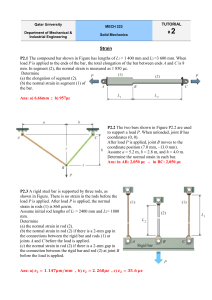

MEN255 Material Science HOMEWORK - 2 A cylindrical specimen having a diameter of 12,8 mm and a gauge length of 50,800 mm is pulled in tension. Use the load–elongation characteristics shown in the following table to complete parts (a) through (h) and present your work as a “Ms Power Point”file adding your voices. Load (N) 0 7330 15100 23100 30400 34400 38400 41300 Length (mm) 50,800 50,851 50,902 50,952 51,003 51,054 51,308 51,816 Load (N) 44800 46200 47300 47500 46100 44800 42600 36400 Length (mm) 52,832 53,848 54,864 55,880 56,896 57,658 58,420 59,182 Fracture (a) Plot the data as “engineering stress” versus “engineering strain”. (b) Plot the data as “True stress” versus “True strain” up to 12th data point. (c) Compute the modulus of elasticity. (d) Determine the yield strength at a strain offset of 0,002. (e) Determine the tensile strength of this alloy. (f) What is the approximate ductility, in percent elongation? (g) Which alloy would it be ? Explain the reasons.