PIHT-TRC-HT-DOC-J3010-IH-0001 - Heat Treatment Procedure IFA

advertisement

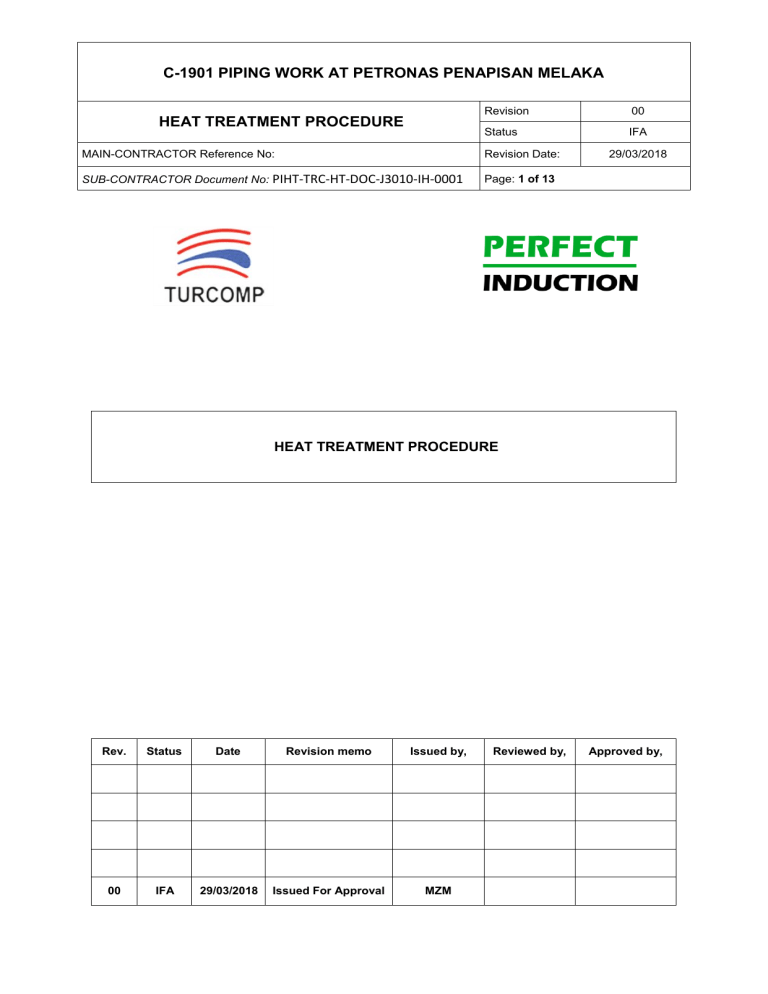

C-1901 PIPING WORK AT PETRONAS PENAPISAN MELAKA HEAT TREATMENT PROCEDURE Revision 00 Status IFA MAIN-CONTRACTOR Reference No: Revision Date: SUB-CONTRACTOR Document No: PIHT-TRC-HT-DOC-J3010-IH-0001 Page: 1 of 13 29/03/2018 HEAT TREATMENT PROCEDURE Rev. Status Date Revision memo Issued by, 00 IFA 29/03/2018 Issued For Approval MZM Reviewed by, Approved by, C-1901 PIPING WORK AT PETRONAS PENAPISAN MELAKA HEAT TREATMENT PROCEDURE Revision 00 Status IFA MAIN-CONTRACTOR Reference No: Revision Date: SUB-CONTRACTOR Document No: PIHT-TRC-HT-DOC-J3010-IH-0001 Page: 2 of 13 29/03/2018 Table of Contents 1. Introduction ................................................................................................................................. 3 2. Abbreviation ................................................................................................................................ 3 3. References ................................................................................................................................... 3 4. Joint Details ................................................................................................................................. 4 5. Heat Treatment Cycle ................................................................................................................ 4 6. Heating Machine ......................................................................................................................... 4 7. Temperature Controls ............................................................................................................... 4 8. Thermocouples ........................................................................................................................... 4 9. Thermocouple Positions .......................................................................................................... 4 10. Thermocouples Compensating Cable .............................................................................. 4 11. Temperature Recording........................................................................................................ 5 12. Insulation.................................................................................................................................. 5 13. Heat Treatment Interruption ................................................................................................ 5 14. Safety precaution ................................................................................................................... 6 Appendix 1: Local Heating Report ................................................................................................ 7 Appendix 2: Heat Treatment Cycle ................................................................................................ 9 Appendix 3: Thermocouple Location ......................................................................................... 11 C-1901 PIPING WORK AT PETRONAS PENAPISAN MELAKA HEAT TREATMENT PROCEDURE Revision 00 Status IFA MAIN-CONTRACTOR Reference No: Revision Date: SUB-CONTRACTOR Document No: PIHT-TRC-HT-DOC-J3010-IH-0001 Page: 3 of 13 1. 29/03/2018 Introduction This procedure describes the method for carry-out localized Heat Treatment to the welded components. 2. Abbreviation QA/QC IFA DOC HT 3. – – – – Quality Assurance / Quality Control Issued For Approval Document Heat Treatment References ASME B31.3 - 2016 – Process Piping C-1901 PIPING WORK AT PETRONAS PENAPISAN MELAKA HEAT TREATMENT PROCEDURE Revision 00 Status IFA MAIN-CONTRACTOR Reference No: Revision Date: SUB-CONTRACTOR Document No: PIHT-TRC-HT-DOC-J3010-IH-0001 Page: 4 of 13 4. 29/03/2018 Joint Details Piping P-Number (P-No.) to be PWHT are as below: a) P-4, b) P-5A c) P-15E 5. Heat Treatment Cycle Heat treatment cycle and processes throughout the repair work stage with reference to design code is provided by Main-Contractor and illustrated in Appendix 2. Note: Refractory dry-out cycle shall be provided by Main-Contractor. 6. Heating Machine Electrical resistance heating by the application of ceramic heater pads (elements) and induction heating by the application of a bundle of coil around the area to be heat treated 7. Temperature Controls The heating elements shall be grouped into independent control zone, each shall be attached with a respectively numbered thermocouple (for control & monitor purposes). Each circuit of the heating elements shall be controlled in manual/semi manual mode through contactor or energy regulators or it shall be made automatic controlled by pre-set programmer control unit. 8. Thermocouples Thermocouples shall be K Type made from nickel-chromium/nickel/aluminium wire to BS1041, Part IV, or equivalent. Certifications shall be made available and indicate a tolerance of less than +/- 0.75% throughout the temperature range from 400 degree C to 800 degree C. Thermocouples shall be attached to the work piece by the direct wire capacitance discharge method. The gap between the two wires per work piece junctions shall not exceed 5mm. 9. Thermocouple Positions The thermocouple recommended positions for PWHT on piping joints are detailed in Appendix 3. 10. Thermocouples Compensating Cable Copper/constantan compensating cable shall be used for extension of the thermocouple to the recording instrument. C-1901 PIPING WORK AT PETRONAS PENAPISAN MELAKA HEAT TREATMENT PROCEDURE Revision 00 Status IFA MAIN-CONTRACTOR Reference No: Revision Date: SUB-CONTRACTOR Document No: PIHT-TRC-HT-DOC-J3010-IH-0001 Page: 5 of 13 29/03/2018 The copper lead (+ve) shall be connected to the nickel-chromium conductor of the thermocouple (non-magnetic), and the constantan lead (-ve) shall be connected to the nickelaluminium conductors (magnetic). 11. Temperature Recording Temperature recorders shall be calibrated at intervals not greater than 12 months. It shall have certification traceable to a national standard and recorded with the certificate being kept and a sticker should be stuck on the instrument. The temperature recorder shall be of the potentiometric self-compensating type, calibrated in degree Celsius with respect to a nickel-chromium /nickel-aluminium thermocouple, type K. The recording chart speed shall be set at 25 or 50 mm/hour and shall be checked during calibration. Prior to start, recording chart shall be signed by inspector. 12. Insulation High temperature ceramic fibre blanket, minimum 25mm thick and density of 96kg/m3, shall be provided for the purpose of insulation. Insulation shall extend for a minimum distance of 200mm beyond the outer edges of the heater zone, or as may be determined by the ruling specification. The number of layers may be adjusted to meet the variations of wall thickness, diameter, gradient requirements and site conditions. Wherever possible, each end shall be blanked off internally before heat treatment to limit convection effects. 13. Heat Treatment Interruption An interruption to the heat treatment process is defined by the failure by one or more thermocouples to maintain the specified heating, cooling rates, temperature differentials or to achieve the soak temperature. This may be the result of power loss, equipment failure or operator error. Once the discrepancies have been identified, the heat treatment cycle shall be placed into hold whilst investigation take place to determine if the fault can be rectify and remedial work carried out safely with a minimum of delay. The heat treatment may be restarted afterward. A check shall be made of the temperatures of all controlling thermocouples, whichever finding had identified any of discrepancies i.e. below the set point, it shall be raised at a rate no greater C-1901 PIPING WORK AT PETRONAS PENAPISAN MELAKA HEAT TREATMENT PROCEDURE Revision 00 Status IFA MAIN-CONTRACTOR Reference No: Revision Date: SUB-CONTRACTOR Document No: PIHT-TRC-HT-DOC-J3010-IH-0001 Page: 6 of 13 29/03/2018 than that specified by the code or specific procedure until the overall temperature differential is within the acceptable limits. If the interruption occurs during the soak period, then the temperature of any thermocouple which falls below the minimum specified soak temperature shall be re-established at a rate no greater than that specified by the code or procedure. The soak time shall be extended to ensure all the thermocouples have recorded temperatures within the soak range for the minimum soak time. In the event that the heat treatment chart indicates discrepancies i.e. overall temperature differentials are increasing between thermocouples which exceed the code / procedure given value, then the heating or cooling rates shall be reduced, or the process put on hold. A note shall be made on the heat treatment chart and the client advised. If the differentials cannot be corrected, the client is to be consulted as to whether or not the heat treatment is continued. If remedial work cannot be carried out in time (to effectively restore the heat treatment cycle), the process shall be aborted after consultation with the client. The heat treatment cycle shall be re-started at another time. A note of interruption and at a time it happened shall be made on the heat treatment chart. A non-conformance report shall be raised. 14. Safety precaution Prior start works, all heat treatment equipment shall be inspected and tested by qualified electrician inspector and approved for site work. The relevant machine certificate shall be provided during inspection. Power supply connection from DB board/electrical tapping point to machine shall be established by qualified electrician with adequate power cable specs. During heat treatment process, the work area shall be cordoned off with red white barricade tape and safety hazard signage shall be displayed mentioned “Hot work in progress” Only authorized personnel shall be allowed inside the work area. Heat treatment personnel shall wear appropriate PPE such as hand glove and N95 dust mask when fit-up the ceramic fibre insulation on the work piece. The MSDS shall be provided for guideline during installation at site. C-1901 PIPING WORK AT PETRONAS PENAPISAN MELAKA HEAT TREATMENT PROCEDURE Revision 00 Status IFA MAIN-CONTRACTOR Reference No: Revision Date: SUB-CONTRACTOR Document No: PIHT-TRC-HT-DOC-J3010-IH-0001 Page: 7 of 13 Appendix 1: Local Heating Report 29/03/2018 C-1901 PIPING WORK AT PETRONAS PENAPISAN MELAKA HEAT TREATMENT PROCEDURE Revision 00 Status IFA MAIN-CONTRACTOR Reference No: Revision Date: SUB-CONTRACTOR Document No: PIHT-TRC-HT-DOC-J3010-IH-0001 Page: 8 of 13 29/03/2018 Heat Treatment report will have minimum information listed as below. Report Number Procedure No.: _______________________ Revision No.: __________ Date: ________________ Governing Code: ___________________________________________________________________ Workpiece Identification Number:______________________________________________________ Material Specification: _______________________________________________________________ Component Dimensions: ____________________________________________________________ Thermocouple, Heater, and Insulation Layout Drawing Number:______________________________ Thermal Cycle Heating Rate: __________________°______/hour (specify max. or min.) above __________ ° ____ Hold Temperature Range: _______________ ___° to _______________________________ ° _____ Minimum Hold Time: ________________ hours Maximum Hold Time: __________________ hours Cooling Rate: _______________°______/hour (specify max. or min.) above __________ ° _______ C-1901 PIPING WORK AT PETRONAS PENAPISAN MELAKA HEAT TREATMENT PROCEDURE Revision 00 Status IFA MAIN-CONTRACTOR Reference No: Revision Date: SUB-CONTRACTOR Document No: PIHT-TRC-HT-DOC-J3010-IH-0001 Page: 9 of 13 Appendix 2: Heat Treatment Cycle 29/03/2018 C-1901 PIPING WORK AT PETRONAS PENAPISAN MELAKA HEAT TREATMENT PROCEDURE Revision 00 Status IFA MAIN-CONTRACTOR Reference No: Revision Date: SUB-CONTRACTOR Document No: PIHT-TRC-HT-DOC-J3010-IH-0001 Page: 10 of 13 DEHYDROGENATION Degassing (dehydrogenation) process for old joint is as below: Appendix 3: Thermo PRE-HEAT Preheat temperature during welding is 150°C. 150°C/hr Holding Temperature: 350°C Holding Time: 1 hr PRE-HEAT Preheat using heating pad as below: Ambient Cooling 29/03/2018 C-1901 PIPING WORK AT PETRONAS PENAPISAN MELAKA HEAT TREATMENT PROCEDURE Revision 00 Status IFA MAIN-CONTRACTOR Reference No: Revision Date: SUB-CONTRACTOR Document No: PIHT-TRC-HT-DOC-J3010-IH-0001 Page: 11 of 13 29/03/2018 POST-WELD HEAT TREATMENT CYCLE PWHT Heating and Cooling rates shall be governed under ASME B31.3 (Section 331.1.4) as below: - Cooling rate from 315°C down to ambient temperature for the weld may be allowed to cool naturally. Whilst keeping the whole weld seam insulated, insulation may be removed at 150 °C. PWHT Soaking temperature is defined in ASME B31.3 (Table 331.1.1) as table below: - Appendix 3: Thermocouple Location C-1901 PIPING WORK AT PETRONAS PENAPISAN MELAKA HEAT TREATMENT PROCEDURE Revision 00 Status IFA MAIN-CONTRACTOR Reference No: Revision Date: 29/03/2018 SUB-CONTRACTOR Document No: PIHT-TRC-HT-DOC-J3010-IH-0001 Page: 12 of 13 Below figures shows the generic arrangement on locating thermocouples depending on NPS of pipes. Thermocouple to be used to control the temperature (normally on the weld) is compulsory while monitoring thermocouple is subjected to accessibility and equipment environment. Min. Heated Band Width (7t) t (1) Legend (4) D Nominal Diameter O Rear X Front X O (3) (2) Figure 1: Butt Welds between Pipes of Equal Thickness NOTES: 1. 2. 3. 4. For D < 6” T/C (I) only required. For 6” < D < 12.T/Cs (I) & (2) only required. For 12” < D < 20”. T/C (1 to 4) Additional thermocouples to be fitted at the weld centreline as required for control. Min. Heated Band Width 3.5 t 1 t1 3.5 t2 (1) t2 Legend (4) X O (3) D Nominal Diameter O Rear X Front (2) Figure 2: Butt Welds between Pipes of Unequal Thickness NOTES: 1. 2. 3. 4. For D < 6” T/C (I) only required. For 6” < D < 12.T/Cs (I) & (2) only required. For 12” < D < 20”. T/C (1 to 4) Additional T/Cs to be fitted at 1.5t1, or 1.5t2 positions as required for control. C-1901 PIPING WORK AT PETRONAS PENAPISAN MELAKA HEAT TREATMENT PROCEDURE Revision 00 Status IFA MAIN-CONTRACTOR Reference No: Revision Date: SUB-CONTRACTOR Document No: PIHT-TRC-HT-DOC-J3010-IH-0001 Page: 13 of 13 29/03/2018 D2 t2 Row A D1 (1) t1 (2) X O (3) Row B Row C (4) 1.5 t 1 Row D 3.5 t 2 1.5 t 1 3.5 t 1 3.5 t 1 min. min. Legend D Nominal Diameter O Rear X Front Minimum Heated Zone Figure 3: Pipe to Branch Welds NOTES 1. Additional T/Cs shall be fitted on Rows A.B.C. & D as required for control purposes. 2. For D2 < 6”. T/Cs 2.3 & 4 not required. 3. For 6” >D2 < 12”. T/Cs 3 & 4 not required. 4. For 10” < D2 <20”. T/C 4 not required.