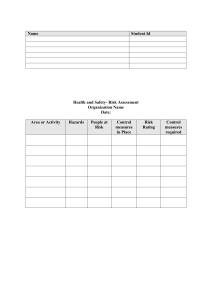

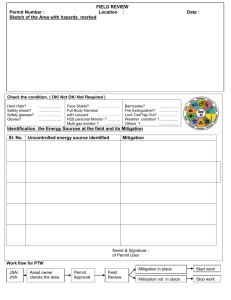

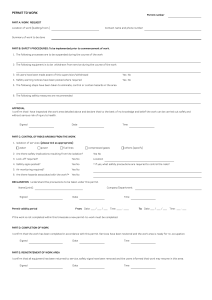

ITEM Tools, equipment and materials required: • Work permit and any isolations • Special PPE requirements • What to do in case of emergency Key responsibilities Does everyone know person in charge and lines of communication? Are you and your workers clear about the procedures and competent for their positions? Is there any isolation required? Is there any likely residual pressure? Position Responsibilities Site Supervisor Responsible for ensuring Toolbox Talks take place and monitoring Work Party Supervisor Carrying out the Toolbox Talk or delegating to competent person for the work activity Work Party Actively participate and ensure they understand what is required of the individual and if in doubt ask Are you trained and competent to perform this work? You have an obligation to stop the work if it’s unsafe. The supervisor conducts the Toolbox Talk and signs to that effect, filling out the boxes below: Key points and issues raised during Toolbox Talk: Is there any Work at Height or access issues? Is there any work above or below where you are working? Are there any Lifting Operations? Is there any Confined Space Entry? Is there any spark potential? static – vehicles – machinery – Are there any hazardous substances (gas / radioactivity / chem)? Is there any spill potential? Have you identified the workers to be equipped with qualified PPE, Gas detector or other safety equipment? Have you made the visitors and contractors clear with HSE orientations and wear PPE? Are you clear of emergency response plan for emergency (fire, explosion, gas and oil leakage, body injury ) Do all involved operators have quick and uninterruptable communications (radio) between you and your different operators to ensure clear instructions and orders? Does HSE and fire fighting team get ready for the sudden incidents? Is a rescue plan in place Lessons from previous days work? Do you ensure the reliable and safe work transition between shifts? Is the work-scope and job described fully understood? All attendees must print their name and sign as being present for the Toolbox Talk Do you need some extra aid from your managers? Y/N Control Permit to Work PCH 10 Life Saving Rule Task observation tool Before conducting work that involves confined space entry, work on energy systems, ground disturbance in locations where buried hazards may exist, or hot work in potentially explosive environments, a permit must be obtained that: • Defines scope of work • Identifies hazards and assesses risk • Establishes control measures to eliminate or mitigate hazards • Links the work to other associated work permits /certificates or simultaneous operations • Is authorized by the responsible person(s) • Communicates above information to all involved in the work • Ensures adequate control over the return to normal operations The PTW system requires the involvement of competent and responsible persons as well as the application of particular safety measures in a controlled sequence. The PTW system ensures that responsibility and accountability for safe working practices is passed in a logical sequence to those responsible for the work being carried out at any given time, and ensures that specified effective safeguards are provided. IN SITUATIONS WHERE WORKING CONDITIONS OR ENVIRONMENTS CHANGE – STOP WORK PERMIT TO WORK The purpose of Permit to Work (PTW) system is to achieve a safe working environment by providing control over the various activities which may have hazardous interactions. The system has four key features: 1. It limits the potentially harmful effects of the action of the person doing the work, by specifying safety precautions and setting limits to the duration and extent of the work. 2. It allows those responsible for overall site safety to be aware of the various hazardous activities and to take a systematic overview which identifies interactions and allows priorities to be set for conflicting work tasks. 3. It encourages formal and careful attention to safe systems of working, by requiring the signature of specified individuals who must confirm that all hazards have been identified and effective precautions taken. 4. It encourages those responsible for overall site safety to plan the carrying out of tasks so that minimal inconvenience and interference is caused to other tasks or production. PCH Permit to Work system tasks are divided into one of the following categories: • Hot work permit • Cold work permit and supported with Confined Space Entry certificate, Excavation certificate, Work at height certificate, Lifting operation certificate, Isolation certificate and Radiography certificate. Certain activities do not normally need to be covered by a permit. These activities include production plant operations, visual inspections of areas (except confined space and areas where increased risk e.g. Working at Height), use of non-hazardous materials, labs and so on. ALL activities MUST have a Toolbox Talk Hazard recognition Typical hazards include: • Hydrocarbons (gas, oil, condensate, diesel, petrol, H2S) • Explosives (detonators, UXO) • Pressure (gas, liquid, vacuum, air) • Height (Lifting, Working at Height and below grade) • Land Transport (vehicles, driving, other drivers, roads) • Weather (sand storms, rain storms, lightning) • Electricity (voltage, electrostatic energy) • Asphyxiating atmospheres (reduced oxygen concentrations, ) • Chemicals • Radiation (NORM in tubular and vessels) • • • Biological (bacteria, protozoa, virus, animals, reptiles, insects) Ergonomic (working environment, task, workload) Security (conflict, terrorism, sabotage, militant activism) Risk assessment The components of a risk assessment involve: 1. Person(s) or representatives from the work crew responsible for the execution of the task. 2. Identifying the hazards of the task/activity. 3. Describing the effects to personnel and equipment associated with the hazard. Ask ‘what if’ to determine the effects. 4. Establishing a risk rating with the team. 5. Identify the likelihood of the event happening. 6. List the controls and safety precautions necessary to reduce the risk to the lowest as reasonably practicable level before starting the work. Controls Elimination: cancelling an activity or deferring or limiting an activity to reduce the exposure to hazards. Prevention: Prevented at source e.g. use of alloys that are resistant to corrosion. Control: Controlled through design features or administrative procedures e.g. fire/gas detection and emergency shutdown. Mitigation: Mitigated by protection of personnel e.g. use of Personal Protective Equipment (PPE). Emergency response: Mitigated through effective emergency response or contingency planning. Human factors All humans make mistakes. How could human errors happen on this job? Think about: • Forgetting or missing a step in a procedure • Operating the wrong valve or control • Working on the wrong equipment • Getting interrupted and restarting the job • Following the wrong procedure • Misreading the label • Feeling tired or unwell • Hurrying to finish • Worrying about someone else’s work Hazard communication Knowledge of the hazards is via Toolbox Talks but don’t forget other • Signs and barrier tape • Chemical inventory lists • Material safety data sheets (MSDSs) container labelling and other forms of warning Hot work Hot work includes welding, burning, cutting, grinding, brazing or hot tapping. Hot work also includes the following operations involving spark potential devices (i.e. opening energized electrical junction boxes, spark producing engines such as welding machines, grit blasting, etc). Permitting of hot work is a key component in controlling work on a location. • Welding • Grinding • Electrical equipment • Firewatcher duties Toolbox Talk A Toolbox Talk is a brief safety discussion about a specific subject at the beginning of the shift, job or task. The talk identifies the hazards that may be encountered and the controls required to be in place for that work task. The controls are allocated and required to be checked prior to the start of the job. Agenda for Toll for Talks • Introduce newcomers • Review of upcoming activity by most knowledgeable person • Discuss issues raised and limitations set by opposite shift • Discuss hazards involved and risk assess upcoming operations • Discuss the controls in place and consider if they are sufficient • Discuss and agree roles and responsibilities of individuals • Ask for opinions of the crew on the operation • Prompts: (Anyone can stop unsafe situation) • Lessons from previous day or from external source • The task (what is going to be done) • Procedures to be followed • Safe access & egress to job site • Identify possible hazards and appropriate precautions to be taken