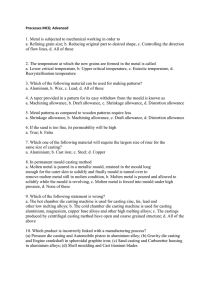

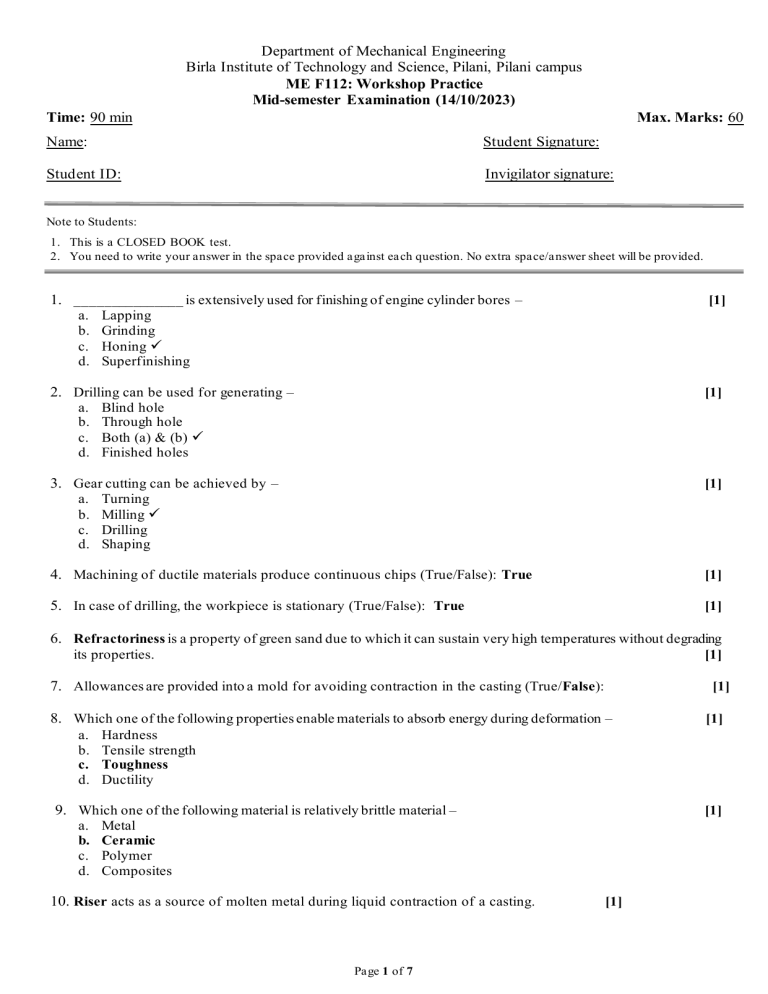

Department of Mechanical Engineering Birla Institute of Technology and Science, Pilani, Pilani campus ME F112: Workshop Practice Mid-semester Examination (14/10/2023) Time: 90 min Max. Marks: 60 Name: Student Signature: Student ID: Invigilator signature: Note to Students: 1. This is a CLOSED BOOK test. 2. You need to write your answer in the space provided against each question. No extra space/answer sheet will be provided. 1. _______________ is extensively used for finishing of engine cylinder bores – a. b. c. d. [1] Lapping Grinding Honing ✓ Superfinishing 2. Drilling can be used for generating – a. b. c. d. [1] Blind hole Through hole Both (a) & (b) ✓ Finished holes 3. Gear cutting can be achieved by – a. b. c. d. [1] Turning Milling ✓ Drilling Shaping 4. Machining of ductile materials produce continuous chips (True/False): True [1] 5. In case of drilling, the workpiece is stationary (True/False): True [1] 6. Refractoriness is a property of green sand due to which it can sustain very high temperatures without degrading its properties. [1] 7. Allowances are provided into a mold for avoiding contraction in the casting (True/False): [1] 8. Which one of the following properties enable materials to absorb energy during deformation – a. b. c. d. 9. Which one of the following material is relatively brittle material – a. b. c. d. [1] Hardness Tensile strength Toughness Ductility [1] Metal Ceramic Polymer Composites 10. Riser acts as a source of molten metal during liquid contraction of a casting. Page 1 of 7 [1] 11. A tool life of 80 minutes is obtained at a speed of 30 m/min and 8 minutes at 60 m/min. Determine the following: [4+1 = 5] a) Tool life equation b) Cutting speed for 4 minutes of tool life 12. Find the time required for one complete cut on a piece of work 350 mm long and 50 mm diameter. The cutting speed is 35 m/min, and the feed is 0.5 mm/rev. Page 2 of 7 [5] 13. At a speed of 33 m/min and the feed of 0.10 mm/rev of the drill, calculate the time required to drill a 15 mm diameter hole in a 25 mm thick plate. Take the length of approach and length of overtravel as 3 mm each. [5] 14. A cylindrical aluminum part (r= 250 mm and h= 20 mm) is to be cast using sand casting. If the mold constant is 2.0 sec/mm2 for aluminum and sand mold. Find out the total time required to solidify the casting. [1.5+1.5+2 = 5] Area A = 2 π r2+ 2π r h = 2 π (250)2+ 2π (250) (20) = 424,115 mm2 Volume V = π r2 h = π (250)2 (20) = 3,926,991 mm3 Chvorinov’s Rule: Time = Cm (V/A)2 = 2 (3,926,991 / 424,115) 2 = 171.5 s = 2.86 min Page 3 of 7 15. What is a composite material? Discuss the different types of composite materials. [2+3 = 5] Explanation on following – Composite materials: It is a material consists of more than one material type (matrix and reinforcement) designed to display a combination of properties of each component. Metal Matrix Composites: metal is matrix and reinforcements may be ceramic or metal. Ceramic Matrix Composites: ceramic is matrix and reinforcement can be ceramic or metal. Polymer Matrix Composites: polymer is matrix and reinforcement are ceramic, or metal, or fibers. 16. Draw a gating system which is generally used for metal casting and label its different components. Page 4 of 7 [2+3 = 5] 17. Why is grinding an energy intensive process as compared to turning? Explain with a schematic. [10] • Amount of material to be removed is less in grinding, this in turn means that higher forces are required for material removal • This is due to reduction in the number of defects as size of material reduces; making the material reach its ideal strength. • In case of turning, amount of material to be removed is larger as compared to grinding, therefore, number of defects also increases, reducing the energy requirement for turning process. Page 5 of 7 18. What is the pattern? With suitable schematic diagrams, discuss different types of pattern allowances that are used to accommodate various dimensional variations of a component during casting. [2.5+7.5 = 10] Explanations based on the following Pattern: it is a replica of casting (final product) with some modifications that can be used to form impressions (cavity) in sand mold. Modifications are – 1. allowances, 2. position for core print 3. elimination of complex surface designs 1. SHRINKAGE ALLOWANCE • Provided to compensate for shrinkage of material. • Pattern is made slightly bigger. • The amount of allowance depends upon type of material, its composition, etc. 2. MACHINING ALLOWANCE • • • Provided to compensate for machining on casting. Pattern is made slightly bigger is size. Amount of allowance depends upon size and shape of casting, type of material, machining process to be used, degree of accuracy and surface finish required etc. 3. DRAFT OR TAPER ALLOWANCE • Q Provided to facilitate easy withdrawal of the pattern. • Typically taper ranges from 1 degree to 3 degree for wooden patterns. 4. DISTORTION ALLOWANCE • This allowance is provided in opposite to the direction of general warping of a casting • Provided on patterns whose castings tend to distort on cooling (c) (b) (b) (c) (a)(a) Casting produced Casting produced when when no no Pattern Pattern with distortion with distortion Requiredshape shape Required of of (b) (c) (a) casting distortion allowance is provided distortion allowance is provided allowanceallowance casting Required shape of casting 5. RAPPING OR SHAKE ALLOWANCE • Provided to permit easy withdrawal of the pattern. • It is a negative allowance. Page 6 of 7 Casting produced when no distortion allowance is provided Pattern with distortion allowance --x-- Page 7 of 7