 :

Table 4.32 :

Table 4.33 :

Table 4.34 :

1:

15

:3

7

FIGURES

Figure 4.1 :

Figure 4.2 :

Figure 4.3 :

Figure 4.4 :

Figure 4.5 :

Figure 4.6 :

Figure 4.7 :

Figure 4.8 :

Table 4.30 :

xiv

4.21

4.21

4.22

it h

in

,7

/2

6/

20

23

Table 4.35 :

Table 4.36 :

Table 4.37 :

Table 4.38 :

Table 4.39 :

Table 4.40 :

Table 4.41 :

R-410A Refrigerant Charge (Ibs. Per 100 Feet of Pipe)

R-407C Refrigerant Charge (Ibs. Per 100 Feet of Pipe)

Suction, Discharge, and Liquid Line Capacities in Tons for Ammonia

(Single-or High-Stage Applications)

Liquid Ammonia Line Capacities in overfeed systems

(Capacity in tons refreigeration except as noted)

Copper Tube Data

Seamless Steel Pipe Data

Internal Working Pressure for Copper Tube Joints

Weight of Copper Tubes in Various Sizes and Gauges External Diameter Weight in Kilograms per meter

Soft Copper Tubing Physical Data

Relative Sizes of Branches and Mains

Recommended Support Spacing for Schedule 40 Pipes

Recommended Support Spacing For Copper Tubing

Temperature versus pressure drop

Initial and Final Concentrations of Refrigerants at Different Locations

Reduction in Performance After Refrigerant Leak / Recharge

it h

in

,7

/2

6/

20

23

Table 4.27 :

Table 4.28 :

Table 4.29 :

|

1:

15

:3

7

ISHRAE HVAC DATABOOK

5.4

5.6

5.8

5.10

5.12

M

A

M

A

6.2

6.3

6.3

6.4

6.5

6.5

6.6

6.7

6.10

6.11

6.11

6.11

6.12

A

6.12

7

6.13

6.13

15

Table 7.1 :

Table 7.2 :

Table 7.3 :

Table 7.4 :

Table 7.5 :

Table 7.6 :

Table 7.7 :

Table 7.8 :

Table 7.9 :

Table 7.10 :

Table 7.11 :

SECTION - 7 : NOISE AND VIBRATION

Decibel Addition Chart

Octave Band properties

Sound Pressure Levels for Each NC Level

Sound Pressure Levels for NR Levels

A-Weighted Octave Band Adjustments

Comparison of Sound Rating Methods

Typical Municipal Code Noise Limits

Typical Sound Absorption Coefficients

Sound Sources, Transmission Paths, and Recommended Noise Reduction Methods

Sound Pressure Scales

Subjective Effect of Changes in Sound Pressure Levels, broadband Sounds

6.14

6.14

6.15

6.16

6.16

6.16

6.17

6.17

6.18

6.18

A

:3

7

7.3

7.3

7.4

7.5

7.5

7.5

7.5

7.6

7.7

7.7

7.8

15

1:

23

/2

0

/2

6

,7

in

N

ith

9,

75

62

N

ith

in

,7

/2

6

/2

0

23

1:

15

:3

7

A

M

6.7

6.8

6.9

6.10

6.15

M

1:

23

20

6/

/2

,7

in

ith

N

9,

Steady State Heat Transfer

Thermal Resistance of Insulation to prevent surface condensation

Conversion of Equivalent Thickness to Actual Thickness for Pipe Insulation

Duct Heat Gain or Loss

Insulating Pipe Hangers

9,

M

6.12

:3

it h

in

,7

/2

6/

20

23

62

75

9,

N

75

62

62

75

9,

N

ith

in

,7

/2

6/

20

23

1:

15

:3

7

A

M

62

75

9,

N

it h

in

,7

/2

6/

20

23

SECTION - 6 : THERMAL INSULATION OF DUCTS AND PIPES

Introduction

Table 6.1 :

Temperature limits of some common insulation materials

Table 6.2 :

Basic Types of Insulation- Low Temperature

Table 6.3 :

Basic Types of Insulation- Intermediate Temperature 60°F

Table 6.4 :

Protective Coverings And Finishes

Table 6.5 :

Comparison of Properties of Thermal Insulation Materials

Table 6.6 :

Building Insulation Materials - Roof / Walls / Floor Etc.

Table 6.7 :

Performance Property guide for Insulation Materials

Table 6.8 :

Maximum difference between Supply Air temperature and Room Dewpoint without

condensing Moisture on Ducts (F)

Table 6.9 :

Insulation Thickness Required to Prevent Surface Condensation

Table 6.10 : Insulation thickness of Cooling Systems

Table 6.11 : Recommended Insulation Thickness of Phenolic Foam, in inches

Table 6.12 : Recommended Thickness of Expanded polystyrene (in mm) for pipe insulation at

carious operating Temperatures

Table 6.13 : Recommended Thickness of High Density Polyethylene in Inches for Pipe insulation at

various operating Temperatures

Table 6.14 : Recommended Thickness of Polyurethane Foam in Inches for Pipe insulation at

various operating Temperatures

Table 6.15 : Thickness Recommendation to Control Condensation in Pipe insulation

of Cooling Lines - Nitrile Foam Rubber.

Table 6.16 : Thickness Recommendation for insulation of Ducting, Tanks and Equipment of

Cooling Systems - Nitrile Foam Rubber

Table 6.17 : Minimum Duct Insulation R-Valuea Cooling and Heating Only Supply Ducts and Return Ducts

Table 6.18 : Minimum Pipe Insulation Thicknessa

Table 6.19 : Minimum Duct Insulation R-Valuea Combined Heating and Cooling Supply Ducts and Return Ducts

Table 6.20 : Minimum Saddle spacing for Use with Fibrous Glass Pipe Insulation

Table 6.21: Minimum Saddle spacing for Use with 2 Ib/ft3 Polyisocyanurate Foam

Insulation (0.5 to 3 in. thick)

Table 6.22 : Emittance Data of Commonly Used Materials

Table 6.23 : Inner and Outer Diameters of Standard Tubing Insulation

Table 6.24 : Inner and Outer Diameters of Standard Pipe Insulation

Table 6.25 : Inner and Outer Diameters of Standard Flexible Closed-Cell Pipe Insulation

Table 6.26 : Inner and Outer Diameters of Standard Flexible Closed-Cell Tubing Insulation

FIGURES

Figure 6.1 :

Figure 6.2 :

Figure 6.3 :

Figure 6.4 :

Figure 6.5 :

75

62

xv

1:

15

:3

7

|

1:

15

:3

7

ISHRAE HVAC DATABOOK

M

A

M

A

:3

15

1:

23

20

6/

/2

,7

in

ith

N

9,

75

62

62

75

9,

N

ith

in

,7

/2

6

/2

0

23

1:

15

:3

7

A

M

A

:3

7

15

23

M

A

7.11

7.11

7.11

7.11

7.11

7.12

7.13

7.14

7.15

7.16

7.16

7.17

7.17

7

A

M

62

75

9,

N

7.9

7.9

7.9

7.10

7.10

7.11

7.11

7.11

7.11

7

:3

15

1:

23

20

6/

/2

0

/2

6

,7

in

N

ith

9,

75

62

7.9

7.18

7.18

7.19

7.20

7.20

7.20

7.20

7.21

7.21

7.22

7.26

7.26

7.26

1:

62

75

9,

N

ith

in

,7

Table 7.26 :

Table 7.27 :

Table 7.28 :

Table 7.29 :

Table 7.30 :

Table 7.31 :

Table 7.32 :

Table 7.33 :

Table 7.34 :

Table 7.35 :

Table 7.36 :

Table 7.37 :

Table 7.38 :

/2

62

75

9,

N

Table 7.17 :

Table 7.18 :

Table 7.19 :

Table 7.20 :

Table 7.21 :

Table 7.22 :

Table 7.23 :

Table 7.24 :

Table 7.25 :

7.8

7.8

7.9

M

NC Curves

RC Curves

Frequency Ranges where various HVAC equipment affect sound levels3

Graph of Sound pressure V/s. Distance in a free field

Typical Sound Absorption Coefficients

Typical Sound Pressure Levels

International standard A, B and C - weighting curves for sound level meters

Typical Elbow Fitting

Table 7.16 :

1:

15

:3

7

FIGURES

Figure 7.1 :

Figure 7.2 :

Figure 7.3 :

Figure 7.4 :

Figure 7.5 :

Figure 7.6 :

Figure 7.7 :

Figure 7.8 :

Table 7.13 :

Table 7.14 :

Table 7.15 :

xvi

7.8

it h

in

,7

/2

6/

20

23

Table 7.39 :

Table 7.40 :

Table 7.41 :

Table 7.42 :

Table 7.43 :

Table 7.44 :

Table 7.45 :

Table 7.46 :

Table 7.47 :

Table 7.48 :

Table 7.49 :

Table 7.50 :

Table 7.51 :

Guidelines for Determining Equipment Sound Levels in Presence of

Contaminating Background Noise

Typical Sound Power Outputs

Recommended Indoor design Goals for Air-conditioning System Sound Control

Recommended Ambient Sound Levels for Different Areas of Occupancy in Buildings

(Space Furnished but unoccupied) Australian Standard 2107-1997

Maximum Recommended “Free” Supply Outlet and Return Air Opening Velocities

Needed to Achieve Specified Acoustic Design Criteria

Sound Attenuation in Unlined Rectangular Sheet Metal Ducts

Ceiling Plenum Attenuation with T-Bar Suspension

Flexible Ducts Attenuation

End Reflection Duct terminated in Free Space

Transmission Loss Values Across Barriers

End Reflection Duct Terminated in Wall

Correction Co-efficient for Wall Construction

Maximum Recommended Duct Velocities to Achieve Specified Acoustic Design Criteria

Maximum Recommended “Free” Supply Outlet and Return Air Opening Velocities

to Achieve Specified Acoustic Design Criteria

Insertion Loss for Rectangular Unlined Duct

Insertion Loss for Round Unlined Duct

Insertion Loss For Square Elbows Without Turning Vanes

Insertion Loss for Square Elbows Without Turning Vanes

Insertion Loss for Round Elbows without Turning Vanes

Insertion Loss for Acoustically Lined Circular Ducts with 25-mm Fiberglass Lining

Insertion Loss for Acoustically Lined Circular Ducts with 50-mm Fiberglass Lining

Insertion Loss for Rectangular Sheet Metal Ducts with 25-mm Fiberglass Lining

Insertion Loss for Rectangular Sheet Metal Ducts with 50-mm Fiberglass Lining

Insertion Loss Values of an Ideal Solid Barrier

Octave Band in Which Blade Frequency Increment (BFI) Occursa

Correction Factor C, for Off-Peak Operation

Specific Sound Power Levels (dB re 1pW) and Blade Frequency Increments (BFI)

for Various Types of Fans

Typical Noise Levels Produced by Mechanical Room Equipment

Attenuation of Miscellaneous Items of Equipment

Equipment Vibration criteria

Equipment Vibration criteria

Equipment Vibration criteria

The Natural Frequency of an Isolator as a Function of its Static Deflection Under Load

Recommended Deflection Ranges for Common Types of Industrial Isolators

Recommended Spring Diameters (inches) For Free-Standing Springs

Common Causes of Vibration other than unbalance at Rotation Frequency

Selection Guide for Vibration Isolation

National Standards on Occupational Noise Exposure Limits

Pumping System Noise Analysis Guide

Recommended Live Lengtha of Flexible Rubber and Metal Hose

it h

in

,7

/2

6/

20

23

Tabie 7.12 :

|

1:

15

:3

7

ISHRAE HVAC DATABOOK

7.3

7.4

7.6

7.6

7.6

7.6

7.8

7.11

M

A

M

A

1:

15

:3

7

xvii

7.16

7.19

7.20

7.21

it h

in

,7

/2

6/

20

23

Noise Barriers

Building Vibration Criteria

Equipment Vibration Criteria

Isolator Natural Frequency

it h

in

,7

/2

6/

20

23

Figure 7.9 :

Figure 7.10 :

Figure 7.11 :

Figure 7.12 :

|

1:

15

:3

7

ISHRAE HVAC DATABOOK

A

7

:3

15

1:

23

20

6/

/2

,7

in

ith

N

9,

75

62

8.15

62

75

9,

N

ith

in

,7

/2

6

/2

0

23

1:

15

A

:3

7

A

8.16

8.16

8.16

8.17

8.18

8.18

8.18

M

8.15

:3

7

15

1:

23

/2

0

/2

6

,7

in

N

ith

9,

75

62

8.2

8.3

8.3

8.4

8.5

8.6

8.6

8.7

8.7

8.7

8.8

8.8

8.9

8.10

8.10

8.11

8.11

8.11

8.12

8.12

8.13

8.13

8.14

8.15

M

62

75

9,

N

ith

in

,7

/2

6/

20

23

1:

15

:3

7

A

M

62

75

9,

N

Common Temperature Measurement Techniques

Thermocouple Tolerances On Initial Values Of Electromotive Force Versus Temperature

Humidity Sensor Properties Humidity Measurement

Air Velocity Measurement

Volumetric or Mass Flow Rate Measurement

Motor and Motor Control Equipment Voltage (Alternate Current)

Characteristics of AC Motors (Nonhermetic)

Fuse Wire Table

Energy Limiting H.R.C Cartridge Fuse Links Direct on Line Start Squirrel Cage Induction Motors

MCB (Current Limiters) Selection Chart Full load current/Recommended rating of MCBs

CISM-M AND D50S-WP Rectangular Bus Bar: Mechanical And Electrical Characteristics

D50S-W - Rectangular Bus Bar - Current Ratings

Aluminum Conductor Steel Reinforced Properties (A.C.S.R)

All Aluminum (Standard) Conductors Properties (A.A.C)

Aluminum Strips Weight (Appx.) in K.G. per 12 RFT

Recommended Cable Sockets (Tinned Copper) For Aluminum Conductor

Starting Torques and Currents

Comparison of Starters

Ready Reckoner for DOL start Motors - 415 V. 3phase, 50 Hz

Ready Reckoner for Star Delta start Motors - 415 V. Sphase, 50 Hz

Recommended Capacitor Ratings

AC Rating of Paper Insulated Power Cables

Estimated Current Ratings for Copper and Aluminum Conductor, Vulcanized

Rubber P.V.C. or Polythene Insulated Cables (Single, Twin, Three and Four Core)

Table 8.24 : Current Ratings And Rating Factors For PVC Cables Current Ratings of Single,

Twin and Multi-Core PVC Heavy Duty Cables 650-1100 V (Aluminum Conductors)

Table 8.25 : XLPE (Cross-Linked Polyethene) Cables Current Ratings for 6.6,11 and 22 KV. Single /

Multi - core Armored / Unarmored Cables Aluminum Conductors

Table 8.26 : Earthing Ready Reckoner Equipment Earthing - Size of Earth Lead (Transformer,

Motors, Generators, Switchgears Etc.)

Table 8.27 : Current Ratings for Copper Conductor Vulcanized Rubber Insulated Flexible Cables to IS 434

Table 8.28 : Overload Relay Selection

Table 8.29 : Current Capacity and Size of Cables for Distribution Transformers

Table 8.30 : Metric Wire Approximate Weights and Lengths

Table 8.31 : Capacities of PVC Conductors

Table 8.32 : Cross Sectional Areas of Steel Conductors

Table 8.34 : Thickness in mm & Weight in Kgs. Approximate Reflection Factor of

Common Surface Materials & Colors

Table 8.35 : Incandescent Lamp Data

Table 8.36 : High Pressure Mercury Vapour Lamps

Table 8.37 : Fluorescent Tubular Lamp Data

Table 8.38 : Effect of Variation of Voltage and Frequency on Motor Performance

Table 8.39 : Degree of Protection

Table 8.40 : Terminal Box Data - Motors

Table 8.41 : Bearing Arrangement

Table 8.42 : Dimensions

Table 8.43 : Dimensions - Cooling Tower Motors

62

75

9,

N

Table 8.1 :

Table 8.2 :

Table 8.3 :

Table 8.4 :

Table 8.5 :

Table 8.6 :

Table 8.7 :

Table 8.8 :

Table 8.9 :

Table 8.10 :

Table 8.11 :

Table 8.12 :

Table 8.13 :

Table 8.14 :

Table 8.15 :

Table 8.16 :

Table 8.17 :

Table 8.18 :

Table 8.19 :

Table 8.20 :

Table 8.21 :

Table 8.22 :

Table 8.23 :

M

SECTION - 8 : ELECTRICAL MOTORS, STARTERS, CABLES AND MEASUREMENT SENSORS

8.18

8.18

8.19

8.19

8.20

8.20

8.20

8.21

8.23

M

A

M

A

Standard Pitot Tube

Degree of Protection

Foot Mounted Motors (B3)

8.26

8.26

8.26

8.27

8.27

8.28

8.28

62

75

9,

N

62

75

9,

N

1:

15

:3

7

FIGURES

Figure 8.1 :

Figure 8.2 :

Figure 8.3 :

xviii

8.24

8.26

8.26

8.26

it h

in

,7

/2

6/

20

23

Table 8.48 :

Table 8.49 :

Table 8.50 :

Table 8.51 :

Table 8.52 :

Table 8.53 :

Table 8.54 :

Cooling Tower Motor - Electrical Performance

Rating Factors for Cable in Free Air

Rating Factors for Cable in Ground

Group rating factors for circuits of three single core cable,

in trefoil and laid flat touching horizontal formation

Group rating factors for Multicore Cable in Horizontal Formation

Rating Factors for Soil Thermal Resistivity

Rating Factors for depth of Laying (to centers of cable or trefoil group of cable)

Current Ratings for 0.6 /1 (1.2) kV Unarmoured XLPE Cable

Current Ratings for 0.6 /1 (1.2) kV Armoured XLPE Cable

Current Ratings for 1.9 / 3.3 (3.6) kV Armoured XLPE Cable

Current Ratings for Armoured XLPE Cable

it h

in

,7

/2

6/

20

23

Table 8.44 :

Table 8.45 :

Table 8.46 :

Table 8.47 :

|

1:

15

:3

7

ISHRAE HVAC DATABOOK

8.5

8.18

8.21

M

A

A

M

SECTION - 9 : GREEN BUILDINGS

7

:3

15

1:

23

20

6/

/2

in

ith

N

9,

75

A

:3

7

15

1:

23

/2

0

/2

6

,7

in

N

ith

9,

75

62

62

75

9,

N

ith

in

,7

/2

6

/2

0

23

1:

15

:3

7

A

M

10.2

10.2

10.2

10.2

10.3

10.4

10.5

10.6

10.7

10.8

10.9

10.11

10.12

10.13

M

62

in

ith

N

9,

75

62

,7

/2

6/

20

23

1:

SI Base and Supplementary Quantities and units

Derived units of SI which have Special Names

Additional Common Derived Units of SI

SI Prefixes

Conversion Factors: Customary and Commonly Used Units to SI Units

Conversion Factors: US Customary and Commonly Used Units to SI Units

Conversion Factors : Customary and Commonly Used Units to SI Units

Conversion Factors : Customary and Commonly Used Units to SI Units

Conversion Factors : Customary and Commonly Used Units to SI Units

Conversion Factors : Customary and Commonly Used Units to SI Units

Alphabetical Listings of Common Conversions

Conversion To SI Units

Conversion Factors

Temperature Converter

,7

Table 10.1 :

Table 10.2 :

Table 10.3 :

Table 10.4 :

Table 10.5 :

Table 10.6 :

Table 10.7 :

Table 10.8 :

Table 10.9 :

Table 10.10 :

Table 10.11 :

Table 10.12 :

Table 10.13 :

Table 10.14 :

15

:3

7

SECTION - 10 : UNITS AND CONVERSIONS

M

A

M

A

A

23

20

15

:3

7

A

in

ith

N

9,

75

62

M

A

:3

7

1:

23

/2

0

,7

in

N

ith

62

75

9,

N

ith

in

,7

/2

6

15

1:

23

Section - 15 : About ISHRAE

/2

6

/2

0

Section - 14 : GLOSSARY

9,

75

62

M

6/

/2

13.2

13.2

13.2

13.3

13.3

13.3

13.3

13.3

13.3

13.4

13.4

13.4

13.4

13.4

13.5

13.5

,7

/2

6/

SECTION - 13 : SAFETY FOR AIR-CONDITIONING

AND REFRIGERATION ENGINEERS

,7

in

ith

N

9,

75

62

1:

15

:3

7

A

7

:3

15

1:

23

20

Section - 12 : INTERNATIONAL CODES AND PRACTICE

Types of Accidents

Physical Injuries From Mechanical Causes

Use of Tools

Miscellaneous Precautions

Electrical Injuries

Electrical Safety Rules

Injuries Due To High Pressure

Refrigerant Cylinders

Corrosion

Precautions

Burns and Scalds

Refrigerant and Other Gases

Construction Materials

Firefighting Precautions

Breathing Toxic Gases

Asphyxiation

M

62

75

9,

N

it h

in

,7

/2

6/

20

23

11.2

11.2

11.2

11.2

11.2

11.2

11.3

11.3

11.3

11.3

11.4

11.4

11.4

11.4

11.5

11.5

11.5

11.5

11.5

11.5

11.5

M

62

75

9,

N

it h

in

,7

/2

6/

20

23

SECTION - 11 : IS CODES & STANDARDS

Air-conditioning Equipment

Chimneys

Electrical wire and cables

Earthing

Fuses

Motors

Switchgear and controls

Wiring Accessories

Noise and Vibrations

Pipes and Fittings

Pump and Valves

Refrigerants and Lubricants

Safety

Sheet metal work

Thermal insulation

Ventilation

International codes and practices

Abbreviations and addresses

Bureau of Indian standards

Regional Offices

Branch sales offices

xix

1:

15

:3

7

|

1:

15

:3

7

ISHRAE HVAC DATABOOK

M

A

M

A

it h

in

,7

/2

6/

20

23

62

75

9,

N

16.2

16.4

16.6

16.9

16.10

16.12

16.14

16.16

16.18

16.19

16.20

16.20

16.21

16.21

:3

7

A

16.22

16.23

16.29

16.30

16.31

16.32

16.32

16.32

16.33

16.33

16.33

16.34

16.35

16.44

16.47

16.48

16.48

16.49

15

1:

23

20

6/

/2

,7

in

ith

N

9,

75

62

62

75

9,

N

ith

in

,7

/2

6/

20

23

1:

15

:3

7

A

M

62

75

9,

N

PROCEDURE TO USE CLTD PROGRAMME

Table 16.1.1 :

Climate conditions for Cities in Deg. C

Table 16.1.2 :

Monthly Mean, Maximum and Range - DB °F

Table 16.1.3 :

Typical Inside Design Conditions - Industrial

Table 16.2.1 :

Cooling Load Temperature Differences for Calculating Cooling Load From Flat Roof

Table 16.2.2 :

Typical Wall Construction

Table 16.2.3 :

Cooling Load Temperature Differences for Calculating Cooling Load From Sunlit Walls

Table 16.3 :

CLTD Corrections For Latitude And Months Applied To Walls And Roofs, North Latitude °F

Table 16.4 :

Adjust for Inside / Outside temperature

Table 16.5.1 :

Shading Coefficient for Single and Insulating Glass with Draperies

Table 16.5.2 :

Shading Coefficient for Louvered Sun Screens

Table 16.5.3 :

Shading Coefficient for Domed Skylights

Table 16.5.4 :

Solar Optical Properties and Shading Coefficients of Transparent Plastic Sheeting

Table 16.5.5 :

Shading Coefficients for Double Glazing with Between-Glass Shading

Table 16.5.6 :

Shading Coefficients for Glass Without or With Interior Shading by

Venetian Blinds or Roller Shades

Table 16.6 :

Maximum Solar Heat Gain Factor BTU/hr - sq.ft.

CLF For Glass Without Interior Shading

Table 16.7.1 :

Table 16.7.2 :

Cooling Load Factors for Glass with Interior Shading, North Latitudes

Table 16.8 :

Cooling Load Factors for Lights

Table 16.8.1 :

Cooling Load Factors when Lights Are on for 8 Hours

Cooling Load Factors when Lights Are on for 10 Hours

Table 16.8.2 :

Table 16.8.3 :

Cooling Load Factors when Lights Are on for 12 Hours

Table 16.8.4 :

Cooling Load Factors when Lights Are on for 14 Hours

Table 16.8.5 :

Cooling Load Factors when Lights Are on for 16 Hours

Table 16.8.6 :

Sensible Heat Cooling Load Factor for people

Rate of Heat Gain from occupants of conditioned spaces

Table 16.9 :

Table 16.10 :

Shadow Lengths and Shadow Widths for Building Exterior Projections

Heat Gain from equipment

Table 16.11 :

Table 16.11a :

Rate of Heat Gain from Miscellaneous Appliances

Table 16.12.1 :

Sensible Heat Cooling Load Factors for Hooded Appliances

Sensible Heat Cooling Load Factors for Unhooded Appliances, Motors, etc.

Table 16.12.2 :

Table 16.13 :

Monthwise Maximum, Minimum Temperatures and Daily Range

Figure

Figure 16.3.1 :

Indoor Shading properties of Drapery Fabrics

Figure 16.3.2 :

Figure 16.3.3 :

Terminology for Deomed skylights

M

A

:3

7

15

1:

23

/2

0

/2

6

,7

in

N

ith

62

75

9,

N

ith

in

,7

/2

6

/2

0

23

1:

15

:3

7

A

M

16.19

16.20

16.20

9,

75

M

it h

in

,7

/2

6/

20

23

Section - 16 : ANNEXURE - PROCEDURE TO USE CLTD PROGRAMME

62

xx

1:

15

:3

7

|

1:

15

:3

7

ISHRAE HVAC DATABOOK

62

62

75

75

9,

9,

,7

in

N

ith

,7

in

N

ith

/2

6

/2

6

23

/2

0

23

/2

0

15

1:

15

1:

:3

7

:3

7

M

A

M

A

62

62

9,

75

9,

75

DESIGN DATA, PSYCHROMETRICS,

IAQ AND COMFORT

23

20

6/

/2

,7

in

ith

N

23

20

6/

/2

,7

in

ith

N

7

:3

15

1:

7

:3

15

1:

SECTION - 1

M

A

M

A

62

75

9,

N

62

75

9,

N

it h

in

,7

/2

6/

20

23

it h

in

,7

/2

6/

20

23

1:

15

:3

7

1:

15

:3

7

A

A

M

M

M

A