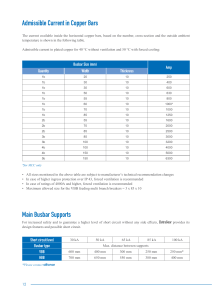

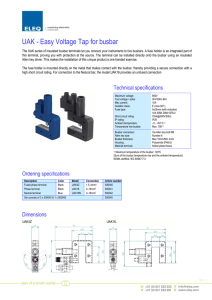

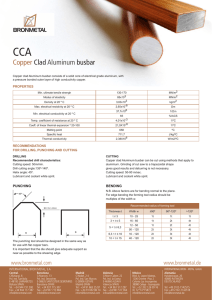

Busbar System We manufacturer the world’s most advanced and flexible Design Verified busbar systems. Supports and holders are made from reinforced self-extinguishing material. Busbars systems utilize standard 10 mm flat bars and are a clamp-type arrangement, this allows the bars to easily slide into their holders, offering easy assembly, as well as minimum resistance during expansion or contraction. The world’s most advanced and flexible Design Verified busbar systems. Both copper and aluminum bars have been tested with the Elsteel busbar holders. Both types have achieved equal test results, with aluminum being the most cost effective solution. Fully insulated busbar systems are also available as standard. We manufacture a range of standard ventilated covers, for busbar joint connections. So, for every type of busbar system required, Elsteel has it covered. All busbar systems are designed, manufactured and most importantly tested by Elsteel. The labour saving to assemble busbar systems, helps hugely towards the cost of copper or aluminum material. Fully Withdrawable inserts are used where very fast changes, upgrades or repairs are essential to your system, whilst the panel remains live. This is typically used on projects where the lives of people are at stake, such as hospitals, railways, tunnels, cement plants etc. Or where high financial costs are at stake. Such as oil & gas platforms, refineries, airports, production lines, etc... The fully withdrawable units can be used for power distribution or MCC. Removable inserts are also used where very fast changes, upgrades or repairs are essential. The panel can remain live whist the change takes place, however outgoing cables need to be disconnected from the unit before it can be replaced, hence the name removable. This type of unit can be used on projects where plug-in devices are requested and specified. There is no need to buy the circuit breaker manufacturers expensive plug-in base. Fixed type - All equipment, like circuit breakers, fuse switches, contactors, terminals etc., are connected by bolted cables, flexible braids and solid copper. Fixed type inserts are widely used for schools, factories, gas filling stations etc. Projects where it is ok to isolate the panel in order to do maintenance, repairs or changes. Protocol can be Modbus, Profibus or Ethernet. Another great benefit, the yearly thermal monitoring survey that many countries insist on, can be limited or even completely avoided. Motor Vision Control Motor Vision Control insert allows the end user to be instantly alerted when a circuit breaker malfunctions. It’s an inexpensive small PLC that can communicate with great ease with other BMS/SCADA systems. It monitors the circuit breaker 24/7 and sends a text message should levels exceed pre-set values. The operator can then chose to re-set the circuit breaker via a text message back to the panel or send a technician to investigate further. For instance, if it's in an ice cream production facility and the freezer supply malfunctions during the night, then the instant warning enables the user to fix the problem instantly. Rather than arrive to work the following morning with a destroyed batch of ice cream. Huge losses can be avoided because of this early warning signal. Temperature Vision Temperature Vision insert is a 24/7 thermal sensing system that allows the user to be instantly alerted to an over temperature situation and therefore can avoid huge financial losses. Thermal sensors are installed in key busbar joint locations throughout the panel. The system can be connected to a site BMS/SCADA system or a desk top PC. Preset maximum temperature levels can be set, so if there is an abnormal temperature change to a connection point, an early warning can be sent to avoid a potential major fault. Key Features Total solution from 250A – 7100A with a short circuit rating up to 120kA / 1 sec and 100kA / 3 sec Main busbar chamber can be in the top, bottom, middle or rear section of the panel Vast range of busbar holders for different ratings of busbars systems Air natural ventilated busbar systems – no need for forced air ventilation Standard 10 mm flat copper or aluminum bars Assembler/panel builder purchases his own copper or aluminum bars Arc fault containment testing in accordance with IEC TR 61641 Easy and quick to assemble