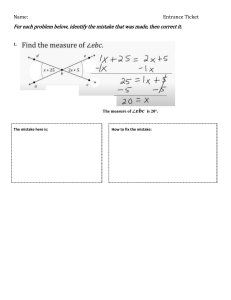

A UFP Industries Presentation Created by: C. Martin plant #477 The 3 Kinds of Companies • The best kind of company • The worst kind of company • Company struggling to get things right The trying to get it Right Company • The kind of company that cares but doesn’t know to move forward. • Want to develop a genuine culture of safety but doesn’t see how to make it happen. • A safety Coordinator that thinks or says, “I really don’t know how to reach these guys.” • How can we get some kind of control over this situation? Every day, every hour, someone trying to earn a living injures a hand, bones crushed, fingers lost, skin burned, or a whole hand dismembered in a way that could have been prevented. What actually works? • What strategies, policies, processes, attitudes, training, and decisions actually work to reduce or eliminate hand injuries to workers in the real world. In the US Workplace injuries cost more than all cancers combined • Estimated workplace injuries cost $250 billion annually. • The hand is the most commonly injured part of the upper body • 170,000 reported industrial hand injuries a year. The Theme to Hand Safety is Consistency It’s fundamental It’s necessary Training is probably the least consistent factor of all. There’s the problem of reinventing the wheel. The problem of putting out fires instead of looking at the big picture. No other part of the body has the hand’s dexterity, sensitivity, or muscle intelligence. Together we can save hands The hand is built with no less than 27 separate bones connected by a complex network of tendons, ligaments, and muscles. The hand offers a range of motion utterly unique in its beauty and capability The human hand is not a minor miracle but a major miracle What does the insurance industry estimate the cost of loss of finger or hand? The loss of a thumb or a pointer finger $125,000 The loss of a whole hand $ 250,000 All because of the lack of the right PPE, lack of attention, or lack of supervision. Cuts Common hand injuries in the work place Pinch points Lost fingers Impacts and crushing Abrasions Repetitive injuries Heat Cold Chemicals Electricity Vibration (HAVS) Long term effects from hand injuries Long term effects are the most insidious: HAVS, carpal tunnel, and chemical exposure included. The Human Factors Human factors greatly increase the risk. It’s rare that an injury is any one single person’s fault. Lose focus on a task Failed to do an inspection that would have led to a barrier being placed to prevent hands from moving too close to moving parts. At some point, either verbally or through body language a manager has communicated that “Our protocols are a good idea, but they are optional.” Workers have lost trust and respect for management, the worker believes management does not care, so they no longer listen when management sets safety policies or run training sessions to improve safety. Safety Trainers often have no experience with the actual work being done. No thinking through of safety issues Humans tend to get complacent and just do things the way they always been done. How has technology changed the PPE? Are you still using the same PPE that the company originally started with? Have you thought about if there are better options out there? Top Ten Hand Safety Mistakes Mistake #2 Mistake #3 Mistake #4 Using misguided safety incentives Mistake #5 • Saying you can’t fix stupid. You see a sign on the wall with a picture showing a man with several fingers cuts off and underneath the picture it says “Steve wasn’t listening. Steve cut his fingers off. Don’t be Steve.” Mistake #6 • Forgetting your workers speak different languages Mistake # 7 Ignoring cultural issues Mistake #8 BAD PPE BUYING AND STORING HABITS Mistake #9 Mistake #10 Keeping Useless Stats We’re a hot mess of cognitive biases • A lot of safety depends on changing the normal and habitual way we see dangers and make decisions, so we will make safer decisions. To do that, we first have to be consciously aware of our biases. Overconfidence bias is close to the top of dangerous biases. Put simply, people believe they are more agile and smarter as well as better at most tasks than they actually are. • A big problem with all PPE, and especially with gloves, is noncompliance. Overcoming PPE Noncompliance The decision to use protective gloves This Presentation will continue at a later date • This portion brought to you by Cobra Martin with the help from Author and long-time family of glove makers Joe Geng and the book Rethinking hand safety.