Electrical Power Plant Systems Assignment: Thermodynamics & Cycles

advertisement

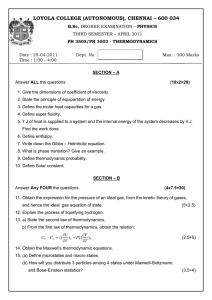

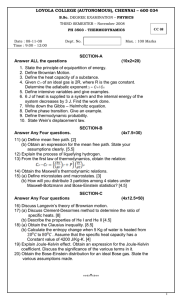

DAR ES SALAAM INSTITUTE OF TECHNOLOGY DEPARTMENT OF CIVIL ENGINEERING PROGRAMME: BACHELOR’S DEGREE IN OIL AND GAS ENGNEERING CLASS: BENG 20-OG MODULE NAME: ELECTRICAL POWER PLANT SYSTEMS MODULE CODE: EEU 07103 INSTRUCTOR: DR. MWAKA ASSIGNMENT TASK: a) Review the fundamental principle of thermal dynamics b) Identify the most thermodynamic cycles c) Analyze the thermal efficiencies, operation condition and cycle variation PREPARED BY: S/N. STUDENT’S NAME REG. NUMBER 1 MAKANJI, LEOPORD LEON 210141627583 2 UPENDO ERICK NYAGALI 210141617626 3 DAVID E. MARK 210141628003 4 SAFINESS BONNY 210141618566 5 MWANGALIKA, KENNEDY B. 200141623914 SUBMITTION DATE: JUNE, 2023 1 Table of Contents CHAPTER ONE ........................................................................................................................................... 4 1.0 Thermodynamic Fundamentals ........................................................................................................... 4 1.1 Introduction ................................................................................................................................... 4 1.2 Thermodynamics................................................................................................................................. 5 1.3 The First Law of Thermodynamics ..................................................................................................... 6 1.3.1 Thermodynamic System ....................................................................................................... 7 1.3.2 Process .................................................................................................................................. 7 1.3.3 Cycle ..................................................................................................................................... 7 1.3.4 Heat ....................................................................................................................................... 8 1.3.5 Work ..................................................................................................................................... 8 1.3.6 Thermodynamic Property ..................................................................................................... 8 1.4 The Second Law of Thermodynamics ................................................................................................ 9 CHAPTER TWO ........................................................................................................................................ 11 2.0 Thermodynamic Cycle ...................................................................................................................... 11 2.1 The most common thermodynamic power cycles that represent internal combustion engines. ....... 12 2.1.1 Carnot Cycle .............................................................................................................................. 12 2.1.2 GAS POWER CYCLES ............................................................................................................ 13 2.1.3 VAPOUR POWER CYCLES .................................................................................................... 17 2.3 Conclusion ........................................................................................................................................ 21 CHAPTER THREE .................................................................................................................................... 22 3.0 Thermal efficiency, operation conditions, and cycle variations play crucial roles in determining the performance and characteristics of thermodynamic cycles. ................................................................... 22 3.1 Thermal Efficiency ........................................................................................................................... 22 3.2 Operation Conditions ........................................................................................................................ 22 2 3.3 Cycle Variations................................................................................................................................ 22 3.3.1 Regenerative Cycle .................................................................................................................... 22 3.3.2 Reheat Cycle .............................................................................................................................. 23 3.3.3 Combined Cycle......................................................................................................................... 23 3.3.4 Cogeneration Cycle .................................................................................................................... 23 3.3.5 Trigeneration Cycle.................................................................................................................... 23 3.4 Conclusion ........................................................................................................................................ 23 REFERENCES ........................................................................................................................................... 24 3 CHAPTER ONE 1.0 Thermodynamic Fundamentals 1.1 Introduction Energy plays a critical role in driving almost all practical processes and is essential to sustain life. Energy exists in several forms, for example, light, heat, and electricity. Energy systems are widespread and used in diverse industries such as power generation, petrochemical processing, refrigeration, hydrogen production, chemical processing, and manufacturing. Interest is growing in producing superior energy products at minimal cost, while satisfying concerns regarding environmental impact, safety, and other issues. It is no longer adequate to develop a system that simply performs a desired task. For various reasons, it is often important to optimize processes so that a chosen quantity, known as the objective function, is maximized or minimized. For example, the output, profit, productivity, product quality, and so on, may be maximized, or the cost per item, financial investment, energy input, and so on, may be minimized. The success and growth of industries today is strongly based on their ability to optimize designs and systems. When an engineer undertakes the analysis of an energy system and/or its application, she or he should deal with several basic factors first. These depend on the type of the problem being studied, and often involve such disciplines as thermodynamics, fluid mechanics, and heat transfer. Consequently, it is helpful to introduce several fundamental definitions and concepts before moving on to detailed energy systems applications, especially for readers who lack a background in thermodynamics, fluid mechanics, or heat transfer. This provides such a review, and is intended to give novice and practicing energy systems engineers a strong understanding of fundamentals, including physical phenomena, basic laws and principles, and governing relations, as well as a solid grounding in practical aspects. This introductory chapter covers relevant fundamentals involved in the optimization of energy systems. We begin the chapter with a summary of fundamental definitions and physical quantities, with their units, dimensions, and interrelations. We then consider introductory aspects of thermodynamics, with a particular focus on energy, exergy, and heat transfer. 4 1.2 Thermodynamics Thermodynamics is a branch of physics that deals with the conversion of energy from one form to another and the study of the relationship between heat, work, and energy. In the context of an electrical power plant, thermodynamics plays a crucial role in understanding and optimizing the energy conversion processes involved in generating electricity. Energy is needed for almost every activity. In simple terms, energy is usually thought of as the ability to carry out useful tasks like producing work and heating. Energy is contained in the fuel we use, the food we eat, and the places we live. Energy enables such outcomes as transportation, fresh water, and thermal comfort in buildings. Energy use has drawbacks too. It can be dangerous if not used cautiously and often leads to pollution and environmental damage. Energy can be converted from one form to another, but cannot be created or destroyed. Work and heat are two categories of energy in transit. Thermodynamics plays a key role in the analysis of processes, systems, and devices in which energy transfers and transformations occur. The implications of thermodynamics are far reaching and applications span the range of human enterprise. Nature allows the conversion of work completely into heat, but not the reverse. Additionally, converting heat into work requires a device, which is often complex (e.g., an engine). Although energy can be transformed into different forms, the principle of conservation of energy states that the total energy of a system can only change if energy is transferred into or out of the system. This implies that it is impossible to create or destroy energy. The total energy of a system can this be calculated by adding all forms of energy in the system. Examples of energy transfer and transformation include generating or making use of electric energy, performing chemical reactions and lifting an object. Lifting against gravity performs work on the object and stores gravitational potential energy; if the object falls, gravity does work on the object, which transforms its potential energy into kinetic energy associated with its speed. 5 The name “thermodynamics” stems from the Greek words therme (heat) and dynamis (power), which is descriptive of efforts to convert heat into power. The discipline of thermodynamics is based primarily on two fundamental natural laws, known as the first and second laws. The first law of thermodynamics is simply an expression of the conservation of energy principle. It states that energy, as a thermodynamic quantity, is neither created nor destroyed during a process. The second law of thermodynamics states that energy has quality as well as quantity, and that processes naturally occur in the direction of decreasing quality of energy. 1.3 The First Law of Thermodynamics The first law of thermodynamics (FLT) embodies the principle of energy conservation, which states that, although energy can change form, it can be neither created nor destroyed. The FLT defines internal energy as a state function and provides a formal statement of the conservation of energy [2]. However, the first law provides no information about the direction in which processes can spontaneously occur, that is, reversibility aspects of thermodynamic processes. For example, the FLT cannot indicate how cells can perform work while existing in an isothermal environment. The FLT provides no information about the inability of any thermodynamic process to convert heat fully into mechanical work, or any insight into why mixtures cannot spontaneously separate or un-mix themselves. A principle to explain these phenomena and to characterize the availability of energy is required. Such a principle is embodied in the second law of thermodynamics (SLT), which we explain later in this chapter. A simple example of energy conversion is the process in which a body that has some potential energy at some elevation falls, and part of the potential energy is converted into kinetic energy. Experimental data show that the decrease in potential energy is equal to the increase in kinetic energy if air resistance is negligible. This simple example demonstrates the conservation of energy principle. In order to analyze energy systems, we need to use energy balance equations, which express the balance of the energy entering and leaving a system and the energy change in the system. That is, the net change in the total energy of the system during a process is equal to the difference between the total energy entering and the total energy leaving the system during that process, o This relation can be written as 6 Ein − Eout = ΔEsystem The energy E may include internal energy U, kinetic energy (KE) and potential energy (PE) terms as follows: E = U + KE + PE 1.3.1 Thermodynamic System A thermodynamic system is a region or device or combination of devices that contains a certain quantity of matter. It is important to carefully define the system under consideration during an analysis and its boundaries. Three important types of systems can be defined: Closed system. Such a system is defined as one across the boundaries of which no material crosses. It therefore contains a fixed quantity of matter. Sometimes this is also called a control mass. Open system. This is defined as a system in which material (mass) is allowed to cross the boundaries. The term open system is sometimes referred to as a control volume. Isolated system. This is a closed system that is independent and unaffected by the surroundings. No mass, heat, or work crosses its boundary. 1.3.2 Process A process is a physical or chemical change in the properties of matter or the conversion of energy from one form to another. In some processes, one property remains constant. The prefix “iso” is employed to describe such as process, for example isothermal (constant temperature), isobaric (constant pressure), and isochoric (constant volume). 1.3.3 Cycle A cycle is a series of thermodynamic processes in which the end point conditions or properties of the matter are identical to the initial conditions. 7 1.3.4 Heat Heat is the thermal form of energy, and heat transfer takes place when a temperature difference exists within a medium or between different media. The definitive experiment that showed heat to be a form of energy, convertible into other forms, was carried out by Scottish physicist James Joule. Heat transfer always requires a difference in temperature, and higher temperature differences provide higher heat transfer rates. The units for heat are joules or kilojoules in the International System (SI) and the foot pound force or British thermal unit (Btu) in the English system. In terms of sign conventions in thermodynamic calculations, a common one states that heat transfer to a system is considered positive, while heat transfer from a system is negative. If there is no heat transfer involved in a process, it is called adiabatic. 1.3.5 Work Work is the energy that is transferred by a difference in pressure or force of any kind, and is subdivided into shaft work and flow work. Shaft work is the mechanical energy used to drive a mechanism such as a pump, compressor, or turbine. Flow work is the energy transferred into a system by a fluid flowing into, or out of, it. Both forms are usually expressed in kilojoules. Work can also be expressed on a unit mass basis (e.g., in kJ/kg). By one common convention, work done by a system is usually considered positive and work done on a system (work input) is considered negative. The SI unit for power or rate of work is joules per second, which is a Watt (W). 1.3.6 Thermodynamic Property A thermodynamic property is a physical characteristic of a substance, often used to describe its state. Any two properties usually define the state or condition of a substance, and all other properties can be derived from these. Some examples of properties are temperature, pressure, enthalpy, and entropy. Thermodynamic properties can be classified as intensive (independent of the size or scale, e.g., pressure, temperature and density) and extensive properties (dependent on size or scale, e.g., mass and total volume). Extensive properties become intensive properties when expressed on a per unit mass basis, such as is the case for specific volume. 8 Property diagrams of substances can be presented in graphical form and present the main properties listed in property tables, for example refrigerant or steam tables. In analyzing an energy system, the thermodynamic properties should be defined so as to permit the simulation (and hence optimization) of the system. In this book, Engineering Equation Solver (EES) and Refprop software are utilized to calculate thermodynamic properties. 1.3.6.1 Specific Internal Energy Internal energy represents a molecular state type of energy. Specific internal energy is a measure per unit mass of the energy of a simple system in equilibrium, and can be expressed as the function cvdT. For many thermodynamic processes in closed systems, the only significant energy changes are internal energy changes, and the work done by the system in the absence of friction is the work of pressure-volume expansion, such as in a piston-cylinder mechanism. 1.3.6.2 Specific Enthalpy Specific enthalpy is another measure of the energy per unit mass of a substance. Specific enthalpy, usually expressed in kJ/kg or Btu/lb, is normally expressed as a function of cpdT. Since enthalpy is a state function, it is necessary to measure it relative to some reference state. The usual practice is to determine the reference values, which are called the standard enthalpy of formation (or the heat of formation), particularly in combustion thermodynamics. 1.3.6.3 Specific Entropy Entropy is the ratio of the heat added to a substance to the absolute temperature at which it is added, and is a measure of the molecular disorder of a substance at a given state. 1.4 The Second Law of Thermodynamics As mentioned earlier, the first law is the energy conservation principle. The second law of thermodynamics (SLT) is instrumental in determining inefficiencies of practical thermodynamic systems, and indicates that it is impossible to achieve 100% efficiency (in terms of reversible conversion) in energy conversion processes. Two primary statements of the second law follow: Kelvin/Planck statement: It is impossible to construct a device, operating in a cycle (e.g., a heat engine), that accomplishes only the extraction of heat from some source and its 9 complete conversion to work. This statement describes the impossibility of having a heat engine with a thermal efficiency of 100%. Percentage of Excess Air [%] Figure 1: Effect of varying excess air on combustion flame temperature. Clausius statement: It is impossible to construct a device, operating in a cycle (e.g., refrigerator or heat pump), that transfers heat from a low temperature (cooler) region to a high temperature (hotter) region, of itself. 10 CHAPTER TWO 2.0 Thermodynamic Cycle A thermodynamic cycle is a series of thermodynamic processes for transferring heat and work, in varying pressure, temperature, and other variables returning to its initial position eventually. The first law of thermodynamics explains that the net heat input is equal to the total work output over any cycle. Thermodynamic cycles often use quasistatic processes to define the operation of actual devices. If the cyclic process operates in a clockwise direction around the loop, then it represents a heat engine, hence W will be positive. If the cyclic process operates in the counterclockwise direction around the loop, then it represents a heat pump, hence W will be negative. A Thermodynamic cycle consists of four phases. Figure 2: Thermodynamic cycle Heat addition: b, c, d, e in a boiler at constant pressure P1 changing the water at b to superheated steam at e. Isentropic expansion: e, f in a prime mover from initial pressure P1 to backpressure P2. 11 Heat rejection: f, a in a condenser at constant pressure P2 with wet steam at f converted to saturated liquid at a Isentropic compression: a, b of water in a feed pump from pressure P1 to pressure P1. Two primary classes of thermodynamic cycles are: Power cycles: converts some heat input into mechanical work. Heat pump cycles: transfers heat from low to high temperatures using mechanical work input 2.1 The most common thermodynamic power cycles that represent internal combustion engines. 2.1.1 Carnot Cycle The Carnot Cycle has been described as being the most efficient thermal cycle possible, wherein there are no heat losses, and consists of four reversible processes, two isothermal and two adiabatic. It has also been described as a cycle of expansion and compression of a reversible heat engine that works with no loss of heat. By using the second law of thermodynamics it is possible to show that no heat in the engine can be more efficient than a reversible heat engine working between two fixed temperature limits. This heat engine is known as the Carnot cycle and consists of the following processes. 12 Figure 3: Carnot Cycle 1 to 2 isentropic expansions 2 to 3 Isothermal heat rejection 3 to 4 isentropic compression 4 to 1 Isothermal heat supply The Carnot cycle has a low work ratio. Although this cycle is the most efficient system for power generation theoretically. The Carnot cycle is not practical used,not only because of unavoidable frictional losses (could be minimised with appropriate lubrication), becourse there are several reasons such as low work ratio, economical aspects, and practical difficulties but also because of the heat transfer with negligible temperature jump, that would render the heat transfer rate infinitesimal for a finite size engine with finite thermal transmittance with the heat sources. However, heat transfer rates may be highly increased if the gas moves through a porous media that serves as intermediate heat source, as in the cycles of Stirling and Veuillemier. 2.1.2 GAS POWER CYCLES Inside a heat engine, a working fluid cyclically evolves taking heat from a hot source and rejecting heat to the environment, producing some mechanical work in the way (usually shaft work). Gases are the best working substances because of their ease to exchange thermal to mechanical energy by compression or expansion, whereas liquids have little compressibility. We 13 call ‘gas cycles’ those where the working substance stays all the time in the gas phase, and vapour cycles those where the gas condenses to liquid in some part of the cycle (and back again). Although any cycle may in principle be used as a heat engine or as a refrigerator and heat pump by just reversing the direction of the process, in practice there are big difference and the study is split between power cycles and refrigeration cycles. Many gas cycles have been proposed, and several are currently used, to model real heat engines: The Otto cycle (approximates the actual petrol engine), the Diesel cycle (approximates the actual diesel engine), the mixed cycle ( an hybrid of the last two that is better than both), the Brayton cycle (approximates very well the actual gas turbine engine), and the Stirling cycle (used in some exotic applications). We restrict the analysis to the so called ‘air standard’ model, which assumes air with temperature-independent properties as the working fluid, neglecting fuel addition effects (the air to fuel mass ratio is close to 15:1 in Otto engines, almost 30:1 in Diesel engines, and almost 40:1 in Brayton engines), and we consider an equivalent heat addition. 2.1.2.1 Otto Cycle The Otto cycle is a first approximation to model the operation of a spark-ignition engine, first built by Nikolaus Otto in 1876, and used in many cars, small planes and small power systems (below say 200 kW) down to miniature engines. This is a reciprocating internal combustion gas engine (the master in the 20th c.; in the 19th c. it was the external combustion steam engine). The Otto engine typically uses gasoline as fuel, but may run on liquefied petroleum gases (LPG), natural gas (NG), alcohol etc. The Otto cycle is the idealized thermodynamic cycle used in spark-ignition internal combustion engines, commonly found in automobiles. It consists of four processes: isentropic compression, constant-volume heat addition (due to combustion), isentropic expansion, and constant-volume heat rejection (due to exhaust). The Otto cycle is characterized by a spark ignition and a relatively high compression ratio. 2.1.2.2Diesel cycle The Diesel cycle is a first approximation to model the operation of a compression-ignition engine, first built by Rudolf Diesel in 1893, and used in nearly all boats (the first in 1903), nearly all 14 trucks (the first in 1923), many locomotives (the first one in the 1940s, but taken over by electric drive after a few decades of prominence), a large share of cars (the first one in 1936, but it took decades to gain market), many medium-large electric auxiliary-power and cogeneration systems, and even some small airplanes. It is the reference engine from 50 kW to 50 MW, due to the fuel used (cheaper and safer than gasoline) and the higher efficiency. The Diesel cycle is the idealized thermodynamic cycle used in compression-ignition internal combustion engines, typically found in trucks, ships, and some cars. It is similar to the Otto cycle but with constant pressure heat addition instead of constant volume. The Diesel cycle consists of four processes: isentropic compression, constant pressure heat addition (due to fuel injection and combustion), isentropic expansion, and constant volume heat rejection. 2.1.2.3 Brayton Cycle The Brayton cycle, named after the American engineer George Brayton (that built a two-stroke reciprocating engine in 1876 and advanced combustion chambers at constant pressure), is a good model for the operation of a gas-turbine engine (first successfully tested by F. Whittle in 1937, and first applied by the Heinkel Aircraft Company in 1939), nowadays used by practically all aircraft except the smallest ones, by many fast boats, and increasingly been used for stationary power generation, particularly when both power and heat are of interest The Brayton cycle is a thermodynamic cycle that describes the workings of the gas turbine engine, the basis of the jet engine, and others.It is also sometimes known as the Joule cycle.A Brayton-type engine consists of three components: A gas compressor. A mixing chamber. An expander The Ideal Brayton cycle has Isentropic Process – Ambient air is drawn into the compressor, where it is pressurized. 15 Isobaric Process – The compressed air then runs through a combustion chamber, where fuel is burned, heating that air-a a constant-pressure process, since the chamber is open to flow in and out. Isentropic Process – The heated, pressurized air then gives up its energy, expanding through a turbine (or series of turbines). Some of the work extracted by the turbine is used to drive the compressor. Isobaric Process – Heat Rejection (in the atmosphere). The actual Brayton cycle has Adiabatic Process – Compression. Isobaric Process – Heat Addition. Adiabatic Process – Expansion. Isobaric Process – Heat Rejection. Figure 4: Brayton cycle 16 The four steps of the cycle are 1 to 2 Isentropic Compressions 2 to 3 Reversible Constant Pressure Heat addition 3 to 4 Isentropic expansion 4 to 1 Reversible Constant Pressure Heat rejection. The efficiency of the Brayton cycle can be improved by Intercooling Regeneration Combined cycle system to increase overall efficiency. The cogeneration system makes use of waste heat for heating feed water. 2.1.2.4 Stirling Cycle The Stirling cycle is a closed-cycle thermodynamic process that operates on the principles of compression and expansion of a fixed mass of gas (typically helium or hydrogen) at different temperatures. It is known for its high efficiency and ability to operate with external heat sources, making it suitable for applications such as heat pumps, cryocoolers, and some power generation systems. 2.1.3 VAPOUR POWER CYCLES 2.1.3.1 Rankine cycle Most large electricity generating plants (central power stations), and very large ship engines, use water vapour (steam) as working fluid, following some variation of the basic Rankine cycle (named after the Scottish inventor William Rankine, that in 1859 wrote the first book on Thermodynamics), the only vapour power cycle in practical use since 1840 until in 1984 Alexander Kalina patented in the USA the cycle named after him. 17 The heat source for the boiler is usually the combustion products of a fuel (mainly coal) and air, or the primary refrigerant of a nuclear reactor, and the heat sink in the condenser is usually a water loop, open like in a river, or closed like in a cooling tower. The Rankine cycle is a thermodynamic cycle commonly used in steam power plants. It is an idealized representation of a steam power generation process. The cycle involves four main processes: heat addition at constant pressure (in a boiler), isentropic expansion (in a turbine), heat rejection at constant pressure (in a condenser), and isentropic compression (in a pump). The Rankine cycle is widely utilized due to its applicability to a range of power generation technologies. The Rankine cycle is a type of thermodynamic cycle used in many power stations to generate electricity. The Rankine cycle is the real-world approach to the Carnot cycle. Superheated steam generated in a boiler is expanded into the steam turbine. The steam turbine drives a generator, to convert the work into electricity. The power plant generates electric power by using fuels like bagasse, coal, oil, or natural gas. Generally, a Power plant consists of a Boiler, Turbine, Condenser, and Feed pump. Fuel is burned in the boiler furnace and the superheater heats the water to generate steam. The steam is further heated to a superheated state in the superheater. This pressurized steam is used to rotate the steam turbine which powers the generator. Electrical energy is generated when the generator windings rotate in a strong magnetic field. After the steam leaves the turbine it is cooled to its liquid state in the condenser. The liquid is pressurized by the pump prior to going back to the boiler. Rankine Cycle Process The Rankine cycle is a heat engine with a vapor power cycle.Here, water is used as a working fluid.Typically, the Rankine cycle operates at a pressure between 0.06 bars and 50 bars.The pump and turbine in an ideal Rankine cycle are isentropic. It means no entropy is generated in the pump and turbine, and hence work output is maximized. The Rankine cycle consists of four states that are identified by number in the diagram to the right. 18 Figure 5: Rankine cycle State 1-2: The liquid is used as a working fluid, pumped from low pressure to high pressure since the pump requires little input energy. State 2-3: The high-pressure liquid enters a boiler drum and is heated by an external heat source at constant pressure to become a dry saturated vapor. State 3-4: The dry saturated vapor expands through a turbine, generating power. This decreases the temperature and pressure of the vapor, and some condensation may occur. State 4-1: The wet vapor enters a condenser where it gets condensed at a constant pressure and temperature to become a saturated liquid. The pressure and temperature of the condenser are fixed by the temperature of the cooling coils as the fluid is undergoing a phase change. Stages 1-2 and 3-4 are represented by vertical lines on the T-S diagram and resemble the Carnot cycle. The Rankine cycle shown here prevents the vapor from ending up in the superheat region after the expansion in the turbine, which reduces the energy removed by the condensers. The work output of the Steam turbine and the work input to the Pump are given by Work Output =W1 = m (h1-h2) 19 Work Input = W2= m (h4-h3) The Heat supplied Q1 to the boiler, & heat rejected Q2 from the condenser are Q1 = m*(h1-h4) Q2 = m*(h2-h3) The total work output of the cycle is given by: W total= W1 – W2 The Thermal Efficiency of a Rankine cycle is: N thermal = W/Q1 The efficiency of the Rankine cycle is not as high as the Carnot cycle but the cycle has fewer practical difficulties and is more economic. Regeneration helps improve the Rankine cycle efficiency by preheating the feed water into the boiler. Regeneration can be achieved by openfeed water heaters or closed-feed water heaters. In open-feed water heaters, a fraction of the steam exiting a high-pressure turbine is mixed with the feed water at the same pressure. In a closed system, the bled from the turbine is not directly mixed with the feed water, and therefore, the two streams can be at different pressures. 2.2.3.2 Organic Rankine Cycle “Organic” is a term used in chemistry to describe a class of chemicals that includes Freon and most of the other common refrigerants. A Rankine cycle is a closed-circuit steam cycle. An “organic” Rankine cycle uses a heated chemical instead of steam as found in the Rankine Cycle. Chemicals used in the Organic Rankine Cycle include Freon, butane, propane, ammonia, and the new environmentally-friendly refrigerants. 20 2.3 Conclusion These are just examples of thermodynamic cycles commonly used in engineering applications. Each cycle has its specific characteristics, advantages, and limitations, and they are tailored to suit different energy conversion needs and technologies. 21 CHAPTER THREE 3.0 Thermal efficiency, operation conditions, and cycle variations play crucial roles in determining the performance and characteristics of thermodynamic cycles. 3.1 Thermal Efficiency Thermal efficiency is a measure of how effectively a thermodynamic cycle converts heat energy into useful work. It is defined as the ratio of the net-work output to the heat input. A higher thermal efficiency indicates a more efficient conversion of energy. The theoretical maximum efficiency for a cycle is determined by the Carnot efficiency, which depends on the temperature at which heat is added and rejected. Real-world cycles typically operate at lower efficiencies due to various factors like irreversibility, mechanical losses, and heat losses. Optimizing system design and operation parameters helps improve thermal efficiency. 3.2 Operation Conditions The operating conditions of a thermodynamic cycle refer to the specific values of pressure, temperature, and other relevant parameters at different stages of the cycle. These conditions depend on the specific application and design considerations. For example, in a steam power plant using the Rankine cycle, the operating conditions include the pressure and temperature at which steam is generated in the boiler, expanded in the turbine, condensed in the condenser, and compressed in the pump. The operating conditions greatly affect cycle performance, efficiency, and the overall system design. 3.3 Cycle Variations Thermodynamic cycles can have variations or modifications to suit specific requirements and improve performance. Some common cycle variations include: 3.3.1 Regenerative Cycle The regenerative cycle incorporates a feedwater heater to preheat the liquid entering the boiler or heat exchanger using the waste heat from the cycle itself. This reduces the heat input required, improves efficiency, and increases the average temperature at which heat is added. 22 3.3.2 Reheat Cycle In a reheat cycle, the steam from the turbine is reheated before entering a subsequent stage of expansion. This helps to increase the average temperature at which heat is added and improves cycle efficiency by reducing the temperature difference between the heat source and the working fluid. 3.3.3 Combined Cycle A combined cycle power plant combines the Brayton cycle (gas turbine cycle) with the Rankine cycle (steam turbine cycle). The exhaust heat from the gas turbine is utilized to produce steam, which drives a steam turbine for additional power generation. This configuration increases overall efficiency by utilizing waste heat effectively. 3.3.4 Cogeneration Cycle Cogeneration, or combined heat and power (CHP), systems generate both electricity and useful heat simultaneously. These cycles are designed to maximize the utilization of waste heat produced during power generation for heating, cooling, or industrial processes, thus increasing overall energy efficiency. 3.3.5 Tri-generation Cycle Tri-generation systems, also known as combined cooling, heat, and power (CCHP) systems, generate electricity, heating, and cooling simultaneously. They utilize waste heat for both heating and cooling applications, providing a comprehensive energy solution. Cycle variations are implemented based on specific needs, such as maximizing efficiency, reducing environmental impact, or fulfilling diverse energy demands in an integrated manner. 3.4 Conclusion Therefore, by understanding and analyzing thermal efficiencies, operation conditions, and cycle variations are vital for designing and optimizing thermodynamic systems. Engineers strive to improve thermal efficiencies, select appropriate operation conditions, and implement cycle variations to enhance energy conversion, reduce energy losses, and achieve sustainable and efficient power generation. 23 REFERENCES Dincer, I. and Cengel, Y. A. (2001) Energy, entropy and exergy concepts and their roles in thermal engineering. Entropy 3:116–149. Dincer, I. and Rosen, M. A. (2012) Exergy: Energy, Environment and Sustainable Development. Second Edition, Elsevier. Raéznjeviâc, K. (1995) Handbook of Thermodynamic Tables, Begell House, New York. Cengel, Y. A., Boles, M. A. and Kanoglu, M. (2011)˘ Thermodynamics: An Engineering Approach, McGraw-Hill, New York. Bejan, A., Tsatsaronis, G. and Moran, M. J. (1996) Thermal Design and Optimization. John Wiley & Sons, Inc., New York. Kotas, T. J. (1986) Exergy method of thermal and chemical plant analysis. Chemical Engineering Research & Design 64:212–229. Szargut, J., Morris, D. R. and Steward, F. R. (1988) Energy Analysis of Thermal, Chemical, and Metallurgical Processes, Hemisphere, New York. Kotas, T. J. (1985) The Exergy Method of Thermal Plant Analysis, Krieger, Malabar, Florida. Palacios-Bereche, R., Gonzales, R. and Nebra, S. A. (2012) Exergy calculation of lithium bromide–water solution and its application in the exergetic evaluation of absorption refrigeration systems LiBr-H2O. International Journal of Energy Research 36:166–181 24