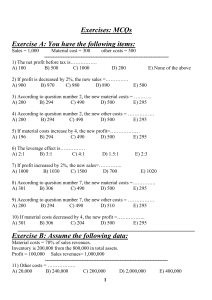

horngrens-cost-accounting-a-managerial-emphasis-16th-global-edition-chapter-11-questions-and-solutions

advertisement