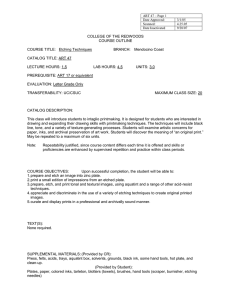

Journal of The Electrochemical Society You may also like An Overview of Dry Etching Damage and Contamination Effects To cite this article: Stephen J. Fonash 1990 J. Electrochem. Soc. 137 3885 View the article online for updates and enhancements. - Black silicon method X: a review on high speed and selective plasma etching of silicon with profile control: an in-depth comparison between Bosch and cryostat DRIE processes as a roadmap to next generation equipment H V Jansen, M J de Boer, S Unnikrishnan et al. - Foundations of low-temperature plasma enhanced materials synthesis and etching Gottlieb S Oehrlein and Satoshi Hamaguchi - High quality shadow masks for top contact organic field effect transistors using deep reactive ion etching Muhsen Aljada, Karyn Mutkins, George Vamvounis et al. This content was downloaded from IP address 128.227.1.50 on 21/04/2023 at 16:51 An Overview of Dry Etching Damage and Contamination Effects Stephen J. Fonash* Center for Electronic Materials and Processing, The Pennsylvania State University, University Park, Pennsylvania 16802 ABSTRACT Plasma or dry etching techniques, such as reactive ion etching, magnetron reactive ion etching, electron cyclotron resonance etching, ion beam etching, and plasma etching, can result in damage and contamination of the materials used in device structures and interconnects. The damage that can take place occurs because of ion b o m b a r d m e n t , radiationinduced b o n d i n g changes, and charge buildup. If not removed, damage can have effects which vary from gettering to creating traps in insulators and gap states in semiconductors. The contamination that can take place can have two forms: residue layers and permeation. The former are ultrathin layers of reaction products that can coat surfaces whereas the latter is the e m b e d d i n g or implantation, and perhaps subsequent diffusion, of impurities. These impurities can range from metals whose source is the processing chamber to hydrogen which is often found in the etch recipe or may even be found due to the presence of water in the processing chamber. If not removed, residues can interfere with s u b s e q u e n t processing such as oxidation and can cause series resistance in contacts. Impurities, if not removed, can have a range of effects from modifying carrier lifetimes to interfering with subsequent processing. Hydrogen, in particular, can affect materials in a n u m b e r of ways including modifying doping activation. Dry etching techniques such as reactive ion etching (RIE), magnetron reactive ion etching (MRIE), plasma etching (PE), ion beam etching (IBE), electron cyclotron resonance (ECR) etching, and reactive ion beam etching (RIBE) can cause damage and contamination effects in exposed materials (1-14). I n fact, damage is often inherent in these processes due to the presence of ion bombardment, which can create b o n d i n g damage in semiconductors and insulators (1-9, 11, 13), as well as due to the presence of UV radiation, which can create b o n d i n g damage in insulators (10). Contamination is also often inherent in these processes due to the presence of residue layers made up of reactant species and reaction products and due to the presence of impurities which may permeate the etched material during the dry etching exposure (3,4, 11-22). These damage and contamination effects that can be inherent in dry etching are shown schematically in the model of Fig. 1 together with an indication of their depth of influence for the case of silicon. As may be seen, these inherent damage and contamination effects basically can produce three different kinds of layers in a material: residue layers (surface films), permeated layers (impurity permeation), and damaged layers (bonding damage) (4). The boundaries between these layers are not distinct; often they meld into one another. Damage can also occur due to charge b u i l d u p and discharge resulting from etching (5), and, in addition, surface roughening can take place due to partial masking of an etching surface by residues and impurities (23, 24). If not controlled, these various damage and contamination effects present in dry etching, if not controlled can quite adversely influence material properties, subsequent processing, and device performance. Dry etching damage and contamination effects manifest themselves in a number of ways in etched dielectrics from shifts in neutral trap densities and positive charge (10) to increased leakage currents (25). Dry etching effects manifest themselves in etched silicon in changes in surface properties (4), in changes in generation lifetimes (12), in changes in doping activation (20-23), a n d can even result in changes in diffusion lengths (26). S u b s e q u e n t processing steps on a silicon surface, from silicidation (27) to oxidation (19), can be impacted if the reacting surface has been exposed to prior dry etching. I n fact, gate oxides grown on dry etched silicon have been demonstrated to have properties that strongly depend on the etching and the subsequent cleaning processing (19). Capacitor structures fabricated on dry-etched Si surfaces show that the oxides display increased interface state densities which are strongly dep e n d e n t on the etching ion species and energy (28) as well as breakdown voltages that also depend on etching history (5, 19, 25). All of these various effects of dry etching on material properties and s u b s e q u e n t processing propagate * Electrochemical Society Active Member. into devices in a n u m b e r of ways: from shifts in the turnon voltage in FETs to extraneous series resistance in contacts. Given the crucial importance of dry etching to the fabrication of micron and submicron features, it becomes necessary to be fully aware of all of the damage and contamination aspects of dry etching and of their implications to material properties, s u b s e q u e n t processing, and device performance. This overview examines the causes of damage and contamination, the methods of detection of damage and contamination, and approaches to damage and contamination control. Damage and Contamination Residues--their effect, detection, and repercussions.-The residue layer is a surface film stemming from the etching process. Whether or not such a layer is present depends on the etching chemistry. When present, it is composed, to varying degrees, of reactant species and reaction products; hence, its composition depends on the etching gas and the exposed materials. It may also contain impurities. The selectivity and even anisotropy, in some cases, of m a n y dry etching recipes is based on the formation of a residue in the form of a reaction-blocking coating layer on the slowly (or effectively not) etched material (17, 29, 31). Surface Region I Residue Layer (Tens of Angstroms) Region 2 Bonding Damaged Layer * (Up to hundreds of Angstroms) Region 3 Impurity Permeation Layer (Up to ~10 microns) p~.SSIBI F IMPIJRITIE5 IN REGION 3 [~ Oxygen Metaliic~ Hydrogen Fig. 1. Schematic representation of the various damage and contamination layers produced by dry etching. Depths indicated are intended to give a representation of the possible extent in silicon. J. Electrochem. Soc., Vol. 137, No. 12, December 1990 9 The Electrochemical Society, Inc. 3885 J. Electrochem. Soc., Vol. 137, No. 12, December 1990 9 The Electrochemical Society, Inc. 3886 Hence, this type of contamination is inherent in many selective dry etching approaches. I n the case of fluorocarbon-based RIE chemistries, the presence of reaction-blocking, polymer-like residue layers on Si for recipes designed to etch SiO2 over Si has been confirmed by several groups (17, 32, 33), and the effect of the ion b o m b a r d m e n t on the polymeric nature of these RIE-produced films has been explored (30). A recent review of RIE etching (31) has examined reaction-blocking residue layer formation as a function of substrate (photoresist, Si, WSi2, TiSi2, and Ti) and etching chemistry. That recent study also explores residue layers on the RIE etching surface. That is, it examines RIE etching situations where the residue layers are not part of a selectivity mechanism but are simply layers of reactants and reaction products on the surface of the material that is undergoing etching. In particular, that work showed that CF4/Oz RIE of Si produced a SiFxO~ layer whose composition and thickness control the etch rate of the silicon (31). The presence of residue layers as well as the nature of their b o n d i n g has also recently been established for CC12F2 MRIE of silicon (11), as well as for CF4ECR etching of silicon (13, 14). The latter work also compared the residues present in CF4ECR etching of Si with those present if RIE is used or if a hybrid RF-biased ECR (hybrid ECR/RIE) is used. The results showed that ECR etching exhibited a t h i n n e r residue layer than the RIE or the hybrid ECR/RIE. Interestingly, the ECR etching has the lowest self-bias voltage suggesting that, for this chemistry, residue formation was enhanced by ion bombardment. The principal techniques that have been used to establish the presence and chemical makeup of these different kinds of residue layers are x-ray photoelectron spectroscopy (XPS), secondary ion mass spectroscopy (SIMS), and Auger electron spectroscopy (AES) (14, 16, 29, 31); in addition, electrical measurements have been used to infer the presence of residue layers since these layers, when sufficiently thick, can cause series resistance in Schottky barrier and ohmic contacts (4). Ellipsometry has also proven to be useful in determining the presence of residue layers (34-36). Recently it has been used for in situ process monitoring of residue effects (23, 24). An obvious repercussion of the presence of residue layers is that these layers can cause series resistance as seen in Fig. 2. These data show the current-voltage (I-V) characteristics for Au Schottky barrier contacts made on n-type Si (35). The control I-V is for devices made on wet etched Si surfaces; the other I-V is for Au contacts made on CC1F~-Iz RIE exposed Si surfaces. As can be seen, the forward characteristic of the device made on the RIE exposed Si surface shows the presence of what can be phenomenologically described as a series resistance. Further charac1 IO - 4 I' / I / -- I 1 I I /Fcrword i / ~ / / I~ / / / ~ Reverse ///Sy -- ...... eve, e I 0 , r O.l I 0.2. f O.3 t r [ 0.4 0.5 0.6 BIAS (VOLTS} [ 0.7 l (3.8 I 0.9 .LO Fig. 2. I-V characteristics of Au/.-Si. the CCIE3 + H2 RIE was 50% overetch ef blanket Si02 en Si. terization in this case substantiated that this resistance was indeed coming from a residue layer on the Si surface (35). Another repercussion of the presence of surface layers containing reaction products, and perhaps impurities, can be surface roughening. This can occur if the residue layer is discontinuous or if there are islands of impurities on the surface. The resulting micromasking can result in roughening of the etching surface (23, 24). Residue layers can also affect further processing. As noted earlier, their presence can affect, for example, the interface quality (3, 10), growth (3, 10), and breakdown characteristics (19) of oxides grown on RIE- and PE-exposed Si surfaces. Residues--controL--Determining if a residue layer is present and establishing its composition are obvious, necessary steps in reconditioning an exposed surface after dry etching. For example, rapid thermal annealing (RTA) for the removal of the dry etching-induced b o n d i n g damage in silicon, discussed later, is not successful in cases where polymer-like surface films are present unless these residue layers are removed prior to RTA (37, 38). A n u m b e r of detailed studies have been u n d e r t a k e n to examine residue layer removal (19, 31, 37-39). I n a study of silicon overetching using the highly SiO2 selective etch CC1FJH2 RIE, it was found that both 02 ashing and 02 RIE, followed by an HF dip, were effective in removing a polymer-like residue on the Si surface (35). It was also found that, i r a Cr~O3 etch, followed by an H F dip, was used after O2 ashing, the surface further improved due to additional Si removal (35). An HF dip is required after these aforementioned residue removing procedures since they all produce a thin silicon oxide layer (35). Rather than using oxygen-based plasma techniques (Oz ashing, O3 RIE) to volatilize residue layers or all wet-chemistry techniques (35), alternative approaches such as the use of hydrogen-based plasma (39) or UV/O~ exposures for volatilization (40) have recently been explored. Impurity contamination and permeation--the effect, its detection, and repercussions.--Impurities, particularly metallic impurities such as Fe, Ni, A1, Na, Cr, K, and Zn, have been detected by a n u m b e r of groups (2, 3, 13, 14, 19, 28) on the surface, and in the near-surface region, of materials exposed to dry etching techniques as varied as PE, RIE, ECR, and MRIE. These impurities are believed to arise from dry etching processing chambers and their fixturing. In a recent study it has been found, for example, that when "Lexan" (a high-temperature polymer) is used to cover wafer trays in an RIE reactor in place of the tray coating "Ardel," the a m o u n t of metallic impurities such as Ca, Na, K, and Z n present on the surface, and in the near-surface region, of an etch sample can be greatly diminished (19). In the case of ECR and hybrid ECR/RIE etching, it has been shown that the high plasma densities involved in these techniques result in significant contamination from the ECR chamber walls (13). This was also solved by covering the involved surface. I n this situation the chamber walls were covered with an anodized A1 liner (13). The presence of metallic impurities can be detected in a n u m b e r of ways. Since it is well established that oxidation stacking faults (OSF) can be caused by metallic impurities (41), OSF can be used as a detection mechanism. For example, high-temperature oxidation of RIE-exposed Si, followed by oxide stripping and a SECCO etch, has been used to demonstrate the presence of OSF on an RIEexposed Si surface with an optical microscope (19). Since this was done on Si surfaces where the residue had been removed prior to oxidation, the presence of these stacking faults was attributed to metallic impurities such as Cr and Fe (19). This was substantiated using SIMS. Since residue cleaning procedures, including RCA cleans, were not able to remove this metallic contamination, it was suggested that the metallic contamination must have permeated (-100/~) into the silicon during the RIE (19). It is interesting to note that the same study did not find these stacking faults for PE-exposed material. In general, PE involves lower plasma potentials and should, therefore, cause less "scrubbing" of the chamber and fixturing. The lower plasma potentials should also result in less effective "ira- J. Electrochem. Soc., Vol. 137, NO. 12, December 1990 9 The Electrochemical Society, Inc. planting" of impurities into the etching surface. A similar stacking fault study was also u n d e r t a k e n to compare CF4RIE, ECR, and hybrid ECR/RIE etching of Si. The results of this study, for the case when a chamber lining was used, indicated that high stacking fault densities were only found for the RIE exposure (13). This metallic contamination and permeation which can be present due to dry etching can also be detected by SIMS in m a n y cases (19, 28). Of course, the utility of SIMS will depend on the detection limit for a given species. It has also been detected in some studies by electrical techniques such as deep level transient spectroscopy (DLTS) (41-43) and minority-carrier generation lifetime (3, 12, 13). I n general, the presence of metallic impurities from dry etching can affect s u b s e q u e n t processing and device performance. A n example is the poor-quality oxides (poor interface state properties, low breakdown voltage) that can result if the metallic impurities, resulting from the dry etching of the silicon, are not successfully removed prior to oxidation (2, 3, 19, 44). The use of such oxides in gate/ SiOJSi structures leads to severely degraded device performance (2, 3, 19, 44). The repercussions of the metallic impurity contamination and permeation that can result from dry etching can also be significant for p-n junctions. For example, in cases where RIE was done prior to the j u n c t i o n formation, it has been found that high leakage currents are present, if care is not taken to remove metallic impurities. These high leakage currents are believed to be due to stacking faults, which are nucleated and made electrically active by metallic contaminants from the etching chamber (45). Impurity contamination and permeation--control.Clearly the best way to control impurities is to avoid their presence using techniques such as the coatings discussed in the previous section. However, when impurities are present, just as in the case of residue layers, care must be exercised in their removal. Currently, wet or mixed dry/ wet cleaning approaches are being utilized; however, there has also been exploration of all-dry cleaning procedures for removing metallic impurities (46). These approaches usually rely on actually removing surface layers of the contaminated and permeated materials themselves. I n some cases these cleaning techniques have been combined with various types of gettering procedures (42-45). Some of the dry/wet and wet cleaning procedures that are currently being used to remove the residue layer and metallic impurity contamination and permeation present after dry etching of Si are listed in Table I, We note that cleaning procedures that remove more of the Si at the dryetched Si surface at low temperatures are more effective in restoring the material. This is believed to be due to the fact that the use of low temperatures retards deeper movement of the metallic impurities while the consuming of the Si near-surface region allows the capture of these impurities (45). This experimental observation provides further evidence for the various kinds of permeation conceptualized in Fig. 1. Hydrogen permeation--the effect, its detection, and repercussions.--Hydrogen is present in m a n y dry etching recipes. However, even w h e n it is not purposefully part of the etching, hydrogen is present as an impurity since it is relatively abundant, in the form of H20, at the pressures of current technological interest in dry etching. Regardless of its source, hydrogen is readily converted in a dry etching processing chamber into species such as atomic hydrogen and H § which can then easily move through SiO2 and Si (47, 48). The first demonstration that this hydrogen permeation effect is present in dry etching showed that hydrogen at the atomic percent level permeated 400A beneath a CFgH2-etched Si surface (17). S u b s e q u e n t studies of hydrogen permeation during dry etching have showed the surprising result that hydrogen can actually permeate microns below an etched surface at concentrations sufficient to cause significant dopant deactivation (18, 20, 22, 49). Very recent work has established that this hydrogen permeation can take place through both n-type and p-type Si (50). This result is important because it sheds light on the 3887 Table I. Some post dry etching surface cleaning approaches for silicon Name 02 ash/acid clean [Ref. (35)] 02 ash/acid clean/ dilute HF dip [Ref. (35)] O3ash/acid clean/Si wet etch [Ref. (35)] 02 RIE/acid clean [Ref. (35)] Si wet etch [Ref. (35)] H2 plasma clean [Ref. (39)] O2 ash/acid clean/ RCA clean [Ref. (45)] O2 RIE/acid clean/ RCA clean [Ref. (45)] 02 ash/chromic acid etch/acid clean/ RCA clean [Ref. (45)] Procedure~ 02 ashing followed by hot H2SO4I-INO3 clean 02 ashing followed by hot H2SO4/I-INO3 clean and then a 5% HF dip. 02 ashing followed by hot H2SO4/HNO3 clean/BHF (40:1) dip. Si then subjected to silicon etch using chromic (Cr203) acid solution with a follow-on HC1/H202 clean. 02 RIE followed by hot H2SOJHNO3 clean. Silicon etch using chromic (Cr203) acid solution. H2 plasma with low RF power, high pressure, and high H2 gas flow. 02 ashing followed by buffered HF dip, followed by H2SO4/HNO3clean, followed by an RCA clean.~ O2 RIE, followed by buffered HF dip, followed by H2SOjHNO3 clean, followed by an RCA clean,b 02 ashing, followed by buffered HF dip followed by a CrO3-H20-HFetch followed by H2SO4/HNQ clean, followed by an RCA clean,b a Deionized water rinses are used as appropriate. b RCA clean is a wash in NH4OH-H202 solution followed by a wash in HC1 + H202 solution. question of whether the hydrogen permeates during dry etching exposures as a neutral or charged, mobile species (47). Other very recent work further suggests that hydrogen is amphoteric in silicon and can move as a positively charged species in p-type Si and as a negatively charged species in n-type Si (51). Whatever the actual permeating hydrogen species is, its infusion as a result of dry etching can be detected using a variety of techniques. These range from the 1H + 15N nuclear reaction technique (17, 35) to SIMS and to spreading resistance profiling. The I~N nuclear reaction technique determines the total hydrogen population in a sample; i.e., it detects H2, H, H-, and H § species. However, it can only detect a fraction of an atomic percent at best. SIMS also determines the total hydrogen population, and by using deuterium in place of hydrogen in etch recipes, the hydrogen background problem (hydrogen coming from the SIMS chamber itself) can be avoided. If deuterium is used, total hydrogen concentrations of permeated hydrogen >-1015 cm -3 can be detected (52). The spreading resistance profiling (SRP) approach to monitoring the permeation of hydrogen caused by dry etching makes use of the fact that the presence of hydrogen in silicon results in doping deactivation and, hence, results in a change in carrier concentration (i.e., resistance). Every lost carrier is attributed to effective doping deactivation by a hydrogen species (18). This doping deactivation effect occurs to some extent in n-type silicon but it is very p r o n o u n c e d in p-type Si (47). It is noted that SRP need not detect all the hydrogen that is present in a sample; it only detects hydrogen that is involved in doping deactivation. Using SRP, hydrogen injected during dry etching has been detected at concentrations as low as 1014 cm -3 (52). From this discussion of spreading resistance profiling it is obvious that one repercussion of hydrogen permeation during dry etching is this p h e n o m e n o n of doping deactivation in p- and n-type materials. Figure 3 shows doping deactivation in p-type Si samples caused by hydrogen permeation during CHF3/C2F6 PE or CHFJO2 RIE. The PE parameters were 60 sccm: 60 sccm CHF3:C2F6 at 700W and 500 mtorr. The RIE heavy damage parameters were 75 sccm: 9 sccm CHF3:O2 at 1300W and 20 mtorr whereas the RIE light damage used 1000W and 60 mtorr. Fortunately, doping deactivation anneals out; for example, in p-type material it is found to anneal out at temperatures in the 200~176 range (22). We note that Fig. 3 also displays another p h e n o m e n o n associated with hydrogen permeation J. Electrochem. Soc., Vol. 137, No. 12, December 1990 9 The Electrochemical Society, Inc. 3888 I 1 I f S U L K ACCEFTOR CONCEZq'TRATIt3N 9 4~4k 4~ 9 gee "/~e ee e 9 ~o LJ ~ .~ o o 9,~, o 0 PE HEAVY D A M A G E ,a~. oo ='~' o o Do o ~. REGION I 9 REGION II oo RIE HEAVY D A M A G E o REGIDN | a 9 REGIDN l! ~z 1 t I I 2 3 t t 4 5 OEm'HO~) Fig. 3. Active dopant concentration profiles calculated from spreading resistance data for bulk p-type silicon etched under the RIE and PE heavy damage parameters. These ore defined in the text. Note the delineation between region I and II. in p-type Si during dry etching; namely, a two-region behavior. I n general it is found that there is a near-surface region in which hydrogen-related species causing deactivation move more slowly and in which doping deactivation anneals out differently compared to the second deeper, but adjacent layer (22, 49). A repercussion of this hydrogen permeation in terms of device structures is seen in the SRP data of Fig. 4. Here a p-n j u n c t i o n has been formed by 100 keV implant of B § (dosage of 1El3) into n-type silicon. The resulting junction after an activation anneal is seen in the figure. As may also be seen, a subsequent dry etching exposure after the activation anneal causes the j u n c t i o n to shift -2000/1, due to preferentially more effective deactivation of the boron by the hydrogen which permeated during the dry etching (53). This j u n c t i o n shift caused by the dry etching necessitates an additional anneal (at -20O~ ) to reactivate all the dopant and restore the junction position. Hydrogen permeation that occurs during dry etching may also have repercussions, other than that seen in Fig. 4, on subsequent processing and device structures. I n particular, the presence of hydrogen injection raises the question of whether hydrogen present in materials due to dry etching can collect at SiOJSi interfaces and at metal/silicon interfaces during subsequent processing. In the latter regard, it has been suggested that the presence of hydrogen from dry etching can affect contact resistance (54). We also note that hydrogen can affect processing and device behavior through the b o n d i n g damage and b o n d i n g passivation 19 I ....... IEI3 -----IEI3 E u18 ACTIVATED AFTER DEUTERATION Z O m I.-. <( Z hi Z Q .................. . / / : n" tlJ ill: 0 -J 14 I .25 I I .I .50 .75 I.O D E P T H (t, ffcrons} l 1.25 I L5 Fig. 4. Carrier concentration profiles for n-type epitaxial silicon implanted with HB+ at 100 keV to a dose of IE|3 cm -z after activation and subsequent deuterafion. changes it can cause. These are discussed further in the section which deals with b o n d i n g damage. Hydrogen permeation--controL--Hydrogen permeation is very much a part of dry etching as it is now practiced. The use of new dry etching approaches such as magnetically enhanced RIE or ECR etching will not remove this hydrogen permeation problem. I n fact, present evidence suggests that these dry etching approaches may actually exacerbate the problem due to the a b u n d a n t presence of H and H § (54). Removing the source of the hydrogen, present in m a n y etch recipes and present ultimately through the base pressures currently used for dry etching appears to be the only solution to fully preventing hydrogen permeation during dry etching. However, it is currently not clear how serious a problem this hydrogen permeation really presents. It does obviously cause dopant deactivation but, at least in the case of p-type silicon, where the effect is significant, it is easily annealed out. It does also cause extended structural defects, which we treat in the next section as part of dry etching bonding damage; these have been reported to exist as far as 0.5 ~m below etched Si surfaces (55, 56). However, its most insidious role may lie in its effects at interfaces and in dielectrics. These remain to be explored and understood. Bonding damage--the effect, its detection, and repercussions.--The b o n d i n g damage that results from dry etching exposure has its roots in three distinctly different causes. One is the ion b o m b a r d m e n t inherent in at least all current anisotropic dry etching, another is UV radiation, and the third is hydrogen. These causes can obviously be present together. The ion b o m b a r d m e n t inherent in current anisotropic dry etching techniques is needed to create that anisotropic etching by doing one or more of the following: (i) it produces physical sputtering of chemically weakened bonds, (ii) it can result in damage-enhanced chemical reactivity, (iii) it can provide energy to drive chemical reactions, and (iv) it can remove residue layers exposing material to etching attack (4). This same b o m b a r d m e n t that gives anisotropy also produces undesired b o n d i n g damage. This damage often increases with ion energy (4, 7, 11, 57); however, recent work comparing RIE, ECR, and hybrid ECR/RIE etching underscores the fact that this may not always be the case (13). That study points out that the rate and extent of ion bomb a r d m e n t damage plays off against the rate of damage removal by etching. The result is that there can be less residual ion damage with increased ion energy, if ion damage removal by etching dominates with the increasing of ion energy (13). The effects of dry etching ion b o m b a r d m e n t damage are easily seen with the very simple yet very sensitive monitor provided by current-voltage characteristics of metal/ semiconductor contacts made on etched surfaces (6). The data of Fig. 2 give one example for n-type Si. As noted in the first section, the presence of a residue layer can be seen in these data. However, the figure also shows that dry etching exposure (CCIF~rI2RIE) has resulted in a lower barrier height for contacts made on the RIE-treated n-type Si surface. This is seen in the increased reverse current of the contact made to the RIE surface. Figure 5 shows the same barrier lowering p h e n o m e n o n for n-type Si subjected to CCl4 RIE, a chemistry for which residue effects are relatively insignificant (58). This etching was done at a power level of 300W and the pressure, as seen in the figure, was varied between 20 and 100 mtorr. The damage is seen to increase as the pressure during this RIE etching is reduced. Figure 6 shows the use of the I-V characteristics of metal/Si contacts to p-type Si to monitor dry etching damage. Here the pressure was held constant at 100 mtorr of CClgI-Ie while the power was varied from 100 to 600W. I n the case of p-type material the barrier is seen to increase with RIE exposure. I n particular, it increases more with higher power. I n general, it is found that dry etching damage causes metal/silicon contact barrier heights to decrease on n-type Si and increase on p-type Si. It is well documented for PE and RIE that this damage-caused barrier height shift at etched Si surfaces is enhanced with in- J. Electrochem. Soc., Vol. 137, No. 12, D e c e m b e r 1990 9 The Electrochemical Society, Inc. I I 3889 100 --, 600 Watts I 50~ Without RIE I00 4O [ 3O 20 V 600 500 400 I0 I L~IA) 0, -I0 -20 300 -30 -40 -60 200 tO0 Watts Fig. 6. Effect of power during RIE on linear I-V curves for Au/p-Si contacts. Au contact was made after RIE treatment. Gas used was CCI4 + He and x-axis is 0.2V/div. and y-axis is 5 mA/dlv. I -3 1 I ] I I -Z -1 I 2 3 v (~ttsl Fig. 5. Effect of pressure for CCI4 RIE (300W, i-1/2 rain) as seen for linear I-V curves for Au/n-Si contacts. The Au/n-Si contacts were made after RIE. creased power or decreased pressure (57). Increasing power and decreasing pressure in RIE or PE are both well k n o w n to increase the energy of b o m b a r d i n g ions (55, 59). This shift in barrier height (Fermi level position) at a dryetched silicon surface is found to be ubiquitous. It is well k n o w n to occur for ion beam-etched Si (7, 59, 60), plasmaetched silicon (4, 19), reactive-ion-etched silicon (4, 8), and magnetron-reactive-ion-etched silicon (i1). Interestingly, it is also found to occur for argon ion-implanted silicon (61). Because the effect is i n d e p e n d e n t of etching tool and etching chemistry and is present in inert gas ion implantation, where impurity implantation and permeation should be very minimal, this barrier height change effect is attributed to b o n d i n g damage caused by ion b o m b a r d m e n t (4). The threshold energy for this ion bombardment-caused b o n d i n g damage is found to be 30-50 eV in silicon (8). One can see this b o n d i n g damage implied by Fig. 2, 5, and 6 directly in Fig. 7. This figure shows the reflected high-energy electron diffraction (RHEED) signature of an unetched control Si wafer and of a Si wafer given a blanket CC14 etch. This is the same etch used for the data of Fig. 5 and, as noted earlier, this RIE etching chemistry leaves a relatively insignificant residue (58). Hence, the haze of amorphized material and the rings indicative of a polycrystalline Si structure seen in the RHEED pattern of this RIEexposed Si surface can be interpreted as direct evidence of Si b o n d i n g damage (37). Other direct measures of b o n d i n g damage such as electron spin resonance (ESR) (37) and Rutherford backscattering (RBS) (17) have been used to directly ascertain that the b o m b a r d m e n t of dry etching does cause b o n d i n g damage. Techniques, which offer more potential for routine assessment of dry etching damage, have also been examined. These include ellipsometry (23, 24, 36), which has been employed in situ, spectroscopic ellipsometry (34, 62), and the therma-wave technique (52, 63). Some thermawave (TW) data are shown in Fig. 8 as a function of anneal temperature. Here the following designations have been used: RIE heavy--CHFJO2 at 1300W and 20 mtorr, RIE light--CHF3/O2 at 1000W and 600 mtorr, and P E - - C H F J C2F6 at 700W and 550 mtorr (52). As may be seen from these data, reduction of the TW signal (at about 200~176 anneals) does not m e a n the dry etching damage is removed. Indeed, the figure shows the TW signal rises above control at the higher annealing temperatures and finally falls to the control at temperatures -<800~ The effects of anneal- ing on b o n d i n g damage are discussed more fully in the following section. The b o n d i n g damage caused by b o m b a r d m e n t is seen in both silicon and insulators, whereas UV b o n d i n g damage is only seen in insulators. Bonding damage from UV radiation manifests itself in the creation of neutral traps and positive charge in the case of SiO~ (10). Hydrogen-caused b o n d i n g damage has been reported so far only in the case of silicon where it has been observed, using cross-sectional transmission electron microscopy, that hydrogen can permeate Si and produce fissures and "bubbles" as far as 0.5 ~m beneath the surface (55, 56). Of course, hydrogen b o m b a r d m e n t also produces surface b o n d i n g damage and it can cause the same b o n d i n g damage effects seen in Fig. 5 and 6. From the point of view of RHEED, the surface actually appears more damaged when hydrogen is purposefully present in an RIE recipe (18). However, such a surface may appear electrically (through I-V characteristics) to be less damaged when hydrogen is present due to the well-known ability of hydrogen to passivate bonding damage including b o n d i n g damage caused by the hydrogen itself (18, 64). Bonding damage---controL--One obvious solution to the problem of b o n d i n g damage is to eliminate the presence of its causes during dry etching. However, anisotropic etching may require particle energies that are high enough to cause b o n d i n g damage for any dry etching technique. Another solution is to have the etching rate sufficiently high that ion-bombardment-damaged layers are effectively removed by the etching itself. This will necessitate very careful control of physical and chemical effects. If bonding damage does occur, the only recourse is to remove it or to anneal it out. I n the case of Si m a n y of the silicon cleaning procedures listed in Table I are designed to remove at least some of the damaged silicon layer shown schematically in Fig. 1. If annealing is chosen to remove dry etching bonding damage, one has to be careful that the high temperatures involved do not drive in impurities. Consequently, any impurities and residue layers present must be removed before attempts are made to anneal out b o n d i n g damage. Rapid thermal annealing of b o n d i n g damage has been shown to be effective, for example, if it is utilized after residue and impurity removal (38). I n general, relatively high temperatures are required for dry etching damage removal. Using Schottky barrier structures as a monitor it has been found that furnace anneals as high as 800~ or more (for 30 min) can be required to return a dry-etched surface to its original electrical properties (26). This can be seen in the data of Fig. 9 which give the reverse currents (at 1.5V) for Schottky diodes fabricated on Ar ion beam-etched p-type silicon. The control line is for Schottky diodes made on wet-etched Si subjected to the same anneals; the Ar-etched data are for J. Electrochem. Sac., 3890 Vol. 137, No. 12, December 1990 9 The Electrochemical S o c i e t y , Inc. Fig. 7. RH EED pattern for < 100> pSi (a, left) offer only wet chemical etching, and (b, right) after CCI4 reactive ion etching. As may be seen, the pattern of (b) is far different from the streaks and Kikuchi lines of the clean, smooth (100) Si surface pattern of (a). Schottky diodes made on Ar dry-etched Si after the various (30 min) anneals indicated. Similar results are seen for PE- and RIE-exposed Si (50, 52). I n particular, the thermawave data of Fig. 8 are for PE- and RIE-etched p-Si and it can be seen that they also show that anneals at -800~ are needed for full recovery. It is interesting to note that the bonding damage created by the b o m b a r d m e n t of dry etching can have advantageous effects, if understood and utilized (26). As ar~ example, Fig. 10 shows the diffusion length measured in the p-Si samples of Fig. 9 by the surface photovoltage technique. These SPV diffusion length data are presented as a function of the anneal temperature used after the Ar dry etching. The diffusion length enh a n c e m e n t seen in the Ar-bombarded samples relative to the control (wet-etched) for anneals in the 600~176 range is believed to be due to gettering by the dry etching damage (26). On the other hand, this gettering by dry etching damage can also be disadvantageous. For example, deleterious gettering caused by dry etching b o n d i n g damage has been reported in cases of trench etching (54). Charge buildup damage--the effect, its detection, and repercussions.--There is an additional type of damage, charge buildup damage, that can occur in dry etching. Its origins lie in the fact that charge buildup can occur at dielectric/conductor interfaces as a result of exposure to dry etching. The presence of this charge can lead to insulator breakdown or to increased leakage current (5, 65). These damage effects are believed to occur when this charge at a ~ dielectric/conductor interface becomes isolated from potentially neutralizing charge in the plasma, due to turningoff of the etching plasma, or from potentially neutralizing charge in the substrate, due to isolation of the conductor by etching, and a transient discharge occurs across the insulator (5, 65). Charge buildup damage is readily apparent in changes in breakdown in dielectrics and in changes in leakage currents. Charge buildup damage--control.--Attempts at controlling charge buildup damage focus on avoiding transients and on trying to provide charge that can readily reach and neutralize the stored charge at dielectric/conductor interfaces (5, 65). An example can be found in recent work which has shown that charge buildup damage effects may be less severe in hybrid ECR/RIE etching than in RIE (65). This is proposed to occur basically because the self-biasing voltages and, therefore, the stored charges, involved in ECR plasmas themselves are relatively small. Hence, if the higher voltage RF substrate biasing (using to obtain the ion energies needed for anisotropic etching in hybrid ECR/ RIE etching) is turned off before t u r n i n g off the ECR plasma, the result can be substantially reduced charge buildup damage. This reduced level of damage is believed to occur because the ECR plasma provides the charge needed to neutralize the stored charge built-up by the voltages of the RF bias used during etching while the ECR plasma itself results in little charge buildup (65). In addition, it was demonstrated that this reduced level of damage that is found to be present in this approach can be annealed out with a 450~ anneal. RJE HE.~VY EPI 10-31 508 " PE EPI ' 9 RIE LIGHT EP[ 400 9 10 -4. E control line 300 " ,. 200 10-5. t~ g 100 10.6" .-I 2;0 ,;o ,;o ---"-EP--- 8;~ 10 -7 0 TEMPERATURE Fig. 8. Therma-wave signal as a function of annealing temperature for high temperature (30 rain) isochronal anneals of epitaxial silicon subjected to the RIE heavy damage case, RIE light damage case, and PE heavydamage case etches. 400eV J 9 9 ~ 9 200 400 Ar bombardment 9 i 600 9 = 800 ,' 1000 Temperature (~ Fig. 9. Leakage current of Schottky barriers mode on Ar IBE p-type and on wet-etched controls as a function of anneal prior to metalli- zation. J. Electrochem. Soc., Vol. 137, No. 12, December 1990 9 The Electrochemical Society, Inc. 300 200 ,5 o: '~ 1 O0 -----0--9 0 400ev Argon Bombardment 9 0 Controls i 200 ~ 400 9 ~ S00 - 9 800 1000 Temperelure (~ Fig. 10. Diffusion length as measured by SPV for the materials in Fig. 9. Diffusion length was measured after the anneals indicated. Summary Dry etching is an e x t r e m e l y important technique for pattern transfer in t h e fabrication of microelectronic circuits. It can, however, affect the materials being etched as well as subsequent processing and ultimately, device performance. The detrimental effects of dry etching include residue layers, i m p u r i t y and hydrogen permeation layers, and b o n d i n g d a m a g e layers, as well as surface roughening effects and charge b u i l d u p damage. Acknowledgments The research reported in this article that was u n d e r t a k e n at the Center for Electronic Materials and Processing at P e n n State was s u p p o r t e d b y the National Science Foundation, IBM, and Intel Corporation. The author wishes to thank Dr. X.-C. Mu of Intel for his efforts in proofreading and Ms. F a w n Houtz for her efforts in preparing the manuscript. Manuscript received Dec. 8, 1989; revised manuscript received J u l y 10, 1990. This was P a p e r 243 presented at the Hollywood, FL, Meeting of the Society, Oct. 15-20, 1989. The Pennsylvania State University assisted in meeting the publication costs of this article. REFERENCES 1. L. M. Ephrath, IEEE Trans. Electron Devices, ED-28, 1315 (1981). 2. L. M. E p h r a t h and R. S. Bennett, This Journal, 129, 1822 (1982). 3. S. Pang, Solid State Technol., 27, 249 (1984). 4. S. J. Fonash, ibid., 28, 201 (1985). 5. T. Wantanabe and Y. Yoshida, ibid., 27, 263 (1984). 6. S. Ashok, S. J. Fonash, and R. Singh, Appl. Phys. Lett,, 39, 423 (1981). 7. R. Singh, S. J. Fonash, S. Ashok, P. J. Caplan, J. Shappirio, W. Hage-Ali, and J. Ponpon, J. Vac. Sci. Technol., A1, 334 (1983). 8. S. Ashok, P. Chow, and B. J. Baliga, Appl. Phys. Lett., 42, 687 (1983). 9. F. Ohira, This Journal, 130, 1201 (1983). i0. L.M. Ephrath and D. J. DiMaria, Solid State Technol., 24, 183 (1981). Ii. T. Kuroda and H. Iwakuro, Jpn. J. Appl. Phys., 29, 923 (1990). 12. J. P. Gambino, C. C. Parks, G. S. Oehrlein, and M. A. Jaso, Abstract 205, p. 304,The Electrochemical Society Extended Abstracts, Vol. 89-1, Los Angeles, CA, May 7-12, 1989. 13. A. S. Yapsir, G. Fortufio-Wiltshire, J.P. Gambino, R. H. Kastl, and C. C. Parks, J. Vac. Sci. Technol., A8, 2939 (1990). 14. A. S. Yapsir, G. S. Oehrlein, G. Fortufio-Wiltshire, and J. C. Tsang, Appl. Phys. Lett., In press. 15. J.W. Coburn, " P l a s m a Etching and Reactive Ion Etching," American V a c u u m Society Monograph Series, New York (1982). 16. J. L. Vossen, J. H. Thomas III, J. S. Maa, O. R. Mesker, and G.O. Fowler, J. Vac. Sci. Technol., A1, 1452 (1983). 3891 17. G. S. Oehrlein, R. M. Tromp, Y. H. Lee, and E. J. Petrillo, Appl. Phys. Lett., 45, 420 (1984). 18. X.-C. Mu, S. J. Fonash, A. Rohatgi, and J. Rieger, ibid., 48, 28 (1986). 19. F. K. Moghadam and X.-C. Mu, IEEE Trans. Electron Dev., 36, 1602(1989). 20. X.-C.Mu, S. J. Fonash, and R. Singh, Appl. Phys. Lett., 49, 67 (1986). 21. S. J. Jeng and G. S. Oehrlein, ibid., 50, 1912(1987). 22. J. M. Heddleson, M. W. Horn, and S. J. Fonash, J. Vac. Sci. Technol., B6, 280 (1988). 23. D. J. Thomas, P. Southworth, M. C. Flowers, and R. Greef, ibid., BT, 1325(1989). 24. D. J. Thomas, P. Southworth, M. C. Flowers, and R. Greef, ibid., BS, 516 (1990). 25. F. J. Montll]o, R. G. Frieser, and W. K. Chu, Abstract 279, p. 681, The Electrochemical Society Extended Abstracts, Vol. 81-2, Denver, CO, Oct. 11-16, 1981. 26. R. Herlocher Ill and S. J. Fonash, in "Plasma Processing," PV 90-14, G. S. Mathad and D.W. Hess, Editors, p. 304, The Electrochemical Society Softbound Proceedings Series, Pennington, NJ (1990). 27. A. Climent and S. J. Fonash, J. Appl. Phys., 56, 1063 (1984). 28. S. W. Pang, D. D. Rathman, D. J. Silversmith, R.W. Mountain, and P. D. DeGraff, Appl. Phys. Lett., 54, 3272 (1983). 29. J. W. Coburn and H. F. Winters, J. Vac. Sci. Technol., 16, 391 (1979). 30. J. H. Thomas III, X,-C. Mu, and S. J. Fonash, This Journal, 134, 3122 (1987). 31. G. S. Oehrlein, S. W. Robey, J. L. Lindstrom, K . K . Chan, M . A . Jaso, and G . J . Scflla, ibid., 136, 2050 (1989). 32. C. G. Tuppen, R. Heckingbotton, M. Gill, C. Heslop, and G. J. Davies, Surf. Int. Anal., 6, 267 (1984). 33. K. Suzuki, K. Ninomiya, and S. Nishimatsu, Vacuum, 34, 953 (1984). 34. X.-C. Mu, S. J. Fonash, B. Y. Yang, K. Vedam, A. Rohatgi, and J. Reiger, J. Appl. Phys., 58, 4282 (1985). 35. X.-C. Mu, S. J. Fonash, G.S. Oehrlein, S.N. Chakravarti, C. Parks, and J. Keller, ibid., 59, 2958 (1986). 36. J. L. Buckner, D. J. Vitkavage, and E. A. Irene, ibid., 63, 5288(1988). 37. S. J. Fonash, R. Singh, A. Rohatgi, P. Rai-Choudhury, P . J . Caplan, and E . H . Poindexter, ibid., 58, 862 (1985). 38. S. J. Fonash, Y~-C. Mu, S. Chakravarti, and L. C. Rathbun, This Journal, 135, 1037 (1988). 39. J. P. Simko, G. S. Oehrlein, and T. M. Mayer, ibid., To be published. 40. J. Ruzyllo, G. T. Duranko, J. T. Kennedy, and C. G. Pantano, in " U L S I Science and Technology/1987," PV 87-11, S. Broydo and C.M. Osburn, Editors, p. 281, The Electrochemical Society Softbound Proceedings Series, Pennington, NJ (1987). 41. T. Hosoya, Y. Ozaki, and K. Kirata, This Journal, 132, 2436 (1985). 42. M. O. Watanabe, M. Taguchi, K. Kanzaki, and Y: Zohta, Jpn. J. Appl. Phys., 22, 281 (1983). 43. M. Matsumoto and T. Sugano, This Journal, 129, 2823 (1982). 44. J. P. Gambino, G. S. Oehrlein, C. C. Parks, and J. F. Shepard, in "Microcontamination Conference Proceedings," p. 51, Canon Publications, Inc., Santa Monica, CA (1987). 45. J. P. Gambino, M. D. Monkowski, J. F. Shepard, and C. C. Parks, This Journal, 137,976 (1990). 46. D. F r y s t a k and J. R. Ruzyllo, in " P l a s m a Processing," PV 88-22, G. S. Mathad, G.C. Schwartz, and D.W. Hess, Editors, p. 125, The Electrochemical Society Softbound Proceedings Series, Pennington, NJ (1988). 47. S. T. Pantelides, Materials Science Forum, 11-12, 573 (1986). 48. S. J. Pearton, J. W. Corbett, and T. S. Shi, Appl. Phys., A43, 153 (1987). 49. M. W. Horn, J. M. Heddleson, and S. J. Fonash, Appl. Phys. Lett., 51, 490 (1987). 50. J. M. Heddleson, M. W. Horn, and S. J. Fonash, This Journal, 137, 1960 (1990). 51. A. J. Tavendale, S. J. Pearton, and A.A. Williams, Appl. Phys. Lett., 56, 949 (1990). 52. M.W. Horn, Ph.D. Thesis, The Pennsylvania State University, University Park, P A (1989). 3892 J. Electrochem. Soc., Vol. 137, No. 12, December 1990 9 The Electrochemical Society, Inc. 53. J. M. Heddleson, M. W. Horn, and S. J. Fonash, "Semiconductor Fabrication: Technology and Metrology," ASTM STP 990, Dinesh C. Gupta, Editor, American Society for Testing and Materials, Philadelphia, PA (1989). 54. K. Skidmore, Semicond. Int., J u n e (1989). 55. N. M. Johnson, D. K. Biegelson, and M.D. Moyer, Phys. Rev., B31, 5525 (1985). 56. S. J. Jeng, G. S. Oehrlein, and G. J. Scilla, Mater. Res. Soc. Symp. Proc., 104, 247 (1987). 57. A. Rohatgi, M. R. Chin, P. Rai-Choudhury, P. Lester, R. Singh, and S. J. Fonash, Abstract 320, p. 508, The Electrochemical Society Extended Abstracts, Washington, DC, Oct. 9-14, 1983. 58. A. Rohatgi, P. Rai-Choudhury, S. J. Fonash, P. Lester, R. Singh, P . J . Caplan, and E.H. Poindexter, This Journal, 133, 408 (1986). 59. S. J. Fonash, S. Ashok, and R. Singh, Appl. Phys. Lett., 39, 423 (1981). 60. R. Singh, S. J. Fonash, P. J. Caplan, and E. H. Poindexter, ibid., 43, 502 (1983). 61. S. Ashok and A. Mogro-Campero, IEEE Electron Device Lett., EDL-5, 48 (1984). 62. F. Ohira, This Journal, 130, 1201 (1983). 63. P. Garoghty and W. L. Smith, Mater. Res. Soc. Symp. Proc., 68, 387 (1986). 64. J. W. Corbett, T.C. Covelti, V. Desnica, and L.C. Snyder, in "Microscopic Identification of Electronic Defects in Semiconductors," N. Johnson, S. Bishop, and G. D. Wadkins, Editors, Materials Research Society, Pittsburg, PA (1985). 65. S. Samukawa, Abstract 167, p. 238, The Electrochemical Society Extended Abstracts, Los Angeles, CA, May 7-12, 1989. Dry Etching of GaAs, AIGaAs, and GaSb in Hydrochlorofluorocarbon Mixtures S. J. Pearton,* W. S. Hobson, U. K. Chakrabarti,* G. E. Derkits, Jr.,* and A. P. Kinsella AT&T Bell Laboratories, Murray Hill, New Jersey 07974 ABSTRACT Reactive ion etching (RIE) of GaAs, AIGaAs, and GaSb in the hydrochlorofluorocarbons CHC12F and CHC1F2 has been investigated as a function of etch time, discharge power density, pressure, and additive gas (Q~ or H~). There is no incubation time required for the c o m m e n c e m e n t of etching, and the etch rates are in the range 200 A - m i n - 1 (for A10.3Ga0.TAs)to 1000 A - m i n - 1 (for GaAs) for moderate power densities (0.56 W- cm- 2 ). The etched surfaces have smooth morphologies for all three materials, and there is no significant lattice disorder introduced into GaAs, as detected by photoluminescence and diode current-voltage measurements, provided the discharge power densities are kept below -0.7 W 9cm -2. Hydrogen passivation of the Si dopants in n-type GalAs is detected for both gases, but is more prevalent with CHC1F2. Thin (-< 40/~) surface residue layers of C1 [comprising 5-9 atom percent (a/o)] and F (0.9-3 a/o) for GaAs and GaSb, and 23 a/o for A1GaAs) are found on all samples after RIE, but these can be removed by simple solvent cleaning. The dry etching of Ga-based III-V semiconductors generally utilizes chlorine-containing gas mixtures because of the high volatitities of the resulting etch products (1). Dichlorodifluoromethane (CC12F2, better k n o w n as Freon12 or Halocarbon-12) represents a particularly useful dryetching gas for GaAs, AlGaAs, and other compound semiconductors, because of its nonflammable, noncorrosive, and relatively nontoxic nature relative to pure C12 or SIC14 (2-6). A further advantage is that it contains fluorine, which provides a natural etch stop in removal of GaAs overlayers from A1GaAs, due to the formation of the nonvolatile species A1F~ (7-10). Since the first demonstrations of dry etching of GaAs with CC12F2 mixtures, this gas has become accepted as the most widely used for this purpose (2). However, chlorofluorocarbons (CFCs) are now identified as among the most potent ozone-destructive chemicals, and, to protect the environment, both the manufacturers and users of CFCs have agreed to reduce the production, sales, and emissions of these gases drastically by 1994 and to abolish them by the year 2000 (11). This is, ruefully, a severe problem for those who use conventional CFCs in dry etch processes, because the a m o u n t of these gases released into the atmosphere from etching is vanishingly small compared to the world-wide use for other purposes. For example, in 1988, 0.75 billion pounds of CFCs were used as refrigerants, 0.48 billion pounds as propellants in aerosol cans, 0.48 billion pounds for cleaning purposes and 0.73 billion pounds as a foaming agent (12). A total of 0.10 billion pounds of CFCs were used for other purposes, but the contribution to this from dry etch processes was insignificant. However, a complete halt to the use of all Freon-12, carbon tetrachloride, methyl chloroform, and so on, m u s t be planned for. * Electrochemical Society Active Member. The best available replacement for conventional CFCs are the so-called hydrochlorofluorocarbons or HCFCs. This is controversial i n some quarters because such gases also contain chlorine and as such still constitute an ozonedepleting chemical. The hydrochlorofluorocarbons, however, do represent a significant improvement over conventional CFCs because they are estimated to have an order of magnitude lower life time in the atmosphere and an equivalently lower ozone-depletion potential (11). Even so, there are moves to phase out HCFCs as well (the date for a complete b a n ranges from 2010 to 2050, depending on the advocate). While a completely chlorine-free dry etch chemistry for III-V materials based on C~/H2 does exist (13-17), the etch rates for GaAs and AIGaAs are very small under low self-bias conditions, and it seems to make sense to explore reactive ion etching (RIE) of these materials using hydrochlorofluorocarbons to determine if these gases give suitable etching characteristics. In this paper, we report the use of chlorodifluoromethane (CHCIF2, Freon 22) and dichlorofluoromethane (CHC12F, Freon 21) for RIE of GaAs, A1GaAs, and GaSb. It is of particular interest to investigate the etching characteristics of these gases, since they contain both CH and C1 units, and it is not clear whether they will behave like C~2or CC12Frbased mixtures. We have investigated the dependence of the etch rate on time, discharge composition (relative to 02 or H2 diluent gases), power density, and pressure. The surface morphologies of the etched features were examined by scanning electron microscopy (SEM), the introduction of near-surface lattice disorder monitored by photoluminescence (PL), capacitancevoltage (C-V) and current-voltage (I-V) measurements, and the surface chemistry after etching obtained from electron spectroscopy for chemical analysis (ESCA) and Auger electron spectroscopy (AES) data. We conclude that