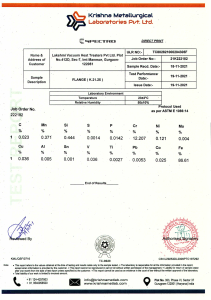

I<rishna Metallurgical Laboratories Pvt. Ltd. Name & Address 0/ Customer Sample with description as provided by the customer. Report no:Micron Precision Screws Ltd 8Th Mile Stone Job Order No:I Delhi Road I Rohtak - 124001 Sample Reed.Date:Testing Start Date:PARTNO.-6564741,PARTDESCRIPTION-1I2" Test Completion Date:20NFx1.75'WheelBolt Report Issue Date:D.P. Yadav Contact Name/No. Laboratory Environment Temperature 23 ± 5°C Relative Humidity 50 ± 10% Sample Drawn By:- 247700 22G247700A 25-07-2022 25-07-2022 25-07-2022 25-07-2022 Customer Test equipment details Model UID Metallurgical Microscope Microscope with LCDscreen KML/INS/08 CASE DEPTH: ((As periS 6416:1988. RA' 96 by Microscopic method)) MAGNIFICATION100 X OBSERVA TION:- S.No CASE DEPTH UNIT L1 0.129 L2 0.123 mm mm mm mm mm mm L3 0.116 L4 0.132 Ls 0.125 AVERAGE 0.125 Case Depth = 0.125mm ____________ EndofReporl __ ~n"i,\VV Tested By ReVi~ KMUQSF/0716 Note D-U-H-4 NumMr. 17-370 ... 1. • This report refers to the values obtained at the time of testing and results relate only to the sample tested .• The laboratory is responsible for all the information provided in the report, except when information is provided by the customer, • This report cannot be reproduced in part or full without written permission of the manaqement.e Liability for return of sample cease after one month from the date of test report unless specified by the customer, • This report cannot be used as an evidence in the court of law without the written approval of the'laboratory, • Tolalliability of our work is limited to invoiced amount. CIN:U29253DL2009PTC197292 + 91 124-4257803 + 91 9540956500 info@krishnametlab.com www.krishnametlab.com Q Plot No. 353, Phase VI, Sector 37 Gurugram-122001 (Haryana) India I<rishna MGttallurgical Laboratories Pvt. Ltd. Report No:Name & Address of Customer Micron Precision Screws Ltd 8Th Mile Stone, Delhi Road, Rohtak - 124001 Sample with description as provided by the customer. PART NO.- 6564741, PART DESCRIPTION-1/2"20NFx1.75"Wheel sou Contact Name/No. O.P. Yadav Laboratory 23±2°C Relative Humidity 50±10% job Order No:- 22G2477008 Sample Reed. Date:- 25-07-2022 Test Start Date:- 25-07-2022 Test Completion Date:- 25-07-2022 Report Issue Date:- 25-07-2022 Sample Drawn 8y:- Environment Temperature 2477008 Make Model Fuel Instruments and Engineers Pvt. Ltd. (FIE) MV1-PC -- Customer UID KMLlINS/31 Micro Vicker Hardness Test:Test Method:-IS:1501 (PART-1)-2020 C~SE HARDNESS Reading Observation 1 482 HVO.1 2 480 HVO.1 3 485 HVO.1 Average ____ End of Report__ •• KMUQSF/0716 Note 482 HVO.1 = 1 ~ ReVi~ I!l . • D4J-H-S Number: 17-370-"11 • This report refers to the values obtained at the time of testing and results relate only to the sample tested.• The laboratory is responsible for all the information provided in the report, except when information is provided by the customer.• This report cannot be reproduced in part or full without written permission of the manaqement.e Liability for retum of sample cease after one month from the date of test report unless specified by the customer.• This report cannot be used as an evidence in the court of law without the written approval of the laboratory. • Total liability of our work is limited to invoiced amount. CIN:U29253DL.2009PTC197292 + 91124-4257803 + 91 9540956500 info@krishnametlab.com www.krishnametlab.com Q Plot No. 353, Phase VI, Sector 37 Gurugram-122001 (Haryana) India I<rishna Metallurgical Laboratories Pvt. Ltd. Report No:Name & Address of Customer Micron Precision Screws Ltd 8Th Mile Stone, Delhi Road, Rohtak - 124001 Sample with description as ~rovided by the customer. PART NO.- 6564741, PART DES.CRIPTION-1/2"20NFx1.75"Wheel Bolt Contact Name/No. O.P. Yadav 247700C Job Order No:- 22G247700C Sample Reed. Date:- 25-07-2022 Test Start Date:- 25-07-2022 Test Completion Date:- 25-07-2022 Report Issue Date:Sample Drawn By:- Laboratory Environment Temperature 23±2°C Relative Humidity 50±10% 25-07-2022 Customer Make Model UID Fuel Instruments and Engineers Pvt. Ltd. (FIE) MV1-PC KMLlINS/31 !VJicro Vcicker Hardness Test:Test Method:- IS:1501 (PART-1 )-2020 CORE HARDNESS Reading Observation 1 354 HVO.1 2 366 HVO.1 3 360 HVO.1 Average ____ = 360 HVO.1 End of Report __ i- \~/~(1\~ Tested By Re~ KMUQSF/0716 Note D-U-N-a Numbtlr: 87-370-1111 • This report refers to the values obtained at the time of testing and results relate only to the sample tested .• The laboratory is responsible for all the information provided in the report, except when information is provided by the customer.• This report cannot be reproduced in part or full without written permission of the management. • Liability for return of sample cease after one month from the date of test report unless specified by the customer.• This report cannot be used as an evidence in the court of law without the written approval of the laboratory. • Total liability of our work is limited to invoiced amount. CIN:U29253DL2009PTC197292 + 91124-4257803 + 91 9540956500 info@krishnametlab.com www.krishnametlab.com Q Plot No. 353, Phase VI, Sector 37 Gurugram-122001 (Haryana) India I<rishna Mfittallurgical Laboratories Pvt. Ltd. Name & Address of Customer Report no:Micron Precision Screws Ltd 8Th Mile Stone Job Order No:, Delhi Road, Rohtak - 124001 Sample Reed. Date:PART NO.- 6709170, PART DESCRIPTION9/16"-18UNFx2'Wheel Bolt Sample with description as provided by the customer. D.P. Yadav Contact Name/No. Laboratory Environment Temperature Relative Hwnidity I 23 ±5°C 50± 10% 247701 22G247701A 25-07-2022 25-07-2022 Testing Start Date:Test Completion Date:- 25-07-2022 Report Issue Date:- 25-07-2022 Sample Drawn By:- Customer Test equipment details Model UID Metallurgical Microscope Microscope with LCDscreen KML/INS/08 MAGNIFICATION100 X OBSERVA TION:- S.No CASE DEPTH UNIT L1 0.109 L2 0.129 L3 0.115 L4 0.128 mm mm mm mm mm mm Ls 0.121 AVERAGE 0.120 Case Depth = O.120mm _______________EndofReporl. __ ~~~ry\(yv Tested By R~ KMUQSF/0716 Note D-U-N-S Numt.r:'7-370~1' • This report refers to the values obtained at the time of testing and results relate only to the sample tested .• The laboratory is responsible for all the infonnation provided in the report, except when infonnation is provided by the customer.• This report cannot be reproduced in part or full without written pennission of the manaqements Liability for retum of sample cease after one month from the date of test report unless specified by the customer.• This report cannot be used as an evidence in the court of law without the written approval of the laboratory. • Total liability of our work is limited to invoiced amount. CIN:U29253DL2009PTC197292 + 91124-4257803 + 91 9540956500 info@krishnametlab.com www.krishnametlab.com Q Plot No. 353, Phase VI, Sector 37 Gurugram-122001 (Haryana) India I<rishna Metallurgical Laboratories Pvt. Ltd. Report No:Name & Address of Customer Micron Precision Screws Ltd 8Th Mile Stone, Delhi Road, Rohtak - 124001 Sample with . description as provided by the customer. PART NO.- 6709170, PART DESCRIPTION-9/16"18UNFx2"Wheel Bolt Contact Name/No. O.P. Yadav Laboratory ~. Environment Temperature 23±2°C Relative Humidity 50±10% " 247701B Job Order No:- 22G247701B Sample Reed. Date:- 25-07-2022 Test Start Date:- 25-07-2022 Test Completion Date:- 25-07-2022 Report Issue Date:- 25-07-2022 Sample Drawn By:- Customer Make Model Fuel Instruments and Engineers Pvt. Ltd. (FIE) MV1-PC UID KMLIINS/31 . Micro Vicker Hardness Test:Test Method:-IS:1501 (PART-1)-2020 CASE HARDNESS Reading Observation 1 409 HVO.1 2 407 HVO.1 3 411 HVO.1 Average 409 HVO.1 = ____ Tested By KMuaSF/0716 Note End of Report __ . .• [!] •[!] Re~ -.: . D-U-H-S Number: .7-370 .... 11 • This report refers to the values obtained at the time of testing and results relate only to the sample tested.• The laboratory is responsible for all the information provided in the report, except when information is provided by the customer.• This report cannot be reproduced in part or full without written permission of the management. •. Liability for return of sample cease after one month from the date of test report unless specified by the customer.• This report cannot be used as an evidence in the court of law wHhoutthe written approval of the laboratory. • Tolalliability of our work is limited to invoiced amount. CIN:U29253DL2009PTC197292 .\. + 91 124-4257803 + 91 9540956500 info@krishnametlab.com www.krishnametlab.com Q Plot No. 353, Phase VI, Sector 37 Gurugram-122001 (Haryana) India ~~ U~ I<rishna Metallurgical Laboratories Pvt. Ltd. Report No:- Name & Address of Customer Micron Precision Screws Ltd 8Th Mile Stone, Delhi Road, Rohtak - 124001 Sample with. description as provided by the customer. PART NO.- 6709170, PART DESCRIPTION- 9/16"18UNFx2"Wheel Bolt Contact Name/No. O.P. Yadav Job Order No:- 22G247701C Sample Recd. Date:- 25-07-2022 Test Start Date:- 25-07-2022 Test Completion Date:- 25-07-2022 Report Issue Date:- Laboratory , 247701C Sample Drawn By:- Environment Temperature 23±2°C Relative Humidity 50±10% 25-07-2022 Make Model Fuel Instruments and Engineers Pvt. Ltd. (FIE) MV1-PC Customer UID KMLlINS/31 Micro Vicker Hardness Test:Test Method:- IS:1501 (FART-1 )-2020 CORE HARDNESS Reading Observation 1 370 HVO.1 2 363 HVO.1 3 359 HVO.1 Average ____ = 364 HV01 End of Report__ · .~~\y/ Tested By Re~ KMUQSF/0716 D4J-H-S Number: .7-370 .... 11 Note • This report refers to the values obtained at the time of testing and results relate only to the sample tested.• The laboratory is responsible for all the information providedin the report, except when information is provided by the customer.• This report cannot be reproduced in part or full without written permission of the management.• Liability for return of sample ceese after one month from the date of test report unless specified by the customer.• This report cannot be used as an evidence in the court of law without the written approval of the laboratory. • Total liability of our work is limited to invoiced amount. CIN:U29253DL2009PTC197292 + 91124-4257803 + 91 9540956500 info@krishnametlab.com www.krlshnernetlab.corn Q Plot No. 353, Phase VI, Sector 37 Gurugram-122001 (Haryana) India