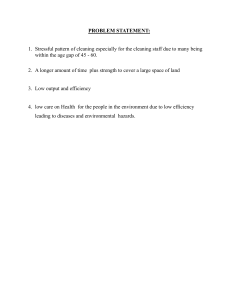

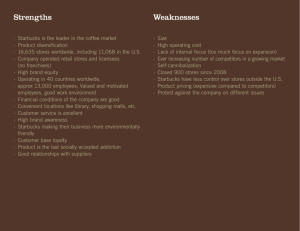

Starbucks on the go Operator Manual Supplied by Selecta UK Selecta Helpdesk: 0344 736 0204 Site Name: Weekly Cleaning Day: Version EG, January 2015 Version Control Instructions: Over time, ways of working may change. To ensure you are kept fully up to date, this operator manual will be updated accordingly. To ensure each manual is fully up to date, any change will be documented below. Site Name: Date What was changed? Version Removed Version in Place Placed by Version EG, November 2014 Contents 1. Starbucks, Our Coffee and Our Drinks 2. Responsibilities 3. Know Your Starbucks on the go 4. Whole Bean 5. Customer Assistance 6. Regular Spot Checks 7. Basic Hygiene & Safety 8. Know Your FM840 9. Machine Capacity 10. Your Condiment Station 11. Know Your Dates 12. Filling Your Hoppers 13. Milk Management & Safety 14. Fault Finding 15. Chemical Use 16. Daily Cleaning 17. Weekly Cleaning Appendix: • Milk Disposal Chart • Cleaning Check Sheet • Over Temperature Log • Daily / Weekly Checks • Service Call Log • Chemical Data Sheets • Fault Finding Codes Version EG, January 2015 Starbucks & Our Coffee Overview At Starbucks it has always been, and will always be, about great quality coffee. They are passionate about ethically sourcing the finest coffee beans, roasting them with great care, and improving the lives of people who grow them. Starbucks Coffee Company Founded in 1971 as a whole-bean specialty coffee roaster, Starbucks has come a long way since the first store opened in Seattle’s Pike Place Market. Everyone that works at Starbucks is passionate about the coffee and we hope you will be too. As the largest coffee house chain in the world they can do a lot of good by helping developing countries sell coffee throughout the globe. Starbucks on the go produces the same quality beverages that are available in the coffee houses, but your installation needs a little loving to do this and the coming pages will help you with that... Ethical Sourcing & Quality Starbucks only buys the highest quality Arabica coffee grown at high altitude. The company works closely with the farmers through our Farmer Support Centres to help them improve quality & yield. From seedling right through to roasted coffee, quality checks are made to ensure only the very best gets to your cup. To make sure, each coffee batch is sampled by our Green Coffee Team a total of 26 times before it reaches the roasting plant. The company applies the same care & attention to roasting each coffee to perfection balancing time and heat to develop the flavour, acidity & body to its peak. Ethical sourcing plays a huge part in this, and the company are proud to support Fairtrade; we are already one of the world’s largest purchasers of Fairtrade coffee. Indeed, over 90% of the coffee served in the stores in the UK is Fairtrade certified. In addition to this, the CAFÉ Practises Guidelines, verified by Conservation International, ensures the livelihoods of thousands more coffee farmers around the world by paying premium prices and rewarding farmers for additional social and environmental projects they implement. 1.1 Version EG, V2.0, September 2014 Our Drinks Coffee Caffé Latte Cappuccino A double shot of Starbucks espresso, topped with smooth creamy milk and a small amount of foam. A double shot of Starbucks espresso, topped with steamed creamy milk with a rich foamy consistency. Latte Macchiato Caffé Americano Smooth creamy milk and a rich foam, topped of with a double shot of Starbucks espresso. A double shot of Starbucks espresso, topped with hot water. Served black, but customers can add milk. Espresso Espresso Macchiato A double shot of Starbucks espresso. The foundation to all our coffee based beverages. Its rich in flavour, with a caramelly sweetness. A double shot of Starbucks espresso, topped with a little steamed milk. Caffé Mocha A double shot of Starbucks espresso, mixed with rich chocolatey sauce and topped with smooth creamy milk. Tea Chai Tea Latte Tea A tea beverage, made with a chai concentrate with prominent flavours of black tea and spices such as cardamom, cinnamon and black pepper. Finished off with smooth creamy milk and foam. We provide a selection of Tazo® Teas. The different varieties available are: • • • • • Awake English Breakfast Calm Chamomile China Green Tips Early Grey Refresh Mint Hot Chocolate Hot Chocolate Rich chocolatey mocha sauce, mixed with smooth creamy milk. Customisation Customisation To help customers adjust their beverage to suit their personal tastes, they can customise many beverages with: • Extra shot of Starbucks espresso • Caramel or Vanilla Syrup 1.2 Version EG, V2.0, September 2014 Responsibilities Store Responsibilities: Introduction: This section helps to explain what the main responsibilities are for any owner of the Starbucks on the go installation. This should ensure that the customer always receives a Starbucks Experience whilst using the installation, but also to clarify whats is required in certain circumstances. Overview: • • • • • • • • • • Maintain the supply of power, water and dispose of waste at timely intervals. Supply semi-skimmed milk (1.5% - 2% fat). Assign trained colleagues to manage the machine throughout the day. Assign a ‘Coffee Champion’ to manage training. Comply with the requirements as set out in this manual. Ensure all food safety and Health and Safety procedures are followed. Ensure the machine and lighting in the furniture is always on when the store is open. Keep the machine locked & closed when unattended. Display agreed Starbucks marketing materials. If you have any questions about your coffee machine, please contact the Selecta Helpdesk on 0344 736 0204 or your Selecta Field Account Manager. The machine kept fully stocked: • Keep machine stocked with (refer to display guidelines for help): • Coffee, Semi-Skimmed Milk • Syrup, Chocolate and Tea • Cups, Lids & Sleeves • Sugars, Stir Sticks, Napkins & Milk Jiggers The machine is Clean and Presentable: • Keep the machine looking clean & presentable at all times of the day. • Ensure the floor and area surrounding the machine is clean and tidy, following your store procedures • • • • • & safety guidelines. Complete the daily cleaning procedure every day as instructed and only with approved chemicals. Follow the Milk Management guidelines to ensure the milk is not left in the machine for longer than 2 days. Milk disposal must be documented in your Due Diligence pack and kept as evidence. Complete the weekly cleaning procedures as instructed. Record all completed cleaning using the ‘Cleaning Check Sheet’ in your Due Diligence pack. This should be retained as evidence of cleaning being performed. Take and record daily temperatures of the milk and any ‘Over Temperature’ within the Due Diligence pack as required. 2.1 Version EG, January 2015 Responsibilities Continued Store Responsibilities contd. Respond to any service faults: • Respond immediately to any On-Screen Prompts. • Use your ‘Fault Finding’ guide to understand and correct any operating issues. • Report any technical faults, that you are unable to resolve, to the Selecta Helpdesk by calling 0344 736 0204. • Please refer to the Fault Finding section of this manual, before logging a call with Selecta. In situations where no fault can be found or failure is assigned to an operating cause, there may be a cost incurred. Listen carefully to any instructions given by the Selecta Helpdesk and follow their instructions within • any time lines indicated. • It is the responsibility of the operator to cancel any engineer call outs that are no longer required, in order to avoid any liability for incurred service costs. Assist customers at the Starbucks on the go: • Answer any customer questions that arise. • Aid customers with using the machine if they have difficulty. • If a customer has a question which you can not answer, please contact your Selecta Field Account Manager or alternatively the Selecta Helpdesk on 0344 736 0204. Receiving Orders & Stock Control: • Upon receipt of all deliveries, check contents and sign to confirm they match the delivery note. Keep • • • • • the delivery note for your records. Report any discrepancies and receipt of any delivery within 24 hours to your local Selecta Depot. Your Field Account Manager will provide details of this. Do not transfer stock between sites. If there is a stock challenge, please contact your Field Account Manager. Ensure all Starbucks products are stored securely within the designated Starbucks storage area. Ensure that the Starbucks storage area & products are kept in a clean, dry, pest & odour free area at all times. Keep machine and furniture cleaning supplies separate from consumables (Coffee Beans, Cups, Sugars, etc). 2.2 Version EG, January 2015 Know Your Starbucks on the go Overview Just like a Starbucks Coffee House, the Starbucks on the go is a place where people can connect and relax, whilst enjoying a Starbucks beverage. The furniture is made from real oak, to give an authentic coffeehouse look and feel. LED lighting is used, along with Starbucks branding on the back panel. Starbucks Lightbox Starbucks Logo Background Image The Siren Franke FM840 Condiment Holder Cups, Lids, Sleeves, Stirrers, Tazo Tea, Sugars, Napkins and Milk Jiggers. Milk Cooler Waste Bin Syrup Station 3.1 Version EG, V2.0, September 2014 Know Your Starbucks on the go Making Your Perfect Beverage With your Starbucks on the go, you can create a number of great Starbucks beverages, just like you can in your local coffee house. To do this, just tap on your preferred drink on the touchscreen and then customise as required. Please see the steps below: 1. Select your cup size and place on the drip tray. 2. Select your favourite drink. 3. Then you can customise your drink in the following ways, before pressing the Green Tick: • Bean type (Fairtrade Espresso Roast or Kenya) • Syrup (Caramel or Vanilla Enjoy your Starbucks beverage with care, as it will be HOT. 3.2 Version EG, V2.0, September 2014 Whole Bean Coffee Overview Starbucks only use high-quality Arabica coffee, which has been grown at high altitudes. There is another coffee bean called Robusta, which Starbucks do not use. This coffee is grown at lower elevations and has a harsher flavour characteristic. Only 3% of the coffee grown around the world is good enough to make it into any bag of Starbucks® coffee. Starbucks offer 26 different coffees, which are either single origin or blends from the following growing regions: Latin America, Africa / Arabia and Asia / Pacific. In the Starbucks on the go, we currently offer Fairtrade Espresso Roast and Kenya. Kenya MEDIUM ROAST Beloved, like the elephant that symbolises it. And big – awash with a full-bodied juiciness that makes it instantly recognisable to its many, many fans. These qualities are all true of Starbucks Kenya coffee. You can recognise Kenya through its tell-tale citrus flavours – grapefruit most often, but sometimes lemon and sometimes tart orange. There’s a sparkle to this coffee, a bright acidity, that makes it so refreshing to drink. In fact, it's a terrific iced coffee on a hot summer day. Fairtrade Espresso Roast DARK ROAST This is the heart of Starbucks most popular coffee beverages. It's a special blend of beans from Latin America and Asia/Pacific darkly roasted to produce a rich and caramelly sweetness. Because this dense, full-bodied brew has a stout taste that stands up against milk, it’s the perfect foundation for making a latte or cappuccino at home. Here’s an interesting fact: Espresso was invented in Italy by an enterprising soul who was seeking a way to prepare coffee in less time, in order to serve commuters rushing to catch trains. Which is somewhat ironic when you think about it, because coffee lovers in Italy (and all over the world) now prefer to savour their espresso in long, slow sips. Version EG, August 2014 Customer Assistance Cup Sizes The condiment holder will always contain 3 cup sides depending on your location. These will either be Demi, Short and Tall or Demi, Tall and Grande. Customers Needing Assistance Some customers may need assistance with using the machine, particularly wheelchair users who may find the touch-screen too high. It is important to assist anyone that may need help with the machine, using the following steps: • Politely ask if they would like assistance. • Assist the customer with choosing and customising their drink. • Once the drink has poured, assist with provision of condiments as needed. Firmly place a lid • on the cup and a sleeve if they request. Ask the customer if they would like some help taking their beverage to the till. Please keep a special look out, for children or vulnerable people, as there is a risk of scalding if they are not careful when using the machine. 5.1 Version EG, January 2014 Regular Spot Checks Overview: Starbucks is a premium brand, which customers have come to expect a certain level of service from. To ensure your customers continue to receive this, there are a couple of spot checks that should regularly be carried out. Check the unit is clean: Regularly check that the machine and furniture is clean. Some of the key areas to particularly look at are: • • • • Liquid spills and sugar on the counter top. Drips or debris around the waste bin. Finger prints on the Touch-Screen. Spillages on the floor around the unit, follow your stores safety procedures where applicable. Only use paper towel and sanitiser on the counter top and doors. Please spray sanitiser onto the cloth, rather than directly on the surface, to help prevent any potential cross-contamination. This should not come into contact with any part of the machine. Do not use any scrubbers or scourers, as this could damage the surfaces. • For the Touch-Screen, only use the Franke Micro Fibre Cloth. Check the unit is stocked: Regularly check that the machine and unit is stocked to meet the needs of your customers. Some of the key areas to particularly look at are: • • • • • Coffee Beans and Milk. Coffee Cups and Lids. Sugars, Sweeteners and Milk Jiggers. Napkins. Wooden Stirrers. If you have recently experienced an overly busy period, please also check the following: • • • • Milk levels in the cooler. Syrups. Chocolate Powder. Do the Waste Bins need emptying. 6.1 Version EG, V2.0, September 2014 Basic Hygiene & Safety Basic Hygiene: Overview: The Starbucks on the go installation, includes the use of fresh product. It is important that these products are handled safely, to reduce the risk of any potential cross-contamination. To help you achieve this, please follow the simple guidelines below in addition to your own companies guidelines. • • • • • Always wash your hands before opening any ingredients and filling the machine. Before filling, always check the dates of the product, to ensure it has not past its Best Before or Discard On date. When filling, always ensure you have chosen the correct product. An example of this, is to ensure the Kenya coffee, goes in the Kenya hopper. Do everything possible to prevent any cross contamination, of foreign bodies falling into any part of the machine. One way to prevent this, is to open one hopper at a time. If you have any suspicion that a foreign body may have fallen into a container or hopper, please remove and empty the whole contents. 7.1 Version EG, V2.0 September 2014 Know Your FM840 Overview Your Starbucks coffee machine has been manufactured by Franke, with a model number of FM840. It is a state of the art machine, which provides Starbucks Espresso and market leading milk foam. It will produce a variety of popular Espresso based beverages, along with Hot Chocolate and Tea. The guide below, highlights the key parts of your Franke FM840. The Outside: Hot Chocolate Hopper Whole Bean Hopper’s Two types of whole bean coffee: Fairtrade Espresso and Kenya Touchscreen Hot Water & Coffee Outlet Drip Tray 8.1 Version EG, V2.0, September 2014 Know Your FM840 The Inside Main Unit Hot Chocolate Mixer Espresso Brewer Vending Interface Platform (VIP) This enables sales and drink mix data to be extracted from the machine. Espresso Grounds Bin Syrup Station - (in cupboard) Syrup Pumps Syrup Pipes The following syrups are used with corresponding pipe number: 1. Empty 2. Caramel Syrup 3. Vanilla Syrup Syrup Tray & Removable Mat 8.2 Version EG, V2.0, September 2014 Know Your FM840 Internal Fridge - (in cupboard) Double Milk Containers Chai Concentrate 8.3 Version EG, V2.0, September 2014 Machine Capacity Machine Capacity: The number of drinks your machine can produce with one fill of ingredients, will vary depending on your actual site consumption mix of: • Cup size • Drinks Type • Customers choice of customisation options On average, your machine can deliver 110 drinks with one fill of ingredients. To minimise potential stock wastage, monitor the amount of ingredients required for a typical day, so you only fill with what is required. Additional Information Beans: When beans are opened, they only last 7 days. If you have low volumes, please be aware of this for the beans in the hopper. Any part opened bag must either be sealed with clips or stored in an air-tight container. Chocolate: The chocolate hopper could get blocked and stop working correctly if it is overfilled. Unless you have very high daily volumes, please keep this hopper only Half Full. This helps to prevent any potential blockages and stopping the machine from working. 9.1 Version EG, V2.0, September 2014 Your Condiment Station Overview The condiment station provides our customers with all the items required to finish their chosen beverage. Please find below a summary of how to stock the unit and present it correctly. Selection of Cups Please note: The base of the cup should be no higher than the machine. Lids Sleeves and Stirrers Selection of Tazo® Teas Filled left to right: Calm Chamomile, China Green Tips, Refresh Mint, Early Grey and Awake English Breakfast. General Condiments Brown and white sugar, sweetener, napkins and milk. Filling the condiment station: Product Comments Sugars and Sweetener Please ensure that these are fully stocked, but are also neatly lined up. Milk Jiggers These must be stacked neatly and tidied throughout the day. Teas When stocking the station, please follow the order above. When opening a new box, ensure the perforated tab is removed neatly. Cups Only stack the cups so the base is no higher than the machine. Ensure all Starbucks logo’s are facing forward. Sleeve, lids and wooden stirrers Ensure there is always sufficient levels available and neatly stacked. Ensure the Starbucks logo is always facing forward. 10.1 Version EG, V2.0, September 2014 Your Condiment Station Filling To access the condiment station to fill it with various products, please follow the below steps: 1 2 Remove the products from the front tray on top, so it can be lifted out. The tray simply lifts up. 3 Condiments & Tazo Tea’s You now have access to filling Sugars etc; and also lifting out Tea boxes to replace when required. Whilst filling the condiment unit, take time to ensure it is clean. Any product that is visible to the customers, must be neatly displayed with any Starbucks Logo’s visible. 10.2 Version EG, V2.0, September 2014 Know Your Dates Overview All Starbucks products have a shelf life whilst sealed, which is always printed on the packaging. When a product is opened, a new shelf life applies, which is highlighted below. Definitions: Best Before - The quality of the product will not be at its best after this date and should not be used. Exp Date - This date means the same as a Best Before date. Use By - A product cannot be sold after this date and should not be used after midnight of that date. Please find below a list of all the Starbucks products we use, along with guidance on dates. Whole Bean Exp Dates are printed under the name. Once opened - 7 days If only part of a bag is being used, it must be sealed with clip or in an air-tight container. Never store in a fridge or freezer, only ambient. Fresh SemiSkimmed Milk Syrups Hot Chocolate Chai Tea MIlk Best Before dates are printed towards the bottom of the bottle. Best Before dates are printed at bottom of packet. Best Before dates are printed on top of carton. Use By dates will be printed on the packaging. Once opened - 30 days Once opened 6 Months 11.1 Once opened: • 1 day ambient • 5 days chilled. Once opened: • 2 days chilled*. *Regardless of longer packaging dates. Version EG, V2.0, November 2014 Know Your Dates continued. Condiment Milk Best Before date is on box. Keep the original box, to help with identifying dates. xxx Tazo Tea Best Before date is on bottom of box. Notes • When you open a Syrup, Chai Tea or Whole Bean, please write the following information inline with the dates above: • Opened on date • Discard on date 11.2 Version EG, V2.0, November 2014 Filling Your Hoppers Coffee Bean Hoppers 1 2 Unlock the appropriate hopper lid, one at a time.This prevents potential cross contamination. 4 3 Remove hopper lid and place to the side 5 Cut open a new bag of Starbucks beans and fill hopper Date Coding / Storage: • When a bag has been opened, you must record the Opened and Discard date on the bag. • Once opened, coffee lasts 7 days and is to be stored ambient. Ensure the hopper is ‘locked’ after refilling Part used bags must be sealed with clips or in an air-tight container and dated Hot Chocolate Hopper 1 Unlock the Hot Chocolate Hopper lid and fill with Starbucks Hot Chocolate Mix. To prevent the hopper from blocking, only fill it HALF FULL (approximately 5cm from rim), unless production levels are high. After filling has been completed, seal any half used bags, date code and then Lock the hopper lid. 12.1 Version EG, August 2014 Milk Management & Safety Overview To ensure you maintain the high standards expected to deliver Starbucks beverages and do not exceed any shelf life restrictions, milk must only ever be in the machine for a maximum of 2 days. This not only ensures you can maintain high quality beverages, but also that you have the opportunity to clean the milk containers. Milk Disposal Milk Disposal Chart Instructions: On each of the days identified below, the milk must be disposed from both containers in the machine and then fully cleaned. This is best done before serving your first customer on the below days. This document is to be changed every 2 weeks. Please refer to the Operator Manual for further details. Site Name: Week 1 Monday Wednesday Friday Sunday Date Amount Disposed Name Signature Week 2 Tuesday Thursday Saturday Date Amount Disposed Name Signature Version EG, V2.0 September 2014 This is used to record when the milk container is emptied, cleaned and filled. It is best practice to complete this on the relevant morning before serving customers. This happens on a 2 weekly cycle as identified on the above document. 13.1 Version EG, January 2015 Milk Management & Safety Cleaning the Milk Containers When you need to clean the containers (every 2 days), please follow the instructions below. Put 20ml of Franke Cleaning Fluid and approximately 1litre of hand hot water into the milk container. Don't forget to also wash all parts of the lid. Then ‘rinse’ with cold water and leave to dry before refilling. Using a Wypall, wash the inside of the container to remove any milk residue. Replenishing the milk containers Between milk disposal and cleans, you can refill your milk container(s) as often as you wish. • Check that the milk has a minimum of 2 days shelf life left, when filling the container and at least 5℃. To support longer operational times between fills, some machines are equipped with two 12 litre milk containers. As each container empties of milk, the machine will automatically switch over to the other container. • When your machine does this, there will be a notification on the screen to let you know of this, so you can top up the empty container accordingly. To help support profitability, you will want to bear in mind wastage, When filling your milk container on day 2, take into account the following usage guidelines, so you reduce the amount of milk filled, based on your daily consumption. Milk Usage Tall / Grande Short / Tall 13.2 Drinks/Day Milk Litres Used/Day Drinks/Day Milk Litres Used/Day 10 2 25 5.5 20 3.5 50 11 30 5 75 16 40 7.0 97 21.0 50 8.5 125 27 75 12.5 150 32 100 17 175 38 125 21 200 43 Version EG, January 2015 Milk Management & Safety Temperature Monitoring Many of the machines will have a telemetry device fitted, which will constantly monitor milk temperature. If yours does not, you will be required to take daily records of the milk temperature. The temperature must be below 5℃. To do this, please follow the instructions below: Cleaning Check Sheet Instructions: This document is to be completed daily / weekly. The Merchandiser completing the cleaning must Date, Sign and Print their Name, when the appropriate cleaning has been completed. Your Weekly Clean date is on the front cover of this pack. Record the milk temperature daily, if you do not have telemetry. Site Name: Day Milk Temp (0-5 oC) Monday 4.2 ✓ for Weekly Clean day. Date Name Daily Clean Signature Weekly Clean Signature Tuesday Wednesday Thursday Friday During your daily cleaning cycle, take a temperature reading of the milk. Saturday Sunday Monday Tuesday Wednesday Thursday Friday Saturday Sunday Version BI, December 2014 Enter the daily reading on your current Cleaning Check Sheet. If it is above 5℃, follow the High Temperature section, High Temperatures Ensure you record the 1st temperature you took. Follow these steps. • Close the fridge door. • Wait 30 minutes. • Re-check the temperature (2nd reading). Over Temperature Log Instructions: If you experience a High Temperature reading, please identify the action taken in the log below. If you experience a temperature higher than 5℃, close the fridge door and wait 30minutes, before testing again. Site Name: Date 1st reading 2nd reading Action Taken Name Signature • If temperature is within 0-5℃, no action required. If the temperature is still high, place a call with the help desk. Please document the above steps within the Over Temperature Record. Version BI, December 2014 13.3 Version EG, January 2015 Fault Finding Overview: The Franke FM840 is a premium coffee machine, made to the the highest possible standards in Switzerland and should provide you with trouble free Starbucks beverages. At times, a fault might appear that reduces the performance of the machine or stop it working all together. Many of these faults can be rectified by the user, which the below information talks you through. In the event that you can’t resolve this locally, Selecta are just a phone call away to support you. Please try to resolve faults locally before calling Selecta, to save any unnecessary costs being incurred. 1 2 Colour Codes: There a 3 types of fault. System still fully working, but needs attention. System is working, but with limitations. System can not operate. You will see a coloured tab in the top right corner Tap the tab, for more information Common Faults & Action: Error Code Error Text Action 3 Communication LP Restart the system. 72 Initialize Brewing Unit Restart the system. Clean the Brewing Unit with a brush. 99 Water Filter The water filter needs replacing. This is part of the maintenance plan. Call Selecta. 120 No Coffee Powder Potential blockage. Check the powder chute and clean with a brush. Check photocell is clean on bean monitor. Make sure hopper is positioned correctly and topped up. 125 Powder Flap Open The flap opened to put in the cleaning tablet is open. Close it. 130 Filling with Cold Milk Milk container is empty or not able to draw through. Fill container and check pipes are not caught / kinked. 226227 Cleaning Required Complete a full Daily Cleaning Cycle. 228229 Clean Flavour Station The Flavour (syrup) station must be cleaned. This appears 7-9 days after last cleaning. 230 Prepare Flavour Station Prepare the Flavour Station and ensure syrup is coming through the nozzle. 231 Prepare Milk System The Milk System needs preparing. 252256 Cleaning Cancelled During cleaning, if the correct process is not followed or the water tank was full, this will appear. Cleaning needs to be restarted. * More Error Codes can be found within the Appendixes of this manual. Version EG, V2.0 September 2014 Fault Finding Continued Further Support Needed: If you have tried everything possible to resolve the fault on site, but cant get your machine working, please call the Selecta Helpdesk for further support. A sticker can be found on your Coffee Machine, highlighting the contact number and your Machine Identification Number. Call the help desk and quote your Machine ID. Contact Number Machine Identification Number Version EG, V2.0 September 2014 Chemical Use Overview: Please find in the Appendix, the relevant data sheets for the chemicals you are required to use for cleaning. This includes the Cleaning Tablets, Cleaning Solution and Chlorine Tablets. All staff that are required to use these products, must read through this information. Dependant upon your country, these help you to conform to either: • COSHH - Control of Substances Hazardous to Health Regulations 2002 (UK) • CLP - Classification, Labelling and Packaging of substances and mixtures. (Regulation (EC) No 1272/2008 15.1 Version EG, January 2015 Page 20 You will need: Filling and emptying y Daily Cleaning - FM840 Explanation of symbols • Machine Keys So that you can get the most •outFranke Milk Cleanser Cleaning Container (jug) of your FM800, we would like to familiarize •you with the symbols used in the Operating Hard Surface Sanitiser solution Franke instructions and software. For• us, thoroughCleaning information Tabs and open communication go without saying. • Thermometer 03 • 04 • Grounds Brush and red handle Franke Microfibre cloth • brushes Tablets • Sanitising Symbols used in the Operating instructions • Paper Towels • Plastic Bin Liners DANGER indicates potentially life- i ! DANGER threatening danger oron grave the injury. machine screen. Please Note: Cleaning instructions are highlighted 1 ! WARNING Empty, clean and dry the bean ! CAUTION hopper. NOTE WARNING indicates risk of injury. 2 01 Replace the bean hopper. Slide the safety pusher back until it stops. 3 This symbol indicates tips, shortcuts Tap for more info and additional information. on each screen Describes and illustrates a step that you must perform. CAUTION directs your attention to a danger of minor injuries. NOTE makes you aware of the risk of damaging the machine. 01 Steps on a colored background are optional. They must be performed depending on the model of your machine. Cleaning the add-on unit or individual components. CAUTION - Maybe HEAVY and will stop clean cycle when full. Tap FRANKE and enter 7777, OK. Empty container. Risk of injury! The screw conveyor of the pow4 der container can cause cuts and crushing injuries. Exercise care when cleaning the powder container. Tap Cleaning and Maintenance. Page 3 CAUTION Explanation of symbols ! 5 Tap Clean Coffee Machine, then confirm. Remove Mixer - Pull off tube, turn red lever Anti-Clockwise, pull mixer. 6 Chocolate Mixer Tips: • • • • • • 16.1 Clean Mixer, using brushes and ‘Cold Water’ if required at a sink. Ensure cut-out and notch line up when putting together, White ring can be inserted anyway up. Push into machine and lock red ring clockwise. Reconnect tube. Give a gentle pull on the mixer to ensure it is secure. CRITICAL to prevent leaks. Version EG, V2.0 September 2014 Daily Cleaning Continued 7 Brush out the inside of the machine, paying particular attention to the top of the brewer. Ensure the top grounds chute is also cleaned and replaced correctly. 8 7. Outlet Head: A B A. Wash all parts with ‘Cold’ water and brush inside, paying attention to all the holes. B. When replacing rubber insert, ensure the prongs are ‘through’ the holes. • Listen for the ‘2 Clicks’, when replacing the head, to ensure both sides have locked in correctly. 9 Your machine will now commence the cleaning cycle and offer several screen prompts for activities that need to be carried out. After opening flap, wait 3 seconds before dropping Franke cleaning tablet in the machine. 16.2 Version EG, V2.0 September 2014 Daily Cleaning Continued The Milk System: 10 11 12 Chai Chai • Follow on screen prompts. • Remove milk tubes into the cleaning jug. • Either Store in a Fridge or Dispose of the milk, according to your Milk Disposal Chart. 13 • If your installation does not have Telemetry for temperature recording, please take a reading and record in the Cleaning Check Sheet. • Sanitise probe before and after use. 15 14 A • When prompted, add 100ml of Franke cleaning fluid and press continue. • The cleaning cycle will continue. • Close the fridge door and press continue. • Your jug will fill with water and start to rinse the milk system B Chai • Check that any spills have been wiped up in the fridge. • Replace your milk containers and tubes. A = Blue Tube. B = Red Tube. • Check the screen for prompts to fill the milk. • When you confirm, the machine will pull through the milk. • If you are performing a Weekly Clean, jump to this now and return to point 14 after that is complete. 16.3 Version EG, V2.0 September 2014 04 y 17 16 Empty, clean and dry the bean hopper. ! CAUTION - Maybe HEAVY CAUTION Risk of injury! Empty container and drop a The Chlorine screw conveyor the powTabletofinside. der container can cause cuts and crushing injuries. Exercise care when cleaning the powder container. 19 Page 20 03 Filling and emptying Daily Cleaning Continued 18 Replace the bean hopper. Slide the safety pusher back until it stops. Tap ‘Wipe Protection’. Clean display using Microfibre cloth. Remove rubbish chute, clean with Sanitiser and ensure the recess in counter top is also clean. General Cleaning Tips: • When using sanitiser, spray onto the cloth first to save any potential cross contamination of chemical onto food products or coffee machine. • Check the inside of cupboards for any excessive spills or debris and clean appropriately. • Check under the condiment station, to ensure no spills or excessive sugar are underneath. • When cleaning the counter top, dry any chemical residue off quickly, to prevent smears. • Finally clean the Drip Tray, but ensure that no paper towel goes into the waste pipe. • Only use the Microfibre cloth to clean the outside of the machine. 16.4 Version EG, V2.0 February 2016 Weekly Cleaning - FM840 mbols General You willweneed: st out of your FM800, would like to familiarize you with the symbols usedInformation: in the Operating For us, thorough information and open communication go without saying. • Machine Keys • Hard Surface Sanitiser perating instructions • Paper Towel • Cleaning Container (Jug) ANGER indicates potentially lifeMilk Cleanser • Franke eatening danger or grave injury. ARNING indicates risk of injury. Please Note: Detailed cleaning instructions are highlighted on the machine screen as you progress, to help guide you in more detail. i 01 AUTION directs your attention to a nger of minor injuries. 1 OTE makes you aware of the risk of maging the machine. Complete this Weekly Cleaning on your chosen day, which is highlighted on the front cover of this manual. This symbol indicates tips, shortcuts Tap for more info and additional information. on each screen Describes and illustrates a step that you must perform. 2 3 Steps on a colored background are optional. They must be performed depending on the model of your machine. 01 eaning the add-on unit or dividual components. Page 3 Explanation of symbols Remove the grounds chute. This just pulls off. 4 Rinse hot water through the chute, to remove any excess coffee. Leave to Air-Dry 5 Tap FRANKE and enter 7777, OK. 6 Chai Tap Cleaning and Maintenance. 17.1 Tap Clean Flavour Station, then confirm. Remove all syrups and chai after being prepared. Version EG, V2.0 September 2014 Weekly Cleaning continued. 7 8 9 Chai Put the Syrup tubes into a jug, with 500ml of Hand Hot water and 30ml of Cleaning Fluid. 10 Remove the milk containers and place tubes in a clean cup. Put the Chai tube into a jug, with 500ml of Hand Hot water and 30ml of Cleaning Fluid. 11 Follow the on-screen prompts, which will include you having to refill the jugs with Hand Hot water (500ml) to rinse the system and then the cycle will be complete. Keep the fridge door shut as much as possible. Before replacing milk containers, give the inside of the fridge a wipe over with some sanitised solution sprayed onto a paper towel. Before starting the Clean Cycle, dip a paper cloth into the solution and wipe down the hard tube. Syrup Station: • When immersing tubes into the jug, please try and ensure the ‘bungs’ are also immersed. • Remove the rubber mat and clean with sanitiser. • Check the surrounding area for any syrup splashes and clean accordingly. • When putting tubes into bottles / cartons, ensure the tube goes to the bottom. • Double check that all bottles / cartons are date coded. 17.2 Chai Filter Check Check the filter is clean. If some debris is still present, remove and use brush and cold water to clean. Version EG, V2.0 September 2014 Weekly Cleaning continued. 12 14 13 For each syrup, tap Starting. You will then see the next screens. Tap Prepare Syrup System, then confirm. 15 16 17 The pump will start, when you see a constant flow, Press Stop. Repeat previous steps for each syrup available. Enter the amount in ml. Tap OK. Your are prompted to check how much of each syrup is left. Please estimate in ml, how much is left. Coffee Hoppers - empty product, wipe inside with damp cloth. Ensure dry before replacing product. 19 Replacing Grounds Chute 18 Empty Grounds bin and General Waste, wash inside and out. 17.3 Check the chute is Dry Inside. Open machine door, hold the top of the coffee grounds container, then push the grounds chute upwards onto the pipe at the bottom of the machine. Version EG, V2.0 September 2014 Weekly Cleaning continued. 20 The Condiment Unit Remove all the products and tray from the condiment unit. Clean the whole of the condiment unit, inside and out. Don't forget to also clean the underneath. 22 21 Clean cupboards inside and out. Finally, check that the top surface, outside of the cabinets, conversation table and background are clean. 23 Return to point 14 of the Daily Cleaning section, to ensure all daily tasks are complete and machine ready for operation. What Next? When you have completed all the cleaning, you must vend a Test Drink once per week. • A Tall Vanilla Latte is a great drink to check, as it involves all aspects of the machine (Espresso, Milk and Syrup). 17.4 Version EG, V2.0 February 2016 Milk Disposal Chart Instructions: On each of the days identified below, the milk must be disposed from both containers in the machine and then fully cleaned. This is best done before serving your first customer on the below days. This document is to be changed every 2 weeks. Please refer to the Operator Manual for further details. Site Name: Week 1 Monday Wednesday Friday Sunday Date Amount Disposed Name Signature Week 2 Tuesday Thursday Saturday Date Amount Disposed Name Signature Version EG, V2.0 September 2014 Cleaning Check Sheet Instructions: This document is to be completed daily / weekly. The Merchandiser completing the cleaning must Date, Sign and Print their Name, when the appropriate cleaning has been completed. Your Weekly Clean date is on the front cover of this pack. Record the milk temperature daily. Highlight any high temperatures and complete the ‘Over Temperature Record’. Site Name: Day Milk Temp (0-5 oC) ✓ for Weekly Clean day. Date Name Daily Clean Signature Weekly Clean & Drink Test Signature Monday Tuesday Wednesday Thursday Friday Saturday Sunday Monday Tuesday Wednesday Thursday Friday Saturday Sunday Version EG, September 2015 Over Temperature Log If you experience a High Temperature reading, please identify the action taken in the log below. If you experience a temperature higher than 5℃, close the fridge door and wait 30minutes, before testing again. Site Name: Possible Outcome / Action: • 2nd reading is < 5℃ - All O.K. Continue serving great coffee. • 2nd reading is > 5℃ - Call Helpdesk, Dispose of Milk, Stop using machine until fault fixed. Date 1st reading 2nd reading Action Taken Name Signature Version EG, September 2015 Daily / Weekly Checks Day / Date Task Performed a daily clean Milk and Coffee levels are correct for days usage. Milk Management procedures have been followed D A I LY Fill levels of Syrup and Chai have been checked Dates on all ingredients have been checked. Any out of date product thrown. Condiment station has been filled and cleaned where required. All bins emptied and cleaned if required. Stock levels reviewed. Is the installation presentable to a customer Have you locked all the doors required. No errors present on the screen A test drink to be pulled off. Use a Vanilla Latte to check all aspects of the machine. W E E K LY Syrup / Chai cleaned Furniture and surround cleaned inside / out. Hoppers cleaned. Condiment unit deep cleaned. Version EG, September 2015 Service Call Log Instructions: If you experience a problem with your machine and need to call the Helpdesk, please record the details below. Site Name: Date Issue / Problem Log Number Reporting Name Signature Version EG, January 2015 RMS - F109 BioSpot 4K Chlorine Tablets Internal Use Selecta Safety Data Sheet Bio Spot 4K Chlorine Tablets Chemical Product: Manufacturers Name: Zenith Hygiene Manufacturers Contact Number: 01707 270260 Hazards Identification First Aid Measures Harmful - Harmful if swallowed. Irritant - Irritating to eyes. Contact with acids liberates toxic gas. Rinse immediately with plenty of water holding the eyelids open Inhalation: Remove from source of exposure. Wash Thoroughly Skin: Remove product from mouth. Do not induce Ingestion: vomiting. Drink small amounts of water. If Problems persist seek medical advice. Fire Fighting Measures Handling and Storage Substance does not in itself represent a fire hazard. In the event of a fire from other causes the product is compatible with: Water, Carbon Dioxide Co2 extinguisher, foam and dry powder extinguisher. May evolve toxic fumes if involved in a fire. Fire fighters should wear self contained breathing apparatus and other PPE. Handling: Avoid contact with eyes. Rinse and dry hands after use, for prolonged contact protection of the hands may be necessary. Prevent the formation of dust. Storage: Store in original containers. Avoid extremes of temperature. Do not mix with any other chemicals. Personal Protection Composition/ Information on Ingredients Hand: Eyes: Skin: Respiration: For prolonged contact wear rubber gloves Not required Not required Not required Eyes: Sodium dichloroisocyanurate dihydrate >30% Disposal Considerations Regulatory Information This product is not classified as hazardous waste under the Special Waste Regulation. For disposal contact a licensed waste management company. Rinse out containers at least twice and recycle. Version 2.0 Hazard Symbol: Xn HARMFUL, contains Sodium dichloroisocyanurate dihydrate. Risk Phrases: R22 - Harmful if swallowed. R36 irritating to eyes. R31 - Contact with acids liberates toxic gases Safety Phrases: S26 - In case of contact with eyes, rinse immediately with plenty of water and seek medical advice. "Uncontrolled When Distributed" RMS - RA36 COSHH Risk Assessment Internal Use SELECTA UK AND IRELAND LTD - COSHH PRODUCT ASSESSMENT Please refer to Manufacturer's Safety Data Sheet (SDS) What is the name of the chemical product? What does the product What is the What is the product used look like? See section 9 of manufacturer's name and for? telephone number? Manufacturers SDS Biospot Chlorine (formally Zenith Hygiene Systems. Sanitising waste buckets Steraclean) Tablets 4K 01707 270 260 Describe the hazard warning (e.g. Irritant, Harmful or Nonhazardous) See section 3 of Manufacturers SDS or product label What are the Risk Phrases? (e.g. Causes severe burns) See section 15 of the Manufacturers SDS Harmful and irritant R22 - harmful if swallowed, R36 - irritating to eyes, R31 - contact with acids liberates toxic gas White Tablet Dilutions Routine Disinfection - 1 tablet in 5 litres of water Waste Disposal Units - 1 tablet in 400ml of water Cloths & Mops etc - immerse overnight in a bucket containing 1 tablet per 15 litres of water What are the Safety Precautions, including PPE where appropriate? See sections 7 & 8 of SDS and any safety information on the product label. Handling - avoid contact with the eyes, rinse and dry hands after use, prevent the formation of dust. Storage - store in original containers, avoid extremes of temperature, do not mix with other chemicals. First Aid. Eyes - flush eye with water for at least 15 minutes. Seek medical attention if problem persists. Skin - flush immediately with water. PPE - for prolonged contact, the use of rubber gloves resistant to detergents is recommended Ingestion - drink large quantities of water, do not induce vomiting. Inhalation - remove to fresh air For further information regarding first-aid, fire fighting, spillage or accidental release, handling, storage and disposal considerations - see manufacturer's guide. Assessed By : Sandy Newman Signature: Date: February 2014 This COSHH Product Assessment must be reviewed every 12 months or sooner if there are changes to the product or its use and after any accident or incident involving this substance. Version: 2.2 ' Uncontrolled When Distributed' RMS - F132 Special cleaner for milk and cream dispenser Internal Use Selecta Safety Data Sheet Special cleaner for milk - and cream dispenser Chemical Product: Manufacturers Name: Schulz & Sohn Manufacturers Contact Number: Hazards Identification 4903019240 First Aid Measures Notes to Physician Inhalation: Treat Symptomatically Fresh Air. If symptoms persist, consult a doctor Wash the skin immediately with soap and water. Get Skin contact: medical attention if irritation persists Xi Irritant Ingestion: Drink water. Do not emesis. Consult a doctor Make sure to remove any contacts before rinsing. Promptly wash eyes with plenty of water while lifting Eye contact: eye lid. Rinse for several minutes. Then consult a doctor Fire Fighting Measures Handling and Storage CO2, poweder or water spray, adapt the extinguishing agent on the surrounding area. Special hazards caused by the substance, its products of combustion or resulting gases: Carbon Monoxid (CO) Personal Protection Hand: Eyes: Skin: Respiration: Follow the genral preventative measures at working with chemicals. Keep receptacles tightly sealed. Do not store together with alkalis (caustic solutions) - Exothermic reaction with alkalis. Do not use with other cleaner Composition/ Information on Ingredients Wear suitable protective gloves if risk to Wear safety goggles if risk of splashing Wear protective clothing to prevent skin Fresh air Not applicable Auto ignition temperature (oC) Disposal Considerations None Regulatory Information Disposal should be in accordance with local, state or national legislation - not with household garbage. Do not Safety Phrases: Xi Irritant allow to reach sewage system Risk Phrases: R38 Irritating to skin 41 Risk of serious damage to eyes 2 Keep out of the reach of children 26 in case of contact with eyes, rinse immediately with plenty of water and seek medical advice 37/39 wear suitable gloves and eye/face protection Version 2.0 "Uncontrolled When Distributed" RMS - RA36 COSHH Risk Assessment Internal Use SELECTA UK AND IRELAND LTD - COSHH PRODUCT ASSESSMENT Please refer to Manufacturer's Safety Data Sheet (SDS) What is the name of the chemical product? What is the manufacturer's name and telephone number? Special cleaner for milk and cream dispenser Sculz & Sohn +4903019240 What is the product used What does the product Describe the hazard warning (e.g. What are the Risk Phrases? for? look like? See section 9 of Irritant, Harmful or Non-hazardous) (e.g. Causes severe burns) See section 3 of SDS or product See section 15 of the SDS SDS label Cleaner to support the Liquid Xi Irritant R38 Irritating to skin 41 Risk Franke Starbucks system of serious damage to eyes 2 Keep out of reach of children 26 in case of contact with eyes, rinse immediately with plenty of water and seek medical advice 37/39 wear suitable gloves and eye/face protection Dilution Check container and adhere to instructions What are the Safety Precautions, including PPE where appropriate? See sections 7 & 8 of SDS and any safety information on the product label. Keep away from foodstuffs, beverages and feed. Immediately remove all soiled and contaminated clothing, wash hands before breaks and at end of work Avoid contact with skin and eyes. Protective gloves for hands when working with large quantities or in technical production application Engineering measures - No particular ventilation requirements - Hand Protection - Use suitable protective gloves if risk of skin contact. Eye Protection - if risk of splashing, wear safety goggles or face shield. Other clothing - wear appropriate clothing to avoid skin contact - HYgiene measures - Wash at end of eah work shift and before eating, smoking and using the toilet. Wash promptly if skin becomes wet or contaminated, when using do not eat, drink or smoke. For further information regarding first-aid, fire fighting, spillage or accidental release, handling, storage and disposal considerations - see manufacturer's guide. Assessed By : Sandy Newman Signature: Date: February 2014 This COSHH Product Assessment must be reviewed every 12 months or sooner if there are changes to the product or its use and after any accident or incident involving this substance. Version: 2.2 ' Uncontrolled When Distributed' RMS - F131 Cleaning tablets Internal Use Selecta Safety Data Sheet Cleaning tablets Chemical Product: Manufacturers Name: Sculz & Sohn Manufacturers Contact Number: Hazards Identification 4903019240 First Aid Measures Notes to Physician Inhalation: Symptoms of poisoning may occur even after several hours, therefore medical observation for at least 48 hours after the accident In case of unconsciousness place IP stably in side position for transportation Immediately wash with water and soap and rinse Skin contact: thoroughly Xn Harmful Ingestion: Get medical attention Make sure to remove any contacts before rinsing. Promptly wash eyes with plenty of water while lifting Eye contact: eye lid. Rinse for at least several minutes. Then consult a doctor Fire Fighting Measures Handling and Storage CO2, powder or water spray, apply extinguishing agent Follow the general preventative measures of workking with on the surrounding area. Special precaution: special chemicals, keep receptacles tightly sealed. KEEP away from hazards caused by sustance its products of combustion foodstuffs, bevcerages and feed. or resulting gases: Carbon Monoxid (CO) Personal Protection Hand: Eyes: Skin: Composition/ Information on Ingredients Wear suitable protective gloves if risk to contact of skin Impermeable Flash Point (oC) Not applicable Wear safety goggles Wear protective clothing to prevent skin contact - Wash hands before breaks and at end of work Auto ignition temperature (oC) Not applicable Respiration: Use a air filter class P2 if dust formation Disposal Considerations Version 2.0 Regulatory Information "Uncontrolled When Distributed" RMS - F131 Cleaning tablets Internal Use Must not be disposed with household garbage. Do not allow product to reach sewage system Safety Phrases: 24/25 Avoid contact with skin and eyes, 26 In case of contact with eyes, rinse immediately with plenty of water and seek medical advice, 46 If swallowed, seek medical advice IMMEDIATELY and show the container and safety sheet Risk Phrases: 22 Harmful if swallowed. 34 Causes burns, 36 Irritating to eyes, 41 Risk of serious damage to eyes, 52 Harmful to aquatic organisms 8 Contact with combustable material may cause fire Version 2.0 "Uncontrolled When Distributed" RMS - RA36 COSHH Risk Assessment Internal Use SELECTA UK AND IRELAND LTD - COSHH PRODUCT ASSESSMENT Please refer to Manufacturer's Safety Data Sheet (SDS) What is the name of the chemical product? What is the manufacturer's name and telephone number? Cleaning tablets Sculz & Sohn +4903019240 What is the product used What does the product Describe the hazard warning (e.g. What are the Risk Phrases? for? look like? See section 9 of Irritant, Harmful or Non-hazardous) (e.g. Causes severe burns) See section 3 of SDS or product See section 15 of the SDS SDS label Coffee machine cleaner Tablet Xn Harmful 22 Harmful if swallowed, 34 Causes burns 36 irritating to eyes 41 risk of serious damage to eyes 52 harmful to aquatic organisms 8 contact with combustable material may cause fire Dilution Not applicable What are the Safety Precautions, including PPE where appropriate? See sections 7 & 8 of SDS and any safety information on the product label. Follow the general preventative measures at working with chemicals. Keep receptacles tightly sealed. Keep away from foodstuffs, beverage and feeds. Immediately remove contaminated and soiled clothing. Use Air filter class P2 if DUST formation, Protective gloves and tightly sealed goggles. Engineering measures - No particular ventilation requirements - Hand Protection - Use suitable protective gloves if risk of skin contact. Eye Protection - if risk of splashing, wear safety goggles or face shield. Other clothing - wear appropriate clothing to avoid skin contact - HYgiene measures - Wash at end of eah work shift and before eating, smoking and using the toilet. Wash promptly if skin becomes wet or contaminated, when using do not eat, drink or smoke. For further information regarding first-aid, fire fighting, spillage or accidental release, handling, storage and disposal considerations - see manufacturer's guide. Assessed By : Sandy Newman Signature: Date: February 2014 This COSHH Product Assessment must be reviewed every 12 months or sooner if there are changes to the product or its use and after any accident or incident involving this substance. Version: 2.2 ' Uncontrolled When Distributed' Fault Finding Codes Overview: Please find below a full list of all the error codes you might encounter on your machine. If you can resolve this yourself, the actions will highlight what you can try. If after following the guidance, please call the Selecta Helpdesk for further guidance. Error Code Error Text Action 3 Communication LP Restart the system. 8 Internal CAN Restart the system. 14 28 Temperature / heater Restart the system. Check the temperature sensor Check the connection cable and connector of the temperature sensor Check the circuit and connections 30 32 Reheating The products are locked until the set-point is reached. Once the setpoint temperature has been reached, the error is cleared. Excess temperature Restart the system. 36 38 Boiler Restart the system. Check the water supply Check for leaks under the machine 40 45 Motor timeout Restart the system. Clean the brewing unit with a brush 46 Motor timeout Restart the system. Repeat cleaning 47 Brewing unit photocell Clean and inspect the brewing unit photocell The error is cleared when the photocell is functional again. If the error occurs more frequently than 20 times per week, make a corresponding entry in the error log. 48 49 Brewing unit photocell Automatically corrected Clean the brewing unit with a brush Check the wiring of the brewing unit motor 70 Initialize water circuit Restart the system. Check the water supply Check the water circuit for leaks under the machine 71 Initialize steam boiler level Wait at least 4 minutes to identify the errors reliably. Check the water supply Check the water circuit for leaks 72 Initialize brewing unit Restart the system. Clean the brewing unit with a brush 90 Maintenance required Maintenance according to the maintenance plan is carried out automatically. Call Selecta Helpdesk. 91 System calcified Maintenance according to the maintenance plan is carried out automatically. Call Selecta Helpdesk. 33 Version EG, V2.0, September 2014 Fault Finding Codes continued Error Code Error Text 99 Water filter Action Water filter is replaced automatically according to the maintenance plan. Call Selecta Helpdesk. Grounds tank full Remove, empty and clean the grounds tank Grounds tank door must be open at least 5 seconds Empty grounds tank The grounds tank is full Coffee can be drawn 10 more times Remove, empty and clean the grounds tank Grounds tank door must be open at least 5 seconds 110 114 Flow meter error 1 / 2 Restart the system. Select another product Check the water circuits Check the water supply 112 Clean whisk Restart the system. Clean the mixer chamber and replace 119 Powder dosage 2 The right chamber of the dual chamber dosage system is empty. Fill with machine-suitable powder No coffee powder Check the powder chute and clean with a brush Check the photocell of the bean monitor Fill in coffee beans Check that the bean container is positioned correctly Draw the product again Fill tank Fill the corresponding container Powder flap open The powder flap is used for cleaning and when using ground coffee Close the powder flap Brewing chamber open Restart the system. Draw the product again 130 Filling with cold milk Milk is empty All milk products are locked Fill with cold milk Check the milk suction hose Check the foam proportion of all cold foam products 135 Milk temperature The temperature of the milk is higher than 8° C Check the temperature in the cooling unit 160 Battery dead Call Selecta Helpdesk Never switch off the machine 170 Check the water tank The wastewater bucket is full. Empty the wastewater bucket Check the position of the measuring probes CS billing Restart the system. Check the billing device Switch on the device Flavoring Station communication Switch on the Flavoring Station using the main switch in the station Call Selecta Helpdesk 222223 Foam Master communication Call Selecta Helpdesk 226227 Cleaning required Clean the coffee machine 228229 Clean Flavoring Station Clean the Flavoring Station; this appears 7 and 9 days after the last cleaning 100 101 120 121123 125 126127 200211 221 Version EG, V2.0, September 2014 Fault Finding Codes continued Error Code Error Text Action 230 Prepare flavoring system Prepare the flavoring system 231 Prepare milk system The milk system needs to be prepared. Prepare the milk system. 252256 Cleaning canceled Cleaning was canceled. The grounds door was not open long enough The grounds door was not opened within 20 seconds 263265 Flavoring Station cleaning canceled Flavoring Station cleaning was canceled. The grounds door on the coffee maker was opened The coffee maker was switched off Version EG, V2.0, September 2014