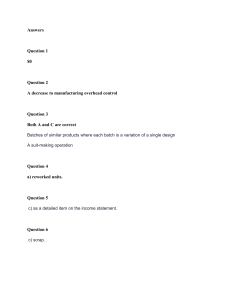

Work in Process Batch – how to tackle black boxes, brown fields, and the individual piece 121,611 1. The green field and the brown field Roman Kuhn proposed in his blog on Product Definition in the Primary Metals Industry (see chapter 3.4) to introduce material levels on more production levels than raw material and finished goods. While this approach gives the planner more insight into production progress and stock of intermediates, manufacturing staff may oppose the additional master data. Another often heard objection is that manufacturing somewhat looses track which production orders actually produce for the same sales order. But we will not discuss in this blog how such concerns have been resolved in existing implementations. Do not get me wrong – an own material level is first choice, especially in “green field” implementations. Second choice, and not a bad one at all, is to use WIP batches. I would like to propose the work-in-process batch (WIP batch) as a new modelling alternative that allows “brown field” implementations to gain more visibility into intermediate products even without introducing new material levels. Let’s take the picture above as a starting point. It depicts a production order with its stock levels and operations. While the production execution system models and manages inventory at all levels, including the intermediates, the “classical” ERP only manages inventory on material level, with all its consequences on transparency e.g. for sales and enterprise level supply chain planning. Warehouse management and external operations with intermediates are also tricky in such set-up, even more if you are required to track and identify lots or individual items across operations. With Business Suite 7 there’s a the new functionality of work in process (WIP) batch to make our life’s a little easier. The little blue-striped squares in the picture above indicate that the WIP batch allows you to model and manage inventory on the intermediate level. You do not only know how much is on stock, but you can give it a “identifier”, the batch number, and – if you like – attributes. So think of a WIP batch – in this context – of a way to model inventory before a production ressource, and to desribe the individual lots, or items, with characteristics. I assume this may be interesting information to optimize production sequence for the next ressource. 2. Recalls and the “real” logistical item flow Let’s forget everything said before and imagine a situation where detailled traceability throughout production is key. In the example below multiple batches were consumed as components, and multiple end product batches were received from production. The real logistical item flow in production is shown in the picture below:Each component item was manufactured into exactly one end product item. So, if a customer complains about bad quality in one end product item (indicated with a green square), we need to track down the component item responsible. This should be the pink square. For the classical batch-where-used list the production order is a black box. It the bad end product to all three component batches, which could be a costly inaccuracy in case of a recall. Work in process batches allow to model the real logistical item flow, be it in such an easy linear 1:1 relationship like above, but also in complex N:M relationships restulting from WIP batch splits and merges during production. Thus, with the enhanced batch-where-used-list considering WIP batches, we would correctly find only the pink square. 3. Know your items well Besides traceability requirements, it may simply be interesting to have a name for each item in production. Even more, to collect characteristics for each item, as it moves through production. Some characteristics ma be derived from the component, others relate to process parameters during an operation, and again others are item related measurements. A key improvement when modelling items as WIP batches is the continuous collection of item related data operation by operation in the WIP batch characteristics. This greatly simplifies communication with underlying systems, as ERP is now able to receive this information timely and item related (and not just at final goods receipt where process parameters for a specific item may no longer be known). 4. Outlook Three very different scenarios discussed above, we still did not talk about subcontracting, quality management, integration to production order split. Another topic that usually is raised in every discussion is costing and valuation of WIP. And yes, I did not say a word on how this is implemented and set-up. Enough food for thought for another blog, it seems.