ِّ

الر ِّح ِّيم ِِّ

ح

الر

هللا

ِّب ْاَس ِّم

ْ

من َّ

َّ

ِّ

ُ

ْ

ً

ْ

{}27

اَسِ ِّي

َو ْ

احلل ُ

عق َدة ِّمن ِّل َ

{}28

يَ ْفقَ ُهوا قَ ْو ِّل

صدق ﺍﷲ ﺍﻟﻌﻅﻳﻢ

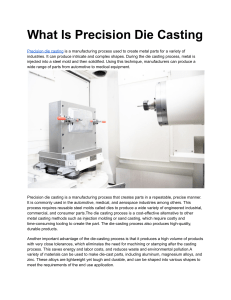

Gold

Crown

Reduced

tooth

Impression

Die

Wax

Pattern

Wax Sprue

Wax Pattern

Wax Sprue

Crucible

Former

Ring

+

Investment material

+

Wax pattern

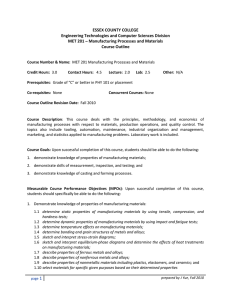

Investment Materials

Ceramic materials used for

making a mould into which the

metal or alloy is cast.

Ideal Requirements:

1) Should withstand high temperature without

decomposition during casting.

2) Should have sufficient expansion to compensate

for the casting shrinkage.

3) Should have sufficient strength at;

- Room temperature, to withstand manipulation

without fracture.

- High temperature, to withstand the force of molten

alloy entering the mold.

4) Should be porous to allow escape of air or gases

during casting.

5) Should produce a smooth surface and fine details

of the casting.

6) Should be broken away easily after casting.

Composition:

1- Refractory material 65% :

[Silica]

Function:

1) It withstands high temperature.

2) It produces thermal expansion of the

investment which is caused by the

displacive transformation of silica from

to form during casting.

Effect of Heat on

Refractory Material

Reconstructive

870C

Β-Quartz

(Hexagonal)

525C

1713C

1470C

Β-Tridymite

(Rhombohedral)

Β-Cristobalite

(Cubic)

Β-Fused quartz

(amorphous)

270C

160C

Displacive

αQuartz

αTridymite

αCristobalite

(Hexagonal)

(Rhombohedral)

(Cubic)

(1.4% expansion

at 600C).

(1% expansion

at 600C).

(1.6% expansion

at 400 C )

transformation

2- Binder 30%:

Gypsum

Gypsum

bonded

investment

Magnesium

ammonium

phosphate

Phosphate

bonded

investment

Polysilisic

acid

Silicate

bonded

investment

Role of Binders:

1- Binds the silica particles.

2- Provides more strength to the

material.

3- In some types of investment, It

provides setting and hygroscopic

expansion, which share in the

compensation of the casting

shrinkage of the metal.

3- Modifiers 5% :

Chemicals added in small amount to

modify various physical properties

Functions:

1- They prevent oxidation of the molten

alloy during casting e.g. graphite.

2- They produce smooth surface mould.

Types of Investment Materials

Gypsum

bonded

investment

Phosphate

bonded

investment

Silicate

bonded

investment

Gypsum Bonded Investment

It is suitable for alloys which melt

below 1000C

→ Gold Alloys

WHY???

Effect of temperature on

Gypsum Bonded investment

** Heating from 200- 400ºC it contracts due to the

dehydration of the binder. This can be eliminated by addition

of chemicals (boric acid).

** From 400- 700ºC, it expands again due to the

transformation of the α form to the form of silica.

** Above 700ºC, CaSO4 will react with carbon in the

investment leading to evolution of sulfur trioxide gas (SiO3)

→ contamination and porosity of the casting.

** Above 1200°C, during melting of high fusing dental alloys

(base metal) such as nickel chromium and cobalt chromium

alloys, this will lead to decomposition of the binder

(gypsum). leading to evolution of sulfur trioxide gas

(SiO3) causing porosity of the casting.

Phosphate and Silicate

Bonded Investment

It is suitable for alloys which melt

Above 1000C

→

Base metals

Titanium

Castable Ceramics

Comparison Between Three Types of Investments

Point of

comparison

Gypsum

Bonded

Investment

Phosphate

Bonded

Investment

1) Form of

supply

Powder / water

Powder / water

&

Powder /

Special liquid

(Silica sol)

Silicate

Bonded

Investment

Powder / 2

liquids

On mixing

powder +

water;

2) Setting

Reactions

CaSO4.1/2H2O

+ H2O

CaSO4.2H2O

-Acts as a

binder

On mixing powder

+ water;

Ammonium

diphosphate +

MgO + H2O

Magnesium

Ammonium

Phosphate

-Acts as a binder

-Gives sufficient

strength at room

temperature.

(Green strength)

On mixing the 2

liquids:

a) Hydrolysis

Ethyl silicate + HCl

Silicic acid sol +

alcohol

-Acts as a binder

b) Gelation

Powder (silica) +

Silicic acid sol

Polysilicic acid gel

c) Dryness

On heating at 170°C

there is loss of

alcohol & water

silica particles tightly

packed together.

Contraction.

Setting

expansion

due to crystal

growth

3)Properties

a)

Dimensional

Hygroscopic

changes

expansion

during

when

setting

allowed to

set under

water, giving

additional

room for

crystal

growth.

Setting

expansion due to

crystal growth,

which is higher

when mixed with

special liquid.

Setting shrinkage

during gelation due

to formation of

coherent Polysilicic

acid gel (change

from sol to gel)

Green shrinkage

during dryness at

170°C.

Hygroscopic

expansion is

negligible when

mixed with water,

- High heat

but high when mixed shrinkage at 700°C

with special liquid

due to transformation

of Polysilicic acid gel

into Cristobalite.

From 200400°C

Shrinkage due

to dehydration

of the binder.

b)

This can be

Dimensional eliminated by

changes

addition of

during

chemicals

heating

(boric acid).

From 400700°C

Thermal

expansion of

silica due to

displacive

transformation

from to .

Thermal

expansion of silica

due to displacive

transformation

from to .

Thermal

expansion of high

amount of silica at

higher temperature,

due to displacive

transformation from

to.

- Strong

c) Strength

- Sufficient

strength at

room & high

temperatures

to withstand

the driving

force of the

gold alloys

during

casting.

- Stronger

- Magnesium

ammonium

phosphate (binder)

gives sufficient

strength at room

temperature.

(Green strength).

-At high

temperature,

Ammonium diacid

phosphate + silica

silico- phosphate

complex the

strength.

- Strongest

- As silica particles

are tightly packed

together.

Porous

Porous

So venting is

required to allow

escape of air from

mold. In order to

prevent

backpressure

porosity &

incomplete casting.

d) Porosity

4) Casting

ring

Non Porous

- Metallic ring

lined with wet

asbestos paper

- Rubber

ring which is

removed after

setting of the

investment

- Rubber ring

which is

removed after

setting of the

investment

5) Uses

- Casting of

gold alloys

As the total

amount of its

expansion is

equal to the

solidification

shrinkage of

gold alloys

(1.6 %).

Casting of;

- Base metal

alloys (when

mixed with special

liquid). - Or gold

alloys (when

mixed with water).

- Casting of Base

metal alloys

As the total amount

of its expansion is

equal to the

solidification

shrinkage of base

metal alloys

(2.3 %).