DEGREE PROJECT IN MECHANICAL ENGINEERING,

SECOND CYCLE, 30 CREDITS

STOCKHOLM, SWEDEN 2021

Evaluation of thermal expansion in

busbars used for battery electric

vehicles

FREDRIK LARSSON

KTH ROYAL INSTITUTE OF TECHNOLOGY

SCHOOL OF INDUSTRIAL ENGINEERING AND MANAGEMENT

Evaluation of thermal

expansion in busbars used

for battery electric vehicles

FREDRIK LARSSON

M.Sc Mechatronics

Date: September 14, 2021

Supervisor: Andrii. Berezovskyi.

Examiner: Martin Edin Grimheden.

Host company: Scania AB

Swedish title: Utvärdering av termisk expansion i busbars för

implementering inom batteridrivna fordon

© 2021

Fredrik Larsson

Abstract | i

Master of Science Thesis MMK TRITA-ITM-EX 2021:470

Evaluation of thermal expansion in busbars

used for battery electric vehicles

Fredrik Larsson

Approved

2021-07-01

Martin Edin

Grimheden

Examiner

Commissioner

Scania

Andrii

Berezovskyi

Contact person Arikson

Heraldus Panji

Supervisor

Abstract

Thermal expansion can be an issue in solid busbars, the expansion is caused

by several factors and can cause plastic deformation in connection points or

structure around it. The expansion occurs due to temperature differences in

the busbar as a result of altered ambient temperature and/or joule heating. The

environment where a vehicle is used can be harsh and varying in temperatures a

lot. For future fast charging systems, a high amount of current will be passed in

the conductors. In a stationary installation, this could be solved by increasing

the cross-section area. In vehicles, the weight, cost, and space limitations call

for optimization of the conductor.

In this thesis, there are several geometrical alterations done to the busbar

to investigate the possibility to reduce the amount of stress acting on the

connection points. The main geometrical evaluation is to compare a straight

busbar to a U-shaped busbar. In the U-shape, the height, bend radius, and

cross-section shape are investigated. To investigate this issue a simulation

model was developed using Comsol, this software was used to evaluate stress

values, max temperature, losses, and displacement.

The results from the simulation showed that the U-shape has a large potential

to reduce the amount of stress. Also, the cross-section shape tests showed

that the steady-state temperature was lower for the more flatter shaped busbar.

ii | Abstract

This is true both for the U-shape and straight busbar. This resulted in

reduced amount of thermal expansion causing lower amount of stress, without

adding any weight. The weight parameter is extremely important for vehicle

implementation.

The last test is looking at the busbar material where nickel-plated copper is

compared to anodized aluminum. This test is divided into two parts, the first

one is looking at an aluminum busbar compared to a copper busbar of the

same geometry. This test showed that the losses in the aluminum busbar were

much higher, but the steady-state temperature and max stress were lower. The

second part of the test investigated the compensated aluminum busbar, this one

is modeled by compensating the cross-section area for the higher resistance

value of aluminum. The results from this busbar compared to the standardshaped busbar showed a substantially lower stress, temperature and weight.

But the overall dimensions are larger due to the compensated cross-section

area. Having this larger Cross section area might hinder the implementation

of aluminium busbars in parts of the vehicle where there is a lack of space,

like in a battery box.

Keywords

Busbar, Battery electric vehicle, Thermal expansion, Cross-section shape,

Sammanfattning | iii

Examensarbete MMK TRITA-ITM-EX 2021:470

Utvärdering av termisk expansion i solida metallskenor

för användning inom batteridrivna fordon

Fredrik Larsson

Godkänt

2021-07-01

Martin Edin

Grimheden

Examinator

Uppdragsgivare

Scania

Andrii

Berezovskyi

Kontaktperson Arikson

Heraldus Panji

Handledare

Sammanfattning

Termisk expansion i solida busbars är ett vanligt problem vid kraftig temperaturvariation.

Problemet ökar med längden av busbaren och kan leda till plastisk deformation

i infästningen av busbaren. Temperaturvariationen kan ske genom varierad

omgivningstemperatur eller genom resistiv uppvärmning. Om en busbar ska

användas i ett fordon för kraftöverföring är arbetsmiljön mycket påfrestande.

Den termiska uppvärmningen går normalt att motverka genom att öka tvärsnittsarean,

men i ett fordon där vikt, kostnad och platsbrist minskar möjligheten för ökad

tvärsnittsarea blir optimering av ledaren extra viktig.

För att undersöka problemet utvecklades en simuleringsmodell med hjälp av

Comsol. Denna programvara använder för att utvärdera spänningskoncentrationer,

maxtemperatur, förluster och utböjningar i busbaren. För att undersöka eventuella

lösningar togs det fram flera geometriska variationer till busbaren, där möjligheten

att använda en “U-form” utgjorde basen i en jämförelse mot en vanlig rak

busbar. För U-formen undersöktes U-höjden, böj-radien samt tvärsnittsformen.

Även en jämförelse mellan nickelpläterad koppar och anodiserad aluminium

genomfördes för att urskilja eventuella för och nackdelar med materialen.

Resultaten från simuleringarna visade att U-formen gav klart lägre spänning i

kontaktpunkterna. Även tvärsnittsformen påverkade temperaturen och spänningen

i busbaren, där den plattare varianten presterade bättre på alla parametrar som

iv | Sammanfattning

undersöktes i simuleringen.

För utvärderingen av materialet utfördes två tester, det första testet jämför en

busbar i aluminium mot en i koppar med exakt samma geometri, detta test

visade att temperaturen samt spänningen blir lägre i aluminiumvarianten, dock

ökar förlusterna kraftigt då aluminium har högre resistans än koppar. I den

andra testet användes en kompenserad aluminiumbusbar där tvärsnittsarean

har ökats för att ge samma resistans som kopparvarianten. Denna busbar fick

en mycket lägre sluttemperatur, spänning och vikt. förlusterna blev detsamma.

Den högre tvärsnittsarean ger dock en fysiskt större busbar.

Acknowledgments | v

Acknowledgments

I would like to thank the UECB team at Scania for allowing me to work on

this thesis topic together, special thanks to Heraldus Panji Arikson Pardede

for all the support and rewarding conversations around the topic of busbars

and cables. I would also like to thank Andrii Berezovskyi for the phenomenal

support throughout the whole project.

Additionally, I would like to thank Martin Edin Grimheden for giving vital

feedback on the thesis.

And finally, I would like to thank Fredrik Asplund for helping me steer this

project in a proper direction suitable for a master’s thesis.

Stockholm, June 2021

Fredrik Larsson

vi | CONTENTS

Contents

1

2

3

Introduction

1.1 Problem . . . . . .

1.2 Research questions

1.3 Purpose . . . . . .

1.4 Goals . . . . . . .

1.5 Delimitations . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Background

2.1 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 Skin effect . . . . . . . . . . . . . . . . . . . . . .

2.1.2 Connectors . . . . . . . . . . . . . . . . . . . . . .

2.2 Megawatt charging system . . . . . . . . . . . . . . . . . .

2.3 Related work area . . . . . . . . . . . . . . . . . . . . . . .

2.3.1 Busbar for inverter . . . . . . . . . . . . . . . . . .

2.3.2 Thermal expansion in long busbars . . . . . . . . .

2.3.3 Mechanical modelling of busbars under short-circuit

conditions . . . . . . . . . . . . . . . . . . . . . . .

2.3.4 Copper busbars . . . . . . . . . . . . . . . . . . . .

2.3.5 High Thermal Conductivity Insulation . . . . . . . .

Method

3.1 Quasi-experiment . . . . . . . . . . . . . . . . . . .

3.2 Research Paradigm . . . . . . . . . . . . . . . . . .

3.3 Research Process . . . . . . . . . . . . . . . . . . .

3.4 Data Collection . . . . . . . . . . . . . . . . . . . .

3.5 Assessing reliability and validity of the data collected

3.5.1 Mesh refinement analysis . . . . . . . . . . .

3.5.2 Validity of method . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1

2

2

2

3

3

.

.

.

.

.

.

.

5

6

7

7

8

8

8

9

. 9

. 10

. 10

.

.

.

.

.

.

.

13

13

14

14

16

16

16

16

Contents | vii

3.5.3

3.5.4

3.5.5

4

5

6

Reliability of method . . . . . . . . . . . . . . . . . . 17

Data validity . . . . . . . . . . . . . . . . . . . . . . 18

Reliability of data . . . . . . . . . . . . . . . . . . . . 18

Implementation

4.1 Hardware . . . . . . . . . .

4.1.1 Cross Section Shape

4.1.2 U-height . . . . . .

4.1.3 Bend radius . . . . .

4.1.4 Material . . . . . . .

4.2 Simulation platform . . . . .

4.3 Simulation data . . . . . . .

4.3.1 Losses . . . . . . . .

4.3.2 Temperature . . . .

4.3.3 Stress . . . . . . . .

4.3.4 Displacement . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

19

19

19

21

22

22

24

25

26

27

27

27

Results and Analysis

5.1 System documentation . . . . . . . . . . . . . . . .

5.2 Test protocol specifications and visual representation

5.3 Test 1: Cross section shape . . . . . . . . . . . . . .

5.4 Test 2: U-height . . . . . . . . . . . . . . . . . . . .

5.5 Test 3: Bend radius . . . . . . . . . . . . . . . . . .

5.6 Test 4: U-shape . . . . . . . . . . . . . . . . . . . .

5.7 Test 5: Material . . . . . . . . . . . . . . . . . . . .

5.8 Reliability Analysis . . . . . . . . . . . . . . . . . .

5.8.1 Mesh refinement . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

29

29

30

35

39

40

40

44

45

45

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Conclusions

51

6.1 Research questions conclusion . . . . . . . . . . . . . . . . . 52

6.2 Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.3 Future work . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

References

55

viii | Contents

LIST OF FIGURES | ix

List of Figures

2.1

Busbars, a stationary installation . . . . . . . . . . . . . . . .

3.1

A flowchart depicting the steps of the research process. . . . . 15

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

Test1: Busbar, cross section view.

Cross section shape difference . .

U-height steps . . . . . . . . . . .

Bend radius steps . . . . . . . . .

Comsol interface . . . . . . . . .

Losses in a busbar . . . . . . . . .

Stress plot . . . . . . . . . . . . .

Busbar displacement . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

20

21

22

23

25

26

28

28

5.1

5.2

5.3

5.4

5.5

CSS1, CSS2 and CSS3 from left to right. . . . . . . . . . .

Test 2: Height options for the U-shape . . . . . . . . . . . .

Test 2: Bend radius options required for the U-shape . . . .

A straight busbar used as a reference in test 4. . . . . . . . .

Test 5: Compensated aluminium busbar next to standard

copper busbar. . . . . . . . . . . . . . . . . . . . . . . . . .

Test 5: Test protocol summary specifications. . . . . . . . .

Test1: Busbar with CSS1 . . . . . . . . . . . . . . . . . . .

Test1: Busbar with CSS2 . . . . . . . . . . . . . . . . . . .

Test1: Busbar with CSS3 . . . . . . . . . . . . . . . . . . .

Stress plot, forced temperature, CSS1 . . . . . . . . . . . .

Stress plot, forced temperature, CSS3 . . . . . . . . . . . .

Test 2: Displacement UH1, Magnified 15×. . . . . . . . . .

Test 2: Displacement UH3, Magnified 15× . . . . . . . . .

Test 3: Current density, Bend radius 1 . . . . . . . . . . . .

Test 3: Current density, Bend radius 3. . . . . . . . . . . . .

Test 4, Straight busbar displacement, Magnified 15× . . . .

.

.

.

.

30

31

32

32

.

.

.

.

.

.

.

.

.

.

.

.

33

34

36

36

36

38

38

40

41

42

42

43

5.6

5.7

5.8

5.9

5.10

5.11

5.12

5.13

5.14

5.15

5.16

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

6

x | LIST OF FIGURES

5.17

5.18

5.19

5.20

5.21

5.22

5.23

5.24

5.25

5.26

Test 4, Straight busbar stress plot . . . . . . . . . . . . . . .

Mesh analysis base settings . . . . . . . . . . . . . . . . . .

MRF = 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MRF = 12 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Losses calculation for different MRF values. . . . . . . . . .

surface temperature difference between MRF value 1 and 12.

Stress difference between MRF value 1 and 12. . . . . . . .

Stress difference between MRF value 5 and 12. . . . . . . .

Final mesh settings. . . . . . . . . . . . . . . . . . . . . . .

Mesh as a result of final settings. . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

43

45

46

46

47

47

48

48

49

49

List of acronyms and abbreviations | xi

List of acronyms and abbreviations

AC Alternating current

BEV Battery Electric Vehicle

BR Bend radius

CSA Cross section area

CSS Cross section shape

DC Direct current

EMC Electromagnetic compatibility

ICE Internal combustion engine

MCS Megawatt charging system

MRF Mesh refinement factor

UH U-height

xii | List of acronyms and abbreviations

Introduction | 1

Chapter 1

Introduction

In this thesis, the problem of thermal expansion in busbars for implementation

in automotive applications are investigated. A busbar is a metal rod that is used

to carry high amounts of current and can in some cases replace cables. The

surrounding environment of the busbar is assumed to be in a Battery Electric

Vehicle(BEV). The difference between a stationary installation of busbars and

vehicle installation is mostly related to higher temperature variations together

with varying performance parameters like weight, losses, and more. In this

thesis, geometrical alterations to the busbars are investigated together with

varying the material between copper and aluminium.

BEV are on the rise all over the world, and most companies are actively

working on it or planning to do so[1]. The change from the combustion engine

to propulsion by electric machine is a vital step in reaching a sustainable

mode of transportation. In this project, the use of a busbar for transferring

power within a BEV will be evaluated. The current solution is mostly to use

cables[2], but when the current demand is high, the resistive losses within

the cable result in the need for thicker conductors. This leads to expensive

and very bulky cables that are complicated to install. Another method is to

use busbars, these allow a more effective and compact way of transferring

DC power. An issue with using a solid busbar is that the high temperature

differences that can be present in a vehicle together with the resistive heating

of the conductor might result in high forces acting on the connection points

due to thermal expansion. These phenomena are investigated in this report.

2 | Introduction

1.1

Problem

The main issue with using a solid busbar within a BEV is that the solid

busbar will experience a length difference when its temperature varies[3]. This

temperature is affected by the external temperature around the vehicle, heat

generated from nearby components, and the heating that occurs as a result of

transferring high current through a conductor. The expansion can result in high

stresses on the connections of the units that are connected and the surrounding

mounts. The cross-section area of the busbar, dimension variations, total

length, and material will all affect the final stress values due to the thermal

expansion.

1.2

Research questions

RQ1: Can the change of the busbar shape to the U-shape sufficiently mitigate

the thermal expansion effects caused by high temperature differences without

introducing negative effects of increased length and current density heat issues

in the bends required for the U-shape?

RQ2: How does the dimensional change of the cross section affect the thermal

expansion for a rectangular shaped busbar?

RQ3: What material is most suitable to allow high current transfer together

with a low amount of thermal stress in the environment of a battery-electric

truck?

1.3

Purpose

Having a good understanding of how varying several base characteristics of

a busbar affect the final result will be a vital step in reaching higher charging

speed and power output in a BEV. From a wider perspective, the ability to

reduce the charging time is one of the most important problems facing BEV,

and the issue is even greater when looking at transportation and construction

vehicles where "uptime" is a key factor to reduce the cost and increase the

efficiency for the customer.

Reducing the amount of ICE-based vehicles and replacing them with BEVs,

Introduction | 3

fuel cells, or similar will be an important step in the fight against global

warming and air pollution.

The busbar could also be used to simplify complex systems where the high

heat generated within cables calls for the use of water cooling, active cooling

increases both complexity, cost, maintenance requirements and could reduce

the efficiency of the power transfer considering the power demand to drive the

system.

Having a good understanding of this topic can also aid the efficiency of battery

packs, as the busbars are in general more space-efficient.

1.4

Goals

The goal of this project is to create a simulation model that can be used to draw

conclusions regarding the thermal expansion behaviour for implementation

within a battery electric vehicle.

Subgoal 1: Create a simulation model that is sufficient to answer the defined

research questions.

Subgoal 2: Evaluate the usability of a U-shaped busbar.

Subgoal 3: Deliver simulation data that can be applied in practical applications.

1.5

Delimitations

The simulation model is looking at only one conductor, thus the interaction

between the conductors’ positive and negative sides is not investigated. If the

conductors are mounted close to each other, the heat generated by the busbars

might interact with each other to increase the total temperature.

Another delimitation is the modeling of the isolation material around the

conductor. This isolation can heavily affect the max temperature that will be

reached in the busbar. The reason this was not added is that the isolation

material would not be affected by the choice of material or variations of

geometry. Thus, this would not affect differences in results, altering the

geometry and material.

4 | Introduction

The terminal connectors are also not investigated in this report. The applied

solution in the simulation environment is similar to using a bolt and nut

connection, the current passing through the bolt is "solidly" connected to the

busbar.

There are also limitations in geometry, the length is defined by Scania as

the maximum length of the busbar, note that the thermal expansion issue

is more prominent the longer the busbar is. For the bend radius, U-height,

and cross-section area, the values are chosen to be reasonable from a BEV

implementation perspective.

Another aspect that is not considered is the potential cooling effect of having

the vehicle moving, this could, depending on implementation, cause something

similar to air-cooling. In this simulation model, there is no cooling of that sort

implemented. one reason is that the charging that represents the worst case

scenario is done stationary, thus no high amount of cooling would occur.

Another limitation is in the materials chosen, there could be other materials

that could be investigated, also the surface treatment is limited to one for

copper and one for aluminum.

Background | 5

Chapter 2

Background

BEV are not new, but the magnitude and type of implementation have changed

a lot in the last years. The most common way of transferring power is through

cables, there are several reasons for using cables, but the main benefit is the

flexibility. As cables are used to connect several components together the

tolerance of installation and cable does not have to be that fine to allow the

connection of cables. The use of busbars are more common in high-power

installations where the distances are small and the current high. It’s also

common in high power electronic units as a way of allowing a compact and

efficient way of transferring power.

When looking at busbar research, the most common topics are related to

inter-electronic use where short distances heavily reduce the consequences of

thermal expansion. Instead, problems are related to AC implementation and

EMC issues.

For long busbars where the length is much greater than the width and height,

the temperature-driven expansion will mostly occur in the length direction.

In reality, a volume-based expansion is present but the difference in the

dimensions other than length is very small. In this thesis, a volume-based

simulation model was developed using Comsol Multiphysics (from hereon

Comsol).

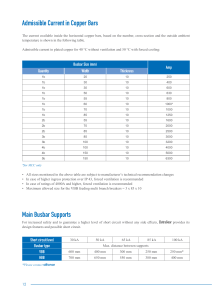

The difference between a stationary installation of busbars in a power station

and an installation within a BEV is related to isolation material, surface

treatment of the conducting material, and quality attributes that vary. For the

isolation material, many stationary installations use no isolation around the

conductors as can be seen in figure 2.1.

6 | Background

Figure 2.1: Busbars, a stationary installation

For the BEV implementation, the environment is harsh, the weight and cost

are important and the service life is long. This promotes the use of heavily

optimized power-transfer systems.

2.1

Cables

The most common way of transferring high power within a vehicle is by

using cables. The benefits are flexibility, that they are easy to connect and

the connectors are heavily standardized. The main principle is using multistrand cable, where several strands of copper or aluminium are tightly packed

in isolation material,this is what gives the flexibility of the cable.

There are also solid cables where there is only one strand of a high thickness

(depending on current demand). But these are unusual for high power

applications as they easily become hard to bend.

Depending on the application, the design of cables change heavily. For a DC

application, the resistance can be calculated using the following equation:

R = (RA L)/A,

where RA is the resistivity of the matierial, L is the length of the conductor

and A is the CSA.

As can be seen, the total CSA directly affects the resistance, and with that

the geometry of the cable. In the case of high power charging, the amount

of current will be high, this makes it inevitable to use thick conductors

Background | 7

and/or water-cooled cables. Using thick conductors results in cables that are

extremely hard to bend, and prices increase accordingly.

Using a liquid-cooled cable has been shown to solve thermal issues in charging

cables connecting to the vehicle inlet [4], but it affects the efficiency of the

power transfer as the generated heat is the result of losses. Also, the cost and

complexity of adding a cooling system to the power transfer should in itself be

a reason to look for alternative solutions.

2.1.1

Skin effect

Another important aspect to consider is what type of power is being transferred.

If the cable will transfer DC power, then the CSA and length is the most

dominant aspect to consider, but if the power is a high frequency AC, then the

skin effect will limit the design options and cause lower efficiency [5]. Skin

effect will cause the current to travel closer to the surface of the conductor, this

increases the resistance in the conductor causing higher losses and inefficient

transfer of current. the higher the frequency the greater the issue.

Using a cable with many individual conductors will mitigate this issue, but

looking at a busbar for a replacement will require redesign of the busbar by

using several thin layers or a wide flat busbar to allow a efficient power transfer.

2.1.2

Connectors

One benefit of using cables is that there are many standardized connector types,

this allows for rapid design when designing power-transfer for an electric

vehicles. One issue with connectors is that the connectors usually have higher

resistance than the cable that is connected. This leads to heat being generated

in and around the connector. Thus, the design of the connector becomes vital

when looking at the whole power transfer in the vehicle. The goal should be to

have as low resistance as possible to reduce the risk of damaging the isolation

material close to the connector. The connector design is not covered within

this thesis, and could potentially be a good next step for further development.

8 | Background

2.2

Megawatt charging system

The transport sector in the United States is responsible for 28 % of the total

greenhouse gas emissions. Among this sector, medium and heavy duty trucks,

boats and planes are responsible for 34 % [6].

These values show that not only the passenger cars needs to be overhauled,

but also the truck sector. One of the important factors to consider when

investigating heavy duty trucks is uptime. This is important as the customers

want their equipment to be ready to be used as much as needed, on demand. At

the same time, large heavy duty truck has to hold batteries many times larger

than any personal vehicle. These requirements indicate that the truck industry

cannot rely solely on the same charging infrastructure (delivering the same

power) as what is used for passenger cars, as the maximum charging power

would not be sufficient.

"For perspective, electrifying one large truck on the road is equivalent to

electrifying 25 passenger vehicles"[6]

One solution could be the Megawatt charging systems (MCSs). The goal is to

develop a charging connector that can deliver charging power in the megawatt

range, this would reduce the charging time substantially. In the preliminary

specifications for the MCSs the amount of current required would be between

1000 and 3000 ampere[6]. As this amount of current has to be transmitted in

the truck on the way to the battery, the development of the power transfer had

to be performed at the same time as the MCSs to reduce the "time to market".

2.3

Related work area

2.3.1

Busbar for inverter

There has been other research that investigate how a busbar can be used, how

to optimize it both with the help of simulations and practical experiments. One

paper is investigating the use of a busbar in an inverter [7]. In this article there

are several aspects that are investigated, and busbar designs are compared,

one of the aspects is how sharp cornering bends can affect the amount of eddy

current close to the bend, and that these bends can increase the losses and thus

the temperature of the busbar. This aspect is investigated in this thesis as the

Background | 9

bends radius is altered in three steps. The difference is that in this thesis the

DC, instead of the AC power transfer will be evaluated.

This article is also looking at simulation results and comparing them to

measurements of the stray inductance and stray capacitance. The results

between the simulations and the measurements are very similar with only few

percent difference for the capacitance, the values for the inductance were more

unreliable on lower frequencies, the simulations conducted in this article are

more complex than what is presented in this thesis, this is due to the use of high

frequency AC power being transferred in the busbar, this requires modeling of

the skin effect. In this thesis the simulations are not as advanced, this implies

that the validity of the simulation has potential to be of higher accuracy.

2.3.2

Thermal expansion in long busbars

Another paper is investigating the thermal expansion behaviour for long busbar

[3]. The focus is not on the geometry but rather on connection points, isolation,

interaction of using several busbars, and how to support the busbar when

mounting it to a construction. The amount of current is also considerably

higher at 200kA compared to 1KA. As the amount of current is so dominating,

the use of flexible and welded plate joints are investigated heavily. The results

show that the connection points of the busbar are the weak point of the

construction, and that extra care has to be taken to these. Another interesting

part is that this paper is also using FEM based simulation to obtain the results.

2.3.3

Mechanical modelling of busbars under shortcircuit conditions

This paper is investigating the electrical, mechanical, thermal, and magnetic

effects of having a busbar in a short-circuit load case[8]. The simulationdriven analysis is also using the Comsol software to perform the analysis. The

main difference is the load case as the short-circuit peak current is taking place

after 0.01 seconds.

Another difference is that in this paper, the busbars are used in a three-phase

system, where all the conductors are modeled in the simulation environment.

The short circuit is causing Lorentz forces to act on the busbars in the shortcircuit moment. This effect is not analyzed in this thesis.

10 | Background

Other similarities are busbar size and nominal current, the busbar is used with

a current of 1650 ampere, but the short circuit current is as high as 50KA.

The cross-section shape is 120x10 mm on each conductor In this paper, a

comparison between the simulation results and manual calculations on the

deflection showed a 0.9% difference. As this model is set up in a similar way

to the model in this thesis the reliability of the simulation results increases.

2.3.4

Copper busbars

In this guide for the design of busbars, there is plenty of general practical

information[9]. In the maintenance section, the issue with copper and

aluminium natural oxidization is described. The first issue with oxidized

copper is that the surface is really good at isolating heat in the busbar. This

promotes the use of any kind of plating in order to protect the copper surface.

The section also describes the phenomenal thermal properties of the natural

oxidization of aluminium. An issue with the high conductivity of aluminium

oxide is the potential risks connected to arcing. According to this guide,

oxidized copper is much less likely to sustain arcing than oxidized aluminium.

Note that this guide is produced by the copper alliance, so they might be biased.

The paper is covering many important aspects, including the skin effect and

how different shapes, skin dept, the proximity of poles, and more. Also, the

CSS is mentioned under section "shape factor for rectangular bars" where the

following sentence can be found;

"There are no analytic formulae for this case. Resort must be made to

numerical methods such as finite elements, finite differences or current simulation,

i.e. particle elements"

This sentence argues the use of simulations to figure out the effect of altering

the CSS, which is covered in this thesis.

2.3.5

High Thermal Conductivity Insulation

This paper investigates different isolation materials to combat thermal issues

in electric vehicle cables[10]. This aspect is not covered in this thesis but

shows the importance to reduce temperatures in the conductor, for one of the

materials the thermal conductivity was enhanced by 90%. This should be

seen as a compliment and not an alternative solution to reducing conductor

Background | 11

temperatures, this paper was covering cable isolation but there should be no

issue in deploying the same materials for busbars. it can even be easier on

busbars as the isolation does not have to be flexible.

Another important aspect to consider is the safety of these isolation materials

as they will work in a harsh environment, and has to last for a very long time.

This is not covered in this article.

12 | Background

Method | 13

Chapter 3

Method

3.1

Quasi-experiment

To be able to answer the research questions, a quasi-experiment approach was

chosen. The reason is that a full-scale experiment was not viable due to several

reasons.

In the tests performed, the geometrical factors are altered in three steps. The

size of these steps are chosen from the perspective of implementation.

The only factor that is altered during each test is the factor corresponding to

that specific test. This is done to make sure the result is isolated from other

factors. All combinations of variables are not analyzed by a "full factorial

experiment" the approach can not be considered as a standard experiment but

rather a Quasi-experiment.

In this thesis, the variables can be divided into independent variables, dependent

variables, and control variables.

The dependent variables are what is affected by the independent variables, the

dependent variables are stress, temperature, losses, and displacement.

Control variables are current, ambient temperature, and initial temperature.

Depending on what test is performed, the geometries or materials that are not

altered will also be a part of the control variables. For example, in test 1,

the CSS is altered, then it becomes an independent variable, where the other

factors covered in the other tests) become control variables.

14 | Method

3.2

Research Paradigm

The research paradigm in this thesis is Positivism. It can be described

as "Positivism (objective), "it assumes that the reality is objectively given

and independent of the observer and instruments. The researchers test

theories, usually in a deductive manner, to increase predictive understanding

of a phenomenon. The view of positivists is used in projects that are of

experimental and testing character" [11].

3.3

Research Process

The approach of this thesis can be summarized in figure 3.1.

The literature study was conducted to find related work both on cables and

busbars, but also on the environmental challenges of implementation in a

vehicle. The use case was important to define in order to limit the evaluation

for the scope of this thesis. This process was carefully conducted together with

personnel at Scania.

The goal was to find a generalization of a case that that would be representative

of the real-world. The results from this study gave the initial geometrical

boundaries. By combining the literature study and the use case, the framework

of the worst-case study could be set. The detailed worst case scenario were also

defined together with Scania personnel working with cable harness.

The next step was to develop the design options that would be evaluated by

the use of multiphysics simulations. This led to several iterations in order to

refine the CAD models and the simulation platform. When the models were

working properly the final simulations results could be derived.

Method | 15

Figure 3.1: A flowchart depicting the steps of the research process.

16 | Method

3.4

Data Collection

In order to perform a large amount of tests, and derive relevant data, a

simulation-based approach was preferred. The software Comsol was chosen

as it is widely accepted as a proper simulation tool for both educational and

professional use. Before the final values were derived, a mesh analysis was

conducted to make sure the mesh is not affecting the precision of the results.

3.5

3.5.1

Assessing reliability and validity of the

data collected

Mesh refinement analysis

One way of investigating how fine the mesh has to be is to perform a mesh

refinement analysis, this can be done by altering the parameters defining the

mesh manually or by the use of a parameter sweep. The first step is to

define a base set of values, in the interface of Comsol, there are predefined

recommended values depending on the required precision. To alter the mesh,

a Mesh refinement factor is added to the max/min element size. increasing

the value will lower the max/min element size. by analyzing the simulation

output the user is able to determine approximately how fine the mesh has to

be. In this report, both the actual values of simulation data output and a visual

representation of the difference of altering the MRF will be shown.

3.5.2

Validity of method

As the tests are performed by only altering one factor at a time (independent

variables), the interaction between the different independent variables are not

analyzed, and the control variables are kept constant in all cases. The external

validity is considered high as the effect of thermal expansion is important in

both small and large components, the power transfer does not have to be as high

as represented in this report. The important factors are the proportion between

the amount of current and conductor size. This will define if the expansion

issue is to be considered or not. In general, the results can be translated in

most busbar design issues, where heat is an important factor.

Method | 17

The internal validity is harder to review, in order to increase the internal

validity practical tests should be conducted to evaluate how accurate the results

are. One Way the internal validity is analyzed is by separating the two effects

caused by altering the CSS. These are differences in inertia and larger surface

area.

Construct validity is also considered to be high as the simulation software

is straightforward in what it measures, and how it is done. These types of

simulations are not unusual and many guides can be found in order to make

sure the software is set up correctly.

Conclusion validity can be broken down into two questions, first, is there a

chance that the concluded relationship is in fact true?

Secondly, is there a risk that there is a relationship that is not shown/covered

in the tests.

As the testing is limited within a certain range of geometry (for example the

bend radius used) there could be other conclusions drawn if the smallest and

largest bend radius were expanded. Having for example a 90-degree turn of the

busbar is not analyzed. Also, altering the length of the busbar could potentially

show or hide effects that are covered/uncovered in this thesis.

3.5.3

Reliability of method

The simulation output data is heavily affected by the control variables that are

initial and ambient temperature, current, surface emissivity

The values that are presented in section 5.1 are based on a really pessimistic

premises. To use the simulation model in order to derive practical values

with higher precision the busbar specifications needs to be defined with higher

precision. The goal of the simulation model has been to set it up as "real to

life" as practically possible, but in order to fine tune the simulation parameters,

some practical tests could be done to increase the validity of the simulation

parameters.

The reliability of the simulation model in itself is very high, the type of

simulations that are covered in this thesis are not unusual.

The largest threat to validity in this thesis is probably the comparison between

the aluminium and the copper, the reason is that the surface treatment is heavily

affecting the end temperature, and thus also the amount of expansion resulting

18 | Method

in the maximum stress. In order to increase the validity of the comparison

between the aluminium and the copper, a further investigation into different

surface treatments in combination with different isolation materials could be

conducted.

Another aspect to investigate is the interaction of positive and negative side of

busbar being routed close to each other, this cross interaction might result in

higher temperature.

3.5.4

Data validity

As the input data for the simulation is not based on any real worlds measurements

the validity is hard to interpret. The data used is based on a worst case

scenario derived together with personnel at Scania. The data derived from the

simulation model is reliable as the method for setting up the model is known.

But to increase the reliability a physical experiment should be performed in

order to compare the simulation results with real world experiments. The

results from the physical measurements can be used to fine-tune the simulation

parameters.

3.5.5

Reliability of data

As the tests are performed in a simulation environment the repeated simulation

gives the same results as expected. The mesh settings are the same in all the

tests covered in this thesis.

Implementation | 19

Chapter 4

Implementation

4.1

Hardware

The first mission was to analyze the system to understand what challenges

and possibilities there were, and why the standard solution of cables were

insufficient in some cases. This information, together with contact persons

at Scania led to the busbar design space specifications. These specifications

are both covering dimension limitations, environment temperature span, max

current and more. This information was used to decide what parameters to

change and what to alter in the simulation environment.

From a design perspective for implementation in a BEV the geometrical

limitations result in higher demand for optimization in the power transfer

medium. In this report three main geometrical alterations are evaluated, these

are cross section shape, U-shape busbar and bend radius, these are compared

to a standard straight busbar with the same length and cross section area.

4.1.1

Cross Section Shape

The first reason CSS is analyzed is due to the change of force required to bend

an object with an altered cross section inertia. Note that the cross section area

is not changed as this would alter the total resistance of the conductor. The

CSS inertia can be manually calculated using the following formula:

20 | Implementation

J = (W H 3 )/12

where "W" is the width, and "H" is the height of the busbar cross section, as

can be seen in figure 4.1.

Figure 4.1: Test1: Busbar, cross section view.

note that the "H" is the length acting in the same direction the bending is

present in. For a rectangular shaped busbar experiencing thermal expansion

this equation explains why the busbar is only bending in one direction. This

effect is exploited in this thesis to analyze if altering CSS can be used to

mitigate thermal expansion issues.

Another benefit of using a more flat shaped busbar is that the total surface area

is greater, maintaining the CSA. This ensures that more heat is radiated away

from the surface, this effect is described by Stefan-Boltzman law:

Pterm = σ(T 4 − T04 )A

where referes to the emissivity value of the material, σ is the StefanBoltzmann constant and A is the total surface area. T is the temperature of

the busbar and T0 is the temperature of the surrounding environment.

One interesting aspect of altering the CSS is that the stress will be reduced

Implementation | 21

due to both effects, and it might be hard to figure out if the potential benefits

of altering the CSS is due to the altered inertia or the lower temperature as

a result of the larget total surface area. One solution to this is to isolate the

altered inertia effect by lowering the current to zero and increase the ambient

temperature, this ensures that the temperature difference is zero, and thus no

effect from the change in surface area is noted. The isolated effect of altered

inertia can now be shown.

In this report three different CSS are investigated, the three geometries are

chosen to be reasonable for implementation in a BEV. The difference between

the least and most flat-shaped busbar can be seen in figure 4.2.

Figure 4.2: Cross section shape difference

4.1.2

U-height

The second parameter to be analyzed is the height of the "U". The idea is to

investigate if the height can be used to reduce stress by having a longer leaver

arm for clamping of the "U". It is not obvious that a tall "U" is a viable option

as the total length of the busbar will increase, this directly results in a higher

total resistance as can be seen in the following equation:

R = (ρL)/A

where ρ is the resistivity of the material, L the total length of the conductor

and A the cross section area.

This increased total length together with the higher resistance will lead to

a longer total free length expansion. This expansion is explained by the

following equation:

∆L = αLO ∆T

22 | Implementation

where ΔL is the change in total length, α the coefficient of thermal expansion,

L0 the initial length, and ΔT the difference in temperature acting on the object.

Note that this equation is accurate for parts where the length is much greater

than the other dimensions of the object.

The three steps of U-height can be seen in figure 4.3

Figure 4.3: U-height steps

4.1.3

Bend radius

Altering the bend radius is interesting from several perspectives. One of the

issues with having a sharp corner in any electrical conductor is that the current

density in the bend increases, as a result, local hot spots can occur. Another

issue with having a bend that is too sharp is that it can be hard and/or expensive

to manufacture. In this thesis, the bend radius is investigated to see how it

affects the different parameters that are simulated. The three analyzed bend

radius steps can be seen in figure 4.4

4.1.4

Material

For the main part of the thesis, a copper busbar is used, the reason is that the

copper material is the most common to use in busbars. An aluminum busbar

will also be compared to the standard copper busbar. Aluminum is a lighter and

cheaper than copper but has a higher electrical resistance. For both materials,

Implementation | 23

Figure 4.4: Bend radius steps

the standard values regarding conductivity, thermal expansion coefficient and

more are used, but when looking at emissivity the surface treatment of the

material will affect how the busbar radiates heat to the environment. For

the simulation of the copper material, a nickel-plated copper was chosen as

it works well in challenging environments [12]

For aluminum, an anodized surface treatment is widely used as it does not

rely on any external material being put on the surface but rather uses the

aluminum’s natural oxidization to create a thin, hard, and durable surface

suitable for use in a vehicle. [13].

Two main tests were performed on the aluminum busbar, the first test was done

by using the aluminum with the same Cross section areas (CSAs) and general

shape as the copper busbar. The main reason is to get a good overview of the

differences between the materials considering the same geometry. This will

make it easier to decide on the proper solution if the design space is limited.

The second test will be performed by compensating the CSAs for the higher

resistance value of the aluminum. This implies that in order to reach the same

resistance as a copper busbar the CSAs must be larger. But how should the size

increase be done in a proper way? The approach in this report is to compensate

the CSS to reach the same inertia as the standard copper busbar. This is done

by solving a system of equations for the inertia (J) and the resistance (R) where

the common parameters are the Width (W) and height (H):

24 | Implementation

J = (W H 3 )/12

R = (pL)/(W H)

this ensures that the difference in performance parameters are not a direct result

of a generally altered inertia.

4.2

Simulation platform

For the simulations, Comsol was chosen as the preferred simulation platform.

The software is widely used in both educational and professional environments.

In the Comsol simulation platform, there are many types of physics that can

be modeled. For this thesis a multi-physics simulation could be developed

using three main physics nodes, these are "Electric current", "Heat transfer in

solids", and "Solid mechanics".

In the "Electric current" node, the connectors, and current are defined. For the

"heat transfer in solids" node all the temperature-related information is present,

both initial temperature, ambient temperature, surface emissivity, heat flux,

and material properties.

The solid mechanics node holds all the mechanical constraints, for this

simulation. The connectors are defined as "fixed constraint" this assumes that

the connectors do not flex or move as they are experiencing force acting on

them. Note that the constraint is working on a surface and not in a volume.

The simulations are performed as “stationary”, this implies that the simulation

will run until the simulation data outputs are not being altered by a defined

margin. This gives simulation data that is representing the "end" scenario,

and as the input data is constant over time we will have the worst-case scenario

presented in the output data.

The interface of the Comsol software can be seen in figure 4.5

In order to set up this simulation model the base physic modules must be

added. these are "Electric current", "Heat transfer in solids" and "solid

mechanics". the next step is to define the control variables, these are ambient

temperature, current, and initial temperature. these variables are not altered

Implementation | 25

Figure 4.5: Comsol interface

in the performed tests and can be globally defined in the "parameter" node.

the next step is to define the material, and to make sure the material properties

are sufficient to perform the simulation. If any property is missing it can be

manually added.

The next step is to define all geometrical, mechanical and electrical boundaries.

These are both connection points for the current, fixed mechanical constraints,

"surface to ambient radiation" and "heat flux". The defined values can be seen

in the section 5.1 system documentation.

The "surface to ambient radiation" is heavily affected by the surface treatment

of the metal, this is why the copper and aluminium surface treatments were

specified, and the treatments were suitable to be used in harsh environments

as is the case with a heavy duty vehicle.

4.3

Simulation data

As the Comsol software is a multiphysics platform a huge amount of data can

be derived from the simulations. In this thesis, the following areas have been

investigated to be able to answer the research questions.

26 | Implementation

4.3.1

Losses

The volumetric losses in the busbars are calculated to derive a value of the

losses at the steady-state of the model. These losses are in the form of Joule

heating, and as a result, the temperature of the busbar is increasing. Keeping

this value as low as possible increases the total efficiency of power transfer in

the busbar. If we consider a standard conductor, this value is mostly affected by

material properties, CSAs and length. Another aspect to consider is how the

resistance is changed by temperature. A material’s resistance is not constant

but increases with temperature. This change of temperature can be calculated

using the following formula:

R = Rref (1 + α(T − Tref ))

where "R" is the resistance at a given temperature defined by "T", Rref is the

resistance at a defined temperature, usually at 20 degrees Celsius. α, is the

material-dependent temperature coefficient. The change in resistance is taken

into account by the simulation software. As a result a more reliable steady

state result can be expected.

To get a better understanding of the losses a visual representation can be seen

in figure 4.6, note that the losses are not uniform in the busbar. The reason

is that the current density is not the same due to the current taking the closest

path from input to output.

Figure 4.6: Losses in a busbar

Implementation | 27

4.3.2

Temperature

The temperature of the busbar is investigated as it is one of the most important

factors to consider when modeling a conductor. If the busbar will be used for

high power charging keeping the temperature low will allow a high charging

capacity over a long period of time. The temperature presented in chapter

5 is the temperature that the busbar reaches at a steady state. The reason

the temperature is increasing is due to a difference in initial temperature and

ambient temperature, as well as joule-heating due to current being transmitted

in the busbar. The thermal power heating up the busbar is a direct effect of the

losses. These losses can be calculated by using the following formula:

P = RI 2

where P is the loss power, "R" the total resistance of the busbar and "I" is the

current passed in the busbar. Note that this is the same loss covered in section

4.3.1.

4.3.3

Stress

To evaluate the mechanical stress as a result of the thermal expansion, the

von Mises stress is derived from the model. As the conducting material is

isotropic, the von Mises stress value will be sufficient to compare different

design options. If the material is experiencing a von Mises stress value higher

than the yield strength of the material, it can be assumed that the material is

experiencing plastic deformation. In the simulation environment, the exact

position of the maximum value is presented, an example of a stress plot can

be seen in figure 4.7.

Understanding what affects the amount of stress is important to reduce the risk

of mechanical failure in the busbar or the surrounding components.

4.3.4

Displacement

The displacement of the busbar is investigated to get a better understanding of

how the different design options affect how the busbar expands.

28 | Implementation

Figure 4.7: Stress plot

To see how the busbar moves during thermal expansion, a displacement

magnification can be added. An example of this can be seen in figure 4.8

Figure 4.8: Busbar displacement

The expansion of the busbar can also be important from an implementation

perspective. As the BEV is exposed to high amounts of vibrations, support of

the busbar will have to be added in many scenarios. These supports can have a

negative effect on the maximum stress if it restricts the busbar from expansion

in certain positions. Optimizing the support placement will allow the U-shape

to work unrestricted.

Results and Analysis | 29

Chapter 5

Results and Analysis

5.1

System documentation

The general load case scenarios can be seen in table 5.1. These factors were

determined during the worst case analysis. The low initial temperature could

be reached when the truck is operating in low temperature environments. The

high ambient temperature could be reached by heat generating components

mounted close to the busbar. The simulation input represents a worst case

combination of these extremes.

Load type

Value

Unit

Current

1000

Ampere

◦

Initial temperature

-40

C

◦

Ambient temperature 80

C

Table 5.1: Load case specifications

The geometrical base specifications can be seen in table 5.2. These values

were also derived together with Scania personnel.

Geometry specification

Value

Unit

Busbar length

700

mm

Connector diameter

25

mm

Cross section area

600

mm2

Table 5.2: Load case specifications

30 | Results and Analysis

Note that both the load case and geometrical specifications were not altered as

a part of this thesis.

5.2

Test protocol specifications and visual

representation

The tests are divided in 5 parts.

The first test is investigating three types of CSS. These can be seen in figure

5.1, and the specifications in table 5.3. Note that the CSAs is not altered.

Figure 5.1: CSS1, CSS2 and CSS3 from left to right.

CCS type

Dimension Unit

CCS1

20×30

mm

CCS2

10×60

mm

CCS3

5×120

mm

Table 5.3: Cross section dimensions

Results and Analysis | 31

The second test is looking at the effect of altering the height of the "U". The

test options can be seen in figure 5.2 and the specifications can be seen in table

5.4.

Figure 5.2: Test 2: Height options for the U-shape

U-height

Dimension Unit

options

UH1

50

mm

UH2

100

mm

UH3

150

mm

Table 5.4: U-height specifications

The third test is looking at the effect of varied BR for the bends required to

model the U-shape of the busbar. The three options are represented in figure

5.3 and table 5.5.

Bend radius Dimension Unit

options

BR1

20

mm

BR2

30

mm

BR3

40

mm

Table 5.5: Bend radius specifications

32 | Results and Analysis

Figure 5.3: Test 2: Bend radius options required for the U-shape

Test 4 consists of a comparison between the U-shape busbar with a standard,

straight busbar. The length between the connectors are the same as for the

U-shape busbar. The CSS is varied in the same three steps as for the U-shape

busbar. In figure 5.4 a straight busbar can be seen.

Figure 5.4: A straight busbar used as a reference in test 4.

The last test is investigating the use of aluminum instead of copper in the

busbar. As the aluminum has a higher resistance, two options were analyzed.

One with the same geometry as the standard copper busbar, and one where

the CSAs and inertia were compensated. The standard busbar and the

Results and Analysis | 33

compensated one can be seen in figure 5.5, the specifications are present in

table 5.6

Figure 5.5: Test 5: Compensated aluminium busbar next to standard copper

busbar.

Aluminium

busbars

CrossUnit

section

area

AL1

600

mm2

AL2

922,3

mm2

Table 5.6: Aluminum busbar specifications

In order to compensate the resistance to reach the same value for the copper

and aluminium busbar, the following equations were used:

RAlu = (ρAlu L)/AAlu

RC op = (ρC op L)/AC op

these equations are set equal to reach the final equation for the aluminum CSA:

AAlu = (ρAlu AC op )/ρC op )

34 | Results and Analysis

in order to find an inertia value the following equations were used.

The first step is the general equation for the inertia (J) of a rectangular shape:

JAlu = (bAlu HAl 3u )/12

this can be rewritten as:

JAlu = (AAlu HAl 2u )/12

where b is the width of the busbar and H is the height.

As the aluminum CSA was calculated and the inertia is set to be the same as

for the copper busbar the value of H can be calculated.

After this value is defined the last step was to calculate the value for b using:

bAlu = AAlu /HAlu

the final cross section dimensions for the compensated aluminum busbar is

8,07 ×114, 34(mm).

The total combination of values in order to perform each test can be seen in

figure 5.6, As can be seen, only one of the factors are changed in every test.

Figure 5.6: Test 5: Test protocol summary specifications.

Note that in most cases the parameters that are not varied as part of the tests

are chosen as the middle value. For example, in test 1, the UH2 and BR2 are

chosen and not altered in that test. The only exception is in test 2 where the

BR2 and BR3 could not be combined with UH1,due to geometrical limitations,

thus the BR1 value had to be used. As a result, the BR1 value was present in

Results and Analysis | 35

all UH tests to make sure that no difference in the results was caused by factors

not covered by the specific test.

5.3

Test 1: Cross section shape

The first test was performed by only altering the CSS. The results from the

tests can be seen in table 5.7

CCS type

CSS1

CSS2

CSS3

Stress

[Mpa]

1001

768

617

Temperature Losses

Displacement

[◦ C]

[W]

[mm]

153,2

34

1,68

133,6

32,6

1,41

112,0

31,7

1,14

Table 5.7: Test1, CSS results

Weight

[Kg]

4,578

4,578

4,578

The results from the stress analysis show that the altered CSS reduce the stress

quite dramatically. The stress reduction from CSS1 to CSS2 is around 32 %.

and from CSS1 to CSS3 38 %. This analysis showed the benefit of altering

the shape of the conductor. In the temperature section the effect of having a

flatter busbar construction results in dramatically reduced temperatures. This

difference is one of the reasons why the stress becomes lower in CSS3. The

differences in Losses are very small, the reason why there is a difference is

due to how the simulation model is constructed. One material factor that

was altered was the resistance of the material. A fine approximation is to

assume that the resistance is constant within a span of temperature, but a more

robust approximation is to alter the resistance with the given temperature of the

busbar. This is the reason why we see a higher loss power in CSS1. As higher

temperature increases the resistance of the material the losses will increase.

The three stress plots can be seen in figure 5.7, 5.8 and 5.9.

36 | Results and Analysis

Figure 5.7: Test1: Busbar with CSS1

Figure 5.8: Test1: Busbar with CSS2

Figure 5.9: Test1: Busbar with CSS3

The result differences in the stress and temperature are interesting as it shows

a strong effect on important performance parameters, without adding weight

Results and Analysis | 37

to the busbar. But how can we be sure what is causing the lower stress? There

are two main effects at work, altered inertia and temperature difference causing

lower thermal expansion. One way to investigate this is to neglect the current

and force the temperature to values in the range of the result values. This will

result in neglected effect of having a temperature difference, and thus, only

the difference in inertia would have the chance to alter the results. The results

from this sub-test can be seen in table 5.8.

CCS type

Stress[MPa] Temperature [◦ C]

CCS1

761,6

120

CCS2

682

120

CCS3

673

120

Table 5.8: Forced temperature, stress results.

The results are interesting and show that the maximum stress that occurs in

the connectors are being reduced, but not by any large margin. But, analyzing

the plot of the stress shows that the stress in the "U-bend" is being reduced

dramatically, as can be seen in figure 5.10 and 5.11.

One way these results are interesting is in the case where an active cooling

system is present if the system allows a certain max temperature and has the

ability to maintain the busbar at that temperature, then the difference in max

stress between the CSS are mainly affected by the inertia of the busbar. The

last part of the test shows that altering only the inertia will reduce the stress,

but mostly at the U-bend and that the max stress will not be affected by any

large margin.

In general, the effect of changing the CSS has a strong effect on the busbar’s

main performance parameters, stress, and temperature. Having a larger surface

area as a consequence of modeling the busbar in a less square shape helps to

increase the convection and heat radiation.

38 | Results and Analysis

Figure 5.10: Stress plot, forced temperature, CSS1

Figure 5.11: Stress plot, forced temperature, CSS3

Results and Analysis | 39

5.4

Test 2: U-height

The second test is investigating the effect of altering the height of the "U". The

results can be seen in table 5.1.

CCS type

UH1

UH2

UH3

Stress

[Mpa]

799

760

781

Temperature Losses

Displacement

◦

[ C]

[W]

[mm]

133,2

29,2

2,64

133,6

33,3

1,42

134,0

37,4

1,07

Table 5.9: Test2, U-height results

Weight

[Kg]

4,13

4,67

5,21

Looking at how the stress changes with the height of the U, it becomes apparent

that altering the height of the U-shape does not necessarily result in a decreased

amount of stress. The amount of stress is being reduced by about 5 % between

the UH1 and UH2, but as the height is increased further, the stress starts to

increase again. There are also other issues with increased U-height. We can

see increased losses of about 22 % between UH1 and UH3. The reason why

we see this difference is due to the increased total length of the busbar. This

causes a higher total resistance and thus also increases the loss-power. One

might ask why this increased loss-power doesn’t cause a higher temperature

in UH3, the reason is that, as we increase the length of the busbar, we are also

increasing the total surface area, and thus increasing the relative convection

and radiation.

Analyzing the displacement shows that increased UH can reduce the amount

of displacement. The difference between UH1 and UH3 can be seen in figure

5.12 and 5.13.

When analyzing the displacement figures, the effect of having the U-shape

becomes visible, we can see the compression of the "U" that acts as a relief

for the thermal expansion that occurs as a result of Joule heating. If this

amount of deformation not causing plastic deformation depends on the specific

material, there are many types of aluminium and copper, and different types

of manufacturing methods that affect mechanical properties of the material.

40 | Results and Analysis

Figure 5.12: Test 2: Displacement UH1, Magnified 15×.

5.5

Test 3: Bend radius

In this test, the effect of altering the bend radius in three different steps are

investigated. The results can be viewed in table 5.1.

Bend

radius

type

BR1

BR2

BR3

Stress

[Mpa]

760

768

761

Temperature

[◦ C]

Losses

[W]

Displacement Weight

[mm]

[Kg]

133,6

33,3

1,42

133,6

32,6

1,41

133,6

32,0

1,41

Table 5.10: Test3, Bend radius results

4,67

4,58

4,49

As can be seen, the difference in results between the bend radius options are

minor. The biggest difference in the results are among the losses which are

smaller in BR3, but by a low margin. The difference is a result of having a

shorter busbar as the sharper bends cause a total shorter path for the current

to take.

When looking at the current density in figure 5.14 and 5.15, we can see how

the current density differs between BR1 and BR3. This difference in current

density does not seem to have any effect on the busbar with the bend radius

span covered within this thesis.

These results show that in the span of the bend radius analyzed in this

thesis, the effect difference is negligible. There could be other benefits of

altering the bend radius in AC applications when considering Electromagnetic

comparability issues, but that is not covered in this thesis. This also implies

that the manufacturer can adjust this value according to their available equipment

and requirements for the specific installation.

Results and Analysis | 41

Figure 5.13: Test 2: Displacement UH3, Magnified 15×

Busbar

type

U-shape

Straight

CSS1

Straight

CSS2

Straight

CSS3

Stress

[Mpa]

768

2160

Temperature

[◦ C]

133,6

152,2

Losses

[W]

32,6

27,8

Displacement

[mm]

1,41

2,35

Weight

[Kg]

4,58

3,77

1380

132,9

26,5

0,26

3,77

1135

111,1

25,9

0,22

3,77

Table 5.11: Test4, Straight busbar compared to the U-shape

The benefit of using the u-shape becomes quite apparent, the most fair

comparison is between the U-shape and the "straight CSS2" as they use the

same CSS. The difference in stress is 44%. The stress reduction, however,

translates into a significant increase in the losses (18% higher for the u-shape

busbar) Also, the weight is increased by around 18%. But this relative weight

increase would be reduced depending on the total length of the busbar, and by

decreasing the amount of U-height. This would also reduce the difference in

power loss while maintaining a lot of the stress reduction on the connectors.

The displacement of the straight busbar can be seen in figure 5.15 And the

stress in figure 5.15.

42 | Results and Analysis

Figure 5.14: Test 3: Current density, Bend radius 1

Figure 5.15: Test 3: Current density, Bend radius 3.

Results and Analysis | 43

Figure 5.16: Test 4, Straight busbar displacement, Magnified 15×

Figure 5.17: Test 4, Straight busbar stress plot

44 | Results and Analysis

5.7

Test 5: Material

The last test is investigating the effect of replacing the copper material with

aluminum. The aluminum’s surface is anodized. The copper is nickel-plated,

both these options are suitable for harsh environments as we have in a vehicle.

The results of this evaluation can be seen in table 5.1.

Busbar type

Stress