Mass Transfer Tutorial Questions: Absorption, Extraction, Drying

advertisement

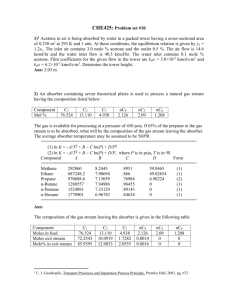

MASS TRANSFER PROCESSES 1B ECE 2201 TUTORIAL QUESTIONS QUESTION 1 In a bioprocess, molasses is fermented to produce a liquor containing ethyl alcohol. A CO2-rich vapor with a small amount of ethyl alcohol is evolved. The alcohol is recovered by absorption with water in a sieve-tray tower. Determine the number of equilibrium stages required for countercurrent flow of liquid and gas, assuming isothermal, isobaric conditions and that only alcohol is absorbed. Entering gas is 180 kmol/h; 98% CO2, 2% ethyl alcohol; 30℃, 110 kPa. Entering liquid absorbent is 100% water; 30℃, 110 kPa. Required recovery (absorption) of ethyl alcohol is 99%. The vapor pressure at 30℃ is 10.5 kPa and the entering liquid absorbent flow rate is 1.3 times the minimum value. QUESTION 2 Sulphur dioxide is recovered from a smelter gas containing 3.5 per cent by volume of SO2, by scrubbing it with water in a countercurrent absorption tower. The gas is fed into the bottom of the tower, and in the exit gas from the top the SO2 exerts a partial pressure of 1.14 kN/m2. The water fed to the top of the tower is free from SO2, and the exit liquor from the base contains 0.001145 kmol SO2/kmol water. The process takes place at 293 K, at which the vapour pressure of water is 2.3 kN/m2. The water rate is 0.43 kmol/s. If the area of the tower is 1.85 m2 and the overall coefficient of absorption for these conditions KLa is 0.19 kmol SO2/s m3 (kmol of SO2 per kmol H2O), what is the height of the column required? The equilibrium data for SO2 and water at 293 K are: kmol SO2/kmol water 0.056 0.14 0.28 0.42 0.56 0.84 1.405 kmol SO2/kmol inert gas 0.7 1.6 4.3 7.9 11.6 19.4 35.3 QUESTION 3 One thousand kg/h of a 45 wt% acetone-in-water solution is to be extracted at 25℃ in a continuous, countercurrent system with pure 1,1,2-trichloroethane to obtain a raffinate containing 10 wt% acetone. Using the following equilibrium data, determine with an equilateral-triangle diagram: (a) the minimum flow rate of solvent; (b) the number of stages required for a solvent rate equal to 1.5 times minimum; (c) the flow rate and composition of each stream leaving each stage. Water side Trichloroethane side Acetone Water Trichloroethane Acetone Water Trichloroethane 0.60 0.13 0.27 0.55 0.35 0.10 0.50 0.04 0.46 0.50 0.43 0.07 0.40 0.03 0.57 0.40 0.57 0.03 0.30 0.02 0.68 0.30 0.68 0.02 0.20 0.015 0.785 0.20 0.79 0.01 0.10 0.01 0.89 0.10 0.895 0.005 QUESTION 4 1000 kg of an acetone-in-water solution, containing 10% acetone by weight is to be extracted using 1,1,2-trichloroethane as solvent. Determine a) percentage extraction of acetone if the extraction is carried out in a single-stage with 1250 kg 1,1,2-trichloroethane. b) percentage extraction if the extraction is carried out in five stages using 500 kg of 1,1,2-trichloroethane in each stage. QUESTION 5 Prepared cottonseeds containing 35 per cent of extractable oil are fed to a continuous counter-current extractor of the intermittent drainage type using hexane as the solvent. The extractor consists of ten sections and the section efficiency is 50 per cent. The entrainment, assumed constant, is 1 kg solution/kg solids. What will be the oil concentration in the out-flowing solvent if the extractable oil content is to be reduced by 0.5 per cent by mass? QUESTION 6 Halibut oil is extracted from granulated halibut arrangement using ether as the solvent. The exhausted livers and it is desired to obtain a theoretical stages are required if 50 kg ether entrainment data are: livers in a counter-current multi-batch solids charge contains 0.35 kg oil/kg 90 per cent oil recovery. How many is used/100 kg untreated solids? The QUESTION 7 a) Air at 60°C and 8% RH is blown through a continuous dryer from which it emerges at a temperature of 35°C. When passing through the dryer, conditions of the air are such that the wet bulb temperature is constant, determine the quantity of water removed per kg of air passing, and the volume of drying air required to remove 20 kg water per hour. b) It is desired to maintain 75% relative humidity in the packaging unit of a plant. For this purpose, fresh air at 42°C dry-bulb and 25°C wet-bulb temperatures is introduced into a spray chamber where the RH is adiabatically raised to 95%. This air is then heated at constant humidity by steam coils to attain 75% RH. Calculate (i) amount of moisture added to the air in the spray chamber (ii) dry-bulb and wet-bulb temperatures of the exit air (iii) heating load on steam coil per kg dry air and QUESTION 8 A wet solid is dried from 35 to 10% moisture under constant drying conditions in 4.17 hours. If the critical and the equilibrium moisture contents are 10 and 5% respectively, how long will it take to dry the solid from 30 to 7% moisture under the same conditions?