Steel Design & Connections Exam Prep - Civil Engineering

advertisement

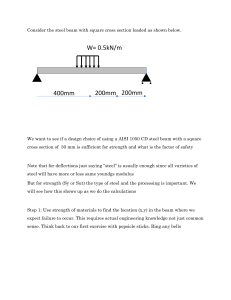

Set 16-Code, Fundamentals, Part 5- Structural Bolted &Welded Connections Steel Design Set 16 Problem 1 (CE May 1994) The “Slenderness Ratio” of a column is generally defined as the ratio of its: A. Unsupported length to its maximum radius of gyration B. Unsupported length to its minimum radius of gyration C. Length to its minimum width D. Length to its moment of inertia Problem 2 (CE May 1994) The following are types of welding inspection: A. radiographic and ultrasound inspection B. Penetrant inspection C. Magnetic particle inspection D. All of the above Problem 3 (CE November 1994) The following are welding process: A. SMAW Shielded metal arc welding B. GMAW gas metal arc welding C. SAW submerged arc welding D. All in the list Problem 4 (CE November 1995, May 1997) In Shield metal Arc Welding designation, E70XX, the E denotes the electrode. The next two indicate the strength in ksi, and the two X’s represent the number indicating: A. Use of the electrode C. method of welding B. Method of welding D. angle of welding Problem 5 (CE November 1995) In computing the net area for a plate with a bolt hole, width of a rivet or blot hole shall be taken as ______mm greater than the nominal dimension of the hole normal to the direction of the applied stress. A. 2.40 B. 1.80 C. 1.60 D. 2.00 Problem 6 (CE May 1997) The AISC allowable tension stress of members except pin-connected members are 0.60 F y for gross section area or 0.50 for netF. uOn the section area across the pin hole of an eye bar, the allowable AISC stress in terms of is: A. 0.55 B. 0.45 C. 0.60 Set 16-Code, Fundamentals, D. 0.65 Part 5- Structural Bolted &Welded Connections Steel Design Problem 7 (CE November 1996) In structural steel design, structures carrying liveload which induce impact, the assumed live load shall be increased sufficiently to provide for it. In not otherwise specified, the increase for supports of elevators shall be: A. 50% B. 75% C. 33% D. 100% Problem 8 (CE May 1994) The allowable stress in structural steel in bending of non- compact section is: A. O.60 C. 0.40 B. 0.70 D. 0.66 Problem 9 (CE May 1994) The slenderness ratio, KL/r of compression members shall not exceed A. 200 B. 0.45 C. 300 D. 240 Problem 10(CE May 1994) In general, tension and compression on extreme fibers of compact or rolled or built up members, symmetrical about and loaded in the plane of their minor axis is: A. F b 0.75 F y B. F b 0.60 F y C. F b 0.40 F y D. F b 0.66 F y Problem 11(CE May 1994) To prevent local buckling, AISC specifies the value of this ratio not to be exceed a certain value, e.g., 76sqrt( )where is in ksi: A. d/t B. L/r C. b/t D. sqrt(I/A) Problem 12(CE November 1994) In built up section, intermediate stiffeners are required when the value of this ratio is exceed e.g., ratio greater than 260 for the unstiffened webs: A. h/t B. L/r C. d/t D. b/t Problem 13 (CE November 1995) Unstiffened structural steel elements subjected to axial compression due to bending shall be considered as fully effective when the ratio of the width to thickness is not greater than _____ for compression flanges of beams and Fy stiffeners on plate girders. A. 333 F y B. 625 F y C. F b 0.60 F y D. 250 F F y y Problem 14(CE May 1996) According to the NSCP, stiffened structural steel elements subject to axial compression or to uniform compression due to bending as in the case of the flange of a flexural member, shall be considered as fully effective when the ratio of width Set 16-Code, Fundamentals, Part 5- Structural Bolted &Welded Connections Steel Design To thickness is not greater than _____ for flanges of square and rectangular box sections of uniform thickness: A. 664 sqrt F B. y 250 sqrt F C. y 832 sqrt F D. y 620 sqrt F y Problem 15(CE November 1996) Web of beams and welded plate girders shall be proportioned that the compressive stress at the web toe of the fillets resulting from concentrated loads not supported by bearing stiffeners, shall not exceed to 0.75 . If R is the concentrated load or reaction in newton, t is the thickness of the web in mm, N is the length of the bearing (not less than k for end reactions) in mm and k is the distance from the outer face of the flange to web toe of fillet in mm. The governing formula for interior load is: R 0.75 F y A. t N 2k R 0.75 F y C. 2t N k R 0.75 F y B. 2 N 2k R 0.75 F y D. t N k Problem 16 (CE November 1996) According to AISC, the minimum A g must ≥ T/(0.6 ) where F y is the yield strength of steel and T is the load. Given the ultimate strength specifications required area An ≥: A. T 0.6 F y B. T 0.5F u C. T 0.65 F u D. F u T 0.55 F , the same u Problem 17(CE November 1995) In the design of the beam-columns, structural members whose loading in compression and bending are both significant, the AISC specifies cm which is a modification or reduction factor which keeps the estimated moments caused by deflection from being too large. For columns in frames subjected to joint translation and sideways, or flames that depends upon the bending stiffness of their members for lateral stability, the value of F y F y cm is: Where ends. M M 1 2 is the ratio of the smaller moment to the larger moment at the B. 0.6-0.4 M 1 M 2 >0.4 A. 0.90 C. 1.0 D. 0.85 Problem 18 A 10-mm gusset plate 300mm wide is bolted to a 20-mm thick column by four 25 mm bolt arranged in a straight line along the 300 mm side. For the gusset plate, F u = 400 MPa. Allowable shearing stress on blots is 160 MPa. What is = 250 MPa, the capacity of the gusset plate? A. 314 kN B. 450kN C. 400kN D. 600kN Problem 19 (CE May 1997) Set 16-Code, Fundamentals, Part 5- Structural Bolted &Welded Connections Steel Design Base on the AISC Specifications, the effect of net area Ae at the root of the thread of a threaded tension member is Ae 0.7854( D 0.9743 n where D is the nominal outside diameter of the threads and n is the number of threads per 25.4. if the load is 25kN and the number of threads per inch of the threaded tension member is 4, =250Mpa. The diameter sufficient to carry the load is: A. 66mm B. 60mm C. 70mm D. 55mm Situation: Problem 20-22 (CE May 1998) A plate with width of 300 mm and Thickness of 20mm is to be connected to two plates of The same width with half the thickness by 25 mm diameter rivets, as shown. The rivet holes have a diameter of 2mm larger than the rivet diameter. The plate is A36 steel F y with yield strength = 248 MegaPascals, allowable tensile stress of 0.60 bearing stress of 1.35 and allowable . The rivets are A502, Grade 2 hot-driven rivets with allowable shear Figure stress of 150 MegaPascals. Problem 20 Which of the following most nearly gives the maximum load, in KiloNewtons that can be applied to the connection wothout exceeding the allowable tensile stress in the plates: A. 750 B. 780 C. 700 D. 730 Problem 21 Which of the following most nearly gives the maximum load, in kilonewtons, that can be applied to the connection without exceeding the allowable shear stress in the rivets: A. 640 B. 590 C. 550 D. 700 Problem 22 Which of the following most nearly gives the maximum load, in KilonNewtons, that can be applied to the connection without exceeding the allowable bearing stress between the plate and the rivets: A. 670 B. 650 C. 620 D. 700 Situation: Problem 23 to 25 A steel hanger consist of a plate 125mm x 6 mm held at the top of by 20-mm rivets in single shear, The rivets are arranged in diamond form so that the first net section has one hole and the second net section has two holes. Allowable stresses are 110 MPa for tension in plates, 83MPa for shear on rivets, and Set 16-Code, Fundamentals, Part 5- Structural Bolted &Welded Connections Steel Design F F y y 165MPa for bearing between the rivets and the plate. Hole diameter is 3mm larger than the rivet diameter. Problem 23 Which of the following most nearly gives the load on the hanger so that the allowable tensile stress in the plates will not be exceeded. A. 67. 32kN C. 58. 17kN B. 72.14kN D. 92. 56kN Problem 24 Which of the following most nearly gives the load on the hanger so that the allowable shearing stress in the rivets will not be exceeded. A. 152kN C. 98kN B. 104kN D. 125kN Problem 25 Which of the following most nearly gives the load on the hanger so that the allowable bearing stress will not be exceeded. A. 65.5kN C. 45.2kN B. 85.7kN D. 79.2kN Situation: Problem 26 to 28 The two plates shown in Figure ST-02 joined together by four 25-mm rivets. Allowable shearing stress for the rivets is 70MPa, allowable tensile stress on net area of the plates is 100MPa, and the allowable bearing stress on contact area between the rivet and the plate is 140MPa. Problem 26 Which of the following most nearly gives the maximum value of P such that the allowable shearing stress in the rivets will not be exceeded. A. 150kN C. 137kN B. 120kN D. 152kN Problem 27 Which of the following most nearly gives the maximum value of P such that the allowable tensile stress in the plate will not be exceeded. A. 104kN C. 150kN B. 160kN D. 120kN Problem 28 Which of the following most nearly gives the maximum value of P such that the Set 16-Code, Fundamentals, Part 5- Structural Bolted &Welded Connections Steel Design Allowable bearing stress will not be exceeded. A. 140kN C. 133kN B. 123kN D. 150kN Problem 29(CE November 1997) A steel plate is 360mm wide and 20mm thick with four bolt holes cut into a plate as shown in the figure. The general expression to the specification method for computing the net area is: A n T B summation( H ) summation( S 4 g 2 Where T=thickness of the plate, B is the width, H=diameter of the holes, S= pitch and g=Gage. Which of the following most nearly gives the critical net area ( An ) of the section In accordance with the 1992 National Structural Code of the Philippines: A. A = 4125 sq.mm. B. A = 4625 sq.mm. C. A = 5625 sq.mm. D. A = 5125 sq.mm. n n n n Situation: problem 30 (CE November 1998) A W16 x 58 is connected to W8 x 31 as shown in the figure. The material is A 36 steel with = 248MPa. The allowable bearing stress is 1.35 . The rivets are A502 grade 2 hot driven rivets with allowable shearing stress of 120MPa. The support is to be designed using the full strength of the A16 x 58 beam based on gross section. The properties of the section are: W16 x 58: Total depth, d=403mm; Thickness of web: 10mm W8 x 31: Flange thickness= 11mm F y F Set 16-Code, Fundamentals, Part 5- Structural Bolted &Welded Connections Steel Design Problem 30 Which of the following most nearly gives the minimum diameter of the rivets without exceeding the allowable shearing stress in the rivets. A. 20mm C. 23mm B. 25mm D. 28mm Problem 31 Which of the following most nearly gives the minimum diameter of the rivets without exceeding the allowable bearing stress in steel. A. 30mm C. 25mm B. 22mm D. 36mm Problem 32 Which of the following most nearly gives the required diameter of the rivets: A. 23mm C. 30mm B. 28mm D. 25mm Situation: Problem 33 to 35 (CE May 2000) In the connection shown in Fgure ST-23, a load transmits 200kN load acting at an eccentricity of 200mm. For this problem a=b=250mm. The load is transmitted to the column by the plates and 822 mm diameter rivets. The plates are adequate to transmit the load to the rivets. The connection can be analyzed by replacing the given load with an equivalent loading composed of a vertical force alone acting through the centroid of the rivets and the moment. Problem 33 Which of the following most nearly gives the maximum shear stress in the rivets in MegaPascas for equivalent vertical force alone acting on the centroid. A. 90 B. 145 C. 120 D. 65 Problem 34 Which of the following most nearly gives the maximum shear stress in the rivets in MegaPascals for equivalent moment alone. A. 700 B.74 C. 720 . 760 Problem 35 Which of the following most nearly gives the maximum shear stress in the rivets in MegaPascals. A. 170 C. 110 B. 160 D. 130 Set 16-Code, Fundamentals, Bolted &Welded Connections Situation: Problem 36 to 38 The gusset is riveted to a larger plate by four-22mm rivets arranged and loaded as shown in Figure ST-9. Problem 36 Which of the following most nearly gives The direct load on each rivet in KiloNewton. A. 8 C. 12 B. 15 D. 10 Part 5- Structural Steel Design Problem 37 Which of the following most nearly gives the force in KiloNewton on the heavily loaded rivet. A. 15 C. 12 B. 18 D. 16 Problem 38 Which of the following most nearly gives the force in KiloNewton on the lightly loaded rivet. A. 13 B. 9 C. 11 D. 15 Problem 39 Which of the following most nearly gives the throat of a 9-mm fillet weld: A. 4.5mm C. 6.4mm B. 7.4mm D. 12.7mm Problem 40 What is the capacity of a 9-mm fillet weld of E70 electrode in a length of 250mm? A. 260kN B. 250kN C. 180kN D. 230kN Problem 41 A double-angle truss member consist of two angles 125mm x 88mm x 10mm thick with the 125mm side welded to a gusset plate. The member is to carry a total tensile force of 848 kN. Using 6-mm fillet weld with E70 electrode, determine the total length of weld required. Use =250 MPa. See accompanying figure. A. 856mm B. 345mm C. 691mm D. 1382mm Set 16-Code, Fundamentals, Part 5- Structural Bolted &Welded Connections Steel Design Problem 42(CE May 1994) The allowable load in shear for an 8.5mm weld having an allowable shearing strength of 124MPa for a total length of 306mm is about: A. 228000N C. 1054N B. 745N D. none of the above Situation: Problem 43 to 45 In the connection shown in Figure ST-01, a load transmits 40kN load acting at an eccentricity of 200mm. The load is transmitted to the column by the plates and 8mm weld. The plates are adequate to transmit the load to the weld. The connection can be analyzed by replacing the given load with an equivalent loading composed of a vertical force alone acting through the centroid of the rivets and a moment. Problem 43 Which of the following most nearly gives the maximum shear stress in the welds in MegaPascals for equivalent vertical force alone acting on the centroid. A. 15 Problem 44 B. 14 C. 18 D. 21 Which of the following most nearly gives the maximum shear in the welds in MegaPascals for the equivalent moment alone. A. 38 B. 46 C. 26 D. 22 Problem 45 Which of the following most nearly gives the maximum shear stress in the weld in megaPascals. A. 63 B. 39 C. 42 D. 52 Answer Key Set 16-Code, Fundamentals, Part 5- Structural Bolted &Welded Connections Steel Design Solution Fundamentals, Bolted & Welded Connecti ns o Solutions to Set 16 5 According to the section 4.14.4 of NSCP, in computing the net area for a plate with a bolt hole, width of a rivet or bolt hole shall be taken as 1.6mm greater than the nominal dimension of the hole normal to the direction of the applied stress. 6 According to the Section 4.14.5 and 4.5.1.1 of NSCP, the allowable stress for pin-connected members is 0.45 . 7 The increase in values for different supports as provided in Section 4.3.3 of NSCP are the following: For support of elevators…………………………..…100% For cab operated traveling crane support Girders and their connections ……………………25% For pendant operated traveling crane support girders and their connections……………….…….10% For support of light machinery, shaft motor driven, not less than ……………………….20% For support of reciprocating machinery or power driven units, not less than…………………50% For hangers supporting floors and balconies………..33% 8 According to Section 4.5.1.4.4 of NSCP, the allowable bending stress on non-compact sections is 0.6 9 According to Section 4.8.4 of NSCP, the slenderness ration for companion shall not exceed 200. 10 F y According to section 4.5.1.4 of NSCP, Tension and compression on extreme fibers of compact hot-rolled or built-up members (except hybrid girders and member of A514 steel) symmetrical about, and loaded in, the plane of their minor axis, the allowable stress is 0.66 12 h/t (See section 4.10.5.3. of NSCP) Set 16-Code, Fundamentals, Part 5- Structural Bolted &Welded Connections Steel Design 13 250 F 14 620 sqrt y See Section 4.9.1.2 F , See Section 4.9.2.2 of NSCP y 15 According to Section 4.10.10 of NSCP, the governing formula is: R 0.75 F y t N 2k 16 According to Section 4.5.1.1 of NSCP for structural steel in tension, except for pin-connected members, A g nor 0.5 F u F t shall not exceed to on the effective area Thus, T≤(0.5 F u ) or A n on the gross area A n ≥T/(0.50 F u ) 17 According to Section 4.6.1 of the NSCP(1.) for compression members subject 0.85 to joint translation(sideway) C m 18 Tension on gross area: F F 0.6 F y 150 MPa t P F xA t g 15030010 450,000 N Tension on net area: F 0.5 F 200MPa A 300 25 x410 2000 mm 85% A 2550 mm 2000 mm t u 2 n 2 2 g P 200 x 2000 400,000 N Bearing on plate: F p 1.5 F u 600MPa P 600(25 x10) x 4 600,000 N Shearing on bolts: E v 160Mpa P 160 4 25 2 x 4 314,159 N Thus, the capacity of the plate is 314, 159kN Set 16-Code, Fundamentals, Bolted &Welded Connections 19 The tensile capacity T of the thread is given by: T F t Ae 0.6 F y F t F y (NSCP Section 4.5.1.1) =250MPa t 0.6(250) 150MPa e 0.7854( D F A 0.7854 n 2 in square inch Part 5- Structural Steel Design N=4 (number of threads) T-250kN 250,000=150 A e 1in 25.4mm 2.58in 2.58 0.7854 D 0.9743 4 2 1666.67 mm x e 2 A 2 2 D=2.06 in x (25.4mm/in)=52.3mm say 55mm 20 to 22 Allowable tensile stress in plates: F F t 0.6 F y 0.60( 248) t 148.8MPa P A n F xA t n 2 =4920 mm P=148.8(4920)=732,096N P=732kN P F v Av F v 150MPa A = total area sheared off(double shear) A 2 A x4 2 425 x4 3927 mm v 2 v b P 150(3927) 589,050 N 589kN 2 P F A F 1.35 F b b b y 1.35(248) 334.8MPa =bearing area of four rivets=25(20)x4=200 A b P=334.8(2000)=669,600N=669.6kN Set 16-Code, Fundamentals, Part 5- Structural Bolted &Welded Connections Steel Design 23 to 25 Based of tensile stress in plates: Tearing along rivet A A (125 23)6 612 mm P F A n t 2 n P 110(612) 67,320 N Tearing along rivets BC: A P n (125 23)6 474 mm net 2 F A t n P P / 4 110( 474) 69,520 N Tearing along rivet D: A n (125 23)6 612 mm 2 P 3P / 4 110(612); P 269,280 N Thus, P=67,320 N=67.32kN 2 mm Based on shearing of rivets: P F A v v 83 x 4 20 (4) 104,300.9 N 104.3kN 2 Based on bearing: P F A p 26 to 28 p 165 x(20)(6) x 4 79000 N 79.2kN Based on shearing on rivets: P F A v s 2 P 70 25 x 4 4 P 137445 N 137.445kN Based on tearing on Net area of plates: For the 14-mm thick plate: 85% A g 1547 mm 2 Tearing along rivet “a”: A (130 27)(14) 1442 mm P FA net t net 2 100(1442) 144,200 N 144.2kN Tearing along rivets “b” and “c”: net (130 27 x 2)(14) net 1064 mm A A P P/4 2 F A net t 3P / 4 1000(1064) P 141867 N 141.867kN Set 16-Code, Fundamentals, Part 5- Structural Bolted &Welded Connections Steel Design 2 For the 10-mm thick plat: 85% Ag 1275 mm Tearing along rivet “d” A (150 27)(10) 1230 mm P FA net t net 2 100(1230) 123,000 N 123kN Tearing along the rivets “b” and “c” net (150 27 x 2)(10) net 960 mm A A P P/4 2 FA t net 3P / 4 100(960) P 128000 N 128kN Thus the safe P=123kN Based on bearing: (The thinner plate is more critical in bearing) P F A p b 1402510x 4 140000 N 140kN 29 A t b H S A tw 2 4g n n n Solving for the critical net width, W n : Path ABEF: S=90-60=30mm G=90(3)=270mm 2 30 W n 360 25(2) W n 4(270) 310.83mm Path ABCEF: 2 W n 360 25(3) 45 4(90) 2 15 290.94mm 4(180) Path ABCDEF: 2 W Use n 360 25(4) W n 280.25mm 45 4(90) 2 x2 60 4(90) 281.25mm then; An txW n 20 x 281.25 5625mm 2 Set 16-Code, Fundamentals, Bolted &Welded Connections Part 5- Structural Steel Design 30 to 32 The full strength (shear) of W16x58 is: F v V dt 0.4 F y w V 0.4(248); V 399776 N 403(10) Shear stress in the rivets: (Considering the 4 rivets in double shear connected to W16 x 58) F b V 4 Dt 1.35 F y w 399776 / 4 1.35(248); D 29.85mm D(10) From the previous results, the diameter of the rivets must be 30mm. 33 to 35 Analyze one side of the bracket: Direct load on one rivet: R R D P/4 D 25kN Stress due to direct load: R R D P/4 D 25kN T=P e=100(200) T=20,000kN-mm X Y (125 125 ) x4 125,000 mm 20,000(125) T 20kN R 125,000 x y 2 2 2 2 2 y x R 2 2 y 20,000(125) T 20kN 125,000 x y x 2 2 20 20 28.284kN 2 R 2 Set 16-Code, Fundamentals, Bolted &Welded Connections R 28.284(1000) 2 A 22 4 Stress 74.4 MPa Stress The most stressed rivets are rivets B and C: R 45 20 S max S max 2 2 49.24kN 49.24kN 22 4 2 129.5MPa 36 to 38 Direct load on each rivets; Part 5- Structural Steel Design R R D 40 / 4 D 10kN R x R y T y 2 x y T x y 2 2 x 2 T=40(100)=4000kN-mm x y 40 120 40 120 32,000 R R R R 0 2 2 1x 2 2x 3x 2 2 2 4x The most heavily loaded rivets are rivets 1 and 4. R 4000(120) / 32,000 15kN R 1y 1 2 R D R2 y 2 R 4y 10 15 2 2 18.03kN R 4 The most lightly loaded rivets are rivet 2 and 3. R R 2y 2 4000(40) / 32,000 5kN RD 2 2 R2 y R 10 5 2 2 3y 11.18kN R 3 39 Throat=t sin 45°=0.707t=0.707(9)=6.36mm 40 P F V 0.707tL; F V 0.3 F u ; F u 70ksi 482.5MPa P 0.3(482.5)(0.707)(9)( 250) P 230,261N 230.26kN Set 16-Code, Fundamentals, Bolted &Welded Connections 41 F u 70ksi 70,000 psix 0.101325MPa 482.5MPa 14.7 psi Part 5- Structural Steel Design Length of the weld on one side, L L1 L2 Based on weld metal shear: P AF F 0.45 F (NSCP Table 4.5.3) F 0.4(250) 100MPa (contact area between the weld and metal) A 2tx1 12L V V V Y V V 424,000=12L(100); L=353mm Use L =691 mm on one side only. Therefore; the total length of weld required is 2L=1382 mm 42 P 0.707tL F V 0.707(8.5)(306)(124) 228024.5 N 43 Stress due to the vertical force alone: f v 40,000 17.68MPa 0.707(8)( 2 x 200) Maximum stress to moment: (at B) T Pe 40,000(200) 8,000,000 N mm 2 2 J L L 12 x y 2 J 2 x 200 200 12 0 100 2 2 J 5,333,333 mm F F BX BX T 2 3 6 8 x10 (100) J 5333333 150 N mm Y 6 F BX Tx 8 x10 (100) J 5333333 Set 16-Code, Fundamentals, Part 5- Structural Bolted &Welded Connections F BY 150 N / mm F f V Steel Design F BX 2 2 F BY 212.13N / mm 212.13(1) 37.51MPa 0.707(8)(10 Stress per mm length at B, Maximum stress in the weld (at B) R D 40,000 100 N / mm 2(200) F BY F BX 10150 150 R R D R 2 2 2 2 R 291.55 N / mm Stress per 1 mm length at B= 291.55(1) 51.55MPa 0.707(8)(1) f v Set 17- Columns, Beams, Part 5-Structural Combined Stress, Plastic Design Steel Design Problems-Columns, Beams, Combined Stress, Plastic Design Set 17 Problem 1 (CE November 1994) The value of the Euler buckling load of a column fixed at the top and bottom and of length L with modulus of elasticity E and moment of inertia I subjected to a central axial compressive load: A. 4 EI / L B. 0.25 EI L 2 2 0.5 EI L EI L 2 2 C. 2 2 D. 2 2 Problem 2 (CE May 1999) A wide flange section for a 5 m long column (hinged at both ends) has the 2 following properties: mm Cross sectional area= 8000 Radius of gyration, Radius of gyration, r r x 100mm y 50mm Modulus of elasticity, E= 200,000Mpa Which of the following most nearly gives the Euler critical load of the column. A. 1230kN B. 1970kN C. 2140kN D. 1580kN Problem 3 According to Section 4.5.1.3.1 of NSCP, on gross section of axially loaded compression members whose cross-sections meet the provisions of the code when KL/r, the largest effective slenderness ratio of any unbraced segment, is less than C c : KL / r F F1 2 E 2 Cc F a 2 y 2C c 2 where 5 3KL / r FS 3 8C c y FS KL / r 3 8C c 3 On gross section of axially loaded compression member, when KL/r exceeds Cc: F a 12 23 2 E KL / r 2 A structural steel column with Fy=250MPa having an unbraced length of 3 m is to carry a total axial load of 1800kN. E of steel = 200GPa. Which of the following sections is most economical(lightest) for the given loads. K=1 A. A 13800 mm ; Ix 293.63x10 mm ; Iy 67.59 x10 mm B. A 115550 mm ; Ix 177.04 x10 mm ; Iy 39.14 x10 mm C. A 16050 mm ; Ix 452.60 x10 mm ; Iy 107.29 x10 mm D. A 15675 mm ; Ix 391.73x10 mm ; Iy 107.28 x10 mm 2 6 2 4 6 6 4 4 6 4 2 6 4 6 4 2 6 4 6 4 Set 17- Columns, Beams, Part 5-Structural Combined Stress, Plastic Design Steel Design Problem 4 (CE November 1994) A steel column has the following properties: Modulus of Elasticity E=200,000MPa, 6 4 yield strength Fy=200Mpa, length L=12m, moment of Inertia I=37.7 x 10 mm 2 8000 mm And area= . The allowable stress is closest to: A. 120Mpa B. 67.4MPa C. 33.7MPa D. 91.1MPa Situation: Problem 5 to 7 (CE November 1998) According to Section 4.5.1.3.1 of NSCP, on gross section of axially loaded compression members whose cross- sections meet with the provisions of the code, when KL/r, the largest effective slenderness ratio of any unbraced segment, is less than Cc: 2 KL r F y 3 F a 1 2 FS 5 3KL r 2C c FS 3 KL / r 3 Where 2 E 2 C c Fy 8C c 8C c On gross section of axially loaded compression member, when KL/r exceeds Cc: 12 E 2 Fa 23 KL ? r 2 A column 3 m long and pinned at both ends is carries an axial load of 190kN. The column is made up of 2 angles of unequal legs with long legs back to back and separated by a guest plate whose thickness is 11mm. Use A36 steel with Fy=248Mpa and E=200,000MPa. Three sections are being considered, as follows, with their respective properties relevant of this problem (length units are in meters): Section A Rx Ry 2L 125 x 75 x 12 0.00454 0.0390 0.0160 2L 150 x 90 x 10 0.00463 0.0480 0.0195 2L 150 x 90 x 12 0.00550 0.0500 0.0251 Problem 5 Which of the following sections gives the largest allowable compressive stress. A. 2L 125 x 75 x 12 C. 2L 150 x 90 x 12 B. 2L 150 x 90 x 10 D. Not enough data Problem 6 Which of the following sections gives the smallest allowable compressive stress. A. 2L 125 x 75 x 12 C. 2L 150 x 90 x 12 B. 2L 150 x 90 x 10 D. Not enough data Problem 7 Which of the following sections gives the most economical(lightest) section for the given load. A. 2L 125 x 75 x 12 C. 2L 150 x 90 x 12 B. 2L 150 x 90 x 10 D. Not enough data Set 17- Columns, Beams, Part 5-Structural Combined Stress, Plastic Design Steel Design Problem 8 (CE November 1994) A 10m steel wide flange beam is laterally supported. The width of the web is the beam is 700mm and web thickness is 10mm. If Fy is equal to 250MPa, the allowable bending stress is: A. 180MPa B. 150MPa C. 165MPa D. 200MPa Problem 9 (CE May 1995) kN mm 2 The structural I-beam supporting a floor carries a floor load of 4.6 . The beam span 6.0m and are simply supported at their ends. Determine the centerline spacing if the allowable stress in the beam is 120MPa and the section modulus 3 3 is 534 x10 mm . A. 3.75m B. 3.45m C.4.0m D.3.0m Problem 10(CE November 1995) A BW 75 x 287 steel I beam has the following dimensions: Total beam depth, H=775mm Web thickness, tw=19mm Flange width, B=360mm Flange thickness, tf=32mm The moment of inertia Ix about the principal axis as: 4 A. 375,086 cm 375,086 mm B. 375,086 mm 6 4 C. D. None in the list Problem 11 (CE May 1996) A structural steel angle 203x152x25.4 carries a moment of 10 kN-m. The longer leg is parallel to the y-axis and the shorter to the x-axis. The inertial properties of the angle are as follows: 6 4 I x 33.6 x10 mm Moment of inertia about the x-axis, Moment of inertial about the y-axis, Product of inertia, I xy I y 13 .4 x10 6 16 .1x10 mm 6 4 mm 4 The stress at point O in MPa which is at x-distance of -41.9mm and y-distance +135.7mm from the centroid is: A. 44.92 compression C. 44.92tension B. 17.31 tension D. 17.31 compression Problem 12 (CE November 1997) A floor is made up of a 150mm thick concrete slab and 50mm thick floor finish both of which has a unit weight of 24 kN/cu.m. The floor also carries a ceiling whose weight is 720Pa and a live load of 2,400Pa. The floor is supported by simply supported beams with a span of 10m spaced at 4.6m on centers, with yield strength (Fy)=248MPa. The allowable shear stress specified in the 1992 National Structural Code of the Philippines is 0.40Fy. Considering the weight of the beam, which of the following sections is the most economic (lightest) section for the given load, assuming that shear stress governs the design. A. W12 x 19; beam weight= 278N/m, depth=309mm, web thickness=6mm B. W10 x 33; beam weight= 484N/m, depth=247m, web thickness=7mm C. BW300 x 41; beam weight =407N/m, depth=300mm, web thickness=6mm D. BW300 x 47; beam weight=460N/m, depth=300mm, web thickness=6mm Problem 13 (CE November 1997) A simply supported steel beam has a span of 6m and is subjected to a vertical concentrated load of 150kN acting at midspan. An allowance of 100% for impact is made for the concentrated load only. The beam is laterally supported only at the supports. The 1992 national Structural Code of the Philippines states that the allowance tensile stress for laterally unsupported members subject to bending is given by the equation: F 2 / 3 F y B C b L R t / 10,550,000 C F 2 b y Where may be taken as 1.0 since the maximum moments does not occur at the supports. Rt Is the radius of gyration comprising the compression flange and 1/3 of the compression web area, taken about the axis in the plane of the web. Steel is A36 with yield strength (Fy)=248MPa. Which of the following most nearly gives the most economic (lightest) section that will limit the flexural stress to the 3 allowable value: 75mm, R t S x 0.00239m A. W18x76; beam weight =1108N/m, B. W21x62; beam weight=911N/m, R C. W24x68; beam weight =1000N/m, D. W27x84; beam weight= 1234N/m, t 53mm, S x 0.0023m 3 R t 63mm, S x 0.0035m R t 57mm, S x 0.00253m 3 3 Situation: Problem 14 to 16 (CE May 1998,May 2000) A simply supported beam with span of 8 m is subjected to a uniform vertical downward load equal to 50 kN/m acting on the plane of the minor axis of the beam section, which includes the beam weight. The beam is restrained against lateral buckling of the top and bottom flanges for the entire span. The material is A36 still with Fy=248megaPascals and modulus of elasticity=20GigaPascals. The allowable flexural stress for laterally braced compact sections is 0.66 Fy. The allowable deflection 1/360 of the span. Three compact sections are being considered, as follows, with their respective properties relevant of this problem (length units are in meters): Section Moment of Inertia (Ix) Beam depth (D) W 24x55 0.000558 0.598 W 21x62 0.000554 0.533 W 21x68 0.000616 0.537 (Note: The symbol x^y means raising the quantity or expression x to the exponent y.) Problem 14 Which of the following most nearly gives the minimum section modulus (Sx), in meter^3, such that the maximum flexural stress will not be exceeded: A. 0.0018 B. 0.0015 C. 0.0024 D. 0.0021 Set 17- Columns, Beams, Part 5-Structural Combined Stress, Plastic Design Steel Design Problem 15 Which of the following most nearly gives the minimum moment of Inertia (Ix), in meters^4, such that maximum deflection will not be exceeded: A. 0.00065 B. 0.00050 C. 0.00060 D. 0.00055 Problem 16 Assuming that shear stress is not critical, which of the sections being considered is the most economic section that is adequate for the given load: A. W 21x62 C. W 21x68 B. W 24x55 D. None of the sections are adequate Situation: Problem 17 to 19 A W 14x500 is used as a beam to support a concrete floor system. The floor is to carry a total load of 120KPa. The beam is simply supported over a span of 7m. the properties of the section are as follows: Depth, d=498mm Thickness of web=56mm Moment of Inertia, Section modulus, I S x 3417 x10 6 13730 x10 3 x 4 mm 3 mm Weight= 7.32 kN/m Assume the beam is laterally supported over its length and that allowable stress in bending is 0.66Fy and in shear on gross section is 0.4Fy. Use A36 steel with Fy=250MPa. Allowable deflection is L/360. Problem 17 Which of the following most nearly gives the center-to-center spacing of the beams without exceeding the allowable shear stress. A. 7.21m B. 6.53m C. 7.21m D.8.51m Problem 18 Which of the following most nearly gives the center-to-center spacing of the beams without exceeding the allowable bending stress. A. 2m B. 2.5m C. 3m D. 3.5m Problem 19 Which of the following most nearly gives the center-to-center spacing of the beams without exceeding the allowable deflection. A. 3.48m B. 4.21m C. 2.87m D. 6.23m Situation: problem 20 to 23 A w 27x178 is used as a beam that is simply supported at its ends. The properties of the section is as follows: 3 4 I 2,909.458x10 mm S 8,237.4 x10 mm r 293.64mm x Weight, W=265.4kg/m 3 3 x Depth, d=706.4mm Area, A 33,742 mm 2 x Set 17- Columns, Beams, Part 5-Structural Combined Stress, Plastic Design Steel Design Web, thickness t 18.4mm b 357.8mm t 30.2mm r 94.49mm w f Flange width, Flange thickness, f t 3 I 231,008x10 mm S 1,291.3x10 mm r 82.74mm F 250MPa 4 y 3 3 y y y Problem 20 Which of the following most nearly gives the allowable bending stress of the beam over an unsupported length of 4m. A. 185MPa B. 125MPa C. 150MPa D. 125MPa Problem 21 Which of the following most nearly gives the allowable bending stress of the beam over an unsupported length of 7m. A. 150MPa B. 165MPa C. 185MPa D. 125MPa Problem 22 Which of the following most nearly gives the allowable bending stress of the beam over an unsupported length of 9m. A. 160MPa B. 125MPa C. 140MPa D. 155MPa Problem 23 Which of the following most nearly gives the allowable bending stress of the beam over an unsupported length of 12m. A. 90MPa B. 105MPa D. 115MPa D. 130MPa Problem 24 (CE November 1997) A simply supported beam has a span of 4.5m. The beam is subjected to an axial tensile force of 250kN and a vertical concentrated load (P) acting at midspan. The member is fully laterally supported for its entire length. The effect of any bolt holes can be neglected. The beam consists of 2-150mm x 90mm x 12mm angles, with long legs back-to-back and spaced 10mm apart. For this problem, the relevant properties of one 150mm x 90mm x 12mm angle are: 3 Area( A) 2751mm 2 Elastic section modulus S 0.000063m x Steel is A36, yield strength (Fy)=248MPa. The allowable tensile stress Fa=0.60Fy and the allowable flexural stress Fb=o.66Fy. Neglecting member weight; which of the following nearly gives the maximum value of the vertical load (P) that member can support: A. P=72kN B. P48MPa C. P=13kN D. P=96kN Situation: problem 25 to 27 (CE November 1999) According to Section 4.6.1 of NSCP, members subjected to both axial compression and bending shall be proportioned to satisfy the following requirements: Set 17- Columns, Beams, Part 5-Structural Combined Stress, Plastic Design Steel Design f F C f 1 f ' F F f f f a mx a bx a bx my 1 by a bx ex a C f f 1 ' F F by ey by (1) (2) In formulas (1), (2) and (3), the subscripts x and y, combined with subscripts b, m, and e, indicate the axis of bending about which a particular stress or design property applies, and Fa=allowable axial compressive stress if axial force alone existed, MPa Fb=allowable bending stress if bending moment alone existed 12 E 2 F' e 23 Kl b r b Euler stress divided by a factor of safety, MPa the ' expression by F el l b is the actual unbraced length in the plane of bending and r b is the corresponding radius of gyration, K is the effective length factor in the plane of bending. As in the case of F a , F b, and 0.6Fy, F’e may be increased 1/3 in accordance to Section 4.5.6. 2 Fa=computed axial stress, MPa Fb=computed bending stress, MPa Cm=a coefficient whose value is as follows: 1. For compression members in frames subject to joint translation (sideway), Cm=0.85. 2. For restrained compression members in frames braced against joint translation and not subject to transverse loading between their supports in the plane of bending, M C 0.6 0.4 M but not less than 0.4 3. 1 m 2 Where M1/M2 is the ratio of the smaller to larger moments at the ends of that portion of the member unbraced in the plane of bending under consideration. M1/m2 is positive when the member is bent in reverse curvature, negative when bent in single curvature. 3. For compression members in frames braced against joint translation in the plane of loading and subjected to transverse loading between their supports, the value of Cm may be determined by rational analysis. However, in lieu of such analysis, the following values may be used: A. For members whose ends are restrained, Cm=0.85 B. For members whose ends are unrestrained, Cm=1.0 Set 17- Columns, Beams, Part 5-Structural Combined Stress, Plastic Design Steel Design Steel column 3.6m long and hinged at both ends is used to carry an axial load of 800kN. The column is subjected to end moment (single curvature) with M 1 90% M 2 Fy=248MPa, E=200GPa. The allowable axial stress Fa=115MPa and the allowable bending stress Fb=149MPa. The properties of the section are as follows: A 0.013m ; S x 0.00012m ; r b 9mm 2 3 Problem 25 Which of the following most nearly gives the computed (actual) axial stress of the column in MPa. A. 61 B. 87 C. 73 D. 54 Problem 26 Which of the following most nearly gives the computed (actual) bending stress of the column in MPa. A. 91 Problem 27 B. 78 C. 66 D. 42 Which of the following most nearly gives the moment capacity of the column in kN-m. A. 3 B. 8 C. 10 D. 23 Situation problem 28 to 30 (CE November 2000) A simply supported steel beam 6m long carries a uniform load of 32kN/m and an axial compressive force of 320kN. The properties of the steel section is as follows: 2 Area A 14700mm S Section Modulus, Flange width, b Flange thickness, f 1921x10 3 x 3 mm 280mm t f 16mm Overall depth, d=390mm 19mm Web thickness, t w According to Section 4.6.1 of the NSCP, for members subject to axial compression and bending, fa f b 1. 0.6F y F b Fa=computed axial stress, MPa Fy=yield strength of steel=248MPa fb=computed bending stress, MPa Fb=allowable bending stress= 0.66Fy. Problem 28 Which of the following most nearly gives the computed axial stress in the beam due to axial force alone acting on the beam, in Megapascals. A. 22 B. 27 C. 16 D. 32 Set 17- Columns, Beams, Part 5-Structural Combined Stress, Plastic Design Steel Design Problem 29 Which of the following most nearly gives the computed bending stress in the beam due to the uniform load alone acting on the beam, in MegaPascals. A. 64 B. 84 C. 70 D. 75 Problem 30 Which of the following most nearly gives the value the interaction equation. A. 0.5 B. 0.4 C. 0..7 D. 0.6 Problem 31 (CE November 1994) The shear capacity V if a steel wide flange section, 600mm deep whose web is 9mm thick, is closest to: (Assume Fy=200MPa) A. 486kN B. 864kN C. 432kN D. 684kN Problem 32 A wide flange beam of depth 800mm carries a total shear of 2000kN. If Fy=250Mpa, the required web thickness is: A. 20mm B. 30mm C. 25mm D. 35mm Problem 33 (CE May 1995) A structural steel I-beam is subjected to a shear of 90kN. The top and bottom flanges are 12mm by 150mm, while the web is 9mm by 300mm. The average shearing stress is V or 33.33Mpa. The moment of Inertia I of the section is dt 6 w 4 108x10 mm And the first moment of the area Q above the neutral axis is 382,050mm^3. However, the maximum shearing stress is: A. 35.37MPa Problem 34 B. 14.29Mpa C. 33.33MPa D. 7.77MPa An A36 ateel girder (Fy=248MPa) has the following properties: b f 250mm, t f 15mm, d 300mm, t w 15mm What is the shear capacity of this beam in kN? A. 523 B. 386 C. 446 D. 495 Problem 35 (CE May 1996) A composite beam system is composed of structural steel sections on which a reinforced concrete floor has been attached. The beams have a span of 8.0m. and spacing of 2.4m. The steel section flange width is 180mm and the slab thickness is 120mm. The effective flange width of the composite section according to AISC specification is: A. 2.1m C. 2.4m B. 2.0m D. 2.58m Set 17- Columns, Beams, Part 5-Structural Combined Stress, Plastic Design Steel Design Problem 36 (CE May 1997) A W 410 x 74.4 supports a slab with a thickness of 150mm. The effective width of the slab was computed to be 2000m. The structural steel section of composite system has the following properties: Beam depth, d =413mm Flange width, bf =180mm Cross-sectional area, A =9480mm^2 Moment of Inertia, I =274.3x10^6mm^4 Where is the new location of the neutral axis from the top of the slab in mm. Use n=10 to transform the area of concrete to steel. A. 234.50mm C. 562.43mm B. 142.59mm D. 152.20mm Problem 37(CE May 1999) A composite section consist of a 100-mm thick slab, 1000mm wide attached on top of wide flange section having a cross-sectional area of 10000mm^2. Determine the required number of shear connectors for the composite section if each has a capacity of 5kN. Use f ' 27 MPa, F y 250MPa. c A. 20 B. 15 C. 23 D. 12 Situation: Problem 38 to 40 A w21 x 57 of A36 steel transfers end reaction 196kN to a wall built of solid brick by means of a solid plate of A36 steel. Assume type S mortar and a brick with Fp=1200kPa. The N dimension of the plate is limited to 250mm. K1 for the beam is 22mm. Problem 38 Which of the following most nearly gives required area of the plate in square mm. A. 163,000 C. 152,000 B. 169,000 D. 185,000 Problem 39 Which of the following most nearly gives the value of “B” rounded-off to the nearest 10mm. A. 720 C. 660 B. 610 d. 580 Set 17- Columns, Beams, Part 5-Structural Combined Stress, Plastic Design Steel Design Problem 40 Which of the following most nearly gives the required plate thickness in mm. A. 36 B. 43 C. 53 D. 25 Problem 41 (CE November 1995) The yield stress of the steel beam is 250 N/mm^2. The beam must be designed for a plastic moment capacity of 288kN-m. The required plastic section modulus is: A. 2300cm^3 C. 4600cm^3 B. 1150cm^3 D. 3450cm^3 Situation: problem 42 to 45 The section of a steel beam is as shown in Figure ST-08. Use Fy=250MPa. Problem 42 Which of the following most nearly gives the area of the section is square meter. A. 0.019 B. 0.024 C. 0.015 D. 0.012 Problem 43 Which of the following most nearly gives the location of the plastic neutral axis from the bottom of the section in millimeters. A. 95 C. 85 B. 90 D. 80 Problem 44 Which of the following most nearly gives plastic section modulus of the section in m^3. A. 0.0007 C. 0.0008 B. 0.0006 D. 0.0009 Problem 45 Which of the following most nearly gives the plastic mment capacity of the section in kN-m. A. 150 C. 190 B. 170 D. 200 Set 17- Columns, Beams, Part 5-Structural Combined Stress, Plastic Design Steel Design Situation: Problem 46 to 48 For the steel section shown: Problem 46 Which of the following most nearly gives the section modulus of the section. A. 4,900,000mm^3 B. 4,300,000mm^3 C. 3,400,000mm^3 D. 5,100,000mm^3 Problem 47 Which of the following gives the plastic section modulus of the section. A. 5,560,000mm^3 C. 4,550,000mm^3 B. 5,120,000mm^3 D. 6,130,000mm^3 Problem 48 Which of the following most nearly gives the shape factor of the section. A. 1.8 B. 1.1 C. 1.3 D. 1.5 Problem 49 (CE May 1999) A fixed ended beam, 6m long carries a uniformly distributed load of w throughout the entire span. If the plastic moment capacity of the beam section is 400 kN-m, which of the following most nearly gives the value of w in kN/m. A. 153 B. 198 C. 178 Problem 50 Determine the plastic moment for the beam loaded as shown. A. 120kN-m B. 100kN-m C. 110kN-m D. 130kN-m Problem 51 Determine the design plastic moment for the beam loaded as shown. A. 94kN-m D. 204 B. 76kN-m C. 83kN-m D. 88kN-m Set 17- Columns, Beams, Part 5-Structural Combined Stress, Plastic Design Steel Design Situation: problem 52 to 54 Situation 9- The members of the rectangular portal frame shown is Figure ST-01 have uniform cross-sections. It is required to determine the plastic moment on three possible modes of failure. Use a load factor of 2. Problem 52 Which of the following most nearly gives the plastic moment Mp through the formation of plastic hinges at B, C, and D (beam mechanism), in kN-m. A. 167 C. 180 B. 123 D. 215 Problem 53 Which of the following most nearly gives the plastic moment Mp through the formation of plastic hinges at B and C (sideway mechanism), in kN-m. A. 89 C. 165 B. 111 D. 120 Problem 54 Which of the following most nearly gives the plastic moment Mp through formation of plastic hinges at C and D (collapse or combined mechanism), in kN-m. A. 240 C. 268 B. 345 D. 220 Set 17- Columns, Beams, Part 5-Structural Combined Stress, Plastic Design Steel Design 2 F Euler critical stress, 3 a 2 200000 2 E L r 5000 50 2 P F a A 197.4(8000) 1579200 N 1579.2kN C c 2 F 2 E 2 2 ( 200000) 250 y 125.66 Try the lightest: Choice B: 6 I 39.14 x10 58.21 r min A 11550 Kl / r (1)(3000) / 58.21 51.54 Since Kl r C c 51.54 1.81 125.66 3 5 3(51.54) FS 3 8(125.66) 8 3 2 51 . 54 1 250 126.5MPa Fa 2 1.81 2 125.66 P F a xA 126.5(11550) 1461075 N P 1461kN 1800kN NOT ADEQUATE Try Choice A: 6 I 67.59 x10 69.98mm r min A 13800 KL / r (1)(3000) / 69.98 42.87 2 197.4MPa KL r C c Since 5 342.87 FS 3 8125.66 8 42.87 1.79 125.66 3 3 2 42 . 87 250 131.54 MPa F a 1 2 1.79 2 125.66 P FaxA 131.54(13800) 1815252 N P 1815kN 1800kN ADEQUATE Set 17- Columns, Beams, Part 5-Structural Combined Stress, Plastic Design Steel Design 4 The reference for this problem is Section 4.5.1.3.1 of NSCP: 6 I r 37.7 x10 68.65mm A 8000 KL r (1)(12000)(68.65) 174.8 C c 2 F 2 E 2 2 (200000) 200 y 140.5 E SinceKL / r C .then F 12 23 KL r 12 (200000) 33.7 MPa F 23 174.8 2 a c 2 2 2 a 5 to 7 C c 2 F 2 E 2 y 2 ( 200000) 248 For 2l 125 x 75 x 12 KL r 1(3) / 0.0195 153.8 C c 126.16 12 E 12 (200000) 29.29MPa F 23 187.5 23 KL r 2 2 2 a 2 For 2L 150 x 90 x 10 KL r 1(3) / 0.016 187.5 C c 12 E 12 (200000) 43.54MPa F 23 153.8 23 KL r 2 2 2 a 2 For 2L 150 x 90 x 12 KL / r 1(3) / 0.0251 119.52 C c KL r 5 3(119.52) 119.52 1.916 3 8(126.16) 8126.16 8C c KL r F 119.52 248 1 1 71.35MPa 2C c FS 2 126.16 1.916 3 5 3( KL / r ) FS 3 8Cc 3 2 F 2 3 2 y a 2 2 Thus, the section with the largest allowable compressive stress is 2L 150 x 90 x 12 with Fa=71.35MPa The section that has the smallest allowable compressive stress is 2L 125 x 75 x 12 with Fa=29.29MPa. Set 17- Columns, Beams, Part 5-Structural Combined Stress, Plastic Design Steel Design For 2L 125 x 75 x 12 (Fa=29.29MPa) P=Fa x A= 29.29 (0.00454 x 1000^2)= 133kN For 2L 150 x 90 x 12 (Fa=71.35MPa) P=71.35(0.0055 x 1000^2) = 392.4kN Thus, the most economical section is 2L 150 x 90 x 10. 8. Reference: NSCP Section 4.5.1.4: Check for compactness of the section: d t 700 70 10 w 1680 F b f b 1680 d 250 y Since F t 106.25 1680 F w , then F b 0.66 F y y 0.66(250) 165MPa 9 120 MC M I S M ; M 64080000 N mm 64.08kN m 3 534 x10 w 6 M wL ;64.08 ; w 14.24kN / m 2 2 8 8 W=floor pressure x spacing between beams 14.24 = 4.6 x S; S= 3m 10 I x 360 775 170.5 711 x2 3 3 12 12 I x 3750858585.75 mm 4 I 375,086cm x 4 1cm /10mm 4 Set 17- Columns, Beams, Part 5-Structural Combined Stress, Plastic Design Steel Design 11 The stress at a certain point O is given by: M I M I M I M I x y f I I I xy I I I xy M 0, M 10 x10 N mm (0)(33.6 x10 ) (10 x10 )( 13.4 x10 ) 41.9 f (33.6 x10 )(16.1x10 ) (13.4 x10 )^ 2 (0)(33.6 x10 ) (10 x10 )( 13.4 x10 ) 135.7 (33.6 x10 )(16.1x10 ) (13.4 x10 )^ 2 f 15.54 60.45 44.91MPa(tension) a y x x xy x y 2 x y xy 2 y x y 6 y x 6 o 6 6 6 6 6 6 6 6 6 6 6 o 12 Fv=0.40Fy=0.40(248)=99.2MPa Solving for the load intensity, w: Weight of concrete, 24(0.15+0.05)(2.4) =22.080kN.m Ceiling weight, 7.20(4.6) =3.312kN/m Live load, 2.4(4.6) =11.040kN/m Total =36.432kN/m Try the lightest beam section: Choice D: W12(19;Wt=278N/m, d=309mm, tw=6mm Total w = 36.432+0.278 = 36.71kN/m Maximum shear, V=R=wL/2 = 36.71(100/2 = 183.55kN f v V dt w 183.33x1000 99MPa F v (OK ) 309(6) Thus the lightest beam is Choice letter D: W12 x 19 13 Maximum bending moment: PL M 4 wL 2 8 2 300(6) w(6) M 4 8 M 450 _ 4.5w(kN m) Actual bending stress: M f S b x Set 17- Columns, Beams, Part 5-Structural Combined Stress, Plastic Design Steel Design Allowable tensile stress: F 0.6F t y 0.6(2480 148.8MPa Try first the lightest section: W 21x62; w 911N / m, r t 53mm, S x 0.0023m 3 Allowable compressive stress: Actual bending stress (tension and compression) M=450+4.5(0.911)=454.1kN-m f b Since 454.1 197,435kPa 197.435MPa 0.0023 f is greater than b F and F t b the section is not adequate. r Try W24 x 68;w=1000N/m, 57mm, S x 0.00253m 3 t Allowable compressive stress: F F b b 2 / 3 F y 2 / 3 248 L r t / 10,550,000(1) C F 6000 / 57 / 10,550,000(1)(248) 100.74MPa 2 y b 2 Actual bending stress(tension and compression) M 450 4.5(1) 454.5kN m 454.5 f b 0.00253 179,644.3kPa 179.644MPa Since f b is greater than F and F t Try W18x76; weight=1108N/m, r the section is not adequate. b 57mm, S x 0.00253m 3 t Allowable compressive stress: 2 / 3 F y F b 2 / 3 248 F b L r t / 10,550,000 C F 6000 57 / 10,550,000(1)(248) 100.74MPa 2 b y 2 Actual bending stress(tension and compression) M=450+4.5(1.108)=454.986kN-m f b 454.986 190,371kPa 190.371MPa 0.00239 In this section, fb<Ft but fb>Fb. The section may be adequate but among the choices, this section is much better. Set 17- Columns, Beams, Part 5-Structural Combined Stress, Plastic Design Steel Design 14 to 16 For simply supported beam with a uniform loading; M wL 8 2 50(8) 2 8 400kN m The allowable flexural stress is: F 0.66F 0.66(248) 163.68MPa M Fb f b The actual flexural stress is Sx b y 6 163.68 400 x10 S S 2,443,792.8 mm x 1m / 1000mm 0.00244m x 3 3 3 x According to the problem, the maximum deflection is L/360=8000/360=22.2mm For simply supported beam with uniform loading, the maximum deflection is at the midspan and is given by the formula: 5wL 4 384 EI 4 4 5(50)(80) x1000 22.22 384(200000) I I 600.06 x10 6 mm x 1 / 1000 0.0006m 4 4 4 The required section must have Try W 21 x 68, with D=0.537m S x S x I I 0.00066 0.0023 0.00244(OK ) C D / 2 0.537 / 2 Therefore, the most adequate section is W 21x 68. 17 to 19 3 0.00244m and I x 4 0.0006m Spacing based on shear: The shear capacity of the section is: F v V dt 0.4F y w V 0.4(248)( 498)(56) 2766489.6 N 2766.5kN This shear serves as the reaction R at the ends. Since the beam is loaded uniformly, then R wL w(7) 2766.5; w 790.4kN / m 2 2 Set 17- Columns, Beams, Part 5-Structural Combined Stress, Plastic Design Steel Design Since the beam weighs 7.32kN/m, then the total load it can carry is 790.4-7.32=783.08kN/m= W net W net =120 x S = 783.08; S=6.53m Spacing based on bending: The moment capacity of the section is: F b Mc M 0.66F y I Sx M 3 0.66(2480, M 2247326400 N mm 13730 x10 M 2247.33kN m w(7) M wL 2 2 2247.33, w 366.91kN / m 8 8 W net 366.91 7.32 359.59kN / m W net 120 xS 360; S 3m Spacing based on deflection: 5wL 4 384 EI 7000 / 360 19.44mm 4 5w(7000) 19.44 384(200000)(3417 x10 ) 6 W 424.95 N / mm 424.95kN / m W W net net 424.95 7.32 417.63kN / m 120 xS 417.63; S 3.48m 20 to 23 Check for compactness: (This may not be necessary anymore since most rolled shapes are compact sections) b 2t f F f d 170 t y w 1680 F y 706.4 1680 18.4 250 38.4 106.3(OK ) 357.8 170 2(30.2) 250 5.9 10.7(OK ) Thus the section is compact. L u 138000 2 ; A f b f t f 357.8(30.2) 10805.56mm d Af F y Set 17- Columns, Beams, Part 5-Structural Combined Stress, Plastic Design Steel Design L u L c 138000 8444mm (706.4 / 10805.56)( 250) 200b F y f 200(357.8) 250 4526mm For an unsupported length of 4m (L=4000mm) SinceL L andL L F 0.66F 0.66(250) 165MPa u c b y For an unsupported length of 7m (L=7000mm) SinceL L andL L F o.6F 0.6(250) 150MPa c b u y For an unsupported length of 9m (L=9000mm) SinceL Lc andL Lu Check if 703000C F C 1 b y L r t 3520000C F b y b (for simply supported beam) L r t 9000 95.25 94.49 703000C 703000(1) 53 250 F 3520000C 3520000(1) 118.66 250 F L Since, 703000C 3520000C F r F L r t 2 2 250 95.25 F 250 F 3 F 3 ( 1 ) 10.55x10 C 10.55x10 b y b y b b y t y 2 2 y 6 b y 6 b 83,000C 83,000(1) 141.0MPa L(d A ) 9000(706.4 / 10805.56) Therefore, F 141.07 MPa F b b f b Set 17- Columns, Beams, Part 5-Structural Combined Stress, Plastic Design Steel Design For an unsupported length of 12m (L=12000mm) L r t 12000 127 94.49 3520000C r F 1170x10 C 1170x10 (1) 72.54MPa F L r t 127 Since, L b t y 3 3 b 2 b 2 83,000C 83,000(1) 105.8MPa L d A 12000(706.4 / 10805.56) Therefore, F 105.8MPa F b b f b Verify also: 24 The beam is subjected to a combined axial and bending stress. The relevant equation is: f F a t f F b 1 b Where: f a F a f b F 250,000 45.44MPa = actual axial stress = A 2751(2) = allowable axial tensile stress = 0.60F = actual bending stress = M/Sx Where M= (P/2)(2.25)=1.125P(kN-m) y 0.60(248) 148.8MPa 2 1.125P(1000) f 2(0.000063x1000 ) 3 b F b = 8.928P (MPa) with P in kN = allowable bending stress = 0.66Fy = 0.66(248)= 163.68MPa 45.44 8.929 P 1; P 12.73kN 148.8 163.68 25 to 27 f a P A 800kN 2 61538.46kPa 61.54MPa 0.013m f F 61.54 115 0.535 0.15 C 0.6 0.4M M a a 1 m 2 Set 17- Columns, Beams, Part 5-Structural Combined Stress, Plastic Design Steel Design M 0.96 12 E 12 (200,000) ' F 23 Kl b r b 231(3600 / 94) f C f C f 1 F f f 1 ' F 1 ' F F F 0.96 f 61.54 C m 0.6 0.4 0.9M 2 2 2 2 2 e mx a a 2 my bx a by a bx by ex 115 f b ey b 61.54 1 149 702.16 65.83MPa 1 702.16 Also: f 0.6F a y f F f bx bx f F 61.54 b 1; 0.6(248) 149 Thus, f b f b 1 by f b 87.38MPa 65.83MPa M S by M 3 65.83 0.00012(1000) x M 7,89,600 N mm 7.9kN m 28 to 30 Axial stress: f a P 320000 21.77 MPa A 14700 Bending stress: M wL 8 2 2 32(6) 8 144kN m 6 f 144 x10 S 1921x10 M 3 b 74.96MPa x Interaction equation: 21.77 74.96 0.604 0.6(248) 0.66(248) Set 17- Columns, Beams, Part 5-Structural Combined Stress, Plastic Design Steel Design 31 According to Section 4.5.1.2.1 of NSCP; 0.4(2000 32 V ;V 432000 N 432kN 600(9) F 0.4F v y V dt w F v V dt 0.4(250) 100 w 2,000,000 8000t 100; t w 25mm w 33 f v VQ 90,000(382,050) 35.375MPa 6 It ( 9 ) 108x10 34 F 0.4F v F v V dt w y 99.2MPa V 99.2;V 446,400 N 446.4kN 300(15) 35 According to Section 4.11 of NSCP, the effective width of the concrete flange shall be taken as not more than 1/4 the span of the beam, and the effective projection beyond the edge of the beam shall not be taken as more than 1/2 the clear distance to the adjacent beam nor more than 8 times the slab thickness. (1) b L / 4 8000 / 4 2000.. 2m (2)b b f 2b1 b 1 1 / 2(2220) 1110 or b1 8(120) 90 b 180 2(960) 2100mm 2.1m Use b=2m Set 17- Columns, Beams, Part 5-Structural Combined Stress, Plastic Design Steel Design 36 Transforming the concrete to steel, its equivalent width is 2000/n=200mm Then; AY G A 39480Y slab G A steel 200(150) 9480 39480mm 2 (200)(150) x75 9780 x356.5;Y G 142.59mm 37 Where Ac is the actual area of effective concrete flange and As is the area of steel beam.According to Section 4.11.4, the total horizontal shear to be resisted by shear connectors at the junction of the steel beam and the concrete slab shall be taken as the smaller value of the following: V V h b 0.85 f ' A 2 0.85 f ' A c 2 AF c c c and V h AF s y 2 0.85(27)1000(100) 1,147,500 N 2 10,000(250) 1,250,000 N 2 2 Thus, useV h 1,147,500 N 1,147.5kN 1,147.5 22.95say 23 Number of shear connectors = 50 V h s y 38 to 40 A Area of plate, R F p 2 196,000 163,333mm 1.2 A=B x N= B(250)=163,333;B=653 mm say 660mm Set 17- Columns, Beams, Part 5-Structural Combined Stress, Plastic Design Steel Design n t B 660 k1 22 308mm 2 2 3f n F 2 p b f t 3(1.188)(308) 186 2 p 196000 1.188MPa 250(660) F 0.75F b 42.63mmsay43mm y (0.75)( 248) 186MPa 41 The plastic moment capacity is given by the relationship Mp=Fy x Z, where Z is the plastic section modulus of the section. 6 Then, 288x10 (250) Z ; Z 1152000 mm 1152cm 3 3 42 to 45 100(200) 60(140) 11600mm 0.0116 mm 2 Area = The plastic NA divides the section into two equal areas. Area below NA=11600/2 Area below NA = 5800 60(40)+2[20(x)]=5800 X=85mm A. 115-10=105mm B. 115/2=57.5mm C.85/2=42.5mm D.85-20=65mm Plastic section modulus: Ay 60(20)(105) 2 x(115)(20)(57.5) Z= +60(40)(65) + 2 x (85)(20)(42.5) Z=691,000mm^3=0.000691m^3 Mp=FyZ=250 x 691,000 = 172.75 x 10^6N-mm Mp=172.75kN-m 2 46 to 48 2 A1 300(40) 12000mm A 300(400 12000mm A 400(40) 16000mm A A A A 40000mm A Y Ay 2 2 2 3 T T 1 2 2 3 G Set 17- Columns, Beams, Part 5-Structural Combined Stress, Plastic Design Steel Design 40000Y 12000(360) 12000(190) 16000(20) Y 173mm G G a 360 173 187 mm b 190 173 17 mm c 173 20 153mm I g I 3 g Ad 2 300(40) 12 3 2 12000(187) 40(300) 12 3 2 12000(17) I g 400(40) 12 891,373,333mm 2 16000(153) 4 I ; c 380 173 207 C 3 891,373,333 S 4,306,151mm 207 S Plastic Section Modulus: The plastic N.A. divides the section 2 A 40,000mm A 20,000 A T aboveN. A. belowN . A. 300(40) 40a 20000 a 200mm, b 100mm Y Y Y Y 1 200 20 220mm 2 200 / 2 100mm 3 100 / 2 50mm 4 100 20 120mm Z Ay 300(40)( 220) 200(40)(100) 100(40)(50) 400(40)(120) 3 Z 5,560,000mm 49 Internal work=external work Mp(40)=1/2(w)(6)(30) 400(4)=9w W=177.78kN/m Set 17- Columns, Beams, Part 5-Structural Combined Stress, Plastic Design Steel Design 50 Internal work = external work M M p 2 5 140(6 ) p 120kN m 51 For collapse mechanism 1: M M p (4 6 ) 90(8 ) 80(2 ) p 88kN m For collapse mechanism 2: M M p 6 90(2 ) 80(5 ) p 82.86kN m Thus, the design plastic moment Mp=88kN-m 52 to 54 Beam Mechanism M p 2 111(6 ) Mp 180kN m Sidesway mechanism: M p ( ) 40(6 ) Mp 120kN m Combined Mechanism: Mp (2 ) 40(6 ) 120(6 ) Mp 240kN m Set 18-Miscellaneous & Part 5-Structural Recent Board Problems Steel Design Situation: Problem 1 to 3: A riveted lap joint is shown in Figure ST-17. The rivet have 16mm diameters, and the permissible stresses are 124MPA for shear in rivets, 296MPa for bearing and 165MPa for tension (on net area) in plates. The plates are 10mm thick. Assume hole diameter be 1.5mm larger than the rived diameter. Problem 1 Which of the following gives the value of P so that the allowable bearing stress in rivets will not be exceeded. A. 285.7kN C. 236.8kN B. 214.5kN D. 257.7kN Problem 2 Which of the following gives the value of P so that the allowable tensile stress in plates will not be exceeded. A. 302.5kN C. 298.3kN B. 254.8kN D. 280.5kN Problem 3 Which of the following gives the safe value of P. A. 124.6kN C. 280.5kN B. 114.3kN D. 236.8kN Situation: problem 4 to 6 (CE May 2002) A plate with width of 400mm and thickness of 12mm is to be connected to a plate of the same width and thickness by 34mm diameter blots, as shown in Figure ST-13. The hole are 2mm larger than the bolt diameter. The plate is A36 steel with yield strength Fy=248MegaPascals. Allowable tensile stress is 0.60Fy. It is required to determine the value of b so that the net width along bolts 1-2-3-3 is equal to the net width along bolts 1-2-4. Set 18-Miscellaneous & Part 5-Structural Recent Board Problems Steel Design Problem 4 Which of the following gives the value of b in millimeters. A. 28.6 B. 37.4 C. 52.1 D. 19.7 Problem 5 Which of the following gives the value of the net area for tension in plates in square millimeters. A. 3624 B. 3214 C. 3867 D. 4178 Problem 6 Which of the following gives the value of P so that the allowable tensile stress on net area will not be exceeded. A. 575 B. 687 Situation: Problem 7 to 9 An axially loaded connection is shown in Figure ST-71. The plate is A36 steel with thickness of 6mm. The rivets are 28mm diameter with allowable shearing stress of 190MPa. Allowable bearing stress on projected area between rivet and plate is 370MPa and the allowable tensile stress on plates on net area is 150MPa. Hole diameter is 1.5mm larger than C. 539 D. 424 the rivet diameter. Problem 7 Which of the following gives the value of P without exceeding the allowable shearing stress in rivets, in KiloNewton: A. 495 C. 465 B. 430 D. 450 Set 19-Timber and Part 6-Structural Timber Construction & Construction Problem 87 Which of the following most nearly gives the uniformly distributed load the beam can carry without exceeding the allowable shearing stress in wood, in kN/m. A. 12.15 C. 12.96 B. 16.2 D. 16.2 Problem 88 Which of the following most nearly give the uniform distributed load the beam csn carry without exceeding the allowable shearing stress in glue, in kN/m. A. 12.15 B. 10.58 C. 16.2 D. 12.96 Situation: problem 89 to 91 Two 75mm x 200mm members are bolted to a 100 x 250mm horizontal member, as shown in Figure TD-44, with four 20-mm volts. The angle between the members is 45 degree, the sloping member transmits a compressive force to the horizontal member and the wood is Yakal (Special Group 1). The allowable load in each bolt for the connection is given in Table 4-4. Problem 89 If failure occur in the inclined member, which of the following most nearly gives the value of F without exceeding the allowable, in KiloNewton, load in the bolts: A. 45.7 C. 68.9 B. 76.3 D. 89.2 Problem 90 If failure occur in the horizontal member, which of the following most nearly gives the value of F without exceeding the allowable, in KiloNewton, load in the bolts: A. 62.4 C. 58.7 B. 68.9 D. 45.7 Problem 91 Which of the following most nearly gives the safe value of F in KiloNewton: A. 76.3 C. 58.7 B. 62.4 D. 89.2 Set 19-Timber and Construction Part 6-Structural Timber & Construction Situation: Problem 92 to 94 A concrete platform weighing 7.2kPa is to be supported during pouring by a timber deck consisting of 25-mm planks resting on wooden joints. Allowable stress of the plank in flexure and shear are 10.34MPa and 0.69MPa, respectively. Allowable deflection of the plank is 1/250 of the span. It is required to determine the spacing of the joist so that the allowable stresses and deflection will not be exceeded. Timber plank weighs 7.86kN/m^3. E=10340MPa. Problem 92 Considering 1m width of plank, which of the following gives the load carried by the plank in KiloNewton per meter. A. 8.1 B. 6.6 C. 7.4 D. 5.2 Problem 93 Which of the following gives the spacing of the without exceeding the allowable shearing stress. A. 3109mm C. 2765mm B. 3457mm D. 1687mm Problem 94 Which of the following gives the required spacing of the joist. A. 1680 B. 740 C. 2765 D. 820 Situation: Problem 95 to 97 (CE November 2001) Section 3.7.3 of NSCP states the following for simple timber solid-column design. Allowable unit stress in N square mm of cross-sectional area of square or rectangular simple solid columns shall be determined by the following formulas, but such unit stress shall not exceed values for compression, parallel to grain Fc in Table 3.1. Short columns (Ie/d of 11 or less); F ' c F c Intermediate columns (Ie/d greater than 11 but less than K) K 0.671 E F F c ' c F 1 I e d 1 c 3 K Long columns (Ie/d of K or greater): F' c 0.30 E I e d 2 Where: Fc=allowable unit stress in compression parallel to grain, MPa ' F c = allowable unit stress in compression parallel to grain adjusted fpr Ie/d ratio where d is the least dimension, MPa E= modulus of elasticity, MPa Ie= effective span length= KeL Set 19-Timber and Part 6-Structural Timber Construction & Construction A 140mm x 140mm Apitong 3m long is used as a column. The column is hinged at both ends with Ke=1.0. The properties of Philippine woods at 80% stress grade is given in Table 4-3. Problem 95 Which of the following gives the classification of the column. A. Long column C. short column B. Intermediate column D. not approved by the code Problem 96 Which of the following most nearly gives the value of the allowable unit stress in compression parallel to grain adjusted for Ie/d ratio, in MegaPascals. A. 5.64 B. 7.54 C. 3.21 D. 4.78 Problem 97 Which of the following most nearly gives the axial load capacity of the column in KiloNewtons. A. 76.5 B. 103.2 C. 93.6 D. 83.3 Set 19-Timber and Construction Part 6-Structural Timber & Construction 1 to 3 From the diagram shown, the critical path is: a-b-d-f-j-k-m-n Duration of project = 65 weeks Earliest start of activity m = 45 weeks 4 to 6 Critical path= A-H-I-J-K-M = 19 days Normal Cost = 1,000 + 2,000 + 1,600 + 250 + 500 + 600 + 800 + 3,000 + 400 + 1,000 + 500 + 500 + 600 Normal Cost = P12,750 Set 19-Timber and Construction Part 6-Structural Timber & Construction Crashing Reduce Activity A to 2 days at an additional cost of P100 Reduce activity H to 3 days at an additional cost of (800/4)(3)=P600 Reduce activity D to 2 days at an additional cost of P50. Reduce activity F to 2 days at an additional cost of P100 Reduce activity L to 1 day at an additional cost of P500. Thus, the least possible time is 15 days and the additional cost (cost of crashing) is P100+600+50+100+500=P1350. Total cost = P12750+1350=P14100. Set 19-Timber and Construction Part 6-Structural Timber & Construction 7 to 9 AAE=P500,000,000.00 120% of P500,000,000=P600,000,000 60% of P500,000,000= 300,000,000 Therefore, only bidders A, C, and D shall be considered as responsive bidders. Average of responsive bids: Average = (550,234,451.98+454,218,557.98+389,122,897.44)/3 Average= P464,525,302.47 AGE=1/2(AAE + Average of responsive bids) AGE=1/2(500,000,000+464,525,302.47)=P482,262,651.23 10 to 12 AAE = P500,000,000.00 Maximum bid price= 120% of P500,000,000 = P600,000,000 Maximum bid price= 60% of P50,000,000=P300,000,000 Therefore, only bidders A,C and D shall be considered as responsive bidders. Average of responsive bids: Average = (550,234,451.98+454,218,557.98+389,122,897.44)/3 Average= P464,525,302.47 AGE=1/2(AAE + Average of responsive bids) AGE=1/2(500,000,000+464,525,302.47)=P482,262,651.23 70% of AGE = P337,583,855.86 According to the rules and regulation, no award of contract shall be made to a bidder whose bid price is higher than either the AAE or AGE, (P500,000,000) or whose bid is lower than 70% of AGE (P337,583,855.86) Among the responsive bidders, the award cant be made t bidder A. It may either be awarded to bidders C or D, and among the two, Bidder D is more desirable.