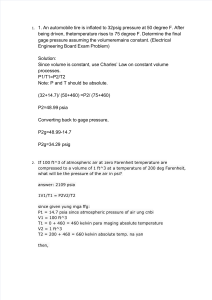

Field Processing of Natural Gas chosen because of its ready availability. The chiller cools the high-pressure gas to 0°F to produce a sales gas with low hydrocarbon dew-point. Glycol is injected to prevent hydrate formation in the heat exchangers. A beneficial result of glycol injection is that water is absorbed, yielding a gas of water dew point no higher than 0°F. Separate dehydration is not required. Approximate ly 65 bhp compression duty is required in the refrigeration unit. The gas contains a finite, though low, H2S content that must be reduced to pipeline specification of ¼ grain per 100 scf. Amine contacting is chosen. The gas must be compressed from the low field pressure of 18 psia to a sales-gas pressure of 700 psia. Reciprocating compressors are used due to the small volume of gas handled. Three stages of compression are required to retain reasonable compression ratios and temperatures in each stage. Amine treating is done at the second-stage discharge pressure. The 700-psia condensate is stabilized using a reboiled tray contactor operating at 400 psia to produce approximately 300 bpd of liquid. This liquid has a vapor pressure of 243 psia at 100°F and is supplied to a pipeline. Fractionation of such a liquid into its individual hydrocarbon products-­ ethane, propane, butanes, and pentanes plus-is not economical for such a small product rate. It is common in the U.S. to pipeline such products to a large-capacity, central fractionation facility. The 700-psia residue gas has a heating value of 1119 Btu/scf, and the production rate is 5.26 MMscfd. 83 11. How does the gas type or source (gas-well gas, retrograde condensate gas, or associated gas) affect its processing? 12. How do production location and quantity of produced gas affect its processing? 13. Name three basic techniques for NGL recovery. Problems 1. A gas well in Alberta, Canada, produces 30 MMscfd of gas with the following composition: Comp. N2 CO2 H 2S Cl C2 C3 Mol % 0.4 11.6 23.0 64.7 0.2 0.1 Wellhead pressure is 835 psia. The gas must be of sales quality: GHV H2 S H20 980 Btu/scf, dry ideal gas 0.25 grain/IOOscf 0°F dew-point