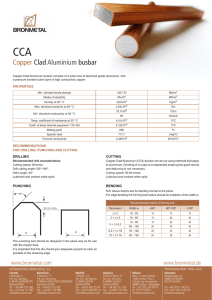

Copper Clad Aluminum busbar

advertisement

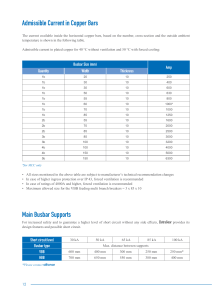

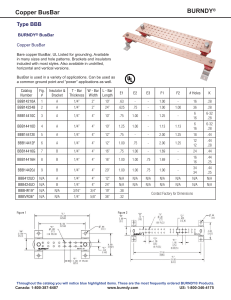

CCA Copper Clad Aluminum busbar Copper clad Aluminum busbar consists of a solid core of electrical grade aluminum, with a pressure bonded outer layer of high conductivity copper. PROPERTIES Min. ultimate tensile strengh Modus of elasticity 130-170 85x103 MN/m2 MN/m2 37,7x106 1/Ωm 65 %IACS 3,63x103 2,65x10-8 Density at 20 º C Max. electrical resistivity at 20 º C Min. electrical conductivity at 20 º C kg/m2 Ωm Coeff. of linear thermal expansion º 20-100 4,01x10-3 21,9X10-6 Melting point 658 ºC Specific heat 711,7 J/kg/ºC Temp. coefficient of resistance at 20 º C 1/ºC 1/ºC 2,38X106 Thermal conductivity W/m2/ºC RECOMMENDATIONS FOR DRILLING, PUNCHING AND CUTTING DRILLING Recommended drill characteristics: Cutting speed: 50m/min. Drill cutting angle:135º-140º. Helix angle: 45º. Lubricant and coolant white spirit. CUTTING Copper clad Aluminum busbar can be cut using methods that apply to aluminium. Grinding of cut saw to a trapezoidal shape gives good results and deburring is not necessary. Cutting speed: 50-90 m/sec. Lubricant and coolant white spirit. PUNCHING BENDING N.B. Above factors are for bending normal to the plane. For edge bending the forming tool radius should be multiples of the width w. Recommended radius of forming tool Thickness t Width w ≤90º 90º-120º >120º t≤3 10 - 25 1t 1t 1t 3<t≤5 16 - 60 1t 2t 4t 12 - 50 1t 2t 4t 50 - 120 2t 3t 4t 6,3 < t ≤ 10 10 - 120 2t 3t 4t 10 < t ≤ 15 40 - 120 2t 3t 4t 5 < t ≤ 6,3 The punching tool should be designed in the same way as for use with flat copper bars. It is important that the die should give adequate support as near as possible to the shearing edge. www.bronmetal.com www.bronmetal.de INTERNATIONAL BRON METAL, S.A Central. C/Bizkargi, 6 Pol. Ind. Sarrikola E-48195 LARRABETZU Bizkaia-SPAIN Tel.: +34 944 731 500 Fax.: +34 944 117 387 info@ibronmetal.com Barcelona C/Marconi, 13 Pol. Ind. Sesrovires E-08635 SANT ESTEVE SESROVIRES Barcelona-SPAIN Tel.: +34 937 715 307 Fax.: +34 937 713 866 infob@ibronmetal.com Madrid C/Nobel, 2-4 Pol. Ind. San Marcos E-28906 GETAFE Madrid-SPAIN Tel.: +34 91 665 25 97 Fax.: +34 91 692 86 74 infom@ibronmetal.com Valencia C/Mont Cabrer, 22 Pol. Ind. la Lloma E-46960 ALDAYA Valencia-SPAIN Tel.: +34 961 517 297 Fax.: +34 961 517 364 infova@ibronmetal.com México Blvd. A. Lopez Mateos, 1206 Oriente -Piso 2 Colonia Las Insurgentes 38080 Celaya - Guanajuato Tel.: +52 352 126 09 16 ID. 72*14*15873 info@ibronmetal.com INTERNATIONAL BRON - METAL GmbH. Alemania Halskestrasse, 26 40880 RATINGEN DEUTSCHLAND Tel: +49 2102-7142515 Fax: +49 2102-7142518 info@bronmetal.de AC/DC CURRENT RATINGS Check parameters to ensure compatability of these current ratings with design specification. Recalculation graphs should be used for design conditions different than those stated. For compatability , recalculation graphs computed for the same base parameters must be used with these tabuled values. These parameters are clearly stated in the tables on this data sheet, and the recalculation grpah data sheet. Size Corner radius Area Weight mm 10x3 20x3 25x3 10x4 16x4 20x4 25x4 30x4 40x4* 10x5 12x5 15x5 20x5 20x5 25x5 30x5 30x5 40x5 40x5 50x5* 60x5* 80x5* 20x6 25x6 28x6 30x6 40x6 50x6 60x6 75x6* 80x6* 120x6 12x6,3 16x6,3 20x6,3 25x6,3 28x6,3 32x6,3 38x6,3 40x6,3 50x6,3 63x6,3 65x6,3* 80x6,3* 82x6,3* 100X6,3* 120X6,3* 16x8 20x8 25x8 mm 0,5 0,5 0,5 0,5 1,5 1 1 1 1 0,5 0,5 sq 1,5 sq 1,5 1,5 sq 1,5 sq 1,5 1,5 1,5 2 2 2 2 2 2 2,5 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 0,25 2 2 mm2 29,79 59,79 74,79 39,79 62,07 79,14 99,14 119,14 159,14 49,79 59,79 75 98,07 100 123,07 158,07 150 198,07 200 248,07 298,07 398,07 116,57 146,57 164,57 176,57 236,57 396,57 354,63 446,57 476,57 716,57 72,17 97,37 122,57 154,07 172,97 198,17 235,97 248,57 311,57 393,47 406,07 500,57 513,17 626,57 752,57 127,95 156,57 196,57 kg/m 0,108 0,247 0,271 0,144 0,225 0,287 0,36 0,432 0,627 0,181 0,217 0,272 0,356 0,363 0,447 0,537 0,545 0,719 0,726 0,977 1,174 1,568 0,423 0,532 0,597 0,641 0,859 1077 1287 1759 1878 2823 0,262 0,353 0,445 0,559 0,628 0,719 0,857 0,902 1131 1428 1600 1972 2022 2469 2965 0,464 0,568 0,714 DC DC Resistance Resistance @ 20º C @ 65º C μOhm/m 890 443 354 666 427 335 267 222 164 532 443 353 270 265 215 179 177 134 133 105 88 66 227 181 161 150 112 89 75 58 55 36 367 272 216 172 153 134 112 107 85 67 64 52 51 42 35 207 169 135 μOhm/m 1050 523 418 786 504 395 316 26 194 628 523 417 319 313 254 211 209 158 156 124 103 77 268 213 190 177 132 105 88 69 65 43 433 321 255 203 181 158 133 126 100 80 76 62 60 49 41 244 200 159 n=1 dc 99 175 211 119 169 205 247 289 373 137 157 187 233 235 280 327 329 418 420 511 599 773 259 311 341 362 461 559 653 803 851 1222 179 224 267 320 352 393 454 474 575 702 727 873 893 1065 1254 266 312 371 n=2 ac 99 175 211 119 169 205 247 289 372 137 157 187 233 235 280 326 328 416 418 508 594 762 259 311 341 361 459 555 646 789 834 1179 179 224 267 320 351 392 452 472 569 693 717 855 873 1034 1207 266 311 370 dc 188 322 386 229 319 382 457 529 676 266 304 358 439 443 522 604 607 762 766 924 1077 1376 492 584 638 673 848 1018 1181 1440 1521 2155 348 431 509 603 658 731 838 874 1048 1269 1312 1563 1596 1891 2213 517 601 708 n=3 ac 188 322 385 229 318 382 455 527 670 266 304 357 437 441 519 599 603 752 756 905 1047 1320 489 579 632 666 833 991 1140 1370 1441 1979 348 430 506 598 651 721 824 857 1018 1218 1256 1476 1504 1755 2022 514 596 698 dc 277 469 560 338 468 559 665 768 977 395 451 528 644 650 763 879 885 1105 1110 1334 1550 1971 725 856 933 984 1232 1473 1703 2069 2183 3075 517 639 750 885 964 1068 1220 1270 1517 1830 1892 2246 2292 2707 3159 768 891 1044 n=4 ac 277 466 557 337 466 556 660 761 961 394 449 525 639 646 755 867 872 1079 1084 1285 1471 1809 18 845 918 965 1192 1400 1590 1867 1950 2538 515 634 743 872 947 1043 1181 1225 1436 1686 1732 1989 2021 2297 2580 760 877 1020 dc 366 615 733 448 617 736 873 1007 1277 525 597 698 849 858 1004 1154 1162 1446 1453 1743 2022 2565 958 1128 1228 1294 1615 1927 2225 2696 2844 3990 686 846 992 1167 1269 1404 1602 1667 1986 2390 2470 2926 2986 3520 4101 1019 1180 1380 ac 365 611 728 447 614 730 863 991 1242 522 594 693 840 848 987 1127 1134 1388 1395 1637 1856 2248 943 1103 1194 1252 1527 1774 1995 2311 2406 3103 681 837 975 1138 1230 1348 1515 1568 1816 2104 2156 2451 2488 2813 3157 1001 1149 1326 Size Corner radius Area Weight mm 30x8 34x8 40x8 50x8 60x8 75x8 80x8 90x8 100x8 10x10 12x10 12x12 15x10 15x10 20x10 20x10 25x10 25x10 30x10 30x10 40x10 40x10 50x10 50x10 60x10 60x10 63x10 75x10 80x10 80x10 100x10 100x10 120x10 18x12 20x12 24x12 30x12 40x12 42x12 50x12 60x12 100x12 120x12 63x12,5 24x15 40x15 50x15 60x15 120x15 32x16 mm 2 2 2 2 2 2 2 2 2 sq 1 sq 1 sq 3 sq 3 sq 3 sq 3 sq 3 sq 3 sq 3 3 3 sq 3 sq 3 sq 3 sq sq 3 sq 3 3 3 3 3 sq 3 3 3 3 3 mm2 236,57 268,57 316,57 396,57 476,57 596,57 636,57 716,57 796,57 100 119,14 144 149,14 150 192,27 200 242,27 250 292,27 300 392,27 400 492,27 500 592,27 600 622,27 742,27 792,27 800 992,27 1000 1192,27 216 232,27 288 360 472,27 504 592,27 712,27 1192,27 1432,27 779,77 360 592,27 742,27 892,27 1792,27 504,27 kg/m 0,859 0,975 1149 1440 1730 2166 2311 2601 2892 0,363 0,432 0,523 0,541 0,545 0,698 0,726 0,879 0,908 1061 1089 1424 1452 1787 1815 2150 2178 2259 2694 2876 2904 3602 3630 4328 0,784 0,843 1045 1307 1714 1830 2150 2586 4328 5199 2831 1307 2150 2694 3239 6506 1831 DC DC Resistance Resistance @ 20º C @ 65º C μOhm/m 112 99 84 67 56 44 42 37 33 265 222 184 178 177 138 133 109 106 91 88 68 66 54 53 45 44 43 36 33 33 27 27 22 123 114 92 74 56 53 45 37 22 19 34 74 45 36 30 15 53 μOhm/m 132 116 99 79 66 52 49 44 39 313 263 217 210 209 163 156 129 125 107 104 80 78 64 63 53 52 50 42 39 39 32 31 26 145 135 109 87 66 62 53 44 26 22 40 87 53 42 35 17 62 n=1 dc 430 476 545 658 769 933 987 1094 1201 225 253 290 295 296 357 365 425 431 491 497 619 625 746 751 870 875 907 1053 1114 1119 1353 1358 1589 383 406 471 558 693 727 831 961 1496 1755 1032 548 798 953 1105 1985 702 n=2 ac 428 473 540 649 755 908 958 1057 1154 225 252 289 294 295 356 363 422 429 487 493 611 617 731 736 848 853 882 1015 1070 1074 1282 1287 1488 381 404 468 552 681 712 809 934 1399 1617 992 542 778 918 1052 1786 688 dc 812 894 1014 1211 1403 1686 1779 1963 2146 439 493 568 575 577 695 709 820 833 937 949 1165 1176 1385 1396 1601 1612 1665 1918 2023 2033 2434 2443 2837 746 790 916 1077 1316 1376 1559 1796 2709 3151 1915 1069 1636 1809 2075 3594 1365 n=3 ac 797 874 985 1161 1328 1568 1644 1795 1942 438 491 563 570 572 686 699 804 816 913 923 1116 1126 1306 1314 1484 1492 1536 1737 1819 1825 2135 2141 2439 734 776 893 1038 1243 1292 1440 1625 2301 2625 1711 1031 1417 1618 1806 2861 1283 dc 1193 1309 1481 1760 2033 2432 2564 2824 3080 654 734 845 855 857 1032 1052 1214 1234 1383 1401 1708 1725 2023 2038 2329 2344 2420 2778 2925 2939 3504 3518 4071 1108 1174 1361 1596 1938 2023 2284 2621 3812 4534 2795 1589 2272 2663 3043 5190 2029 n=4 ac 1154 1256 1399 1620 1820 2090 2175 2338 2494 649 727 834 843 845 1009 1027 1173 1189 1317 1331 1575 1586 1801 1810 2004 2012 2063 2282 2371 2378 2711 2718 3032 1078 1137 1298 1487 1737 1794 1966 2173 2913 3248 2273 1480 1956 2188 2407 3543 1799 dc 1573 1725 1947 2309 2661 2177 3346 3681 4012 869 975 1123 1134 1138 1369 1396 1609 1634 1829 1853 2251 2273 2659 2680 3055 3075 3173 3635 3825 3843 4571 4589 5301 1471 1558 1806 2114 2559 2671 3009 3445 5111 5912 3673 2109 3009 3517 4010 6782 2692 ac 1487 1608 1777 2030 2259 2573 2674 2871 3061 859 959 1098 1108 1111 1317 1340 1518 1536 1687 1703 1984 1996 2242 2252 2478 2488 2547 2814 2921 2930 3330 3338 3713 1401 1476 1670 1890 2176 2241 2440 2690 3581 3981 2814 1885 2440 2723 2988 4347 2258 * 20% Cu by volumen Diameter Area Weight DC Resistance @ 20º C DC Resistance @ 65º C mm 5 6,3 8 10 11 12 14 18 20 24 35 40 mm2 19,63 31,17 50,27 78,54 95,03 113,1 153,94 254,47 314,16 452,39 962,11 1256,64 kg/m 0,071 0,113 0.182 0.285 0.345 0.411 0.559 0.924 1 1,642 3,492 4,562 μOhm/m 1350 850 527 337 279 234 172 104 84 59 28 21 μOhm/m 1593 1004 622 398 329 277 203 123 100 69 33 25 Copper Clad Aluminum busbar Current Ratings (AMPS): 30º C Rise Over 35 º C Ambient dc 67 92 129 176 202 228 283 403 468 604 1029 1243 ac 67 92 129 176 202 228 282 400 464 596 972 1135 PARAMETERS The calculated values on this data sheet are based on the following parameters. Ambient temperature º C Busbar temperature º C Temperature rise º C Supply Frequency Hz Emissivity 35 65 30 60 0,4 n= number of bars in parallel. Current ratings assume still but unconfinded air, with busbar mounted on edge. Current ratings are based on “Temperature Rise of Busbar”, H.B.Dwight; Gen. Elec. Rev., vol 43. For multiple bar arrangements, the space between bars is equal to busbar thickness. AC ratings are based on spacings at which the proximity effect is negligible. These approximate calculated values should not be regarded as a subsitute for experimental testing. www.bronmetal.com