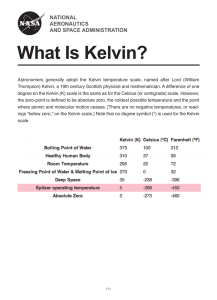

APSC252 Final Exam Formula Sheet Pressure, temperature and specific volume Absolute temperature: 𝑇[𝐾] = 𝑇[°𝐶] + 273.15 Pressure: 𝑃 = 𝐹/𝐴 Absolute pressure: Pabs=Patm+ ρgh Gage pressure: Pgage=Pabs - Patm Specific volume: 𝕍 1 𝑣=𝑚=𝜌 (𝕍: volume) Two-phase mixture Quality: 𝑥 = 𝑚𝑣𝑎𝑝𝑜𝑢𝑟 𝑚𝑚𝑖𝑥𝑡𝑢𝑟𝑒 Specific volume: 𝑣 = 𝑣𝑓 + 𝑥𝑣𝑓𝑔 = (1 − 𝑥)𝑣𝑓 + 𝑥𝑣𝑔 , 𝑣𝑓𝑔 = 𝑣𝑔 − 𝑣𝑓 Specific internal energy: 𝑢 = 𝑢𝑓 + 𝑥𝑢𝑓𝑔 = (1 − 𝑥)𝑢𝑓 + 𝑥𝑢𝑔 , 𝑢𝑓𝑔 = 𝑢𝑔 − 𝑢𝑓 Specific enthalpy: ℎ = ℎ𝑓 + 𝑥ℎ𝑓𝑔 = (1 − 𝑥)ℎ𝑓 + 𝑥ℎ𝑔 , ℎ𝑓𝑔 = ℎ𝑔 − ℎ𝑓 Specific entropy: 𝑠 = 𝑠𝑓 + 𝑥𝑠𝑓𝑔 = (1 − 𝑥)𝑠𝑓 + 𝑥𝑠𝑔 , 𝑠𝑓𝑔 = 𝑠𝑔 − 𝑠𝑓 Compressed liquid (when tables are not available) 𝑣 ≈ 𝑣𝑓@𝑇 𝑢 ≈ 𝑢𝑓@𝑇 ℎ ≈ ℎ𝑓@𝑇 𝑠 ≈ 𝑠𝑓@𝑇 Ideal gas EOS: 𝑃𝑣 = 𝑅𝑇 or 𝑃𝕍 = 𝑚𝑅𝑇 (R: gas constant; 𝕍: volume; 𝑣: specific volume) (T in Kelvin) Specific heats: 𝑐𝑝 = 𝑐𝑣 + 𝑅, 𝑘 = 𝑐𝑝 /𝑐𝑣 , 𝑘𝑅 𝑅 𝑐𝑝 = 𝑘−1 , 𝑐𝑣 = 𝑘−1 Specific enthalpy and specific internal energy: ℎ = 𝑢 + 𝑃𝑣 = 𝑢 + 𝑅𝑇 𝑢 = 𝑐𝑣 𝑇 , Change in specific internal energy (assuming constant 𝑐𝑣0 ) Change in specific enthalpy (assuming constant 𝑐𝑝0 ) ℎ = 𝑐𝑝 𝑇 𝑢2 − 𝑢1 = 𝑐𝑣0 (𝑇2 − 𝑇1 ) ℎ2 − ℎ1 = 𝑐𝑝0 (𝑇2 − 𝑇1 ) Change in specific entropy 𝑃 0 0 ) 𝑠2 − 𝑠1 = (𝑠𝑇2 − 𝑠𝑇1 − 𝑅ln 𝑃2 • Accurate method • Approximate method (assuming constant 𝑐𝑣0 and 𝑐𝑝0 ) 1 𝑠2 − 𝑠1 = 𝑐𝑝0 ln Compressibility factor: 𝑍 = 𝑇2 𝑇1 𝑃𝑣 𝑅𝑇 − 𝑅ln 𝑃2 𝑃1 or 𝑠2 − 𝑠1 = 𝑐𝑣0 ln ; reduced pressure and temperature: 𝑃𝑟 = 𝑇2 𝑇1 𝑃 𝑃𝑐 + 𝑅ln 𝑣2 𝑣1 𝑇 , 𝑇𝑟 = 𝑇 𝑐 (T in Kelvin) (T in Kelvin) Solid and liquid Specific heats: 𝑐 = 𝑐𝑝 = 𝑐𝑣 Change in specific internal energy or specific enthalpy: ℎ2 − ℎ1 ≈ 𝑢2 − 𝑢1 ≈ 𝑐(𝑇2 − 𝑇1 ) 𝑇2 Change in specific entropy: 𝑠2 − 𝑠1 = 𝑐ln (T in Kelvin) 𝑇1 1 Energy, work and heat Total energy: 𝐸 = 𝑈 + 𝐾𝐸 + 𝑃𝐸 = 𝑚𝑢 + ½ 𝑚𝑉 2 + 𝑚𝑔𝑧 (V: velocity) Specific total energy: 𝑒 = 𝐸/𝑚 = 𝑢 + ½ 𝑉 2 + 𝑔𝑧 (V: velocity) Specific internal energy: 𝑢 = 𝑈/𝑚 Specific heat transfer: 𝑞 = 𝑄/𝑚 2 Boundary work: 1W2= ∫1 𝑃𝑑𝕍 (area under the P- 𝕍 diagram; 𝕍: volume) Specific work: 𝑤 = 𝑊/𝑚 2 1 Spring work: 𝑊spring = ∫1 𝐹𝑑𝑥 = 𝐾(𝑥22 − 𝑥12 ) 2 ̇ Shaft power: 𝑊 = 𝑇𝜔 (T: torque) Closed systems (control mass) 1st law: E2 − E1 = 1Q2 − 1W2 2nd law: 𝑆2 − 𝑆1 = ∑ 𝑄𝑘 𝑇𝑘 or + 𝑆𝑔𝑒𝑛 U2 − U1 = 1Q2 − 1W2 (assuming KE=0, PE=0) (𝑆𝑔𝑒𝑛 ≥ 0) (T in Kelvin) Volume flow rate and mass flow rate Volume flow rate: 𝕍̇ = 𝑉𝑎𝑣𝑔,𝑛 𝐴 = 𝑚̇𝑣 (𝕍: volume, V: velocity, 𝑣 : specific volume) Mass flow rate: 𝑚̇ = 𝜌𝕍̇ = 𝜌𝑉𝑎𝑣𝑔,𝑛 𝐴 Steady-state, steady flow through a control volume (open system) Conservation of mass: ∑ 𝑚̇𝑖 = ∑ 𝑚̇𝑒 1 1 1st law: 𝑄̇𝑐𝑣 + ∑ 𝑚̇𝑖 (ℎ𝑖 + 𝑉𝑖2 + 𝑔𝑧𝑖 ) = 𝑊̇𝑐𝑣 + ∑ 𝑚̇𝑒 (ℎ𝑒 + 𝑉𝑒2 + 𝑔𝑧𝑒 ) 2 2nd law: ∑ 𝑚̇𝑒 𝑠𝑒 − ∑ 𝑚̇𝑖 𝑠𝑖 = ∑ 2 𝑄̇𝑐.𝑣. 𝑇 ̇ + 𝑆𝑔𝑒𝑛 ̇ (𝑆𝑔𝑒𝑛 ≥ 0) (T in Kelvin) Applications of the conservation of mass and the 1st law in different steady-state, steady flow devices (note: the following derived relations are valid only if the given assumptions can be applied.) • Throttling valve: 𝑚̇𝑖 = 𝑚̇𝑒 , ℎ𝑖 = ℎ𝑒 (assuming 𝑄̇𝑐𝑣 = 0, 𝑊̇𝑐𝑣 = 0, ΔPE = 0, ΔKE = 0) 1 1 • Nozzle and diffuser: 𝑚̇𝑖 = 𝑚̇𝑒 , ℎ𝑖 + 𝑉𝑖2 = ℎ𝑒 + 𝑉𝑒2 (assuming 𝑄̇𝑐𝑣 = 0, 𝑊̇𝑐𝑣 = 0, ΔPE = 0) 2 2 • Mixing chamber: ∑ 𝑚̇𝑖 = ∑ 𝑚̇𝑒 , 𝑄̇𝑐𝑣 + ∑ 𝑚̇𝑖 ℎ𝑖 = ∑ 𝑚̇𝑒 ℎ𝑒 (assuming 𝑊̇𝑐𝑣 = 0, ΔPE = 0, ΔKE = 0) • Heat exchanger: 𝑚̇𝑖 = 𝑚̇𝑒 (for each of the hot and cold streams, separately) 𝑄̇𝑐𝑣 + ∑ 𝑚̇𝑖 ℎ𝑖 = ∑ 𝑚̇𝑒 ℎ𝑒 (assuming 𝑊̇𝑐𝑣 = 0, ΔPE = 0, ΔKE = 0) • Turbine: 𝑚̇𝑖 = 𝑚̇𝑒 = 𝑚̇ , 𝑊̇𝑠ℎ𝑎𝑓𝑡 = 𝑚̇(ℎ𝑖 − ℎ𝑒 ) (assuming 𝑄̇𝑐𝑣 = 0, ΔPE = 0, ΔKE = 0) • Compressor: 𝑚̇𝑖 = 𝑚̇𝑒 = 𝑚̇ , 𝑊̇𝑠ℎ𝑎𝑓𝑡 = 𝑚̇(ℎ𝑒 − ℎ𝑖 ) (assuming 𝑄̇𝑐𝑣 = 0, ΔPE = 0, ΔKE = 0) 2 Processes • Isobaric process: P=const • Isochoric process: v=const • Isothermal process: T=const • Adiabatic process: heat transfer Q=0 (for closed systems) • Reversible process: 𝑆𝑔𝑒𝑛 = 0 (for closed systems) 𝑄̇𝑐𝑣 = 0 (for control volumes) or ̇ 𝑆𝑔𝑒𝑛 = 0 (for control volumes) or • Isentropic process: reversible adiabatic process • Polytropic process: 𝑃𝕍𝑛 = 𝑐𝑜𝑛𝑠𝑡. (𝕍: volume) Boundary work in a polytropic process o 1W2= 𝑃2 𝕍2 −𝑃1 𝕍1 o 1W2= 𝑃1 𝕍1 𝑙𝑛 𝕍2 = 𝑃2 𝕍2 𝑙𝑛 𝕍2 = 𝑚𝑅𝑇 𝑙𝑛 𝕍2 (𝑛 = 1) (𝑛 ≠ 1) 1−𝑛 𝕍 𝕍 1 𝕍 1 Heat engines • Any heat engine o Net work output: 𝑊𝑛𝑒𝑡,𝑜𝑢𝑡 = 𝑄𝐻 − 𝑄𝐿 o Thermal efficiency: 𝜂𝑡ℎ = 𝑊𝑛𝑒𝑡,𝑜𝑢𝑡 • Carnot heat engine: 𝜂𝑡ℎ,𝑟𝑒𝑣 = 1 − 𝑄𝐻 𝑇𝐿 𝑄 = 1 − 𝑄𝐿 𝐻 (T in Kelvin) 𝑇𝐻 Refrigerators • Any refrigerator o Net work input: 𝑊𝑛𝑒𝑡,𝑖𝑛 = 𝑄𝐻 − 𝑄𝐿 o Coefficient of performance: 𝐶𝑂𝑃𝑅 = • Carnot refrigerator: 𝐶𝑂𝑃𝑅,𝑟𝑒𝑣 = 𝑇𝐿 𝑇𝐻 −𝑇𝐿 =𝑇 𝑄𝐿 𝑊𝑛𝑒𝑡,𝑖𝑛 1 Coefficient of performance: 𝐶𝑂𝑃𝐻𝑃 = • Carnot heat pump: 𝐶𝑂𝑃𝐻𝑃,𝑟𝑒𝑣 = 𝑇𝐻 𝑇𝐻 −𝑇𝐿 =𝑄 𝐻 /𝑇𝐿 −1 Heat pumps • Any heat pump o Net work input: 𝑊𝑛𝑒𝑡,𝑖𝑛 = 𝑄𝐻 − 𝑄𝐿 o (T in Kelvin) 1 𝑄𝐻 𝑊𝑛𝑒𝑡,𝑖𝑛 1 = 1−𝑇 /𝑇 𝐿 𝐻 𝑄𝐿 𝐻 −𝑄𝐿 =𝑄 1 𝐻 /𝑄𝐿 −1 (T in Kelvin) =𝑄 𝑄𝐻 𝐻 −𝑄𝐿 1 = 1−𝑄 𝐿 /𝑄𝐻 (T in Kelvin) ======================================================================================= 3