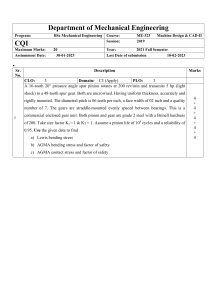

DTS ME 8651-DESIGN OF TRANSMISSION SYSTEMS [III YEAR MECHANICAL]]] Unit-2 Spur gears and parallel axis helical gears Gear terminology – Speed ratios and number of teeth – Force analysis – Tooth stresses – Dynamic effectsFatigue strength – Factor of safety – Gear materials – Module and face width – Power rating calculations based on strength and wear considerationsParallel axis helical gears – Pressure angle in the normal and transverse plane – Equivalent number of teeth – Forces and stresses – Estimating the size of the helical gears – Herringbone gears . Student Name: Roll No: DTS Name of the faculty Department Subject code and subject Title Semester and Branch No. of Periods given in syllabus : : : : : Lesson Plan for Theory Subject K.Vijayarajan Mechanical Engineering ME2352-DESIGN OF TRANSMISSION SYSTEMS III & Mechanical 60hrs UNIT-2 Spur gears and parallel axis helical gears L. No. 1 Topic to be taught 10 Gear terminology – Speed ratios and number of teeth Force analysis – Tooth stresses Dynamic effectsFatigue strength – Factor of safety – Gear materials Module and face width – Power rating calculations based on strength and wear considerationsParallel axis helical gears Module and face width – Power rating calculations based on strength and wear considerationsParallel axis helical gears Tutorial Power rating calculations based on strength and wear considerationsParallel axis helical gears. Power rating calculations based on strength and wear considerationsParallel axis helical gears. Tutorial Pressure angle in the normal and transverse plane – Equivalent number of teeth – Forces and stresses s Estimating the size of the helical gears –. 11 Tutorial 12. Herringbone gears. 2 3 4 5. 6 7. 8 9 Book 1 T (1.1-1.4) T (1.4-1.11) Book 2 NPTEL HAND OUT PAGE NO. 1-2 2-4 T (1.14-1.33) T (1.14-1.33) T (152-180) T (11.1-11.14) T (11.1-11.14) T (11.1-11.14) Text and Reference Books: Book 1.Prabhu. T.J., “Design of Transmission Elements”, Mani Offset, Chennai, 2000, Book 2.Bhandari V.B, “Design of Machine Elements”, Second Edition, Tata McGraw-Hill Book Co, 2007. 4-9 9-10 10-11 12-13 Unit-2 Spur gears and parallel axis helical gears ME8651-DESIGN OF TRANSMISSION SYSTEMS SPUR GEAR In spur gearthe teeth are straight and parallel to the axis of the wheel. The gearing so formed is called spur gearing. They are used to transmit rotary motion between parallel shafts. This gearing may be internal or external. External gears rotate in opposite directions while internal gears rotate in the same direction. Gears may be classified in different manners as given below: 1.Classification based on the relative position of their shaft axes: (i)Parallel shafts Examples: spur and helical gears, rack and pinion, herringbonegears and internalgears. (ii) Intersecting shafts Examples: Bevel gears and spiral gears. (iii) Non-parallel, non-intersecting shafts Examples: Worm, hypoid and spiral gears. 2. Classification based on the relative motion of the shafts: (i) Row gears: In this type, the motion of the shafts relative to each other is fixed. (ii) Planetary and differential gears 5. Classification based on the type of gearing: (i) External gearing (ii) ineternal gearing (iii) Rack and pinion LAW OF GEARING 3. Classification based on peripheral speed (v) : (i) Low velocity gears v < 3 m / s (ii) Medium velocity gears - v = 3 to 15 m / s (iii) High velocity gears v > 15 m / s The law of gearing states that for obtaining a constant velocity ratio, at any instant of teeth the common normal at each point of contact should always pass through a pitch point (fixed point), situated on the line joining the centres of rotation of the pair of mating gears. 4. Classification based on the position of teeth on the wheel: K.Vijayarajan.M.E (i) Straight gears (ii) Helical gears (iii) Herringbone gears (iv) Curved teeth gears Gear Materials ANJALAI AMMAL MAHALINGAM ENGINEERING COLLEGE-KOVILVENNI Page 1 Unit-2 Spur gears and parallel axis helical gears 1. Metallic gears: Steel, cast iron, and bronze. 2. Non-metallic gears; Wood, compressed paper and synthetic resins. Common forms of gear tooth profile 1. Involute tooth profile, 2. Cycloidal tooth profile. What is interference in involute profile? The phenomenon when the tip of tooth on the pinion undercuts the root on its mating gear (i.e., on the wheel) and remove part of the involute profile ME8651-DESIGN OF TRANSMISSION SYSTEMS 7. Addendum circle 8. Addendum: 9. Dedendum circle 10. Dedendum: 11. Clearance: 12. Total depth: 13. Working depth: 14. Tooth thickness: 15. Tooth space: 16. Backlash: 23.Pressure angle 24.Path of contact 25.Length of path of contact 26.Arc of contact 27.Velocity ratio 28.Contact ratio Module Module is the ratio of pitch circle diameter to the number of teeth. Backlash Backlash is the difference between the tooth space and the tooth thickness along the Pitch circle. What factors influence backlash ingear drives? 1. Module: and 2. Pitch line velocity. Why is dedendum value more than addendum value The dedendum value is more than the addendum value to provide necessary clearance between the gears while meshing. In other words, this is to provide necessary clearance between the gears while meshing. of tooth on the wheel is known as interference Pressure Angle Terminology Pressure angle in the angle between the common normal to two gear teeth at the point of contact and the common tangent at the pitch point. The increase of the pressure angle results in a stronger tooth, because the tooth acting as a beam is wider at the base. 1. Pinion: 2. Pitch circle: 3. Pitch circle diameter: 4. Pitch point: 5. Pitch surface: 6. Pitch: K.Vijayarajan.M.E 17. Face width 18.Top land 19.Bottom land 20.Face 21.Flank 22.Fillet WORKING DEPTH OF A GEAR-TOOTH Working depth is the radial distance from the addendum circle to the ANJALAI AMMAL MAHALINGAM ENGINEERING COLLEGE-KOVILVENNI Page 2 Unit-2 Spur gears and parallel axis helical gears clearance circle. It is equal to the sum of the addendum of the two meshing gears. The assumptions made for the above force analysis are: Friction losses in the bearings and gears are negligible. The gears mesh at the pitch circles. The gear teeth have standard involute tooth profiles. The shafts for pinion and gear are parallel. The effect of the dynamic forces is neglected (ii) the components of gear tooth forces. Also draw a free body diagram of gear 2 showing all the forces which act upon it and determine the reaction on the idler gear shaft Given data N1 = 1750 rpm,P =2.5kW=2.5.103,Φ = 20ͦ,m=2.5mm ,Z1=20, Z1=50, Z1=30 The pitch circle diameter of gears 1,2,and 3are given by Pitch circle (pinion) Fr d1=mz1=(2.5).(20)=50mm d2=mz2=(2.5).(50)=125mm d3=mz3=(2.5).(30)=75mm F Ft F ME8651-DESIGN OF TRANSMISSION SYSTEMS considering pinion 1 and gear 2 Ft Fr All three gears have the same pitch line velocity (v). Therefore for pinion 1, the pitch linevelocity is given as Pitch circle (gear) v1 = πD1 N1 60 = π(50 × 10−3 )1750 60 =4.581 m/s t Let the tangential force of pinion 1 on gear 2 is F12 and is given by, Power in kW P =Ft.v Radial component in N Fr= FttanΦ F Resultant Force in (N) F = t P =Ft.v cosΦ Force in (N) F = √Ft2 p v t F12 = = + Fr2 1. A train of spur gears is shown in Fig. (a). Pinion 1 runs at 1750r.p.m. and transmits 2.5 kW power to idle gear 2. The teeth are cut on the 20˚ full-depthsystem and have a module of 2.5 mm. The number of teeth on gears 1,2 and 3 are 20,50and 30 respectively. Calculate: (i) the torque on each gear shaft, and K.Vijayarajan.M.E 2500 4.581 = 545.67N Radial force of pinion 1 on gear 2 is given by r t F12 = F12 × tanΦ = 545.67 × tan20ͦ = 198.61N Resultant force of pinion 1 on gear 2 is given by Ft 545.67 12 F12 = cosΦ = cos20 = 580.69N Torque transmitted by the pinion 1 is given by ANJALAI AMMAL MAHALINGAM ENGINEERING COLLEGE-KOVILVENNI Page 3 Unit-2 Spur gears and parallel axis helical gears 60×P 60×2.5×103 T1= = 2πN1 2π×1750 = 13.64Nm Considering gears 2 and 3: Since gear 2 is an idler, it transmits no torque (power) to itsshaft. Torque transmitted by the gear 2, T2=0 Since gear 2 is an idler, whatever torque it receives from pinion 1 is transmitted to gear 3.Therefore, the tangential component between gears 2 and 3 must be equal to the tangential component between gears 1 and 2, as shown in Fig t t F32 = F12 = −545.67N r r F32 = F12 = 198.61N F32 = F12 = 580.69N Since the same power is transmitted from pinion 1 to gear 3 2πN1 T1 2πN3 T3 = 60 60 N1T1=N3T3 N Z torque transmitted by gear 3, T3= T1(N1 )= T1[Z3 ] 3 30 T3=13.64[40]=20.46.Nm y 2 R b2 = √(( Rxb2 ) + ( R b2 ) ) = √((347.06)2 + (347.06)2 ) = 490.82N 2.The pitch circles of a train of spur gears are shown in figure 25.11.Thespur gear A receives 3 kW powerat 600 rpm through its shaft androtates clockwise. Gear B is. Anidler and gear C is the drivengear. The teeth are 20° full depth. K.Vijayarajan.M.E Given data P=3kW NA=600rpm Φ=20°, ZA=35, ZB=65, ZC=45, mA= mB= mC=6mm Determine (i) the torque transmitted byeach shaft. (ii) the tooth load for whicheach gear must be designed (iii) the force applied to theidler shaft as a result of the geartooth loads. Solution dA= mA ZA=6 x 35 =210mm dB= mBZB=6 x 65 =390mm dC= mCZC=6 x 45 =270mm πD1 N1 v1 = 60 = 6.59m/s t Let the tangential force of pinion 1 on gear 2 is F12 and is given by P = Ft .v p t F12 = = 454.72N v Radial force of pinion 1 on gear 2 is given by r t F12 = F12 × tanΦ = 165.5N Resultant force of pinion 1 on gear 2 is given by Ft 1 Reaction on the idler gear shaft :The shaft reactions in the x and y directions are t r ) Rxb2 = −( F12 + F32 = −(−545.67 + 198.61) = 347.06N y r t )=−(−198.61 R b2 = −( F12 + F32 − 545.67) = 347.06N Therefore the resultant shaft reaction is given 2 ME8651-DESIGN OF TRANSMISSION SYSTEMS F12 = 12 = 483.9N cosΦ Torque transmitted by the pinion 1 is given by 60×P T1=2πN =47.74Nm 1 Considering gears 2 and 3: Since gear 2 is an idler, it transmits no torque (power) to itsshaft. Torque transmitted by the gear 2, T2=0 t t F32 = F12 = 454.72N r r F32 = F12 = 165.5N F32 = F12 = 483.9N Since the same power is transmitted from pinion 1 to gear 3 2πN1 T1 2πN3 T3 = 60 60 ANJALAI AMMAL MAHALINGAM ENGINEERING COLLEGE-KOVILVENNI Page 4 Unit-2 Spur gears and parallel axis helical gears N1T1=N3T3 N Z torque transmitted by gear 3, T3= T1( 1 )= T1[ 3 ] N3 Z1 T3=61.38Nm Reaction on the idler gear shaft :The shaft reactions in the x and y directions are y r t ) R b2 = −( F12 + F32 = −(−165 − 454.72) = 619.5N t r ) Rxb2 = −( F12 + F32 = −(−454.72 − 165) = 619.5N 2 y Gear design using Lewis and Buckingham equations: 1. Selection of material: [PSGD1.40] 2. Calculation of Z 1 and Z 2: If not given assume Number of teeth on pinion Z1 ≥ 17 Then number of teeth on gear, Z2 = i × Z1 3.Calculation of tangential load on tooth (Ft): 𝑃 𝑉 Ft = × 𝐾0 Where P = Power in watts, V = Velocity = 2 R b2 = √(( Rxb2 ) + ( R b2 ) ) =878 N GEAR BLANK DESIGN There are two basic methods of gear design:psg8.5 (i) Gear design using Lewis and Buckingham equations (or gear design based on beamstrength), which is recommended by AGMA (American Gear ManufacturersAssociation); and (ii) Gear design using basic relations (or gear design based on gearlife), which is theconventional method. Assumptions made The Lewis equation is based on the following assumptions: The effect of radial component Fr' which induces compressive stresses, ISnegligible. The tangential component F, is uniformly distributed across the full face width. The tangential force F, is applied to the tip of a single tooth. In other words, it is Assumed that at any time only one pair of teeth is in, contact and takes the totalload . Stress concentration in the tooth fillet is negligible .Forces which are due to tooth sliding friction are negligible. DESIGN PROCEDURE FOR SPUR GEAR K.Vijayarajan.M.E ME8651-DESIGN OF TRANSMISSION SYSTEMS 𝜋𝑑𝑁 60 in m/s, 𝐾0 = Service factor (Assume 1.0 to 1.5)4.Calculation of initial dynamic load (Fd): 𝐹𝑑 = 𝐹𝑡 × 𝐶𝑣 (assuming velocity 12m/s[)PSGD8 .51[ Where 𝐶𝑣 = Velocity factor, [PSGD8.51[ 5.Calculation of beam strength (Fs): 𝐹𝑆 = 𝜋 ∙ 𝑚 ∙ 𝑏 ∙ 𝜎𝑏 ∙ 𝑦 Where y = Form factor, [PSGD8.50,8.53] 𝜎𝑏 = Design bending stress 6. Calculation of module (m): 𝐹𝑠 ≥ 𝐹𝑑 [Design is safe] [PSGD8.51[ eeahest nigneh stanrahr morule [PSGD8.2[ 7.Calculation of b, d and v: Face width (b): b = 10 × m [PSGD8.38] Find pitch circle diameter (d): d =𝑧1 ∙ m Find pitch line velocity (v): v = 𝜋𝑑𝑁 60 8.Recalculation of the beam strength (Fs): 𝐹𝑆 = 𝜋 ∙ 𝑚 ∙ 𝑏 ∙ 𝜎𝑏 ∙ 𝑦 9.Calculation of accurate dynamicload (𝑭𝒅 ): 𝐹𝑑 = 𝐹𝑡 + 21 𝑉 (𝑏𝑐 + 𝐹𝑡 ) 21 𝑉 + √𝑏𝑐 +𝐹𝑡 [PSGD8.51[ Where C =Deformation factor [PSGD8.53[ 𝑃 𝐹𝑡 = 𝑉 10. Check for beam strength (or tooth breakage): ANJALAI AMMAL MAHALINGAM ENGINEERING COLLEGE-KOVILVENNI Page 5 Unit-2 Spur gears and parallel axis helical gears 𝐹𝑑 < 𝐹𝑠 [ Design is safe ] [PSGD8.51[ 11. Calculation of the maximum wear load (Fw): 𝐹𝑊 = 𝑑1 × 𝑏 × 𝑄 × 𝐾𝑊 [PSGD8.51[ 2𝑖 Where Q = 𝑖+1[PSGD8.51[ 𝐾𝑊 = Load stress factor ( Assume 1.5 to2.53) Surface endurance limit( fes( and modulus of elasticity aay re given use tnis fohmula 𝑓𝑒𝑠2 𝑠𝑖𝑛∅ 1 1 𝐾𝑊 = ( + ) 1.4 𝐸𝑝 𝐸𝑔 =pE young’s morulus foh pinion =gE young’s morulus foh pinion 12. Checkforwear: 𝐹𝑑 < 𝐹𝑤 [ Design is safe ] 2. Calculation of Z 1 and Z 2: Number of teeth on pinion Z1=18 Number of teeth on pinion Z2=i x Z1 =3.5 x 18=63 3.Calculation of tangential load on tooth (Ft): 𝑃 Ft = 𝑉 × 𝐾0 Where P = Power in watts, (d1=m.z1 and ‘m’ in mm) V = Velocity = [PSGD8.51[ 1.Design a spur gear drive required to transmit 45 kW at a pinion speedof 800 r.p.m: The velocity ratio is 3.5 : 1. The teeth are 20°full depth involute with 18 teethon the pinion. Both the pinion and gear are made of steel with a maximum safe static stressof 180 N/mm2. Assume medium shock conditions. Given data P=45kW N1=800rpm Φ=20°, i=35, Z1=18, 𝜎b=180N/mm2 Solution: Since both the pinion and gear are made of the same material, the pinion isweaker than the gear. So we have to design only pinion. 1. Selection of material [PSGD 8.5] 𝜋𝑑𝑁 60 = 𝜋×𝑚×𝑍1 ×𝑁1 60×1000 = 𝜋×𝑚×𝑍1 ×18×𝑁1 60×1000 = 0.754 m/s, K0= for medium shock condition from psg data book 8.53 Ft = 13. Calculation of basic dimensions of pinion and gear:[PSGD8.22[ 45×103 0.754𝑚 × 1.25 = 74603 𝑚 4.Calculation of initial dynamic load (Fd): 𝐹𝑑 = 𝐹𝑡 × 𝐶𝑣 (assuming velocity 12m/s[)PSGD8 .51[ Where 𝐶𝑣 = Velocity factor, 6+12 [PSGD8.51[ 6 v<20m/s 6 + 12 =3 6 5.Calculation of beam strength (Fs): FS = π ∙ m ∙ b ∙ σb ∙ y [P= πm] b = face width=10.m(assume), y=form factor [PSGD8.50,8.53] =0.154-(0.912/𝑍1 ) for 20ͦ full depth system =0.154-(0.912/18)=0.1033 𝐹𝑆 = π × m × 10m × 180 × 0.1033 = 584.15m2 6. Calculation of module (m): Given that the pinion and gear are made of steel. Assume steelis hardened to 200 BHN. K.Vijayarajan.M.E ME8651-DESIGN OF TRANSMISSION SYSTEMS 𝐹𝑠 ≥ 𝐹𝑑 223809 584.15𝑚2 ≥ 𝑚 ANJALAI AMMAL MAHALINGAM ENGINEERING COLLEGE-KOVILVENNI Page 6 Unit-2 Spur gears and parallel axis helical gears Module m > 7.26mm eeahest nigneh stanrahr morule[PSGD8.2[choice 1 is 8mm 7.Calculation of b, d and v: Face width (b): b = 10 × m = 10 × 8=80mm [PSGD 8.38] Find pitch circle diameter (d): d =𝑧1 ∙ m=8 x 18=144mm Find pitch line velocity (v): v= 𝜋𝑑𝑁 60 = 𝜋 ×144×10−3 ×100 60 = 6.03𝑚/𝑠 9.Calculation of accurate dynamic load (𝑭𝒅 ): 21 𝑉 (𝑏𝑐 + 𝐹𝑡 ) [PSGD8.51[ 21 𝑉 + √𝑏𝑐+𝐹t Where C =Deformation factor [PSGD8.53[ C =11860e,200FD steel and steel e = 0.038 from module up to 8 and carefully cut gear from databook C=11860e= 11860 x 0.038 = 450.68 N/mm 𝑃 45×103 6.03 = 7462.68𝑁 𝐹𝑑 = 7462.68 + 21 × 6.03 × 103 (80 × 450.68 + 7462.68) 21 × 6.03 × 103 + √80 × 450.68 + 7462.68 = 50908.19𝑁 10. Check for beam strength (or tooth breakage): 𝐹𝑑 > 𝐹𝑠 the Design is un safe that dynamic load is greater than beam strength [PSGD8.51[ In order to reduce the dynamic load 𝐹𝑑 select the precision gears. Therefore e=0.019 for precision gears K.Vijayarajan.M.E Now we find𝐹𝑑 < 𝐹𝑠 it means, the gear tooth has adequate beam strength and it will no fail by breakage. Therefore the design is safe. 11. Calculation of the maximum wear load (Fw): 𝐹𝑊 = 𝑑1 × 𝑏 × 𝑄 × 𝐾𝑊 [PSGD8.51[ 2×3.5 Where Q = 𝑖+1 = 3.5+1 = 1.555[PSGD8.51[ 𝐹𝑆 = 𝜋 ∙ 𝑚 ∙ 𝑏 ∙ 𝜎𝑏 ∙ 𝑦 𝐹𝑆 = 𝜋 × 8 × 80 × 180 × .1033 = 37385.45𝑁 𝐹𝑡 = 𝑉= Then the deformation factor, c = 11860 x e =11860 x 0.019=225.34 21 × 6.03 × 103 (80 × 225.34 + 7462.68) 𝐹𝑑 = 7462.68 + 21 × 6.03 × 103 + √80 × 225.34 + 7462.68 =32920.46N 2𝑖 8.Recalculation of the beam strength (Fs): 𝐹𝑑 = 𝐹𝑡 + ME8651-DESIGN OF TRANSMISSION SYSTEMS 𝐾𝑊 = Load stress factor ( Assume 1.5 to2.53) = 144 x 80 x 1.555 x 0.919 = 16462.6N 12. Check for wear: 𝐹𝑑 > 𝐹𝑤 Since the design is unsafe.that dynamic load is greater than the wear load [PSGD8.51[ To increase the wear load Fwwe have to increase the hardness BHN for steel hardness to 400 BHN, Kw= 2.553 N/mm2 Fw= 144 x 80 x 1.555 x 2.553 =45733.42 N 𝑁𝑜𝑤𝑤𝑒𝑓𝑖𝑛𝑑𝐹𝑑 < 𝐹𝑤 𝑖𝑡𝑚𝑒𝑎𝑛, 𝑡ℎ𝑒𝑔𝑒𝑎𝑟𝑡𝑜𝑜𝑡ℎ ℎ𝑎𝑠𝑎𝑑𝑒𝑞𝑢𝑎𝑡𝑒𝑤𝑒𝑎𝑟𝑐𝑎𝑝𝑎𝑠𝑖𝑡𝑦𝑎𝑛𝑑𝑖𝑡𝑤𝑖𝑙𝑙𝑛𝑜𝑡 wear out .therefore the design is safe. 13. Calculation of basic dimensions of pinion and gear[PSGD8.22[ Module (m)=8mm Number of teeth: Z 1 = 18 and Z2=63 Pitch circle diameter d1=144mm d2=8 x 63=144mm Centre distance a = Face width 𝑚(𝑍1 +𝑍1 ) 2 8(18+63 ) 2 = b=80mm = 324𝑚𝑚 Height factor f0=1,for 20ofull depth teeth ANJALAI AMMAL MAHALINGAM ENGINEERING COLLEGE-KOVILVENNI Page 7 Unit-2 Spur gears and parallel axis helical gears Bottom clearance c=0.25m=0.25 x 8 = 2mm Tip diameter da1=( Z 1+2 f0)m=( 18+2 x 1)8=160mm da2=( Z 2+2 f0)m=( 63+2 x 1)8=520mm Root diameter df1=( Z 1-2 f0)m-2c = (18-2 x 1)8-2 x 2 =124 mm df2=( Z 2-2 f0)m-2c = (63-2 x 1)8-2 x =484mm 2. A compressor running at 300 r.p.m. is driven by a 15 kW, 1200 r.p.m.motor through 14 1/2°0full depth spur gears. The centre distance is 375 mm. The motorpinion is to be of C 30 forged steel hardened andtempered, and the driven gear is to be ofcastiron. Assuming medium shock condition, design the gear drive completely Given data P=15kW N1=1200rpm, N2=800rpm ,Φ=14 1/2°, a=375mm To find : design a spur gear Solution: Since the materials of pinion and gear are different, first we have to evaluate [σb1]. y1 and σb2]. y2 to find out the weaker element. N 1200 i = N1= 800 = 4 Assume Z1=18 2 ME8651-DESIGN OF TRANSMISSION SYSTEMS We find [σb1]. y1>[σb2]. y2 the gear is weaker than the pinion therefore; we have to design the gear only. 1. Selection of material Pinion: C 30 Forged steel; and Gear: Cast iron 2. Calculation of module (m): Since the centre distance (a) is given, we need not toequate Fs and Fdto find the module. Here the module can be calculated using the relation 𝑚(𝑍1 + 𝑍1 ) 𝑚(18 + 72 ) 𝑎= = = 8.333 2 2 nearest higher standard module under choice 1 is 10 mm. 3.Calculation of b, d and v:[ PSGD 8.38[ Face width (b): b = 10 × m = 10 ×10=100mm Find pitch circle diameter (d): d1 =𝑧1 ∙ m=10x 18=180mm D2 =𝑧2 ∙ m=10x 72 = 180mm Find pitch line velocity (v): v= 𝜋𝑑𝑁 60 = 𝜋 ×720×10−3 ×300 60 4.Recalculation of the beam strength (Fs): Z1= i. Z1=4 x 18 =72 For pinion Form factor, y1= 0.270, from psgdbook 8.50,for Z1=18 Permissible static stress [σb]=112N/mm2from table for forged steel. Y [y1= π1] 0.270 [σb1]. y1 = 112 x π =9.625 Form factor, y2= 0.360, from psgdb,for Z2=72 and Permissible static stress [σb]=56N/mm2from table for fron table for cast iron. [σb2]. y2 =56 x 0.36 π K.Vijayarajan.M.E =6.425 = 11.31𝑚/𝑠 𝐹𝑆 = 𝜋 ∙ 𝑚 ∙ 𝑏 ∙ [𝜎𝑏]2 ∙ 𝑦2 0.36 𝐹𝑆 = 𝜋 × 10 × 100 × 56 × = 20160𝑁 𝜋 5.Calculation of accurate dynamicload (𝑭𝒅 ): 21 𝑉 (𝑏𝑐 + 𝐹𝑡 ) 𝐹𝑑 = 𝐹𝑡 + 21 𝑉 + √𝑏𝑐+𝐹𝑡 [PSGD8.51[ Where C =Deformation factor [PSGD8.53[ C =7850e,140FD steel and cast iron e = 0.022 from module upto 10 and precision gear from databook C=7850e= 7850 x 0.022 = 172.7 N/mm 𝑃 15×103 11.31 𝐹𝑡 = 𝑉= = 1326.26𝑁 ANJALAI AMMAL MAHALINGAM ENGINEERING COLLEGE-KOVILVENNI Page 8 Unit-2 Spur gears and parallel axis helical gears 𝐹𝑑 = 1326.26 + 21 × 11.31 × 103 (100 × 172.7 + 1326.26) 21 × 11.31 × 103 + √100 × 172.7 + 1326.26 ME8651-DESIGN OF TRANSMISSION SYSTEMS = 19911.85𝑁 6. Check for beam strength (or tooth breakage): Now we find𝐹𝑑 < 𝐹𝑠 it means, the gear tooth has adequate beam strength and it will no fail by breakage. Therefore the design is safe. 7. Calculation of the maximum wear load (Fw): 𝐹𝑊 = 𝑑1 × 𝑏 × 𝑄 × 𝐾𝑊 [PSGD8.51[ 2𝑖 2×4 Where Q = 𝑖+1 = 4+1 = 1.6[PSGD8.51[ 𝐾𝑊 = Load stress factor =1 N/mm2( Assume 1.5 to2.53) 𝐹𝑊 = 180 x 100 x 1.6 x 1 = 28800N 8. Checkforwear: Now we find Fd < 𝐹w it mean, the gear tooth has adequate wear capasity and it willnot wear out .therefore the design is safe. 9. Calculation of basic dimensions of pinion and gear Module (m)=10 mm Number of teeth: Z 1 = 18 and Z2=72 Pitch circle diameter d1=180mm d2=720mm Height factor f0=1,for 14 1/2ofull depth teeth Bottom clearance c=0.25m=0.25 x 9 = 2.25mm Tip diameter da1=( Z 1+2 f0)m=( 18+2 x 1)9=180mm da2=( Z 2+2 f0)m=( 72+2 x 1)9=666mm Root diameter df1=( Z 1-2 f0)m-2c = (18-2 x 1)9-2 x 2.25 =139.5mm df2=( Z 2-2 f0)m-2c = (63-2 x 1)9-2 x 2.25=625.5mm 3.A reciprocating compressor is to be connected to an electric motor withthe help of spur gears. The distance between the shafts is to be 500 mm.The speed of the electric motor is 900 rpm and the speed of the compressorshaft is desired to be 200 rpm. The torque to be K.Vijayarajan.M.E transmitted is 500 Nm.Taking starting torque as 25% more than the normal torque, determine.(i) Module and face width of the gears using 20 degrees stub teeth and(Ii) Number of teeth and pitch circle diameter of each gear. Assume suitable values of velocity, factor and Lewis factor. Given data Mt= 500N-m =500 x103N-mm,N1=900rpm, N2=200rpm , a=500mm To find : design a spur gear Let the material for pinion is forged steel and the material for gear is cast steel. Hence, design bending stress for pinion [𝜎b]p=224N/mm2 , , design bending stress for gear [𝜎b]g=196N/mm2 To find pitch circle diameters d1+ d2=2a =2 x 500=1000 mm……….[1] 𝑑2 𝑚𝑍2 𝑁 900 = = 1= = 4.5 𝑑1 𝑚𝑍1 𝑁2 200 d2=4.5 d1 substuting above [1]equation 1000 = 182𝑚𝑚 5.5 d2=4.5 x 182 =818 mm To find module and face width : We know the average torque to be transmitted by the pinion. Mt= 500 x 103N-mm Max.torque [Mt]= Mt x 1.25 =500 x 103x 1.25 =625x 103Nmm Max. tangential load produced by the max torque on the pinion. 𝑑2 = 𝑀𝑡 𝑑1 /2 = 625𝑥103 =6.25𝑥103 N 182/2 Design tooth load Fd= Ft cv cv= velocity factor which depend on pitch line velocity. 𝜋𝑑𝑁 pitch line velocity v= 60 V= 𝜋 ×182× 900 60×1000 = 8.6𝑚/𝑠 ANJALAI AMMAL MAHALINGAM ENGINEERING COLLEGE-KOVILVENNI Page 9 Unit-2 Spur gears and parallel axis helical gears 3+ 8.6 𝑐𝑣 = 3 = 3.87 for V<10 m/s Fd= 6.87 x 103 x 3.87 = 26.6 x 103N Since the face width b and module m are same for both pinion and gear, for safe design, the strength factor "[σb] x Y" must be determined in order to equate the beam strength of pinion or gear for which the strength factor is minimum. To select the form factor Y, the number of teeth must be known Z1 = 20 and hence Z1= i x Z1=20 x4.5 = 90 Now for pinion [𝜎b].𝑦=224 x 0.393=88N/mm2 2. Calculation of module (m): Since the centre distance (a) is given, we need not toequate Fs and Fdto find the module. Here the module can be calculated using the relation 𝑚(𝑍1 + 𝑍1 ) 𝑎= 2 3.Calculation of b, d and v: Face width (b): b = 10 × m Find pitch circle diameter (d): d1 =𝑧1 ∙ m D2 =𝑧2 ∙ m Find pitch line velocity (v): v = 𝜋𝑑𝑁 60 9. Calculation of basic dimensions of pinion and gear Module (m)=10 mm Number of teeth: Z 1= and Z 2= Pitch circle diameter d1= d2= Height factor f0= Bottom clearance c= Tip diameter da1=( Z 1+2 f0)m da2=( Z 2+2 f0)m Root diameter df1=( Z 1-2 f0)m-2c df2=( Z 2-2 f0)m-2c FOR GEAR [𝜎b].𝑦= 196 x 1.503 =294.59 N/mm2 Since for pinion is less the beam strength of pinion must be compared with the design tooth load .design is based on pinion tooth strength. [𝑚 ∙ 𝑏 ∙ 𝜎𝑏 ∙ 𝑦] ≥ 𝑝𝑖𝑛𝑖𝑜𝑛 Assuming b = 10m, we get 224 x 10m x m x 0.393 > 26.6 x 103 1 𝐹𝑆 = 𝜋 ∙ 𝑚 ∙ 𝑏 ∙ [𝜎𝑏]2 ∙ 𝑦2 5.Calculation of accurate dynamicload (𝑭𝒅 ): 21 𝑉 (𝑏𝑐 + 𝐹𝑡 ) ][PSGD8.51[ 21 𝑉 + √𝑏𝑐+𝐹𝑡 6. Check for beam strength (or tooth breakage): Now we find𝐹𝑑 < 𝐹𝑠 it means, the gear tooth has adequate beam strength and it will no fail by breakage. Therefore the design is safe. 7. Calculation of the maximum wear load (Fw): 𝐹𝑊 = 𝑑1 × 𝑏 × 𝑄 × 𝐾𝑊 [PSGD8.51[ Where Q = 𝑁𝑜𝑤𝑤𝑒𝑓𝑖𝑛𝑑𝐹𝑑 < 𝐹𝑤 𝑖𝑡𝑚𝑒𝑎𝑛, 𝑡ℎ𝑒𝑔𝑒𝑎𝑟𝑡𝑜𝑜𝑡ℎℎ𝑎𝑠𝑎𝑑𝑒𝑞𝑢𝑎𝑡𝑒𝑤𝑒𝑎𝑟𝑐𝑎𝑝𝑎𝑠𝑖𝑡𝑦𝑎𝑛𝑑 𝑖𝑡𝑤𝑖𝑙𝑙𝑛𝑜𝑡wear out .therefore the design is safe. 2 26.6 × 103 𝑚≥[ ] ≥ 5.5𝑚𝑚 = 6𝑚𝑚 224 × 10 × 0.393 4.Recalculation of the beam strength (Fs): 𝐹𝑑 = [𝐹𝑡 + ME8651-DESIGN OF TRANSMISSION SYSTEMS Face width b = 10mm =10 x 6 =60mm To find actual number of teeth 𝑍 182 Actual no. of teeth for pinion Z1= 𝑚1 = 6 =30.3=32 Z2=32 x 4.5=144 The corrected pitch circle diameter are, d2=m d2=6 x144 =164mm 192+864 The corrected centre distance c = 2 = 528𝑚𝑚 2𝑖 [PSGD8.51[ 𝑖+1 𝐾𝑊 = Load stress factor =1 N/mm2( Assume 1.5 to2.53) 8. Check for wear: K.Vijayarajan.M.E ANJALAI AMMAL MAHALINGAM ENGINEERING COLLEGE-KOVILVENNI Page 10 Unit-2 Spur gears and parallel axis helical gears GEAR DESIGN BASED ON GEARLIFE: 1.Calculation of gear ratio (i): 𝑵 𝒁 i=𝑵𝟏 =𝒁𝟐 𝟐 𝟏 Calculate the 11. Selection of quality of gears: ]PSGD8.3] 12.Revision of design torque [Mt] Revise K: load con. Factor,]PSGD8.15] load factor ]PSGD8.16] Revise ]Mt[: using revised values Use [ 𝑀𝑡 ] = 𝑀𝑡 ∙K∙ 𝐾𝑑 ]PSGD8.15] 13. Check for bending:]PSGD8.13A] 𝜎𝑏 ≤ [𝜎𝑏 [ [ Design is safe ] 14. Check for wear strength: 𝜎𝐶 ≤ [𝜎𝐶 [[ Design is safe ]]PSGD8.13] 15. Check for gear (i) Check for bending: 𝜎 𝑦 𝜎𝑏2 = 𝑏1𝑦 ∙ 1 2. Selection of materials:[PSGD1.40] 3.Gear life: If not given, assume gear life (20000 hrs) 4.Calculation of [Mt]: [ 𝑀𝑡 ] = 𝑀𝑡 ∙K∙ 𝐾𝑑 [PSGD8.15] K∙ 𝐾𝑑 =1.3 assume 60 × 𝑃 2 𝜋𝑁 Initially assume K∙ 𝐾𝑑 = 1.3 5.Calculation of Eeq[𝝈𝒃 [and[𝝈𝒄 [: Eeq = young’s modulus,[PSGD8.14] ]𝜎𝑏 [ = Bending stress,[PSGD8.18] [𝜎𝑏 ]= 1.4𝐾𝑏𝑙 .𝜎 𝑛.𝑘𝜎 −1 𝜎𝑏1 𝑎𝑛𝑑𝜎𝑏2 = Induced bending stress 𝑦1 𝑎𝑛𝑑𝑦2 = Form factor, [PSGD8.18] Calculate [𝜎𝑏2 ] ∶[PSGD8.19] 𝜎𝑏2 ≤ [𝜎𝑏2 [ [ Design is safe ] (ii) Check for wear strength: 𝜎𝑐2 ≤ [𝜎𝑐2 [ [ Design is safe ] 16. Basic dimensions of pinion and gear: 2𝑎 = (𝑍 + 𝑍 )]PSGD8.22] 1 2 9. Revision of centre distance (a): a= 𝑚 (𝑍1 + 𝑍2 ) ]PSGD8.22] 2 10.Calculation of b, d1,V and ψp: Face width (b): b = ψa ]PSGD8.1] Find pitch circle diameter(𝑑1 ):𝑑1 = 𝑍1 ∙mFind pitch line velocity (v): K.Vijayarajan.M.E Revise Kd: Dynamic 2 ]𝜎𝑐 [ = contact stress, ]PSGD8.16] [𝜎𝑐 ] = 𝑐𝑅 ×HB× 𝐾𝑐𝑙 6. Calculation of centre distance(a): Where Ψ = 0.3 ( assume )] PSGD8.13] 7.Calculation of 𝒁𝟏 𝒂𝒏𝒅𝒁𝟐 : Number of teeth on pinion, 𝑍1 : 𝑍1 ≥ 17, 𝑠𝑎𝑦 18 Number of teeth on gear, 𝑍2 : 𝑍2 = 𝑖 × 𝑍1 8. Calculation of module (m) m 𝜋𝑑1 𝑁1 60 𝑏 ψp:ψp = 𝑑 ]PSGD8.1] 1 v= [PSGD8.50] [ 𝑀𝑡 ] = Transmitted torque = ME8651-DESIGN OF TRANSMISSION SYSTEMS [PSGD8.22] 4. In a spur gear drive for a stone crusher, the gears are made of C40 steel. The pinion is transmitting 30 kW at 1200 r.p.m. The gear ratio is 3. Gear is to work 8 hours per day, six days a week and for 3years. Design the drive. Given data P=30kW N1=1200rpm, i=3,pinion and gear materials: C 40 ANJALAI AMMAL MAHALINGAM ENGINEERING COLLEGE-KOVILVENNI Page 11 Unit-2 Spur gears and parallel axis helical gears ME8651-DESIGN OF TRANSMISSION SYSTEMS solution : since thepinion and gear are made of same material (C 40 steel).therefore we have to do the design of pinion alone. 1.Calculation of gear ratio (i): i=3 [PSGD8.50] 2. Selection of materials:[PSGD1.40] Pinion and gear are made of C40 steel. Assume surface hardness >350 3.Gear life: Given that the gear is to work8 hr,perday,six days a week :and for 3 yr. Gear life in term of hr is given by Gear life = 8 x 52 x 6 x 3 =7488 hours=449280 min Life in numbers of cycles, N = 449280 x N1=449280 x1200=53.9 x 107cycles. (iii) To find [𝜎𝑐 ] = contact stress, ]PSGD8.16] [𝜎𝑐 ] = 𝑐𝑅 ×HB× 𝐾𝑐𝑙 CR=26.5 for C40 steel hardness and tempered from table HRC = 40 to 55 C40 steel, from table Kcl=0.585,for HB>350 and N>25 x 107 from table [𝜎𝑐 ] = 26.5 × 55 × 0.585 = 852.64 𝑁/𝑚𝑚2 6. Calculation of centre distance(a): Where Ψ = 0.3 ( assume )] PSGD8.13] 3 𝑎 ≥ [𝑖 + 1] √[ 𝐸𝑒𝑞[𝑀𝑡 ] 0.74 2 ] ×[ ] [𝜎𝑐 ] 𝑖𝜑 0.74 2 2.15 × 105 × 310.34 × 103 𝑎 ≥ [3 + 1] √[ ] ] ×[ [852.64] 3 × 0.3 3 4.Calculation of initial design torque [Mt]: [ 𝑀𝑡 ] = 𝑀𝑡 ∙K∙ 𝐾𝑑 [PSGD8.15] 60 × 𝑃 60 × 30 × 103 𝑀𝑡 = = = 238.73 𝑁𝑚 2𝜋𝑁1 2𝜋 × 1200 K∙ 𝐾𝑑 =1.3 assume [ 𝑀𝑡 ] = 238.73 × 1.3 = 310.34𝑁𝑚 5.Calculation of Eeq[𝝈𝒃 [and[𝝈𝒄 [: (i) To find Eeq = young’s modulus,[PSGD8.14] Eeq =2.15 x 105N/mm2 (ii) To find ] 𝜎𝑏 [ = Bending stress, from [PSGD8.18] [𝜎𝑏 ]= 1.4𝐾𝑏𝑙 .𝜎 Assuming rotation in one 𝑛.𝑘𝜎 −1 direction only 𝐾𝑏𝑙 =0.7 for HB > 350 and N > 25 x 107 from table n=2 for tempered steel from table[PSGD8.18] 𝜎−1 [𝜎𝑏 ]= 1.4×0.7 × 340.5 2×1.5 K.Vijayarajan.M.E = 111.23𝑁/𝑚𝑚2. 7.Calculation of 𝒁𝟏 𝒂𝒏𝒅𝒁𝟐 : Number of teeth on pinion, 𝑍1 = 17, for 200full depth system Number of teeth on gear, 𝑍2 = 𝑖 × 𝑍1 = 3 x 17 = 51 8. Calculation of module (m)] PSGD8.22] 2𝑎 + 𝑍2 ) 1 m = (𝑍 2×155 = (17+ 51) = 4.56𝑚𝑚 from table the nearest higher standard module 9. Revision of centre distance (a):] PSGD8.22] 𝑘𝜎 = 1.5 𝑓𝑜𝑟𝑠𝑡𝑒𝑒𝑙𝑓𝑟𝑜𝑚𝑡𝑎𝑏𝑙𝑒[𝑃𝑆𝐺𝐷8.18] = 0.35𝜎𝑢 + 120 𝑓𝑜𝑟𝐶 40 𝑎𝑙𝑙𝑜𝑦𝑠𝑡𝑒𝑒𝑙𝑓𝑟𝑜𝑚𝑡𝑎𝑏𝑙𝑒 𝜎𝑢 = 630 𝑁/𝑚𝑚2from table [𝑃𝑆𝐺𝐷8.5] 𝑎 ≥ 152.89or a = 155mm a= 𝑚 (𝑍1 + 𝑍2 ) 2 = 5(17+51) 2 = 170𝑚𝑚 10.Calculation of b, d1,V and ψp:] PSGD8.1] Face width (b): b = ψa=0.3 x 170 =51mm Find pitch circle diameter(𝑑1 ):𝑑1 = 𝑍1 ∙m=5 x 17=85mm ANJALAI AMMAL MAHALINGAM ENGINEERING COLLEGE-KOVILVENNI Page 12 Unit-2 Spur gears and parallel axis helical gears Find pitch line velocity (v): v = 𝜋𝑑1 𝑁1 60 𝜋𝑑1 𝑁1 𝜋 ×85×10−3 ×1200 = =5.34m/s 60 60 𝑏 51 ψp= = = 0.6 𝑑1 85 v= 11. Selection of quality of gears: From ]PSGD8.3] for pitch line velocity 5.34 m/s IS quality 8 gears are selected. 12.Revision of design torque [Mt] Revise K: from,]PSGD8.15] for ψp=0.6 and for bearing close to gear,K=1.03 Revise Kd: Dynamic load factor from ]PSGD8.16] IS quality8,HB> 350, and v=5.34 m/s, Kd=1.4 Revise ]Mt[: design torque ]PSGD8.15] [ 𝑀𝑡 ] = 𝑀𝑡 ∙K∙ 𝐾𝑑 = 238.73 x 1.03 x 1.4=344.24Nm 13. Check for bending:]PSGD8.13A] [𝑖 ± 1] [𝑀 ] 𝜎𝑏 = [𝑎𝑚. 𝑏. 𝑌] 𝑡 [3 + 1] = × 344.24 = 86.78𝑁/𝑚𝑚2 [170 × 5 × 51 × 0.366] Y= Form factor = 0.366,for Z1 from table 𝑤𝑒𝑓𝑖𝑛𝑑𝜎𝑏 ≤ [𝜎𝑏 [ 86.78N/mm2<111.23 N/mm2 [ Design is safe ] 14. Check for wear strength:] PSGD8.13] 𝜎𝐶 = 0.74 3+1 𝑖±1 𝑖±1 √ 𝐸 𝑀 𝑎 𝑖𝑏 𝑒𝑞 𝑡 3+1 = 0.74 170 √3×51 × 2.15 × 105 × 344 × 103 =765.9 N/mm2 𝑤𝑒𝑓𝑖𝑛𝑑𝜎𝐶 ≤ [𝜎𝐶 [ 765.9 N/mm2< 852 N/mm2 therefore Design is safe . 15. Basic dimensions of pinion andgear: K.Vijayarajan.M.E [PSGD8.22] ME8651-DESIGN OF TRANSMISSION SYSTEMS Module m=5mm Face width b=51mm Height factor fo=1 for full depth teeth Bottom clearance c=0.25m=0.25 x 5 = 1.25mm Tooth depth h=2.25m=2.25 x 5 =11.25mm Pitch circle dia d1= m. Z1=5 x 17=85mm d2= m. Z2=5 x 51=255mm Tip diameter da1=( Z1+2 fo)m=( 17+2 x 1)x 5=95mm da2=( Z2+2 fo)m=(51+2 x 1)x 5=265mm Root diameter df1=( Z1-2 fo)m-2c=( 17-2 x 1) 5- 2 x 1.25=95mm df2=( Z2-2 fo)m-2c=( 51-2 x 1) 5- 2 x 1.25=242.5mm 5. In a spur gear drive for a stone crusher, the pinionandgears are made of CI 30 andC40 steel. The pinion is transmitting 30 kW at 1200 r.p.m. The gear ratio is 3. Gear is to work 8 hours per day, six days a week and for 3years. Design the drive. Same problem find only wheel design. Pinionandwheeldifferentmaterial So, 1. Findbendingstress and wear stress forwheel 2. Again find bending stress and wearstress for wheel Wheel material: CI grade 30. 𝑵 900 N2 = 𝟏 = = 360 rpm 𝑖 2.5 Life of wheel = 10000hrs.=10000 x 60 x 360 = 21.6 x 107 cycles To find [𝝈𝒃 ]wheel: the design bending stress for wheel is given by Bending stress, from [PSGD8.18] [σb]= 1.4Kbl .σ−1 n.kσ From psgd for cast iron wheel 9 107 9 107 𝐾𝑏𝑙 = √ =√ = 0.918 𝑁 21.6 × 107 ANJALAI AMMAL MAHALINGAM ENGINEERING COLLEGE-KOVILVENNI Page 13 Unit-2 Spur gears and parallel axis helical gears From table for CI, n = 2 From table for CI𝐾𝜎 = 1.2 From table for CI, 𝜎−1= 0.45𝜎𝑢 From table for CI,𝜎𝑢 =290n/mm2 𝜎−1= 0.45× 290 = 130.5 𝑁/𝑚𝑚2 1.4×0.918 [𝜎𝑏 ]wheel= 2×1.2 × 130.5 = 69.88.𝑁/𝑚𝑚2 axis, wind around thecylinders helically like screw threads. Terms used in Helical Gears 1. Helix angle. 2. Axial pitch. 3. Normal pitch. To find [𝝈𝒄 ]wheel: The design contact stress for wheel is given by [𝜎𝑐 ] = 𝑐𝐵 ×HB× 𝐾𝑐𝑙 from, ]PSGD8.16] 𝑐𝐵 = 2.3, 𝑓𝑜𝑟𝐶𝐼𝑔𝑟𝑎𝑑𝑒 30, 𝑓𝑟𝑜𝑚𝑡𝑎𝑏𝑙𝑒 HB = 200 to 260 for CI from table 107 6 107 =√ = 0.879 𝑓𝑜𝑟𝐶𝐼𝑓𝑟𝑜𝑚𝑡𝑎𝑏𝑙𝑒 𝑁 21.6 × 107 [𝝈𝒄 ]wheel= 2.3 x 260 x 0.879 = 525.64 N/mm2 𝜎𝐶 ≤ [𝜎𝐶 [[525.64 N/mm2<525.64 N/mm2] therefore the Design is safe ]PSGD8.13] [ii] Check for bending Calculation of induced bending stress for wheel [𝜎b1].𝑦1 = [𝜎b2].𝑦2 𝑦2=0.471 for 𝑍2=45 𝜎b1=85.89𝑁/𝑚𝑚2 and 𝑦1=0.377 85.89 x 0.377 = 𝜎b2 x 0.471 𝜎b2 = 68.75 N/mm2 𝜎𝑏 ≤ [𝜎𝑏 [ therefore the Design is safe ]PSGD8.13] 6 𝐾𝑐𝑙 = √ HELICAL GEAR A helical gear has teeth in form of helix around thegear. Two such gears may be used to connect two parallelshafts in place of spur gears. The helixes may be righthanded on one gear and left handed on the other. The pitchsurfaces are cylindrical as in spur gearing, but the teethinstead of being parallel to the K.Vijayarajan.M.E ME8651-DESIGN OF TRANSMISSION SYSTEMS 1. What are the advantages of the helical gear over spur gear? Helical gears produce less noise than spur gears of equivalent quality because the total contact ratio is increased. Helical gears have a greater load carrying capacity than equivalent size of spur gears. A limited number of standard cutters are used to 'cut a wide variety of helical gear simply by varying the helix angle. 2. Differentiate the following terms with respect to helical gears Transverse circular pitch; is the distance between corresponding points on adjacent teeth measured in a plane perpendicular to the shaft axis. Normal circular pitch is the distance between corresponding points on adjacent teeth measured in a plane perpendicular to the helix. Axial pitch is the distance between corresponding points on adjacent teeth measured in a plane parallel to the shaft axis. 3. What are the applications of skew helical gears? Skew helical gears are used to connect and transmit motion between two nonparallel and non-intersecting shafts. DESIGN PROCEDURE FOR HELICAL GEAR Gear design using Lewis and Buckingham equations: 1. Selection of material: [PSGD1.40] 2. Calculation of Z 1 and Z 2: If not given assume Number of teeth on pinion Z1 ≥ 17 Then number of teeth on gear, Z2 = i × Z1 ANJALAI AMMAL MAHALINGAM ENGINEERING COLLEGE-KOVILVENNI Page 14 Unit-2 Spur gears and parallel axis helical gears ME8651-DESIGN OF TRANSMISSION SYSTEMS 3.Calculation of tangential load on tooth (Ft): 2𝑖 Where Q = 𝑖+1[PSGD8.51[ 𝑃 𝑉 Ft = × 𝐾0 Where P = Power in watts, V = Velocity = 𝜋𝑑𝑁 60 in m/s, 𝐾0 = Service factor ( Assume 1.0 to 1.5 ) 4.Calculation of initial dynamic load (Fd): 𝐹𝑑 = 𝐹t × 𝐶𝑣 (assuming velocity 12m/s[)PSGD8 .51[ Where 𝐶𝑣 = Velocity factor, [PSGD8.51[ 5.Calculation of beam strength (Fs): 𝐹𝑆 = 𝜋 ∙ 𝑚 ∙ 𝑏 ∙ 𝜎𝑏 ∙ 𝑦 Where y = Form factor, [PSGD8.50,8.53] 𝜎𝑏 = Design bending stress 6. Calculation of module (m): 𝐹𝑠 ≥ 𝐹𝑑 [Design is safe] [PSGD8.51[ eeahest nigneh stanrahr morule [PSGD8.2[ 7.Calculation of b, d and v: Face width (b): b = 10 × mn [PSGD8.38] 𝑚𝑛 Find pitch circle diameter (d): d1 =𝑧1 × 𝑐𝑜𝑠𝛽 Find pitch line velocity (v): v = 𝜋𝑑1𝑁 60 8.Recalculation of the beam strength (Fs): 𝐹𝑆 = 𝜋 ∙ 𝑚 ∙ 𝑏 ∙ 𝜎𝑏 ∙ 𝑦 9.Calculation of accurate dynamicload (𝑭𝒅 ): 𝐹𝑑 = 𝐹𝑡 + 21 𝑉 (𝑏𝑐𝑐𝑜𝑠2 𝛽+ 𝐹𝑡 ) 21 𝑉 + √𝑏𝑐.𝑐𝑜𝑠2 𝛽 +𝐹𝑡 [PSGD8.51[ 𝑃 𝐹𝑡 = 𝑉 10. Check for beam strength (or tooth breakage): 𝐹𝑑 < 𝐹𝑠 [Design is safe] [PSGD8.51[ 11. Calculation of the maximum wear load (Fw): 𝑑1 ×𝑏×𝑄×𝐾𝑊 𝑐𝑜s2 𝛽 K.Vijayarajan.M.E [PSGD8.51[ 13. Calculation of basic dimensions of pinion and gear:[PSGD8.22[ HELICAL GEAR DESIGN BASED ON GEARLIFE: 1.Calculation of gear ratio (i): 𝑵𝟏 𝒁𝟐 = 𝑵𝟐 𝒁𝟏 i= [PSGD8.50] 2. Selection of materials:[PSGD1.40] 3.Gear life: If not given, assume gear life (20000 hrs) 4.Calculation of [Mt]: [ 𝑀𝑡 ] = 𝑀𝑡 ∙K∙ 𝐾𝑑 [PSGD8.15] K∙ 𝐾𝑑 =1.3 assume [ 𝑀𝑡 ] = Transmitted torque = Where C =Deformation factor [PSGD8.53[ 𝐹𝑊 = 𝐾𝑊 = Load stress factor (Assume 1.5 to2.53) Surface endurance limit( fes( and modulus of elasticity aay re given use tnis fohmula 𝑓𝑒𝑠2 𝑠𝑖𝑛𝛼𝑛 1 1 𝐾𝑊 = ( + ) 1.4 𝐸𝑝 𝐸𝑔 =pE young’s morulus foh pinion =gE young’s morulus foh pinion 12. Checkforwear: 𝐹𝑑 < 𝐹𝑤 [Design is safe] [PSGD8.51[ 60 × 𝑃 2 𝜋𝑁 Initially assume K∙ 𝐾𝑑 = 1.3 5.Calculation of Eeq[𝝈𝒃 [and[𝝈𝒄 [: Eeq = young’s modulus,[PSGD8.14] ]𝜎𝑏 [ = Bending stress,[PSGD8.18] [𝜎𝑏 ]= 1.4𝐾𝑏𝑙 .𝜎 𝑛.𝑘𝜎 −1 ]𝜎𝑐 [ = contact stress, ]PSGD8.16] [𝜎𝑐 ] = 𝑐𝑅 ×HB× 𝐾𝑐𝑙 ANJALAI AMMAL MAHALINGAM ENGINEERING COLLEGE-KOVILVENNI Page 15 Unit-2 Spur gears and parallel axis helical gears 6. Calculation of centre distance(a): Where Ψ = 0.3 ( assume )] PSGD8.13] 7.Calculation of 𝒁𝟏 𝒂𝒏𝒅𝒁𝟐 : Number of teeth on pinion, 𝑍1 : 𝑍1 ≥ 17, 𝑠𝑎𝑦 18 Number of teeth on gear, 𝑍2 : 𝑍2 = 𝑖 × 𝑍1 8. Calculation of module (m) :m ME8651-DESIGN OF TRANSMISSION SYSTEMS Calculate [σb2 ] ∶[PSGD8.19] σb2 ≤ [σb2 [ [ Design is safe ] (ii) Check for wear strength: σc2 ≤ [σc2 [ [ Design is safe ] 16. Basic dimensions of pinion and gear: [PSGD8.22] 2𝑎 = (𝑍 + 𝑍 )]PSGD8.22] 1 2 9. Revision of centre distance (a): a= 𝑚 (𝑍1 + 𝑍2 ) ]PSGD8.22] 2 10.Calculation of b, d1,V and ψp: Face width (b): b = ψa ]PSGD8.1] Find pitch circle diameter(𝑑1 ):𝑑1 = 𝑍1 ∙mFind pitch line velocity (v): v = 𝜋𝑑1 𝑁1 60 𝑏 Calculate the ψp:ψp = 𝑑 ]PSGD8.1] 1 11. Selection of quality of gears: ]PSGD8.3] 12.Revision of design torque [Mt] Revise K: load con. Factor,]PSGD8.15] Revise Kd: Dynamic load factor ]PSGD8.16] Revise ]Mt[: using revised values Use [ Mt ] = Mt ∙K∙ K d ]PSGD8.15] 13. Check for bending:]PSGD8.13A] σb ≤ [σb [ [ Design is safe ] 14. Check for wear strength: σC ≤ [σC [[ Design is safe ]]PSGD8.13] 15. Check for gear (i) Check for bending: σ y σb2 = b1y ∙ 1 2 σb1 andσb2 = Induced bending stress y1 andy2 = Form factor, [PSGD8.18] K.Vijayarajan.M.E ANJALAI AMMAL MAHALINGAM ENGINEERING COLLEGE-KOVILVENNI Page 16

![Machine Elements [Opens in New Window]](http://s3.studylib.net/store/data/009054465_1-76bd66345967cd60934cd86eccae6fad-300x300.png)