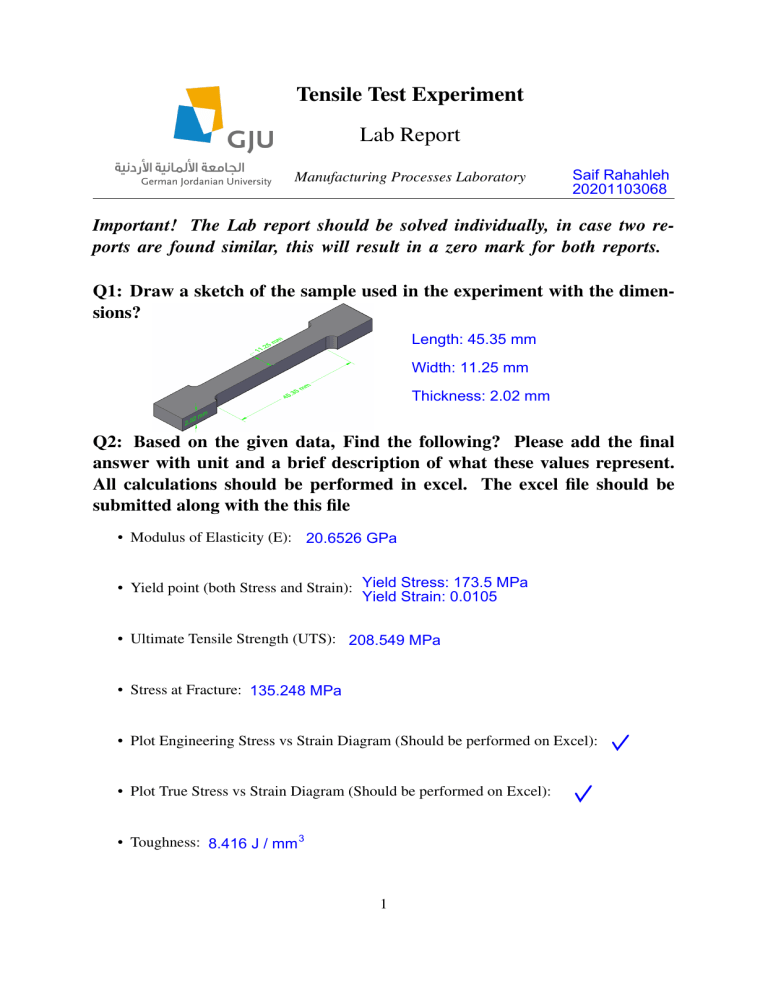

Tensile Test Experiment Lab Report Manufacturing Processes Laboratory Saif Rahahleh 20201103068 Important! The Lab report should be solved individually, in case two reports are found similar, this will result in a zero mark for both reports. Q1: Draw a sketch of the sample used in the experiment with the dimensions? Length: 45.35 mm Width: 11.25 mm Thickness: 2.02 mm Q2: Based on the given data, Find the following? Please add the final answer with unit and a brief description of what these values represent. All calculations should be performed in excel. The excel file should be submitted along with the this file • Modulus of Elasticity (E): 20.6526 GPa • Yield point (both Stress and Strain): Yield Stress: 173.5 MPa Yield Strain: 0.0105 • Ultimate Tensile Strength (UTS): 208.549 MPa • Stress at Fracture: 135.248 MPa • Plot Engineering Stress vs Strain Diagram (Should be performed on Excel): • Plot True Stress vs Strain Diagram (Should be performed on Excel): • Toughness: 8.416 J / mm 3 1 • Using an optical microscope, the area at fracture was measured and it was found to be 40 percent of the initial area. Find the true stress at fracture: σtr = ________ Fat fracture A at fracture F at fracture = 1227.94 N 2 A at fracture = 0.4 * A i = 3.6168 mm = 338.1188 MPa Q3: Describe how the tensile test is conducted, please include all the details related to the load cell size, strain rate, how the elongation is measured, and etc.. - the dimensions of the tensile specimen are measured. - the specimen is gripped to the upper and lower jaws of the universal testing machine. - the machine measures the force applied to the sample using the load cell. - the elongation is measured through an encoder sensor. However, for more accurate measurement, an extensometer is usually employed. Q4: How can you explain the apparent change from strain hardening to strain softening in a metal undergoing tension at room temperature? The apparent change from strain hardening to strain softening in a metal undergoing tension at room temperature can be explained by the formation of voids or cracks, dynamic recovery and recrystallization of the metal's microstructure, and other factors. Q5: Discuss the importance of Tensile Test. Tensile testing is important because it helps determine the mechanical properties of materials, including their strength, elasticity, and ductility. This information is crucial for designing and manufacturing materials used in a wide range of applications. Q6:What are the advantages of a stress- strain curve over a load-elongation curve? The stress-strain curve is relevant to all specimens made from this material despite of specimen shape and size. 2