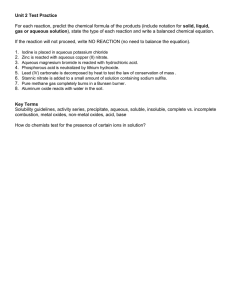

Issue 06.95 LINDE AG Werksgruppe Verfahrenstechnik und Anlagenbau Hollriegelskreuth bei Munchen Orig.:TAW/Dr.Hock 1 LINDE STANDARD Material Selection for Alkaline Service Checked: TAEiRetter v Appr.: 129-30 TAN/Hent. Total 2 Pages SupersedesIssue 12.91 Scope This standardshall applyto the materialselectionand manufactureofvessels,pipingand appertainingvalvesmadeof metallicmaterialsusedfor alkalineservice.“Alkalineservice”shall comprisethe followingrich and lean fluidsfor chemicalwash units for gasescontainingC02 and/orH2S: - Aqueoussolutionsof alkalihydroxides,(i.e. NaOH,KOH)with concentrations>1,0percentby weight. - Organic,alkalinesolutionslike suliinole,sulfoline,MEA,DEA and MDEA. - Aqueous,inhibitedsolutionsof potassiumcarbonate(13enfieldwash). - AqueousNH3-solutions. 2 Purpose The measuresdescribedin this standardshallpreventdamagesdueto stresscorrosioncracking. 3 Measures for Organic Alkaline Solutions and Aqueous Inhibited Solutions of Potassium Carbonate and Aqueous NH3-Solutions 3.1 Materials - For temperaturess 160”Cferriticcarbon-and/orC/Mn-steelswith nominalyieldstrength< 355 N/mm2shallbe used.For pressurevesselsa corrosionallowanceof 3 mm is required. - For chloride-freecausticsolutionsausteniticCrNi-steels,Ti-stabilizedor with C < 0,03V0maybe used. 3.2 Welding - Dissimilarjoints, i.e. weldedjoints betweenausteniticand ferriticsteelsare not permitted. - Socketweldsare not permitted. - Filler materialsshallbe matchingwith the base metal;for ferriticsteelsthe yield strengthof the weld depositshall not be considerablyhigher than that of the base metal. 3.3 Stress-relieving A thermal stress-relievingof ferriticsteelsis required: - For all pressure-retainingweldsin MEA-service. - For pressurevesselswith designpressures>5 bar. - For weldedjoints in contactwith the fluid, if the designtemperatureis above50”C. - For bent pats with cold deforming> 5%, if the designtemperatureis above50°C. After stress-relievingweldingoperationsor coldworkingare ~ allowedon thesecomponents. 4 Measures for Aqueous Solutions of Alkali Hydroxides with Concentrations >1,0 Percent by Weight 4.1 Materials - For causticconcentrations< 30V0by weightwith chloridecontents< O,lYO by weight(as NaCl)and temperatures < loooc”ferriticcarbon-and C/Mn-steelswith nominalyield strengths<355 N/mm*shallbe used.For pressure vesselsa corrosionallowanceof 3 mm is required. - For chloride-freecausticsolutionswith concentrations< 50Y0by weightand temperatures< 120°CausteniticCrNisteels,Ti-stabilizedor with C < 0,03°/0,maybe used. 4.2 Welding - Dissimilarjoints, i.e. weldedjoints betweenausteniticand ferriticsteelsare not permitted. - Socketweldsare not permitted. - Filler materialsshallbe matchingwith the base metal;for ferriticsteelsthe yield strengthsof the weld depositshall not be considerablyhigherthan that of the base metal. Page 2 Issue 06.95 LS 129-30 LINDE AG Werksgruppe Verfahrenstechnik und Anlagenbau 4.3 Stress-relieving Athermal stress-relievingofferriticsteelsisrequired: Forvesselswithdesignpressures >5bar(independentofthe designtemperature) Forweldedjoints incontact with the fluid, ifthe designtemperatureis abovethe curveofdiagram 1. For bentparts withcolddeforming >5%, ifthe designtemperatureis abovethecurveofdiagram 1. Afterstress-relievingweldingoperationsor coldworkingare ~allowed on thesecomponents. 100 90 80 70 60 50 40 I 30 0 5 10 15 20 25 30 Caustic Concentration( % by weight) Diagram 1: Stress-relievingof carbonsteelsafter manufacturein the NaOH/KOH-service. Revision:Revised. PreviousIssues:02.70 (withdrawnsince03.S7),07.89,04.91, 12.91 Copyrightreserved.