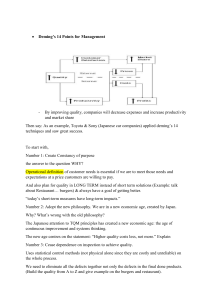

Quality Management & Tools Evolution Prior to the Industrial Revolution, skilled craftsmen performed all stages of production. Pride of workmanship and reputation often provided the motivation to see that a job was done right. Evolution Industrial Aspects Quality Quality The ability of a product or service to consistently meet or exceed customer expectations What is TQM? Meeting quality expectations as defined by the customer Integrated organizational effort designed to improve quality of processes at every business level 4 What is quality management all about? Try to manage all aspects of the organization in order to excel in all dimensions that are important to “customers” Two aspects of quality : 1. Features: more features that meet customer needs = higher quality 2. Freedom from trouble: fewer defects = higher quality Defining Quality – 5 Ways Conformance to specifications Fitness for use Evaluation of usefulness vs. price paid Support services Evaluates performance for intended use Value for price paid Does product/service meet targets and tolerances defined by designers? Quality of support after sale Psychological e.g. Ambiance, prestige, friendly staff 6 Cost of quality 1. Prevention costs – Cost of preparing and implementing a quality plan 2. Appraisal costs – Costs of testing , evaluating, and inspecting quality 3. Internal failure costs – Costs of scrap, rework, and material losses 4. External failure costs – Costs of failure at customer site, including returns, repair, and recalls 5. Opportunity costs A Quality Management System Is… • A belief in the employee’s ability to solve problems • A belief that people doing the work are best able to improve it • A belief that everyone is responsible for quality Elements for Success • • • • • • • • • Management Support Mission Statement Proper Planning Customer and Bottom Line Focus Measurement Empowerment Teamwork/Effective Meetings Continuous Process Improvement Dedicated Resources Modern History of Quality Management • Frederick W. Taylor wrote Principles of Scientific Management in 1911. • Walter A. Shewhart used statistics in quality control and inspection, and showed that productivity improves when variation is reduced (1924); wrote Economic Control of Manufactured Product in 1931. • W. Edwards Deming and Joseph M. Juran, students of Shewhart, went to Japan in 1950; began transformation from “shoddy” to “world class” goods. • In 1960, Dr. K. Ishikawa formalized “quality circles” - the use of small groups to eliminate variation and improve processes. • In the late ‘70’s and early ‘80’s: – Deming returned from Japan to write Out of the Crisis, and began his famous 4-day seminars in the United States – Phil Crosby wrote Quality is Free – NBC ran “If Japan can do it, why can’t we?” – Motorola began 6 Sigma History : how did we get here… • Deming and Juran outlined the principles of Quality Management. – Tai-ichi Ohno applies them in Toyota Motors Corp. – Japan has its National Quality Award (1951) – U.S. and European firms begin to implement Quality Management programs (1980’s) – U.S. establishes the Malcolm Baldridge National Quality Award (1987) – Sri Lanka National Quality Award (1995) by SLSI – Large / Medium / Small categary – Manufacturing / Service / Education / Health Care sectors The Quality Gurus – Edward Deming Quality is “uniformity and dependability” Focus on SPC and statistical tools “14 Points” for management 1986 PDCA method 1900-1993 History of Quality Management Deming’s 14 Points • • • • • • • • • • • • • • Create constancy of purpose for improvement Adopt a new philosophy Cease dependence on mass inspection Do not award business on price alone Work continually on the system of production and service Institute modern methods of training Institute modern methods of supervision of workers Drive out fear Break down barriers between departments Eliminate slogans, exhortations, and targets for the work force Eliminate numerical quotas Remove barriers preventing pride of workmanship Institute a vigorous program of education and retraining Take action to accomplish the transformation History of Quality Management Deming’s Concept of “Profound Knowledge” Understanding (and appreciation) of Systems - optimising sub-systems sub-optimises the total system - the majority of defects come from systems, the responsibility of management (e.g., machines not in good order, defective material, etc. Knowledge of Statistics (variation, capability, uncertainty in data, etc.) -to identify where problems are, and point managers and workers toward solutions Knowledge of Psychology (Motivation) -people are afraid of failing and not being recognised, so they fear how data will be used against them Theory of Knowledge -understanding that management in any form is a prediction, and is based on assumptions The Quality Gurus – Joseph Juran Quality is “fitness for use” Pareto Principle Cost of Quality General management approach as well as statistics 1951 1904 - 2008 History of Total Quality According to Phil Crosby, (1926-2001) Author of Quality is Free & Quality without Fears Quality is . . . An attitude: - Zero Defects (Martin Company) - Continuous Improvement A measurement: - Price of Conformance, plus - Price of Nonconformance (defects) TQ: Transforming an Organization From To Motivation through fear and loyalty Motivation through shared vision Attitude: “It’s their problem” Ownership of every problem affecting the customer Attitude: “the way we’ve always done it” Continuous improvement Decisions based on assumptions/ judgment calls Decisions based on data and facts Everything begins and ends with management Everything begins and ends with customers Crisis management and recovery Doing it right the first time Choosing participative OR scientific management Choosing scientific AND participative management Definition: Total Quality Management • Total Quality Management (TQ, QM or TQM) and Six Sigma (6 ) are sweeping “culture change” efforts to position a company for greater customer satisfaction, profitability and competitiveness. • TQ may be defined as managing the entire organization so that it excels on all dimensions of products and services that are important to the customer. • We often think of features when we think of the quality of a product or service; TQ is about conformance quality, not features. What does Total Quality Management encompass? TQM is a management philosophy: • Continuous improvement • Leadership development • Partnership development Cultural Alignment Technical Tools Customer (Process Analysis, SPC, QFD) Quality Function Development Total Quality Is… • Meeting Our Customer’s Requirements • Doing Things Right the First Time; Freedom from Failure (Defects) • Consistency (Reduction in Variation) • Continuous Improvement • Quality in Everything We Do Continuous improvement philosophy 1. Kaizen: Japanese term for continuous improvement. A step-by-step improvement of business processes. 2. PDCA: Plan-do-check-act as defined by Deming. Plan Do Act Check 3. Benchmarking : what do top performers do? Quality Quality Improvement Traditional Time The Process Improvement Cycle Select a process Document Study/document Evaluate Seek ways to Improve it Implement the Improved process Design an Improved process 20 Seven Basic Quality Tools for Process Improvements 1. 2. 3. 4. 5. 6. 7. Check sheets Process Flowcharts Scatter diagrams Histograms Pareto analysis Control charts Cause-and-effect diagrams 21 1. Check sheet Item ------------------- A B C √√ D E √ √√√ √√√ √√ √ √√ F √ √ √ G √ √√ Check Sheet Simple data check-off sheet designed to identify type of quality problems at each work station; per shift, per machine, per operator 27 Billing Errors Monday Wrong Account Wrong Amount Payment Errors Wrong Account Wrong Amount 23 2. Process flowchart Used to document the detailed steps in a process Often the first step in Process Re-Engineering 3. Scatter Diagram • A scatter diagram helps to show if there is a relationship between two variables • The closer data points are to a diagonal line, the more closely the two variables are related 4. Histogram Frequency 5. Pareto Analysis 100% 75% 50 40 50% 30 20 10 25% 0% A B C D E F Percentage Frequency 60 6. Control Charts Important tool used in Statistical Process Control – Chapter 6 The UCL and LCL are calculated limits used to show when process is in or out of control Performance Metric Time Upper Control Limit Central Line Lower Control Limit Control charts tell you when a process measure is exhibiting abnormal behavior 7. Cause and Effect Diagram – Kaoru Ishikakawa (1968) (Fishbone / Herring Bone / Fishikawa) Machine Man Environment Method Material 7. Cause and Effect Diagram Case : Shortening telephone waiting time… • A bank is employing a call answering service • The main goal in terms of quality is “zero waiting time” - customers get a bad impression - company vision to be friendly and easy access • The question is how to analyze the situation and improve quality The current process Customer A Customer B Operator Receiving Party How can we reduce waiting time? Fishbone diagram analysis Absent receiving party Working system of operators Absent Too many phone calls Lunchtime Out of office Not at desk Not giving receiving party’s coordinates Complaining Absent Lengthy talk Does not know organization well Takes too much time to explain Leaving a message Customer Does not understand customer Operator Makes customer wait Reasons why customers have to wait (12-day analysis with check sheet) Daily average Total number A One operator (partner out of office) 14.3 172 B Receiving party not present 6.1 73 C No one present in the section receiving call 5.1 61 D Section and name of the party not given 1.6 19 E Inquiry about branch office locations 1.3 16 F Other reasons 0.8 10 29.2 351 Pareto Analysis: reasons why customers have to wait 80% of the problems may be attributed to 20% of the causes Frequency Percentage 300 87.1% 250 71.2% 200 49% 150 100 0% A B C D E F Ideas for improvement 1. Taking lunches on three different shifts 2. Ask all employees to leave messages when leaving desks 3. Compiling a directory where next to personnel’s name appears her/his title Results of implementing the recommendations …After Before… Percentage Frequency Percentage Frequency 100% 87.1% 300 300 71.2% 200 Improvement 200 49% 100 100 100% 0% A B C D E F 0% B C A D E F In general, how can we monitor quality…? By observing variation in output measures! 1. Assignable variation : we can assess the cause 2. Common variation : variation that may not be possible to correct (random variation, random noise) In order to measure variation we need… The average (Mean) of the observations: N 1 X N i 1 xi The Standard Deviation of the observations: N 2 ( x X ) i i1 N Example : Capability Index (Cpk) X = 10 and σ = 2 LTL = 9 UTL = 11 LTL X UTL Example : Capability Index (Cpk) X = 10 and σ = 0.5 LTL = 9 UTL = 11 LTL X UTL Six Sigma Quality 6 • A philosophy and set of methods companies use to eliminate defects in their products and processes • Seeks to reduce variation in the processes that lead to product defects • The name “six sigma” refers to the variation that exists within plus or minus six standard deviations of the process outputs Six Sigma Quality New Japanese Techniques • Kaizan – Little Improvement : Continuous minor changes • Kaikaku – Radical Improvement : entire business is changed radically initiated by management. The result will significantly impact business introducing new knowledge, new strategies, new approaches, new production techniques or new equipment. Initiated when management see that ongoing Kaizen work is beginning to stagnate and no longer provides adequate results in relation to the effort. • Kakushin – Revolutionary Improvement