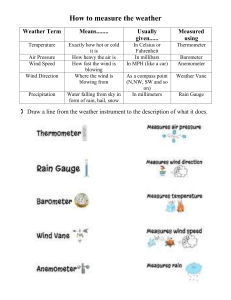

METHOD STATEMENT OF AIR BLOWING / WATER FLUSHING OF PIPES UNIT 129 SHUAIBA REFINERY O2 28-02-2018 Issued for Approval VB VB MA O1 03-02-2018 Issued for Approval PAM PAM MA Rev. Date Description Originator Checked By Approved By Kuwait National Petroleum Company (K.S.C.) Clean Fuels Project Kuwait Petrofac / Samsung / CB&I PSCJ Job No. JI-2025 Consolidated Contractors Co. (Kuwait) W.L.L Subcontract No.: JI-2025/03-001 Subcontractor Doc. No MS-1146-570 CONTRACT NO. CONTRACTOR JOB NO. DOCUMENT NO. REV CFP/EPC/0054-MAB1 JI-2025 P6003SHU-000-51-1-M454 O1 Kuwait National Petroleum Company (K.S.C) Clean Fuels Project KNPC Contract No. CFP/EPC/0054-MAB1 PSCJ Job No. JI-2025 METHOD STATEMENT OF AIR BLOWING / WATER FLUSHING OF PIPES UNIT 129 Record of Revisions Rev. No. Page/Section Description O1 - Issued for Approval O2 - Issued for Approval List of Holds Page/Section MS-1146-570 Description P6003SHU-000-51-1-M454 REV. O2, 28-Feb-2018 Page 2 of 19 Kuwait National Petroleum Company (K.S.C) Clean Fuels Project KNPC Contract No. CFP/EPC/0054-MAB1 PSCJ Job No. JI-2025 METHOD STATEMENT OF AIR BLOWING / WATER FLUSHING OF PIPES UNIT 129 P6003SHU-000-51-1-M454 REV. O2, 28-Feb-2018 Page 3 of 19 Contents 1. SCOPE 4 2. PURPOSE 4 3. REFERENCE DOCUMENTS 4 4. DEFINITIONS 5 5. ABBREVIATIONS 6 6. RESPONSIBILITIES 7 7. WORK PERMIT 8 8. TOOLS & EQUIPMENTS 8 9. PRE-REQUISITES 9 10. HEALTH, SAFETY, AND ENVIRONMENT 9 11. METHODOLOGY 11 12. INSPECTION & ACCEPTANCE 18 13. ATTACHMENTS 19 MS-1146-570 Kuwait National Petroleum Company (K.S.C) Clean Fuels Project KNPC Contract No. CFP/EPC/0054-MAB1 PSCJ Job No. JI-2025 METHOD STATEMENT OF AIR BLOWING / WATER FLUSHING OF PIPES UNIT 129 P6003SHU-000-51-1-M454 REV. O2, 28-Feb-2018 Page 4 of 19 1. SCOPE This method statement covers general requirement and guidelines for the air blowing / water flushing of pipes for unit 129 by oil free compressed dry air to ensure the system is clean and free of debris in line with project requirements. 2. PURPOSE The purpose of this method statement is to provide the detailed methodology regarding the air blowing / water flushing activities. The work steps are analysed, all hazards identified, and the necessary safety mitigations are defined so that the air blowing activities can be executed in a safe and efficient manner. 3. REFERENCE DOCUMENTS Shell DEP 31.40.50.30 Pre-Commissioning of Pipelines Shell DEP 74.00.10.10 Shop and Field Pressure Testing of Piping Systems Shell DEP 70.10.80.11 (Section 5.6.4) Cleaning of Equipment Section 4/Exhibit H/Sub Part 9 Mechanical Completion / Pre-Commissioning/Attachment H-9.2 Commissioning Responsibility Matrix KEPA Regulations Kuwait Environmental Public Authority Regulations P6012MAB.000.10.10.033 Permit to Work Procedures P6012MAB.000.10.10.002 Environmental Management Plan HSE-ENGE-16-1413 Procedure on Environment & Social Assessment P6012MAB.000.10.52.018 Pre – Commissioning Execution Plan ITR – P – 0002B Piping Cleaning and Blowing Report ITR – P – 0003B Piping Chemical Cleaning Report MS-1146-570 Kuwait National Petroleum Company (K.S.C) Clean Fuels Project KNPC Contract No. CFP/EPC/0054-MAB1 PSCJ Job No. JI-2025 METHOD STATEMENT OF AIR BLOWING / WATER FLUSHING OF PIPES UNIT 129 P6003SHU-000-51-1-M454 REV. O2, 28-Feb-2018 Page 5 of 19 ITR – P – 0005B System Leak Test P6012MAB.000.10.10.003 Waste Management Plan SHE –ESHU-03-1406 Procedure for Solid Waste Management P6012MAB.000.10.10.001 HSSE Plan HSE-TSSA-05-1118 HSE Guidelines for Contractor NoHSE-TSSA-12-1133 Safety Guidelines on Pressure Testing HSE-TSSA-06-2029 SWP Work Permit System & Risk Assessment P6012MAB.000.10.52.014 Procedure for Preservation of Project Equipment and Material P6012MAB.000.10.52.002 Pipe Cleaning Procedure P6012MAB-000-51-1-M423 Method Statement of Air Blowing For Pipelines 4. DEFINITIONS Company Kuwait National Petroleum Company (K.S.C) (KNPC) Project Mina Abdullah Refinery- Package 1 /Clean Fuels Project (CFP) Country Kuwait Company Project Number CFP/EPC/0054/MAB-1 Subcontract Number PSCJ Job No. JI-2025 Contractor Joint venture of Petrofac International LTD, Samsung Engineering Co. LTD and CB&I Nederland B.V. (PSCJ) MS-1146-570 Kuwait National Petroleum Company (K.S.C) Clean Fuels Project KNPC Contract No. CFP/EPC/0054-MAB1 PSCJ Job No. JI-2025 CMEI Sub-contractor METHOD STATEMENT OF AIR BLOWING / WATER FLUSHING OF PIPES UNIT 129 P6003SHU-000-51-1-M454 REV. O2, 28-Feb-2018 Page 6 of 19 Consolidated Contractors Co. (Kuwait) W.L.L ( CCC ) 5. ABBREVIATIONS QCP Quality control procedure HSE Health, Safety and Environment. SOW Scope of work TPA Third Party Agency. QA/QC Quantity Analysis - Quality Control RA Risk Assessment ITP Inspection and Test Plan. ECPW Electronic-Consolidated Permit to Work TBT Toolbox Talk EPIC Engineering, Procurement, Installation & Commissioning MS Method Statement PPE Personal Protection Equipment PEFS Process Engineering Flow Scheme ITR Inspection and Test Record AG Above Ground MS-1146-570 Kuwait National Petroleum Company (K.S.C) Clean Fuels Project KNPC Contract No. CFP/EPC/0054-MAB1 PSCJ Job No. JI-2025 METHOD STATEMENT OF AIR BLOWING / WATER FLUSHING OF PIPES UNIT 129 P6003SHU-000-51-1-M454 REV. O2, 28-Feb-2018 Page 7 of 19 6. RESPONSIBILITIES • Pre-Commissioning Manager − Organises resources to perform the air blowing for AG pipes at site as per project specifications. − Ensures the activities are executed according to the relevant project specifications and complies with the quality, schedule, & safety requirements. − Ensures all equipment that require calibration have valid calibration certificates. − Ensures that approved quality procedures and method statements are being followed. − Ensures that technicians are qualified /trained to perform the activities. − Responsible for the safe execution & compliance of this work method statement and implement safety officer’s site intervention concerns. • Pre-Commissioning Engineer / Supervisor − Liaises with Company/Contractor to ensure all necessary permits are obtained. − Ensures all safety mitigations are in place including barricading and signage to alert personnel of the work activity and hazards in the area. − Arranges the required resources to execute the work. − Attends risk assessment meetings and implements the recommendations from the Risk Assessment. − Controls productivity and quality of work. − Ensures the applicable ITR’s are signed. − Responsible for the safe execution & compliance of this work method statement and implement safety officer’s site intervention concerns. • QA/QC Manager − Ensures the relevant project specifications and complies with the quality requirements. − Ensures all equipment that require calibration have valid calibration certificates. − Ensures that approved quality procedures are being followed. MS-1146-570 Kuwait National Petroleum Company (K.S.C) Clean Fuels Project KNPC Contract No. CFP/EPC/0054-MAB1 PSCJ Job No. JI-2025 • − METHOD STATEMENT OF AIR BLOWING / WATER FLUSHING OF PIPES UNIT 129 P6003SHU-000-51-1-M454 REV. O2, 28-Feb-2018 Page 8 of 19 QA/QC Engineer / Supervisor Ensures the activities are executed according to the relevant project specifications and complies with the quality requirements. − Ensures all equipment that require calibration have valid calibration certificates. − Controls productivity and quality of work. − Ensures the applicable ITR’s are signed − Ensures that approved quality procedures are being followed. − Monitors activities to safety with the authority to stop work and withdraw permit if safety is compromised. • Safety Officer − Responsible for the safe execution of the above activities in strict compliance with HSE plan. − Notifies the appropriate supervision or management of observed deviations. − Monitors all activities related to safety with the authority to stop work and withdraw the Work Permit. − Coordinates all safety related issues with Contractor safety officer. • PTW Executer − The work permit executor shall make all preparations and barricade the area to prevent unauthorized personnel. Shall be always present at site and ensure safe execution of work as per method statement and risk assessment. − He shall carry out tool box talk and explain all the hazards and controls to all work men prior to starting of work. 7. WORK PERMIT All permits related to the job shall be obtained prior to the execution of the job and copy available at work site. 8. TOOLS & EQUIPMENTS All tools and equipment shall be fit for purpose and shall be certified with KNPC safety certificate or by KNPC approved 3rd party or, to include but not limited to: MS-1146-570 Kuwait National Petroleum Company (K.S.C) Clean Fuels Project KNPC Contract No. CFP/EPC/0054-MAB1 PSCJ Job No. JI-2025 METHOD STATEMENT OF AIR BLOWING / WATER FLUSHING OF PIPES UNIT 129 P6003SHU-000-51-1-M454 REV. O2, 28-Feb-2018 Page 9 of 19 − Hoses with approved fittings (2”)-Certified hoses with proper fitting shall be used. − All required hand tools like spanners of various sizes etc. − Air Compressor (About 400 / 750 CFM Oil Free compressor with discharge pressure of about 7Bar). − Valves − Warning Tapes and Sign Boards − Torches − Temporary Spools (If required) 9. PRE-REQUISITES Prior to starting the activity, the following activities must be completed: − The system to be cleaned is identified and prepared according to drawing mark-ups and P&IDs as applicable. − All required safety precautions, including barriers, are installed. − All temporary gaskets installed during the operation should be of rated spec for air blowing operation. − Prior to pressurizing /air blowing walk down shall be done to ensure that all systems are ready for use. − Branch piping must be isolated & internals were removed from major equipment’s such as in-line filters, control valves and other instruments to protect them from debris and damage. − Vent pipe shall be routed to the area away from the roads/access/community. − Ensure approved Work Permit Risk Assessment in place. 10.HEALTH, SAFETY, AND ENVIRONMENT 10.1. GENERAL All personnel involved in the execution of the activity shall adhere to the HSE guidelines and work practices in the HSE programs applicable to this project. 10.2. SAFETY INSTRUCTIONS • All personnel involved in the activity will use approved Personal Protective Equipment (PPE) at all times − Coverall / Safety helmet / Safety Glasses MS-1146-570 Kuwait National Petroleum Company (K.S.C) Clean Fuels Project KNPC Contract No. CFP/EPC/0054-MAB1 PSCJ Job No. JI-2025 METHOD STATEMENT OF AIR BLOWING / WATER FLUSHING OF PIPES UNIT 129 P6003SHU-000-51-1-M454 REV. O2, 28-Feb-2018 Page 10 of 19 − H2S Monitor − Safety shoes / Gum Boot − Hand Gloves − Dust mask − Ear Plugs / Ear Muffs • Additional items such as breathing apparatuses will be provided, if required. • The area shall be barricaded and warning signs/notices placed at appropriate locations to identify the cleaning operations area. • All required work permits will be acquired and made available at the respective work sites in the permit boxes. • Nearby personnel will be made aware of the Air Blowing activity by sounding of Air horn before Air blowing. • A plate or obstruction to be provided on the direct hit area of the blowing to prevent projectiles with high velocity flying away outside of the barricaded area • A high standard of housekeeping shall be maintained at all times. • All non-essential personnel shall be requested to leave the area. • Two safety watchmen will be assigned throughout the air blowing period on either side to prevent entry. • All the activities covered in the document shall be performed by qualified & competent personnel. • All material and tools will be removed from the site after the completion of the job. • All electrical tools shall be inspected and colour coded. • Radio / Intrinsic safety Cell Phone communication between personnel will be established at each point of the system to be cleaned. • The workers will be made aware of the safety requirements related to this activity through daily Toolbox Talks (TBT) and by reviewing the related Method Statement (MS) and Risk Assessment (RA). MS-1146-570 Kuwait National Petroleum Company (K.S.C) Clean Fuels Project KNPC Contract No. CFP/EPC/0054-MAB1 PSCJ Job No. JI-2025 METHOD STATEMENT OF AIR BLOWING / WATER FLUSHING OF PIPES UNIT 129 P6003SHU-000-51-1-M454 REV. O2, 28-Feb-2018 Page 11 of 19 10.3. CONFINED SPACE ENTRY • Confined space entry requires a Confined Space Entry Permit. • A confined space must not be entered unless the entrant is trained and qualified for the task. Entrant must present the Confined Space Authorisation Card to the Confined Space Attendant before entry. • Required confined space entry PPE must be worn while inside a confined space as specified on the Work Permit. • Gas tests will be conducted by approved & calibrated gas testing devices and performed by approved users, and will check for the content of: − − Oxygen Combustible and/or toxic gases 10.4. REPORTING OF INCIDENTS Any safety-related incident that occurs will be reported to the discipline and HSE supervisors immediately, and then followed up via the appropriate reporting channels to CONTRACTOR and COMPANY. 10.5. FIRE PREVENTION AND PROTECTION The following shall be adhered to in order to prevent fire hazards: − Fire extinguishers shall be available in all working areas. Fire extinguishers shall be inspected monthly and refilled and repaired as required. − Smoking is prohibited except at designated locations. − All fires will be reported, regardless of their scale, to the supervisors for action. − All vehicles/equipment shall be provided with portable fire extinguishers. − Proper earthing procedures shall be followed for all types of generators, compressors, etc. 11.METHODOLOGY 11.1. AIR BLOWING Air blowing will be applied to the pipelines as per approved pipe flushing plan. Air blowing can be carried out with the following methods: MS-1146-570 Kuwait National Petroleum Company (K.S.C) Clean Fuels Project KNPC Contract No. CFP/EPC/0054-MAB1 PSCJ Job No. JI-2025 • Continuous Air Blowing (Direct Blowing) • Quick Depressurization METHOD STATEMENT OF AIR BLOWING / WATER FLUSHING OF PIPES UNIT 129 − Air Accumulation Method − Cardboard Blasting Method (Disc Rupturing) P6003SHU-000-51-1-M454 REV. O2, 28-Feb-2018 Page 12 of 19 Selection of air blowing will be according to below table: Pipe Size Continuous Air Quick Rupture Disc Water Flushing Blowing Decompression (Film) < 2 Inch Dia √ - - - < 6 Inch Dia - √ - √ < 10 Inch Dia - √ √ - < 30 Inch Dia - - √ - 11.2. WATER FLUSHING Water flushing shall be applied as per approved pipe flushing plan. During cleaning operation, the water velocity shall meet the requirement of the cleaning procedure being followed. A high velocity flow, in the order of 3-4 m/s should be achieved in order to be effective. The water flushing will be preferably be carried out after pressure test, the flushing will remove loose foreign matter and debris from inside of the line and will continue until the line is proven clean, this will prevent equipment problems during commissioning and start-up such as line blockage and /or damage to sensitive components such as orifice plates, compressors, pump impellers, valve seats etc Brief flushing plan for Unit 129 attached MS-1146-570 UNIT WATER FLUSHING / AIR BLOWING PLAN BY SYSTEM AND SUBSYSTEM System No. System Description Sub-System No. Sub-System Description Max Size, mm Water Flushing Air/Steam Blowing Air Steam 02-129-01-U501 U-129 Air compressor / Plant Air Modification 02-129-01-U501-01 Unit 129 Instrument Air compressor Modification Package A 150 - X - 02-129-01-U501 U-129 Air compressor / Plant Air Modification 02-129-01-U501-02 Unit 129 Instrument Air compressor Modification Package B 150 - X - 02-129-01-U501 U-129 Air compressor / Plant Air Modification Fuel 02-129-01-U501-03 Unit 129 Instrument Air Receiver 80 - X - 02-129-01-U501 U-129 Air compressor / Plant Air Modification 02-129-01-U501-04 Unit 129 Instrument Air Distribution Header 80 - X - 02-129-01-U501 U-129 Air compressor / Plant Air Modification 02-129-01-U501-05 Unit 129 Plant Air Compressor Modification Package 150 - X - 02-129-01-U501 U-129 Air compressor / Plant Air Modification 02-129-01-U501-06 Unit 129 Plant Air Distribution Header 100 - X - 02-129-01-U802 U-129 OWS Collection 02-129-01-U802-01 U-129 OWS Collection Header 100 X - - Remarks 11.3. PREPARATION • Air blowing route shall be identified and shown on a marked up P&ID or other drawings as applicable. • The following items shall be indicated as minimum. − Air supply and air blow off points − Major Valve positions − Temporary hoses, valves, blinds, spools and lead pipes − Hoses quality and test certificates to be checked. • Check sheet form and air blowing record sheets are ready. • Pressure gauge will be provided at compressor discharge point and air inlet point of pipeline, to monitor the system pressure during blowing. Pressure will be controlled by valve providing (Refer sketch 13.2). • Temporary block valves or quick open block valves. • Temporary and permanent gasket. • The lines connected to each unit not ready for air blowing (still under construction) shall be blinded until release for ready to air blow. They will be indicated and numbered. Installation and removal of blinds will be controlled by means of blind list. • The following are considered as fragile devices and will be removed from the system. − Control valves − Check valves − Safety valves − Thermo wells − Orifice Plates − Pitot Tube Flow Meters − Venturies − Rotameters − Steam Traps − Internals or filters and strainers • Following items shall be isolated − Process impulse lines for instruments shall be isolated by means of block valve on the impulse pipe itself and whenever possible, shall be disconnected. − Rotating machines such as pumps and compressors. − Static equipment such as columns, drums, and heat exchangers etc. Kuwait National Petroleum Company (K.S.C) Clean Fuels Project KNPC Contract No. CFP/EPC/0054-MAB1 PSCJ Job No. JI-2025 − METHOD STATEMENT OF AIR BLOWING / WATER FLUSHING OF PIPES UNIT 129 P6003SHU-000-51-1-M454 REV. O2, 28-Feb-2018 Page 15 of 19 Special equipment such as De-super heaters, heating coil etc. • Prior to commencement of air blowing, the route and barricade shall be checked. • The point at which pressure is released will be barricaded to keep away personnel from line of fire. • Protect equipment and devices nearby air blow off point. During air blowing operation, large quantity of dirty air will be dispersed near blow off point. This air contains sand, particles of rust etc. and might damage or contaminate the devices or equipment. To prevent from damaging or contamination of equipment, following measures will be considered if necessary. To cover motors and instruments near air flow outlet with appropriate materials as applicable. To direct the outlet flow using elbow or temporary piping to extent the outlet further towards a safe location. • Ensure all the safety measures are installed such as barricades to control and minimise the personnel in area. Area will be barricaded around the inlet and blowout point. • All personnel to wear ear protection. • Safety boards shall be installed to warn personnel of the hazard (e.g. Danger / Waring – PreCommissioning activities in Progress) • Establish Radio / Cell phone connection between personnel involved in the activity. • Ensure all witnessing and approval signatories are aware of the activity and have confirmed availability to complete their responsibilities. 11.4. OPERATION Once all preparation work completed, pre-commissioning supervisor shall inspect the site and check that all protections are installed properly. Pipe restraints, clamps, supports, protection of equipment in the vicinity of air outlet. 11.4.1. CONTINUOUS AIR BLOWING METHOD Air from the compressor can be directly fed into the system which is to be cleaned. Check and confirm compressor instrumentation is working properly. Safety valves are calibrated conduct initial start-up checks and log observations. Ensure earthing for the compressor. MS-1146-570 Kuwait National Petroleum Company (K.S.C) Clean Fuels Project KNPC Contract No. CFP/EPC/0054-MAB1 PSCJ Job No. JI-2025 METHOD STATEMENT OF AIR BLOWING / WATER FLUSHING OF PIPES UNIT 129 P6003SHU-000-51-1-M454 REV. O2, 28-Feb-2018 Page 16 of 19 This continuous blowing method can be employed for smaller diameter pipes depend on compressor availability. If cleaning is not effective then quick decompression by air accumulation method and Valve operations will be employed. • Start the compressor and allow it to run for few minutes to reach stable operation. The operating parameters shall be monitored. Compressor discharge can be lined up to the system. It is important the system is not over pressurised at this stage and the system pressure must be closely monitored. • Check the compressor loading and unloading is ok. • Compressor operator to be standby during the operation. • No refuelling during compressor operation. • Allow the air to flow through the system to clean up. Flow through the system can be controlled by the air inlet valve located at the compressor discharge. • If the air at discharge point is contaminated, increase the air flow by opening the valve more. 11.4.2. • QUICK DE PRESSURIZATION METHOD The quick decompression of the system causes a high velocity of ait inside the pipes. This method facilitated the removal of rust, loose scales in the piping. • The quick decompression method can be achieved either by Air Accumulation method (Valve Operations) or cardboard blasting. • Where the quick decompression method has been selected, the pressure release can be obtained by: − Air accumulation Method (Depends on sacrificial valve size available) This system which is to be cleaned is pressurised with Air. Care is taken to ensure that the system pressure does not exceed the design pressure. The system pressure is continuously monitored by Pressure Gauge and recorded. When the system pressure reaches 1 bar, Valves provided in the system for cleaning are opened to depressurize the system. This is done several times to ensure proper cleaning. If required the system pressure can be increased to a higher pressure e.g. 1.5 Bar or 2.0 Bar provided this is below the design pressure. This operation will preferably be done using a “quick opening valve” after having pressurized the network to the desired level of the pressure. The main header will be cleaned first followed by the branches one by one. MS-1146-570 Kuwait National Petroleum Company (K.S.C) Clean Fuels Project KNPC Contract No. CFP/EPC/0054-MAB1 PSCJ Job No. JI-2025 METHOD STATEMENT OF AIR BLOWING / WATER FLUSHING OF PIPES UNIT 129 P6003SHU-000-51-1-M454 REV. O2, 28-Feb-2018 Page 17 of 19 − Cardboard Blasting Method (Rupturing) − In this method quick decompression valves will be replaced by thin layer of Polythene film. Decompression will start with one layer of film and gradually increased later depending upon the system pressure and cleanliness achieved. Air blowing shall be carried out sequentially i.e. first common header then sub header and finally branch lines as required. • Air supply inlets and blow off points and location shall be identified and marked up in the P&IDs or other drawings as applicable. (Typical Sketch enclosed 12.2) • Large diameter lines shall be cleaned before small diameter ones. • Ensure all pipe supports are competed as applicable. • Air compressor is placed at one end of the line. The hose will be connected to the line through flange connections (anti whip restraints will be used.) • At the other end of pipe flange will be covered with a thin polymer film like LDPE or LLDPE film. • Compressor will be started and air is introduced into the line. The system pressure is closely monitored. The pressure is slowly raised with compressed air through a hose. When the film bursts, the pressure surge carries debris or dirt along with it. • When the film bursts stop the compressor and change the film for another round of blowing. • The pressure at which one layer of film bursts will be recorded by trial runs. The available data shows 0.00120 inch thick film bursts at a pressure of 1.7 psig for a 4” pipe. • If necessary, the film thickness can be gradually increased when higher pressure is needed for blowing. • The air blasting pressure shall never exceed the working pressure of the system and shall never be more than 2 barg. The quick decompression operation is normally carried out less than 2 barg pressure. The pressure will be controlled by valve at compressor discharge point and pressure monitored by pressure gauges provided at compressor discharge point and air inlet point of pipeline (refer sketch 12.2) • This quick decompression method will generate very high air velocity and will be more than 10m/s. • Quick open sacrificial valves will be provided at blowout point for smaller diameter lines. MS-1146-570 Kuwait National Petroleum Company (K.S.C) Clean Fuels Project KNPC Contract No. CFP/EPC/0054-MAB1 PSCJ Job No. JI-2025 METHOD STATEMENT OF AIR BLOWING / WATER FLUSHING OF PIPES UNIT 129 P6003SHU-000-51-1-M454 REV. O2, 28-Feb-2018 Page 18 of 19 12.INSPECTION & ACCEPTANCE • The below method shall use for cleanliness acceptance criteria. − Visual inspection − Inspection by white cloth / Aluminium foil. • Visual inspection Visual inspection is the key to ensure that foreign material is not left in the system. In general for the case of air bowing, a visual inspection, with no contamination visual to the naked eye, is sufficient to call the “System Clean”. In case of any special requirement by vendor for inspection within packages, a baroscopic inspection is to be considered. • Inspection by White Cloth / Aluminium Foil When there is any precision machine at the end of downstream in the blow path and the vendor / company requests, a clean white cloth can be placed in the discharge path to show presence of any debris and contaminants from the piping or the system. • When the portion of system is ready, for Air blowing RFI will raised with mark-ups drawing. • Dew point will be checked –50C Max at pre commissioning level for verification that the line is dried after cleaning. • Reinstatement − Reinstate the lines which were removed for the air blowing if applicable. − Install all the dropped items such as orifice plates, control valves, strainers, relief valves etc. − Use permanent gaskets for reinstatement. • Obtain approval from authorised person (signatories on the ITR who will be witnessing the air blowing) that the line is free of debris and contaminants are complete. • ITR No. P-0002B (refer attachment 13.1) shall be duly filled in and signed off. • Preservation will be done as per project specification. MS-1146-570 Kuwait National Petroleum Company (K.S.C) Clean Fuels Project KNPC Contract No. CFP/EPC/0054-MAB1 PSCJ Job No. JI-2025 13.ATTACHMENTS 13.1. ITR NO. P-002B 13.2. TYPICAL SKETCH FOR AIR BLOWING 13.3. PRECOMMISSIONING MARKUP MS-1146-570 METHOD STATEMENT OF AIR BLOWING / WATER FLUSHING OF PIPES UNIT 129 P6003SHU-000-51-1-M454 REV. O2, 28-Feb-2018 Page 19 of 19