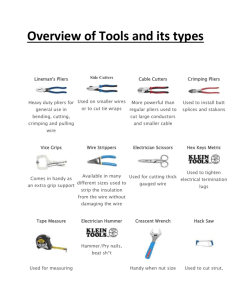

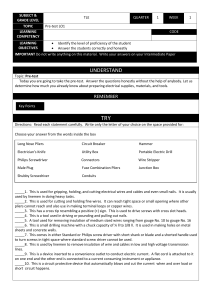

8 TECHNOLOGY AND LIVELIHOOD EDUCATION ELECTRICAL INSTALLATION AND MAINTENANCE (EIM) Quarter 3 - Module 1: Prepare Electrical Materials and Tools for the Task TLE – Grade 8 Quarter 3-Module1: Prepare Electrical Materials and Tools for the Task First Edition, 2020 Republic Act 8293, section 176 states that: No copyright shall subsist in any work of the Government of the Philippines. However, prior approval of the government agency or office wherein the work is created shall be necessary for exploitation of such work for profit. Such agency or office may, among other things, impose as a condition the payment of royalties. Borrowed materials (i.e., songs, stories, poems, pictures, photos, brand names, trademarks, etc.) included in this module are owned by their respective copyright holders. Every effort has been exerted to locate and seek permission to use these materials from their respective copyright owners. The publisher and authors do not represent nor claim ownership over them. Published by the Department of Education Development Team of the Module Writer : Cerenia A. Bercero Editor : Paulo C. Sanico Reviewer : Alpha D. Palconit Illustrator : Cerenia A. Bercero Layout Artist : Management Team: Josephine L. Fadul – Schools Division Superintendent Melanie P. Estacio – Assistant Schools Division Superintendent Christine C. Bagacay – Chief – Curriculum Implementation Alpha D. Palconit Lorna C. Ragos – Education Program Supervisor – EPP/TLE – Education Program Supervisor Learning Resources Management Inilimbag sa Pilipinas ng __________________________________________ Department of Education – Region XI Office Address: F. Torres St., Davao City Telefax: (082) 291-1665; (082) 221-6147 E-mail Address: regionxi@deped.gov.ph * lrms.regionxi@deped.gov.ph 8 Technology and Livelihood Education Quarter 3 – MODULE 1: Prepare Electrical Materials and Tools for the Task Introductory Message This Self-Learning Module (SLM) is prepared so that you, our dear learners, can continue your studies and learn while at home. Activities, questions, directions, exercises, and discussions are carefully stated for you to understand each lesson. Each SLM is composed of different parts. Each part shall guide you step-by-step as you discover and understand the lesson prepared for you. Pre-tests are provided to measure your prior knowledge on lessons in each SLM. This will tell you if you need to proceed on completing this module or if you need to ask your facilitator or your teacher’s assistance for better understanding of the lesson. At the end of each module, you need to answer the post-test to self-check your learning. Answer keys are provided for each activity and test. We trust that you will be honest in doing your task and activities on this module In addition to the material in the main text, Notes to the Teacher are also provided to our facilitators and parents for strategies and reminders on how they can best help you on your home-based learning. Please use this module with care. Do not put unnecessary marks on any part of this SLM. Use a separate sheet of paper in answering the exercises and tests. And read the instructions carefully before performing each task. If you have any questions in using this SLM or any difficulty in answering the tasks in this module, do not hesitate to consult your teacher or facilitator. Thank you. Let Us Learn! Welcome to the world of ELECTRICAL INSTALLATION AND MAINTENACE This module is prepared to help you achieve the required Learning Outcomes and the source of information that will enable you to acquire the knowledge, skills and attitudes in this particular trade independently at your own pace or with minimum supervision or help from your instructor. Electrical tools can make our work easier, faster and efficient. However, these tools when improperly used can cause injuries. To avoid it, one should be mindful and cautious when working with electrical tools. Appropriate personal protective equipment should be used while doing the task or job. Before you perform a specific job, you must first identify the appropriate electrical tools and materials that you are going to use to make your job complete and easier to perform. But before you can decide which type of tools and materials that you are going to pick, we have to make it sure that you have already known them and how to use them according to their purpose. This module has two lessons with the following learning outcomes and performance standards: LO1 Prepare Electrical Materials and Tools for the Task. ( TLE _IAE17/8UT-0a-1 ) 1.1 Prepare a List of Electrical Tools and Materials for a Specific Job. 1.2 Identify electrical supplies, materials, and tools LO2 Request Appropriate Electrical Supplies, Materials and Tools to a Specific Job. ( TLE-IAE17/8UT-0a-2 ) 2.1 Use the Appropriate Form in Requesting for Electrical Tools 2.2 Receive and inspect electrical supplies, materials and tools Lesson 1 Prepare Electrical Materials and Tools for the Task Let Us Try! How well do you know about the use of Electrical supplies, Materials and Tools ? Let’s try to find out by answering the following questions. After honestly answering this, you may check the answers at the last part of this module. Activity 1 Multiple Choice Direction: Choose the letter of the best answer and write in a clean sheet of paper. 1. Which of the following tools is used for griping, holding, cutting electrical wires and cables and even small nails. Usually used by linemen in doing heavy tasks. a. combination Pliers c. Male plug b. long nose pliers d. Fuse 2. What tool will you used for cutting and holding fine wires. This can reach tight space or small opening where other pliers cannot reach and also used in making terminal loops of copper wires. a. combination Plier c. Male plug b. long nose pliers d. Fuse 3. This has a cross tip resembling a positive (+) sign. It is used to drive screws with cross slot heads. a. combination Plier c. Male plug b. long nose pliers d. Philips Screw driver 4. Which among the tools is used for driving or pounding and pulling out nails. a. combination Plier b. long nose pliers c. Claw hammer d. Fuse 5. A tool used for removing insulation of medium sized wires ranging from gauge #10 to gauge #16. a. combination Pliers c. Male plug b. long nose pliers d. Wire Stripper 6. A small drilling machine with a chuck capacity of ¼‖ to 3/8‖. It is used in making holes on metal sheets and concrete walls. a. Portable electric drill c. Male plug b. long nose pliers d. Fuse 7. Comes in either Standard or Philips screw driver with short shank or blade and shorted handle used to turn screws in tight space where standard screw driver cannot be used. a. combination Pliers c. Male plug b. Stubby screw driver d. Fuse 8. Used by linemen to remove insulation of wire and cables in low and high voltage transmission lines. a. combination Pliers c. Electrician’s knife b. long nose pliers d. Fuse 9. What is a device inserted to a convenience outlet to conduct electric current. A flat cord is attached to it on one end and the other end is connected to a current consuming instrument or appliance. a. combination Pliers c. Male plug b. long nose pliers d. Fuse 10. This is a circuit protective device that automatically blows and cut the current when an over load or short circuit happens. a. combination Pliers c. Male plug b. long nose pliers d. Fuse 11. This is a rectangular shaped metallic or plastic (PVC) material in which flush type convenience outlet and switch are attached. a. Utility box c. Male plug b. long nose pliers d. Fuse 12. These are electrical materials used as the passage of wires for protection and Insulation. a. combination Pliers c. Connectors b. Conduits d. Fuse 13. Which are used to attach metallic or non-metallic conduit to the junction or utility boxes. a. combination Pliers c. Male plug b. long nose pliers d. Connectors 14. This is a protective device used to automatically cut off the current when trouble in the circuit such as short circuit or over load occurs. a. combination Pliers c. Male plug b. circuit breaker d. Fuse 15. It is an octagonal shaped electrical material where the connections or joints of wires are being done. It is also where the flush type lamp holder is attached. a. Junction box b. long nose pliers c. Male plug d. Fuse Let Us Study COMMON ELECTRICAL TOOLS Electrical task can be accomplished systematically to save time, effort, and resources. Most of the work cannot be done using bare hands. To do the task, electrical tools are needed to perform the job. This lesson will discuss the function/use of each tool in electrical wiring installations. The following are common electrical tools needed in the installation of electrical wiring. Name of Electrical Tool Function and Usage 1. SCREWDRIVERS These tools are made of steel hardened and tempered at the tip used to loosen or tighten screws with slotted heads. They come in various sizes and shapes. Types of Screwdrivers The blade tip is wedge-shaped and resembles a negative (-) sign. This is used to drive screws with a single slot head. A. Standard/Flat Screwdriver B. Philips Screwdriver This has a cross tip resembling a positive (+) sign. This is used to drive screws with cross slot heads. C. Stubby Screwdriver This comes in either Standard or Philips screwdriver with short shank or blade and a shorted handle used to turn screws in tight spaces where a standard screwdriver cannot be used. D. Allen Screwdriver/Wre nch This could be in the shape of a screwdriver or a wrench. Its function is to drive screws with hexagonal slot heads. 2. HAMMERS These are tools used in driving or pounding and pulling out nails. They are made of hard steel, wood, plastic, or rubber Types of Hammers Picture A. Claw Hammer Is a hammer with one side of the head split and curved, used for extracting nails. B. Mallet (Rubber head) Has rubber head and is usually used to knock wooden pieces together, or to drive dowels or chisels. C. Ball-peen Hammer It is also known as machinist’s hammer used in metalworking. 3. PLIERS These tools are made from metal with insulators in the handle and are used for cutting, twisting, bending, holding, and gripping wires and cables. Types of Pliers A. Combination Pliers (Lineman’s Pliers). This is used for gripping, holding, and cutting electrical wires and cables and even small nails. They are usually used by linemen in doing heavy tasks. B. Side Cutting Pliers This type of pliers is used for cutting fine, medium, and big wires and cables. C. Long Nose Pliers This is used for cutting and holding fine wires. This can reach tight spaces or small openings where other pliers cannot reach. 4. WIRE STRIPPER This is a tool used for removing insulation of medium-sized wires ranging from gauge #10 to gauge #16. 5. Electrician’s Knife This is used by linemen to remove insulation of wire and cables in low and high voltage transmission lines. 6. Portable Electric drill A small drilling machine with a chuck capacity of ¼” to ½”. It is used in making holes on metal sheets and concrete walls. 7. Hacksaw This tool is used to cut metal conduit and armored cable. Materials 1. Convenience outlet Description Is a device that acts as a convenient source of electrical energy for current consuming appliances. It is where the male plug of an appliance is inserted and is usually fastened on the wall or connected in an extension cord. It may be single, duplex, triplex, or multiplex and could be surface type or flush type. Common Types of Convenience Outlet a. Surface type This type of outlet is typically mounted on the surface portion of the wall b. Flush type This type of outlet is typically buried in concrete and is attach to the utility box 2. Male plug Is a device inserted to a convenience outlet to allow the flow of electric current. This is use in making extension wires. 3. Lamp These are devices that hold the lamp and are also called Lamp Sockets or Ceiling Receptacles. These come in many designs and sizes. They are classified as flush, hanging (weather proof/chain), and surface types. holders 4. Switch Is a device that connects and disconnects the flow of electric current in a circuit. There are many shapes, designs, and types and they are classified as hanging, flush, and surface types. 5. Fuse Is a circuit protective device that automatically blows and cuts the current when overload or short circuit happens. 6. Circuit Is a protective device that automatically trips and cut the current when trouble in the circuit such as short circuit or overload occurs. It comes in 2 poles, 3 poles and 4 poles. Breaker 7. Junction Box 8. Utility Box Is an octagonal shaped electrical material where connections, joints or termination of wires are being done. It is also where the flush type lamp holder is attached. This could be made of metal or plastic (PVC) Polyvinylchloride. Is a rectangular shaped metallic or plastic (PVC) material in which flush type convenience outlet and switch are attached. Picture 9.Flat Cord Is a duplex stranded wire used for temporary wiring installation and commonly used in extension cord assembly. It comes in a roll of 150 meters and sizes of gauge # 18, gauge # 16 AWG and gauge # 14 AWG (American wire gauge). 10.Electrical Wire or Conductor Is the means in which electrical current will flow. It is usually made of copper or aluminum with or without outside insulation. Types of Electrical wire or conductor a. Stranded wire Is made of multiple strands of copper or aluminum joined together to make a single wire. b. Solid wire Is made of a single strand of copper or aluminum wire. These are used in wiring installation inside and outside the buildings. 11.Conduits /Pipes Are tubes that are used not only to protect wires but also to route electrical wiring throughout a building. Common Types of Conduits/Pipes a. Rigid Steel Conduit (RSC) Is a thick-walled threaded tubing, usually made of hot-dipped galvanized inside and outside and is threaded at both ends. b. Flexible Non-metallic conduit or corrugated plastic conduit (CPC) Is flexible corrugated plastic tubing that is moisture-resistant and flameretardant. It is easy to bend and installs with snap-lock or glued plastic fittings. c. Rigid Nonmetallic conduit (PVC) Is similar to plastic plumbing pipe and installs with fittings. It can be bent after being heated using portable heat gun. d. Electrical Metallic Tubing (EMT) Are made of electro-galvanized metal. It is typically thin and lightweight. EMT is rigid but can be bent with a simple tool called a conduit bender. e. Flexible Metal Conduit (FMC) Has a spiral construction that makes it flexible so it can snake through walls and other structures. f. Liquid tight Flexible Metal Conduit (LFMC) Is a special type of flexible metal conduit that has a plastic coating and is used with sealed fittings to make it water tight. 12. Clamps Electrical materials are used to hold and anchor electrical conduits to its proper position. 13. Connectors Are used to attach metallic or nonmetallic conduit to the junction or Utility boxes. COMMON ELECTRICAL MATERIALS Electrical materials are developed and constructed for a special purpose, such as: 1. control the flow of current in an electrical circuit 2. carry electrical current from the source to the load or current consuming apparatus; 3. hold and secure wires to its fixtures inside and outside houses and buildings. 4. protect houses, buildings, appliances, and instruments from destruction and damage. The following are the most commonly used electrical materials. COMMON WIRE SPLICES AND JOINTS As a student in Electrical Installation and Maintenance, you should acquire the important knowledge and skills in wire splices and joints and be familiar with the actual application of every splice and joint. This will serve as your tool in performing actual wiring installation. The following are common electrical wire splices and joints. Rat Tail or Pig Tail This kind of joint is commonly used to join two or more conductors inside the junction box. It is suitable for service where there is no mechanical stress when wires are to be connected in an outlet box, switch, or conduit fitting. Y-splice This method of wrapping is generally used on small cables because the strands are flexible and can all be wrapped in one operation. Knotted tap This is used where the tap wire is under heavy tensile stress. Plain tap joint This is used where the tap wire is under considerable tensile stress circuit. Aerial tap This is used as a temporary tap usually done in constructions sites. The easy twist will facilitate tap wire movement Duplex cross joint This is a two-tap wire turned simultaneously and is used where the two tap wire is under heavy tensile stress. Western Union Short-tie Splice This is the most widely used splice or joint in interior wiring installation to extend the length of wire from one point to another Western Union Long Tie This is used extensively for outside wiring to extend the length of wire from one end to another. Cross joint The same application is done as in plain tap but the only difference is that this tap is a combination of two plain taps placed side by side with each other. Wrapped Tap or Tee Joint This is used on large solid conductors where it is difficult to wrap the heavy tap wire around the main wire. EXTENSION CORD An extension cord is a span of flexible electrical power cable with a plug on one end and multiple sockets on the other end. It comes in several varieties to suit the needs of the user. One of the most important considerations is the power handling capacity to make it safe and functional. Electrical gadgets are product of modern technology to make our life better. The number of electrical gadgets available at home and in offices may exceed the existing convenience outlet installed in every room. The best remedy to address the insufficiency of available outlet is to use an extension cord especially if the electrical gadgets need to operate at the same time Tools and Equipment Needed: Materials Needed 1. Standard/Flat Screw Driver 1. Convenience Outlet 2. Philips Screw Driver 2. Flat Cord # 18 AWG 3. Long Nose Pliers 3. Male Plug 4. Side Cutting Pliers 4. Eyelet Wire Connectors 5. Electrician’s knife/ Pocket knife 6. Continuity Tester or Multi-tester REMINDER Be careful in buying an extension cord. You have to look for the Department of Trade and Industry (DTI) markings. The Product Standard (PS) or Import Commodity Clearance (ICC) markings on it signify that the product passed the DTI standard for safety and quality Steps in Making an Extension cord 1. 2. 3. 4. 5. Prepare the plan. Gather all necessary materials and tools needed. Separate one end of electrical wire to about 10 cm. each. Peel off the skin or insulator of the wire ends by 2 cm. Loosen the screw of the male plug. Open cover of male plug with a screwdriver. 6. Insert the wire into the male plug .Twist both ends of the wire to keep the wires making contact with each other. Tighten the screws down to hold the wires securely. 7. Put back the cover of the plug so the wire will not be exposed and cause electric shock. 8. Repeat steps 1 to 4 on the other end of the electrical wire, this time with the female plug. Once the steps have been done you now have a complete extension cord. Let Us Practice Activity 2 Identify Me ! Directions: Identify the following electrical tools and materials. Write your answers in a clean sheet of paper. 1. ________ 2. _________ 3.________ 7. _________ 4. ________ 8. ________ 5. ________ 9. ________ 6. ________ 10. ________ Let Us Practice More ACTIVITY 3 – GATHER ME! Directions: Below is a picture of an extension cord. Prepare a list of the following items in order to create the extension cord: Write your answers in a clean sheet of paper. a. b. appropriate electrical materials; and 1. ______________________ 3. ______________________ 2. ______________________ 4. ______________________ appropriate electrical tools 5. ______________________ 8. ______________________ 6. ______________________ 9. ______________________ 7. ______________________ 10. _____________________ Let Us Remember ACTIVITY 4 Name me ! Directions: Identify the specific name of each of the following electrical wire splices and joints. Write your answer in clean sheet of papers. 1. ______________________________ 2. ______________________________ 3. ______________________________ 4. ______________________________ 5. ______________________________ Let Us Assess Activity 5.1 Directions: Read the statement carefully and choose one that best illustrates an electrical tool or material. Write the letter of your answer in your EIM activity notebook or clean sheet of paper. 1. It is made of multiple strands joined together to make a single wire. a. Solid Wire c. Flat Cord b. Speaker Wire d. Stranded Wire 2. The blade tip is wedge-shaped and resembles a negative (-) sign. This is used to drive screws with a single slot head a. Flat Screw driver c. Allen Screw Driver b. Phillips Screw Driver d. Stubby Screw Driver 3. It is only used to cut wires and cables. a. Long Nose Plier c Combination Plier b. Side cutting plier d. Wire Stripper 4. What tool will you use to tighten or loosen screw? a. hammer c. electric drill b. pliers d. screw drivers 5. Which tool is used by a linemen to remove insulation of wire and cables in low and high voltage transmission lines. a. Hammer c. electrician’s knife b. electric drill d. hacksaw 6. which of the following tools is used to cut metal conduit and armored cable. a. Hacksaw c. vise grip b. screwdriver d. gear puller 7. What particular device that act as a convenient source of electrical energy for current consuming appliance. a. Male plug c . Junction box b. Switch d. Convenience outlet 8. It is also called as Lamp Sockets/Receptacles. a. Lamp Holders c. Utility Box b. Male Plug d . Switch 9. It is a device that connects and disconnects the flow of electric current. a. Junction Box c. Switch b. Utility Box d. Male Plug 10. It is a circuit protective device that automatically blows and cut the current when overload or short circuit happens. a. Circuit Breaker c. Lamp Holder b. Fuse d. Junction Box Activity 5.2 Picture analysis. Pictures below represent the procedures in making an extension cord. Directions: Arrange the following pictures according to steps in assembling an extension cord. Write letter A- F on the space provided before each number. 1.________ 4.__________ 2.________ 5._______ 3.________ Let Us Enhance Change me or choose me Modified TRUE or FALSE: Write True if the statement is correct, and if False, change the underline word/s to make the sentence correct. Write your answer in a clean sheet of paper. _______1. Conduit pipes are used to secure the wires and protect from physical damage. _______2. Circuit Breaker is a circuit protective device that automatically blows and cut the current when an over load or short circuit occurs. _______3. Switch is a device that hold and protect the lamp. _______4. Solid wire is made of multiple strands joined together to make a single wire. _______5. Connectors are used to hold and anchor electrical conduits in its proper position. _______6. Utility box is an octagonal shaped electrical material where the connections or joints of wires are being done _______7. Switch is a devise that controls the flow of current in the circuit. _______8. The primary purpose of the fuse is to cut off the flow of current when overloading occurs in the system. _______9. Junction Box is used to carry electrical current from the source to the load. _______10. Male plug is a device inserted to a convenience outlet to conduct electric current. Let Us Reflect Congratulations ! You have come this far from our lesson. You have learned on how important the different electrical materials and tools used in wiring installation. 1. In a paragraph ! why is it important for you to learn the different electrical materials and tools and their uses in wiring installation ? __________________________________________________________________________________ __________________________________________________________________________________ 2. As a student in Electrical Installation and Maintenance, do you think it’s important for you to acquire knowledge and skills in wire splices and joints ? explain briefly the reasons. _______________________________________________________ __________________________________________________________________________________ 3. Why do we need to make a plan in making an extension cord ? __________________________________________________________________________________ __________________________________________________________________________________ Let Us Learn! This lesson 2 is prepared to help you achieve the required competency and the source of information for you to acquire knowledge and skills in requesting appropriate electrical supplies, materials and tools and receiving and inspecting electrical supplies, materials and tools with minimum supervision or help from your parent/guardian/teacher. With the aid of this material, you will acquire the competency independently at your own pace. This module consists of two (2) Learning Outcomes (LO’s) that contains learning activities for both knowledge and skills supported with information sheets. Work through all the information and complete the activities in each section. Read all information sheets and complete all the activities given, suggested references are included to supplement the materials provided in this module. Learning Outcomes: 2 Request Appropriate Electrical Supplies Materials and Tools Applicable to a specific Job. At the end of this lesson, you will be able to: 1.1 1.2 Use the appropriate form in requesting for electrical tools Receiving and inspecting electrical supplies, materials and tool Lesson 2 Request Appropriate Electrical Supplies, Materials and Tools to a Specific Job. Let us Try Let us determine how much you already know about requesting appropriate supplies, materials and tools for a specific job and receiving and inspecting electrical supplies, materials and tools. Take this test. Activity A Directions: Match the forms in Column B with the corresponding descriptions in Column A. Write your answers in a clean sheet of paper. Column A ______ 1. A document generated by a user department or storeroom personnel to notify the purchasing department of items needed, their quantity, and the time frame. ______ 2. The raw materials, work-in-process goods, and completely finished goods that are considered to be the portion of a business's assets that are ready or will be ready for sale. _______ 3. A form used to request for tools and equipment to be used for a particular job. _______ 4. A written instruction to perform a task according to specified requirements, time frame, and cost estimates. Column B A. Inventory of Materials Form B. Tool and Equipment Form C. Job Order/ Work Order Form D. Borrowers Form E. Purchase Requisition Let us Learn DIFFERENT TYPES OF FORMS Correctness of the entries in different forms used in electrical work is necessary in order to acquire right, complete, and accurate number of materials and tools needed for a specific electrical job. Here are samples of different forms used in electrical work. 1. Purchase requisition is a document generated by a user department or storeroom personnel to notify the purchasing department about items it needs to order, their quantity, and the time frame. It may also contain the authorization to proceed with the purchase. This is also called purchase request or requisition. Below is the sample of Purchase Requisition Form. 2. Inventory are raw materials, work-in-process goods, and completely finished goods that are considered to be the portion of a business's assets that are ready or will be ready for sale. Inventory represents one of the most important assets that most businesses possess, because the turnover of inventory represents one of the primary sources of revenue generation and subsequent earnings for the company's shareholders/owners. Below is the example of the Inventory of Materials Form. 3. Job Order or Work Order Form is a written instruction to perform a task according to specified requirements, time frame, and cost estimates 4. Borrower’s Form is a form used to request for tools and equipment needed for a particular job. It indicates the department the borrower is connected, with the date, the job that is to be done, the person who will approve the request, when it was returned, and if it was in good condition. Sample of the borrower’s form is located below. Receive and Inspect Electrical Supplies, Materials and Tools One of the tasks of a supply officer or logistics officer is the purchase of the company’s supplies, materials, and anything that the company needs. But this duty does not end in just purchasing but also in receiving the deliveries of what was purchased. In receiving the deliveries, understand that you need to ensure that the right materials and supplies were delivered and all are in good condition without defects. A. When you receive a shipment, ask the shipper the following questions: 1. Is it for me? Check the delivery receipt for the consignee's name and address. If your agency has more than one location, make sure the goods are for this exact address. Check the freight to see if it is the same as what is described on the delivery receipt. Look at the label on each item to make sure the shipment belongs to you. 2. Is it damaged? Do not sign the receipt before inspecting for damage. Check for holes, water, stains, and tears. Pick up cartons if you can. Check for rattling. Listen for something broken inside. Check to see if any package has been opened or if the sealing tape has been tampered with. 3. Is the piece count correct? Count the pieces and match the number on the delivery receipt to the number you have counted. If the shipment is on a pallet, check to make sure the pallet is solid with no voids inside the stack. If the shipment is shrink or stretch wrapped, make sure the wrap hasn't been cut and pieces removed. Sign only for the type of unit you receive. For example: two pallets. Don't sign for the number of packages that are supposed to be on the pallet. However, if time permits or the pallet is not banded or shrink wrapped, count the packages, and only then sign for the number of packages. B. If your delivery doesn't check out, do one of the following: 1. Refuse shipment if it isn't yours, if the shipment does not meet the terms specified by your agency, or is damaged to the point where it no longer has a value. 2. If yours, and only partially damaged or short, accept it and note exceptions on the delivery receipt. C. How to note exceptions: 1. Damage Notations: Be specific. Describe the damage accurately. Pinpoint the locations of all defects. If you can see the damage, have the driver wait while you open and inspect the packages. Write down the number and identity of the damaged pieces. This is called a "joint inventory. 2. Shortage Notations: If part of shipment is missing, write the number of pieces actually delivered on the delivery receipt and circle it. Then write down the number of pieces missing and note them as "short." 3. Signatures: Write down all exceptions on both copies of the delivery receipt. Have the driver sign both copies of the delivery receipt in his full name (not initials or nicknames). After the driver signs, you sign also. Write your agency's name, you full name, the date, and the time of day. D. Follow these steps when requesting an inspection: 1.The receiving person is responsible for requesting the carrier to inspect the damaged goods and packaging. The formal request should be made by phone right after discovering any loss or damage. 2. After the phone request, make a request for inspection by the carrier in writing. Note the date and time of your previous phone call and the person contacted. Keep a copy of your request letter on file. 3. Once contacted about damage or shortage, the carrier may waive inspection and tell you so. If so, write down the name of the person who waived the inspection, and the date and time of waiver. Then conduct your own detailed inspection. Write up your findings in a report and attach it to the file. If you can, take photographs to confirm your inspection report. Let us Practice Directions: Match the terms in Column B with the corresponding descriptions in Column A. Write your answers in a clean sheet of paper. Column A Column B 1. One of the tasks of the supply officer or logistics officer in the company is the ________. A. damage 2. In receiving deliveries, understand that you need to __________. B. receipt 3. Check the delivery _________ for the consignee’s name and address. C. address 4. Do not sign the receipt before inspecting for ________. D. count 5. If your agency has more than one location, make sure the goods are for this exact _______. E. ensure that the right materials were delivered F. purchase of supplies and materials Let Us Practice More Directions: Accomplish the table below accordingly. Write your answers in a clean sheet of paper. Tasks to be Done 1. Your supervisor is going to assign a work for you to perform. 2. Listing of items such as property, goods in stock, tools/equipment or the contents of a building. Appropriate Form to be Used 3. Items need to be ordered for a specific job 4. You are going to request tools and equipment for a job. Let Us Remember Directions: Read the statement carefully and choose one that defines the appropriate form. Write only the letter in your answer sheet. 1. A document generated by a user department or storeroom personnel to notify the purchasing department of items needed, their quantity, and the time frame. A. Clearance Form C. Borrower’s Form B. Requisition Slip Form D. School Tools Form 2. A form used to request for tools and equipment to be used for a particular job. c. Requisition Form C. Borrower’s Form d. Job Order Form D. Document 3. In receiving the deliveries, understand that you need to ensure that the right materials and supplies were delivered and all are in good condition without c. defects C. scratch d. supplies D. the carrier 4. What should you ask before receiving the items? c. Is it for me? C. Is it damaged? d. Is the piece count correct? D. All are correct 5. If the shipment is not yours, you should; c. Receive it C. Refuse to receive d. Pretend that its yours D. All are correct Let Us Assess Modified TRUE or FALSE: Write True if the statement is correct, and if False, change the underline word/s to make the sentence correct. Write your answer in a clean sheet of paper. _______1. Correctness of the entries in different forms used in electrical work is necessary in order to acquire right, complete, and accurate number of materials and tools needed for a specific electrical job. _______2. Borrower’s form is a document generated by a user department or storeroom personnel to notify the purchasing department about items it needs to order, their quantity, and the time frame. _______ 3. Inventory are raw materials, work-in-process goods, and completely finished goods that are considered to be the portion of a business's assets that are ready or will be ready for sale. _______ 4. Shortage Notations means part of shipment is missing, write the number of pieces actually delivered on the delivery receipt & circle it. _______ 5. Write down all exceptions on both copies of the delivery receipt. Have the driver sign both copies of the delivery receipt in his nickname. _______ 6. After the passenger signs, you sign also. _______ 7. The receiving person is responsible for requesting the carrier to inspect the damaged goods and packaging. _______ 8. The formal request should be made by texting right after discovering any loss or damage. _______ 9. Refuse the shipment if it is not yours. _______10. Keep a copy of your request letter on file for future reference. Let Us Enhance Directions: Based on the scenario below, make the following forms in a clean sheet of paper. 1. Purchase request form for the electrical materials; and 2. Borrower’s form for the tools Scenario: Your work supervisor has given you a Job Order or Work Order Form. It is stated that you are going to repair the non-functional lights along the hallway of the administration office. Based on your ocular inspection, it was verified that you need 3 - sets of new fluorescent lamp at 40 watts each at Php 250.00 pesos each; 20 meters of stranded copper wire number 14 at Php 20.00 pesos per meter and 3 new sets of flush type single pole switch at Php 100.00 pesos each. Let Us Reflect Congratulations ! You have come this far from our lesson. You have learned now on how to request, receive and inspect the different electrical supplies , materials and tools used in wiring installation. Now, put into writing your realizations and insights gained from this lesson. 1. What part of the lesson did you find interesting and useful to your everyday lives ? ___________________________________________________________________________ ___________________________________________________________________________ 2. Why do think it is important to inspect our received shipment ? _____________________________________________________________________ _____________________________________________________________________ 3. What are the questions that you are going to ask to the shipper, when you receive a shipment ? ____________________________________________ _____________________________________________________________________ Answer key to Activities LO1 Prepare Electrical Materials and Tools for the Task Let us Try Let Us Practice 1. a 1. Screw Driver 2. 3. b d 2. Claw Hammer 4. 5. 6. c d a 7. 8. b c 9. 10. c d 11. 12 13. a b d 14. 15. b a Let Us Practice More (in any order) Let Us Assess a. 1. Male Plug 2. Flat Cord 3. Convenience 3. Convenience Outlet Outlet 4. Eyelet Wire 4. Mallet Connector 5. Flexible Metallic b. 1. Electrician’s Conduit knife 6. Lamp holders 7. Male plug 3. b 4. d 3. Side Cutting 6. a Driver 5. Flat Screw driver 10. Electrician’s 2. a 5. c 4. Philips Screw 9. Wire stripper 1. d 2. Long Nose Plier plier 8. Hacksaw Activity 5.1 6. Multi-tester 7. d 8. a 9. c 10. b Let Us Enhance Let Us Remember Activity 5.2 1. True 1. Rat Tail or 1. A 2. Fuse Pig Tail 2. F 3. Lamp holder 4. Stranded 5. True 6. Junction box 7. True 8. True 9.Wire or Conductor 10. True 2. Knotted Tap 3. B 3. Cross Joint 4. C 4. Plain Tap 5. D Joint 5. Western union long tie Answer key to Activities LO2 Request appropriate electrical supplies, materials and tools to a specific job and receive and inspect electrical supplies, materials and tools. Let us Try Activity 1.1 Let Us Practice 1. F 2. E B 1. B 2. A 3. 3. D 4. A 4. C 5. C Let Us Practice More 1. Job Order or Work Order Form 2. Inventory Form 3. Purchase Requisition Form 4. Borrower’s Form Let Us assess 1. True Let Us Remember 2. Purchase Requisition 1. B 3. True 2. C 4. True 5. Full name 6. driver 7. True 8. Phone 9. True 10. True 3. A 4. D 5. C References K to 12 Basic Education Curriculum Technology and Livelihood Education. Learning Module. Electrical Installation and Maintenance. Exploratory Course Grade 7 and 8. Lesson 1 Prepare Electrical Materials and tools for the task p 8-20 and p 34-45. Department of Education. Curriculum and Instruction Strand. K to 12 Most Essential Learning Competencies. Electrical Installation Maintenance. P383384 https://www.slideshare.net/danielmanaog14/k12-module-in-tle-8-electrical https://www.slideshare.net/jhunalvins29/electrical-supplies-and-materials. https://www.shutterstock.com/ https://www.slideshare.net/MariaLudaDelaPena/steps-in-makingextension-cord-178431290 https://www.slideshare.net/MariaLudaDelaPena/steps-in-makingextension-cord-178431290 https://www.google.com/search?q=equipment+borrowers+slip+form+sample&tbm=is ch&ved=2ahUKEwiejJONjIHqAhVKDOwKHavrD-IQ2cCegQIABAA&oq=equipment+borro&gs_lcp=CgNpbWcQARgDMgIIADICCAAyAggA MgIIADICCAAyAggAMgIIADICCAAyAggAOgcIIxDqAhAnOgQIIxAnOgUIABCxAzoE CAAQQ1DS9w1Y37EOYIzUDmgBcAB4BIABhAeIAZlvkgEGNS02LjEzmAEAoAEBq gELZ3dzLXdpei1pbWewAQo&sclient=img&ei=jfvlXt6RIsqYsAer17QDg&bih=568&biw=1242#imgrc=KGKRiy0Exq9TQM Para sa mga katanungan o puna, sumulat o tumawag sa: Department of Education – Region XI (DepEd- XI) F. Torres St., Davao City Telefax: (082) 291-1665; (082) 221-6147 Email Address: regionxi@deped.gov.ph * lrms.regionxi@deped.gov.ph