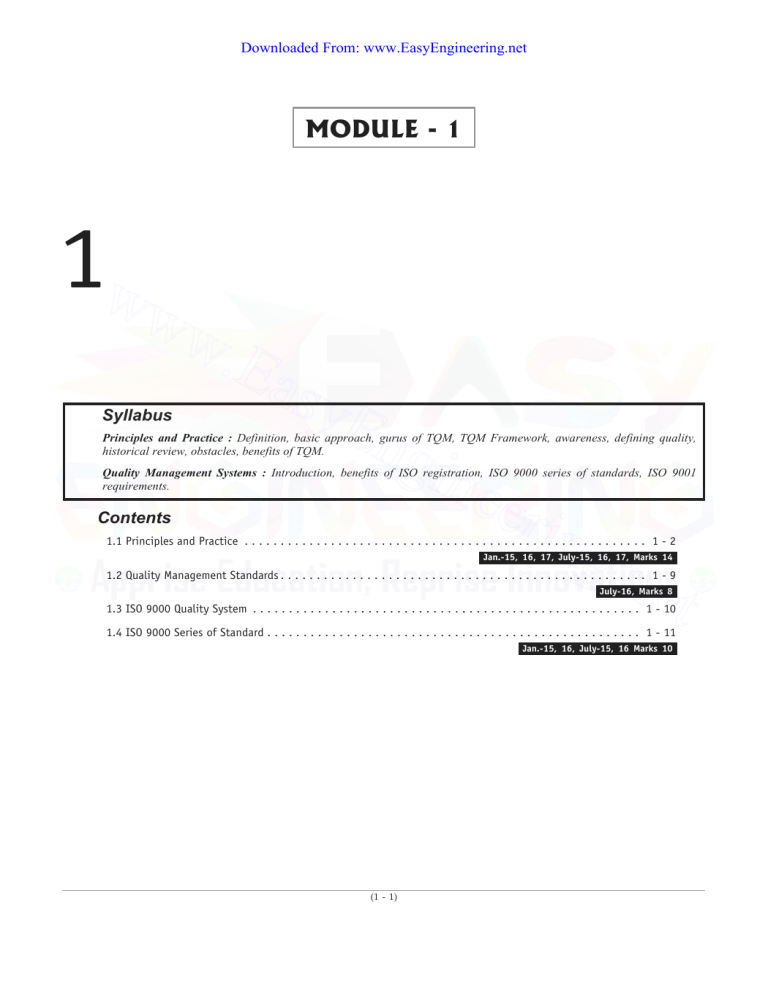

Downloaded From: www.EasyEngineering.net MODULE - 1 1ww w.E Syllabus asy En gi Principles and Practice : Definition, basic approach, gurus of TQM, TQM Framework, awareness, defining quality, historical review, obstacles, benefits of TQM. nee Quality Management Systems : Introduction, benefits of ISO registration, ISO 9000 series of standards, ISO 9001 requirements. Contents rin g.n et 1.1 Principles and Practice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2 Jan.-15, 16, 17, July-15, 16, 17, Marks 14 1.2 Quality Management Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 9 July-16, Marks 8 1.3 ISO 9000 Quality System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10 1.4 ISO 9000 Series of Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 11 Jan.-15, 16, July-15, 16 Marks 10 ® (1 - -1)An up thrust for knowledge TECHNICAL PUBLICATIONS TM Downloaded From: www.EasyEngineering.net Total Quality Management 1-2 1.1 Principles and Practice Principles and Practice and Quality Management Systems 6. VTU : Jan.-15, 16, 17, July-15, 16, 17 ISO definition of TQM : · "Management approach to an organization, centered · TQM stands for "Total Quality Management". An on quality, based on the participation of all its organization uses TQM as a long term approach to members and aiming at long-term success through achieving customer satisfaction. customer satisfaction and benefits to all members of · Total Quality Management requires all employees of the organization for improving the the organization and to society." products, 1.1.2 Basic Approach of TQM processes and services. All employees, no matter what role, are responsible for quality and quality · Six concepts of Total Quality Management are : assurance. When done correctly, the entire business 1. culture is TQM. · Management commitment to TQM principles and ww w.E methods 1.1.1 Definitions of TQM · Various definitions of TQM are : 1. 2. 3. 4. 5. & long term Quality plans for the Organization asy 2. Focus on the customer/client · Customer/client requirements should be considered Total Quality Management (TQM) is a management framework based on the belief that an organization can build long-term success by having all its members, from low-level workers to its highest ranking executives, focus on quality improvement and, thus, delivering customer satisfaction. as the top priority, and it is important to always En gi remember that it is the customer who defines what quality is. Keep the customer satisfied at all times. 3. Quality at all levels of the work force · Involve all the employees in the organization in the nee quality process. It is very important to make your "Total Quality Management (TQM) is an approach to improving the effectiveness and flexibility of business as a whole. It is essentially a way of organising and involving the whole organisation, every department every activity, every single person at every level."-Oakland employees understand how the quality process rin works, for they are the ones who will create/sustain quality, and not you. 4. g.n et Continuously improve the quality process · A very critical concept in TQM is to continuously enhance and refine your quality process. "Total Quality Management is a combination of socio-technical process towards doing the right things (externally), everything right (interally), first time and all the time with economic viability considered at each stage of each process."-Zaire and Simintiras 5. Treating suppliers as partners · Have a close relationship with your suppliers, treat them as if they were partners to your company, this will better involve them in your quality process, and they will start appreciating and respecting your work on TQM, and they will work with you "TQM is the systematic analysis, but the focus is turning from a process driven by external controls through procedure compliance and enhancement to a process of habitual improvement where control is embedded within and is driven by the culture of the organisation." -Foster and Whittle towards achieving your goals when it comes to enhancing quality. 6. Establish processes performance measures for the · Measure the performance of quality process. Use tools to track your quality process and measure its "TQM is a strategic approach to produce the best product and service possible through constant innovation." -Atkinson ® Top level support for TQM performance to see if there is any improvement needed. TM TECHNICAL PUBLICATIONS - An up thrust for knowledge Downloaded From: www.EasyEngineering.net Total Quality Management 1-3 1.1.3 Gurus of TQM Principles and Practice and Quality Management Systems ideas became fundamental to the Japanese, whose · By definition, a guru is a good person, a wise industries developed to lead the world. In the USA, person and a teacher. A quality guru should be all however, it was not until 1979 that Deming was of these, plus have a concept and approach to listened to, when he was working with the Nashua quality within business that has made a major and Corporation. Deming has been awarded one of lasting impact. Japan’s most distinguished honours, the second · The implementation of TQM has been strongly order of the sacred Treasure, for his contribution to influenced by the writings of Deming (1986), Juran Japanese quality. The Deming prize and Deming (1993), Feigenbaum (1993), Ishikawa (1993) and price for application are awarded by JUSE in Crosby (1989) which helped us to understand honour of his contribution to quality. ww w.E · Deming has identified the customer as ‘the most concept of TQM. important part of the production line. It will not 1.1.3.1 W. Edwards Deming (1900-1993) · Dr. William suffice to have customers that are merely satisfied achieved customers that are delighted with your products world-class recognition for his contributions to and services will return again and bring new quality improvement. He was born in Iowa in business with them’. It therefore follows that the October 1900. He received his Ph.D. in mathematical supplier should develop products and services physics from Yale University, then joined the US ahead of customer demands and not wait until the Department customer needs them because by then it will be too physicist. Edwards of Deming Agriculture Deming asy as studied has a under En gi mathematical the eminent nee late and competitors will have stolen the market. statistician R.A. Fisher in London, and he was also · The Deming approach rin is the systematic influenced by the originator of statistical process improvement of quality. Improved quality leads to control (SPC), Dr. Walter Shewhart. reduced rework fewer delays and better utilization g.n et · During 1941 Deming lectured in Statistical Methods of equipment. As productivity improves and the to American industrialists, engineers and inspectors company is able to market better quality at a lower primarily The price, the company is in a good position to provide programme had a dramatic effect on productivity security of employment and consequently stay in involved in the war effort. and scrap reduction. When the war was over, these advances · Deming’s lectures in the 1950s drew upon his attributed to failure to get the message through to statistical background, where one of the central management. themes was variability of process. In each process Japanese not sustained, which business. Deming · Following were a visit to Japan, connected with a census. Deming was invited by whether it be a manufacturing or service operation, the there are two contributions to variability - those Japanese Union of Scientists and Engineers (JUSE) attributable to individual machines or operations to present a lecture course to Japanese research (’special causes’), and those related to weakness of workers, plant managers and engineers on quality the management systems (’common causes’). It is to control methods. Deming, learning from previous the elimination of the common causes that Deming experience, requested that he should also give a addresses his ‘fourteen points’. presentation to Japan’s Chief Executive Officers. · Deming saw the ‘fourteen points’ as the basis for During 1950 he spoke to 100 of the industrial change. leaders, in 1951 he presented to a further 400. In the 1) years following, the widespread adoption of his ® TM Create constancy of purpose towards improvement of product and service, with the TECHNICAL PUBLICATIONS - An up thrust for knowledge Downloaded From: www.EasyEngineering.net Total Quality Management 1-4 Principles and Practice and Quality Management Systems aim to become competitive, to stay in business and to provide jobs. The responsibility of the supervisor must be changed from sheer numbers to quality. 2) Adopt the new philosophy. We are in a new economic age, created by Japan, Transformation of Western management style is necessary to halt the continued decline of industry. We can no longer live with commonly accepted levels of delays, defective materials and workmanship. b) Remove the barriers that rob people in management and in engineering of their right to pride of workmanship. This means, inter alia, abolition of the annual or merit rating and of management by objective. 3) Cease dependence on inspection to achieve quality. Eliminate the need for mass inspection by building quality into the product in the first place using statistical techniques. 4) 5) ww w.E 13) Institute a vigorous programme of education and retraining. New skills are required for changes in techniques, materials and service. 14) Put everybody in the company to work, to accomplish the transformation. Define top management’s commitment to improving quality and productivity. End the practice of awarding business on the basis of price tag. Purchasing must be considered with the design of product, manufacturing and sales to work with the chosen supplies, the aim is to minimize total cost not merely initial cost. asy · In addition to the fourteen points, Deming has highlighted common obstacles to achieving quality. These are the seven deadly diseases of which the En gi Improve constantly and forever every activity in the company, to improve quality and productivity and thus constantly decrease costs. * lack of constancy of purpose. * emphasis an short-term profits. 6) Institute training and education on the job, including management. * mobility of management. 7) Institute supervision. the aim of supervision should be to help people and machines to do a better job. Supervision must react to adverse conditions. * running a company on visible figures alone. 8) 9) first four are : nee rin 1.1.3.2 Philip B. Crosby (1926-2001) g.n et · Philip B. Crosby Snr has obtained world recognition for Drive out fear, through effective communication, so that everyone may work effectively for the company. his consultancy and improvement. approach to quality · After serving in the navy in the Korean War, Corsby Break down barriers between departments. People in research, design sales and production must work as a team to tackle anything that may be encounted with the product or service. become quality manager on the first Pershing Missile Programme. It was here that the concept of zero defects was born. He worked his way up through ITT and for fourteen years was corporate 10) Eliminate slogans, and targets for the work force asking for zero defects and new levels of productivity without provision of the methods to achieve this. vice-president with worldwide responsibilities for quality. Following, the success of his book ‘Quality is Free’, published in 1979. · Crosby advocates a top down approach, this is 11) Eliminate work standards that prescribe numerical quotas for the day. Substitute aids and helpful supervision, using the methods to be described. because, like other gurus, he believes that over 80% 12) a) Remove the barriers that rob the hourly workers of the right to pride of workmanship. under a Crosby programmes. They then cascade the ® of problems are management caused and fewer than 20% are caused by workers. For this reason executives and managers are the first to be educated concepts to all employees in their organization. The TM TECHNICAL PUBLICATIONS - An up thrust for knowledge Downloaded From: www.EasyEngineering.net Total Quality Management 1-5 Principles and Practice and Quality Management Systems work groups if possible, if they are complex or long range they can be referred to a task team specially established by management. ‘four absolutes’ are the cornerstones of the Crosby philosophy. They are : 1. 2. Quality is defined as conformance to requirements. Quality does not mean goodness or excellence, we should all concentrate on identifying requirements and improving them. The system for causing quality is prevention, not appraisal. 3. The performance standard must be zero defects, not ‘that’s close enough. 4. The measurement of quality is the price of non-conformance. Crosby estimates that manufacturing companies spend 25% of turnover on doing things wrong or reworking and service companies spend up to 40% on non-conformance. ww w.E Crosby has asy proposed fourteen-step approach. This is as follows : 1) 3) Quality measurement – The method is to display current and potential non conformance problems in a manner which can be readily understood and evaluated. The objective is to evaluate trends, identify problems and develop corrective actions. 6) Employee education – Training, particularly of supervisors is essential if the ZD launch is to succeed. 9) ZD day – The ZD day is an event which ensures all employees know there has been a change. It is frequently accompanied by celebrations and show business razzmatazz. 11) Error cause removal – Employee are encouraged to submit problems. Management has to react to these suggestions to maintain the momentum of the programme. Management commitment – To make it clear where management stand on quality. A policy statement should be agreed by operating management and implemented. Quality improvement team – The team is set up to manage the quality improvement programme. Members of the team should be drawn from across the company. 5) 8) En gi a 2) 4) Zero defect planning – Zero defects (ZD) is a central plank in the strategy and therefore planning how to launch and how to gain employee commitment to this phase is important. 10) Goal setting – Supervisors encourage their work groups to set improvement goals eg. reduction in defectives and publish results of improvements. · The improve quality (and to reduce the price of non-conformity) 7) nee 12) Recognition – All individuals should receive appreciation for their contribution, the most effective recognition is not financial but peer group oriented. rin g.n et 13) Quality councils – Quality professionals should meet on a regular basis to develop themes for improvements. 14) Do it all over again – The quality improvement programme of never-ending improvement. 1.1.3.3 Joseph M. Juran (1904-2008) Cost of quality – To define and measure the cost of quality. This is the sum of failure, appraisal and prevention costs and according to Corsby it should be less than 2.5% of sales turnover. · Juran suggests an organizational approach which Quality awareness – Quality awareness should be a low key activity and comprise two activities, regular management/employee communication meetings and published information through posters and house magazines. second level consists of a breakdown of first level Corrective action – As problems are identified by previous steps they should be tackled to prevent recurrence. Problems should be solved by local the key aspects of the first quality level involve, ® focuses on management of two levels. A first level, oriented towards top management, emphasizes quality as the fitness for use by consumers, while a quality missions into missions oriented towards departments in the firm. For these departments, it is then necessary to work in accordance with specifications designed to achieve the fitness for use, according to Juran TM TECHNICAL PUBLICATIONS - An up thrust for knowledge Downloaded From: www.EasyEngineering.net Total Quality Management 1-6 Principles and Practice and Quality Management Systems priorities are set up and relationships between the firm and the quality strategy are drawn. 1) Product design 2) Conformance to specification · Throughout these phases, Juran recommends that 3) Availability training be given a top priority. 4) Reliability Research 5) Maintainability and Post sales 6) Serviceability. Maintenance technique · To achieve it, however, Juran recommends that we ww w.E also follow an unending cycle which is given by 1) Market research Prototype design Equipments 2) Product development 3) Design 4) Manufacture and planning 5) Purchasing 6) Production process control 7) Inspection 8) Tests asy Specifications Manufacturing plan En gi Fig. 1.1.1 Juran’s spiral of quality 1.1.3.4 Genichi Taguchi (1924-2012) · Dr. Genichi Taguchi is executive director of the nee American Supplier Institute Inc, and also director of the Japan Industrial Technology Institute. Born in rin 9) Sales and finally feedback through market research. 1924, he graduated from Kiryu Technical College · For Juran, top management is important as it is an and received a doctorate in science from Kyushu University in 1962. essential actor in the everlasting process of market · Taguchi research to manufacture to sales. For the quality joined Laboratory management process, Juran proposes three phases – the (ECL) of g.n et Electrical Nippon Communications and Telegraph The Control Sequence, which seeks to solve sporadic problems. This is in essence the function of quality control. Here statistical techniques as well as tolerance fool proofing are used. Company in 1949 and worked there until 1961 to b) The Breakthrough sequence, which consists of quality improvement by solving chronic problems. To do so, Juran recommends that we use the ‘Universal process’ for quality improvement, consisting of study the symptoms, Diagnose the causes and Apply remedies. In this sequence, Juran advocates a project-by-project improvement. At any time, many such projects are ongoing simultaneously. The breakthrough sequence requires a breakthrough in attitudes. associate. He returned to Japan and was a Professor a) c) improve the productivity of the ECL’s research and development activities. He went to the USA in 1962 and visited Princeton University as a research at Aoyama Gakuin University in Tokyo until 1982. During which time he served as a consultant to major Japanese corporations such as Toyota Motors, Fuji Film and Nippondenso. · His major contribution has involved combining engineering and statistical methods to achieve rapid improvements in costs and quality by optimizing product design and manufacturing processes. Institutionalization of the review process over the quality management process. In such a program, short and long-term goals are made explicit, ® · Taguchi’s techniques aim to go a stage further than the principles of eliminating causes of problems, by TM TECHNICAL PUBLICATIONS - An up thrust for knowledge Downloaded From: www.EasyEngineering.net Total Quality Management 1-7 · Dr. allowing the user to design products or processes that are insensitive to causes. followed other quality control Deming the creator of Plan-Do-Check-Act model. As a matter of fact he expanded that into a 6 step plan · In 1960 Taguchi had shown that if the design intent from a 4 : 1. Determine goals and targets of the target value was the value at which the design, whether product or process, functioned best, then any deviation from that value meant an deterioration Ishikawa believers as well. One of those was W. Edwards Taguchi Loss Function incremental Principles and Practice and Quality Management Systems of performance ww w.E and incurred a loss. This loss was passed on to the next customer, whether internal or external, so that ultimately both the company and society would experience that loss in some way. to a point where the customer would find the · It can be seen that any deviation from target value of a critical characteristic may now be evaluated not Implement the work 5. Chuck the effects of implementation 6. Take appropriate action. 2. Histogram 3. Flow chart 4. Run chart 5. Scatter diagram 6. Pareto chart. · TQM framework consists of important blocks. Upper specification limit L = k(y–T) nee 1.1.4 TQM Framework only in dimensional terms but also in financial ones. Loss (`) Engage in education and training 4. En gi product no longer acceptable and go for sourcing Lower specification limit 3. quality tools : 1. Control chart loss increase parabolically as the deviation increases elsewhere. This concept is shown in Fig. 1.1.2. Determine methods of reaching those goals · Dr. Ishikawa highly believed in the strength of six · Close to the target value, the loss is minimal, but asy 2. 2 Y = Measurement of requirement T (Target value) rin 1. Gurus of quality : Shewhart, Deming, Juran figenbaum, Ishikawa, Crosby and Taguchi. 2. Principles and practices : Leadership, customer satisfaction, employee involvement, supplier partnership. 3. Tools and techniques : Benchmarking, Quality management systems, Quality function deployment quality by design. Management tools, Failure mode and effect analysis. Statistical process control. 4. Product or service realization : Continuous process improvement performance measures. g.n et · Fig. 1.1.3 shows a typical TQM framework. Fig. 1.1.2 Loss function (Taguchi) 1.1.3.5 Kaoru Ishikawa (1915-1989) TQM gurus Tools and techniques Principles and practices Product or service realization · Kaoru Ishikawa is considered the Father of Japanese Quality. He invented the Fishbone diagram (cause and effect diagram) and CWQC - Company Wide Quality Control. He also sponsored the concept of "next operation (process step) as the client" to avoid workplace politics. ® Fig. 1.1.3 TQM framework TM TECHNICAL PUBLICATIONS - An up thrust for knowledge Customer Downloaded From: www.EasyEngineering.net Total Quality Management 1-8 1.1.5 Awareness of TQM Principles and Practice and Quality Management Systems 1. Garvin classified the definition of Quality into five major groups. Those were transcendent, product-based, user-based, manufacturing-based, or value-based. 2. Juran and Gryna, defined Quality as - Fitness for purpose of use. 3. Crosby defined Quality as - Conformance to requirement. 4. Gilmore defined Quality as - Conformance to specification. 5. Parasuraman defined Quality as - meeting and/or exceeding customer's expectation. 6. Besterfield defined Quality as - performance over expectation 7. Crosby defined Quality as - Zero defect products or services · An organisation will not begin the transformation to TQM until it is aware that the quality of the product or service must be improved. · Awareness comes about when an organisation loses market share or realises that quality and productivity go hand-inhand. · It also occurs if TQM is mandated by the customer ww w.E or if management realises that TQM is a better way to run a business and compete in domestic and world market. · Automation and other productivity enhancements might not help a corporation if it is unable to asy market its product or service because the quality is poor. The Japanese learned this fact from practical experience. En gi · Prior to World War II, they could sell their products only at low prices, and even then it was difficult to secure repeat sales. Until recent, corporations have not recognised the importance of quality. 8. Taguchi defined Quality as - Ability to perform to its intended function without harmful effect. 9. The totality of features and characteristics of a product or service that bear on its ability to satisfy stated or implied needs' - Quality Vocabulary Part 1, International terms. · However, a new attitude has emerged the quality first among the equals of cost and service. Quality and productivity are not mutually increased productivity and other benefits. improvement conformance of the is not product limited or to the service rin 10. The total composite product and service characteristics of marketing, engineering, manufacture and maintenance through which the product and service in use will meet the expectation by the customer' - Feigenbaum exclusive. Improvements in quality can lead directly to · Quality nee to 1.1.7 Barriers to TQM specifications; it also involves the inherent quality in g.n et · There are several causes that creates barrier to TQM the design of the system. implementation. Some important obstacles are listed · The prevention of the product, service, and process below. problems is a more desirable objective than taking 1. Lack of understanding of the TQM concepts. 2. Inadequate management support and resources for TQM. 3. Lack of employees commitment. is no universally accepted definition of 4. Inadequate planning for quality. quality and seems to be no consensus definition 5. Poor internal communication and co-ordination. even though most of these definitions are correlated, 6. Poor leadership style and ineffective motivation. 7. Improper education and training to employees. 8. Irregularities in conducting meetings. corrective action after the product is manufactured or a service rendered. 1.1.6 Definition of Quality · There but there exists similarities and common elements. · Quality can be defined in many ways, some definitions are ® TM TECHNICAL PUBLICATIONS - An up thrust for knowledge Downloaded From: www.EasyEngineering.net Total Quality Management 9. 1-9 Ineffective measurement techniques for objectives and goals. 10. Delay in implementing recommendation quality improvement team. Principles and Practice and Quality Management Systems 10.Briefly explain Management. of principles of Total Quality VTU : July-16, Marks 5 11. Briefly explain with suitable examples, 'The Deming Philosophy'. VTU : July-16, Marks 8 11. Not applying proper tools and techniques. 12. Define Total Quality Management and discuss briefly the various dimensions of Quality. 1.1.8 Benefits of TQM VTU : Jan.-17, Marks 10 · Following are some of the important benefits of the 13.With a neat block diagram, briefly explain TQM frame work. VTU : Jan.-17, Marks 6 TQM approach for the organization and as well as ww w.E for employees : 1. Higher productivity 2. Enhancing market image 3. Increase customer loyalty 4. High employee morale 5. Reduce warranty 6. Organizational development 7. Solving lack of absenteeism 14.Define TQM. With the help of a block diagram explain TQM framework. VTU : July-17, Marks 10 asy 15.What are different dimensions of quality ? With an example of a CNC Lahte explain dimensions of VTU : July-17, Marks 10 quality. 1.2 Quality Management Standards En gi VTU : July-16 · ISO 9000 is a set of five world-wide standards that 8. Growing profits 9. Fiscal disciple through eliminating of unnecessary expenditure establish requirements nee for the management of quality. Unlike product standards, these standards are for quality management systems. 10. Repeat customers rin · The purpose is to ensure that a certified company 11. Increased job security has a quality system in place that will enable it to 12. Cost reduction. g.n et meet its published quality standards. · The ISO standards are generic in that they apply to University Questions all functions and all industries. 1. Define TQM. Explain six basic concepts of TQM. VTU : Jan.-15, 16, July-15, 16, Marks 10 · The International Organization for Standardization 2. Explain briefly the contributions of any five GURU's of TQM. VTU : Jan.-15, Marks 10 (ISO) is the specialized international agency for 3. Explain Deming's 14 points. national standards bodies of 91 countries. standardization and at present comprises the VTU : Jan.-15, Marks 14 · The American National Standards Institute (ANSI) 4. Sketch TQM frame work. VTU : July-15, Marks 5 is the member body representing the United States. 5. What are the obstacles implementation of TQM? associated ISO is made up of approximately 180 technical VTU : July-15, Marks 5 with the committees. Each technical committee is responsible for one of many areas of specialization, ranging 6. What are the benefits of TQM ? from asbestos to zinc. VTU : July-15, Marks 4 · Quality 7. Explain contributions made by any two quality VTU : Jan.-16, Marks 8 Gurus. 8. Explain benefits of TQM. system is defined by ANSI as "the collective plans, activities and events that are provided to ensure that a product, process or VTU : Jan.-16, Marks 8 service will satisfy the given needs". 9. Enumerate Deming's 14 principles and explain VTU : Jan.-16, Marks 10 any two of them. · Quality system is defined by ISO as "the organizational structure, responsibilities, procedures, ® TM TECHNICAL PUBLICATIONS - An up thrust for knowledge Downloaded From: www.EasyEngineering.net Total Quality Management 1 - 10 Principles and Practice and Quality Management Systems processes and resources for implementing quality Therefore, engineering and construction firms and management. manufacturing companies who design, develop, produce, install and service their products are 1.2.1 Need for ISO 9000 covered under this standard. The quality system · ISO 9000 is necessary for an organization. It serves requirements for ISO 9001 are listed in Table. 1.3.1. following purposes. 1. To achieve and product/service. maintain 2. To improve quality of process customer and stackholders need. 3. To provide confidence to management and employees about fulfillment of quality process. 4. To provide confidence among consumers and stack holders that they are using quality services / products. ww w.E University Question quality to Quality System Requirements of meet asy Inspection, Measuring and Text equipment Quality System Inspection and Test Status Contract Review Control of Nonconforming Product Design Control Corrective Action Document Control Handling, Storage, Packaging and Delivery En gi 1. What is ISO 9000 and its significance and why it should be adopted ? List ISO 9000 family of VTU : July-16, Marks 8 standards. 1.3 ISO 9000 Quality System Management Responsibility Purchasing Quality Records Purchase Supplied Product Internal Quality Audits Product Identification and Traceability Training Process Control Servicing nee rin Inspection and Testing · The purpose of ISO is to promote the development Statistical Techniques g.n et Table 1.3.1 ISO 9001 Quality Systems of standardization and related world activities in · ISO 9002 specifices a model for quality assurance order to facilitate the international exchange of goods and services and to develop co-operation in when only production and installation conformance interllectual, scientific technological and economic is required. This standard is particularly relevent to activities. process industries where specific requirements for products are stated in terms of an established · The results of ISO technical work are published as design or specification under ISO 9002. international standards and the ISO 9000 series is a · ISO result of this process. · ISO 9000 is a series of five international quality standards developed by the conformance in final organization such as laboratories. · ISO basic definitions and is a road map to use the other 9004 contains guidance on technical, administrative and human factors affecting the standards in the series. quality of products and services. This standard · The ISO 9001, 9002 and 9003 standards are for provides external quality assurance purposes for use in ISO 9001 guidelines for developing and implementing a quality system. ensures 1) conformance to requirements during design and development, production, installation and servicing. ® only the products they supply or divisions within an Switzerland. The ISO 9000 standard provides some situations. requires shops, equipment distributors that inspect and test International Organization for Standardization (ISO) in Geneva, contractual 9003 inspection and testing. This standard concerns small TM ISO 9000 and ISO 9004 provide guidance to all organizations for quality management purposes. TECHNICAL PUBLICATIONS - An up thrust for knowledge Downloaded From: www.EasyEngineering.net Total Quality Management 2) 1 - 11 ISO 9001, ISO 9002 and ISO 9003 are used for external quality assurance purposes in contractual situations. 3) Principles and Practice and Quality Management Systems information system and can also sit comfortably with production management systems of varying complexity. ANSI/ASQC Q90-Q94 are technically equivalent to ISO 9000-ISO 9004 standards, respectively, but use customary American language usage and spelling. · An outstanding characteristic of ISO 9000 for management controls to ww w.E of provides production and VTU : Jan.-15, 16, July-15, 16 it mean to our company and what is involved ? The · There are various models defined to meet different short answer to the first is that virtually all organizations. Three basic models are important. manufactures, particularly those selling to public asy These are - buyers or to multinationals, are expected to adopt 1. ISO 9001 done so, so that this so called ‘voluntary’ standard 2. ISO 9002 is, in fact, becoming mandatory for marketing 3. ISO 9003 the standard and produce evidence that they have En gi purposes. In the case of service companies now that ISO 9001 Model - 1 the ISO 9000 services version is being taken up, the advantage. their contents of customers that conformity rin to specified requirements is met throughout the whole cycle · The answer to the second question of what is detailed nee · ISO 9001 is for those companies that need to assure adoption of the standard has become a marketing the automatically 1.4 ISO 9000 Series of Standard any company interested in ISO 9000 are what does in it quality inefficiencies thereby increasing productivity. · The two most basic questions which are asked by is that delivery and reduces waste, downtime and labour 1.3.1 Scope of ISO 9000 involved is ensure from two design to service. This applies particularly g.n et where there is a contract specifically requiring overviews may be useful. The first is that there are design and where product requirements are stated two fundamental elements in adopting ISO 9000. in performance terms (speed, capacity, integrity). One is the acceptance and adoption of the ISO 9000 This is the fullest or most complete standard philosophy and its installations as a standard, in involving all the quality system elements detailed in other words becoming an ISO 9000 standard ISO 9004 at their most stringent. company, the other element is obtaining the third party approval or certification which allows a ISO 9002 Model - 2 company to demonstrate its ISO 9000 status to · If one has an established design or specification, this is more appropriate. Here all one has to buyers and prospectus. demonstrate is one’s capabilities in production and · The second overview is that ISO 9000 satisfies a installation. It is also less stringent than ISO 9001. number of significant and even critical strategic and corporate requirements in a changing industrial and ISO 9003 Model - 3 marketing environment. Chief amongest these are · Sometimes one can demonstrate only capabilities for marketing considerations, legal aspects, management inspection and test, whether the product is supplied and productivity and changing customer-supplier from a manufacturer for those requirements. About relationships. half of the element of ISO 9004 are required here · ISO 9000 is a ready-made system for providing the and an even lower level of stringency than for kind of integrated but flexible quality management which ® can fit into an overall Model 2. management TM TECHNICAL PUBLICATIONS - An up thrust for knowledge Downloaded From: www.EasyEngineering.net Total Quality Management 1 - 12 Principles and Practice and Quality Management Systems Element of the SO 9000 service ww w.E SO 9001 Model for design or development or production or installation and servicing SO 8402 Vocabulary SO 9004 Quality management quality system elements SO 9000 Guidelines for selection and use of the standards SO 9002 asy Model for production and installation 1.4.1 Elements of the ISO 9000 Series SO 9003 SO 9004 Model for final inspection and test The service standard En gi Fig. 1.4.1 nee Document control Document control Document control 9002, ISO 9003) and its elements are given in the Quality records Quality records Quality records following table. Training Training ISO 9001 Statistical methods Statistical methods · Quality system ISO 9000 models (ISO 9001, ISO ISO 9002 ISO 9003 rin Training g.n et Management responsibility Management responsibility Management responsibility Purchaser supplied product Purchaser supplied product Quality systems Quality systems Quality systems Corrective action Correctice action Product identification and traceability Product identification and traceability Product idetnification and traceability Process control Process control Purchasing Purchasing Inspection and testing Inspection and testing Inspection and testing Control review Contract review Inspection, measuring and test equipment Inspection, measuring and test equipment Inspection, measuring and test equipment Internal quality audits Internal quality audits Inspection and test status Inspection and test status Inspection and test status Control of nonconforming product Control of nonconforming product Control of nonconforming product Handling, storage, packaging and delivery Handling, storage, packaging and delivery Handling, storage, packaging and delivery ® Statistical methods Design control Servicing Table 1.4.1 ISO 9000 models and elements 1.4.2 Implementation of Quality Management System · Implementation of ISO 900 QMS involves following steps. 1. TM TOP management commitment TECHNICAL PUBLICATIONS - An up thrust for knowledge Downloaded From: www.EasyEngineering.net Total Quality Management 1 - 13 2. Appointment of management representative 3. Create awareness 4. Appoint an implementation team 5. Training to team, supervisors 6. Develop time schedule 7. Selecting team head 8. Reviewing present system 9. Documentation ww w.E referenced by it. The interaction between processes making up the QMS is also described. C] Control of documents : All of the documents in your QMS must be legible, identified, reviewed, authorized, up-to-date, issued, distributed, and periodically updated. Obsolete documents have to be identified and protected from unintended use. Documents that come from outside the organization also have to be identified and controlled. 10. Install new system D] Control of records : Certain records need to be kept to demonstrate how the QMS is operating. These records must be legible, and easy to identify and retrieve. A written procedure must describe how they are identified, stored, protected, retrievable, and define their retention and disposal times. 11. Internal audit 12. Management review 13. Preassessment 14. Registration 15. Award of ISO 9000 certificate 1.4.3 Requirements of QMS 1. 2. asy Principles and Practice and Quality Management Systems En gi 1.4.4 Documentation of ISO 9000 · The General requirements : The Quality Management System (QMS) is the collection of processes, documents, resources, and monitoring systems that direct the work of an organization regarding product and service quality. The organization needs to establish, document, carry out, and maintain this system to meet the requirements of ISO 9001:2000. documentation nee is pre-requisite for for all employees, management and other agencies who are involved in implementing QMS. rin · Necessary documentation for QMS are : Documentation requirements A] General : The organization needs to document – either electronically or on paper – the quality policy, quality objectives, and quality manual. Written procedure, plans, and operations need to describe how product and service quality is attained. Certain records, providing evidence of activities that were carried out (i.e. purchase orders, sales contracts, inspection records, design review notes, etc.), have to be retained. g.n et 1. Quality objectives 2. Quality policy manual 3. Quality system procedures 4. Work instructions 5. Records / formats / forms · Documentation pyramid is shown in Fig. 1.4.2. 1.4.4.1 Advantages of Documentation The quantity, detail, and form of the documentation can differ from one organization to another depending on size, type of activities, or complexity of processes. B] Quality manual : The quality manual describes the extent of the QMS and may exclude certain sections of the standard that don’t pertain to the organization. All of the quality procedures are either included in the quality manual or are ® proper implementing QMS. Documentation is the reference TM 1. Documentation provides a reference and regularises the method of day-to-day activities. 2. Documentation brings about clarity of objectives and targets. 3. Documentation brings consistency in operations. 4. Documentation facilitates trouble shooting for tracking processes. 5. Documentation provides employees and customers. 6. Documentation provides basis for continuous development. TECHNICAL PUBLICATIONS - An up thrust for knowledge confidence amongs Downloaded From: www.EasyEngineering.net Total Quality Management 1 - 14 Quality manual The quality manual is the core of the quality system. It should address each area of the ISO standard with a basic statement claiming compliance and how to company maintains compliance. Procedures and instruction describe how all the company's processes are controlled. Procedures are higher level documents, while work instruction are very specific. Procedures and instructions ww w.E Principles and Practice and Quality Management Systems Records must be maintained to show compliance of the quality system, for feedback into the quality system, and historical reasons. Records The ISO 9001 Documentation Pyramid 7. asy En gi Fig. 1.4.2 Documentation demonstrates the ISO quality system certification. University Questions nee 1. What are the necessary step to be followed in implementing ISO 9000 ? 2. List the steps in implementation of ISO - 9000. VTU : Jan.-15, Marks 10 rin VTU : July-15, Marks 6 g.n et VTU : Jan.-16, Marks 10 3. Write a note on documentation of ISO-9000 series. 4. What is ISO 9000 and its significance. Why it should be adopted ? List ISO 9000 family of standards. VTU : July-16, Marks 8 qqq ® TM TECHNICAL PUBLICATIONS - An up thrust for knowledge