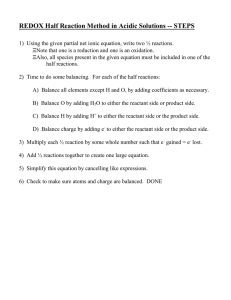

lOMoARcPSD|2224226 Continuous Stirred Tank Reactor Chemical engineering skills & practice 1 (University of Bath) StuDocu is not sponsored or endorsed by any college or university Downloaded by Abdulqadir Aliyu (aliyuabdulqadir@gmail.com) lOMoARcPSD|2224226 Abstract The experiment was carried out by the saponification of ethyl acetate with sodium hydroxide to determine the effect of residence time and temperature on the conversion of reactant in a stirred tank reactor. A calibration graph of reactant conversion against residence time was plotted as shown in Figure 2. From the graph, it was shown that the reactant conversion increases with a decrease in reactant flow rate due to the increase of residence time as expected. At 30 °𝐶, the reactant conversion had increased by 6.76% with a decreasing reactant flow rate whereas the reactant conversion had increased by 4.19% with a decreasing reactant flow rate at 40 °𝐶. The conversion of reactant was expected to increase with an increasing temperature. However, the result was not as expected due to experimental errors. The rate constant at 30 °𝐶 was found to be 0.0675 𝑙 𝑚𝑜𝑙 −1 𝑠 −1 whereas the rate constant at 40 °𝐶 was found to be 0.042 𝑙 𝑚𝑜𝑙 −1 𝑠 −1 . The activation energy was found to be −37447.1 J/mol which was inaccurate as it was calculated with the inaccurate rate constant. 1.Introduction and Theory There are many types of reactors generally used for different purposes in the chemical industry. Continuous-stirred tank reactor (CSTR) are most commonly used in industrial processing, mainly for homogenous liquid-phase flow reactions, where constant agitation is required (Awdry, 2019). The CSTRs consist of a tank, a stirrer, an inlet and an outlet. It is an open system and operates on a steady state-basis where all the conditions do not change with time (Mazzotti, 2015). The flow rate into the reactor is equal to the flow rate out of the reactor. The contents in the CSTR are assumed to be mixed perfectly. Therefore, variables such as temperature and concentration of the reaction mixture are assumed to be uniformed in all parts of the reaction vessel. The general mole balance equation is shown in Equation 1. Since CSTR operates at a steady state and assumed to have perfect mixing, thus form the design equation in Equation 2. 𝑉 𝐹𝐽0 − 𝐹𝑗 + ∫ 𝑟𝑗 𝑑𝑉 = 𝑑𝑁𝑗 𝑑𝑡 𝑬𝒒(𝟏) .𝑉= 𝑑𝑁𝐽 𝑑𝑡 𝐹𝐽0 −𝐹𝑗 −𝑟𝑗 𝑉 = 0 and ∫0 𝑟𝑗 𝑑𝑉 = 𝑉𝑟𝑗 . This allows us to 𝑬𝒒(𝟐) where V represents the reactor volume, 𝐹𝐽0 and 𝐹𝑗 is the input and output flow rate and 𝑟𝑗 is the rate of reaction. The objective of this experiment was to study how the percentage of conversion of reactant was affected by the residence time and temperature in the saponification reaction between sodium hydroxide and ethyl acetate. In this process, hydroxide ions in sodium hydroxide are consumed. Thus, the reaction progress can be determined by measuring the change in conductivity of reactant mixture. The percentage conversion of the reactants, X, was calculated with the conductivity values obtained at different flow rates and temperatures as shown in Equation 3 (University of Bath, 2018). 1 Downloaded by Abdulqadir Aliyu (aliyuabdulqadir@gmail.com) lOMoARcPSD|2224226 𝑋 = (1 − 𝐾 − 𝐾𝑒 ) ∙ 100 𝐾𝑂 − 𝐾𝑒 𝑬𝒒(𝟑) Where X is the percentage conversion of the reactants (%), K is the actual measured value for conductivity (mS/cm), Ke is the conductivity at the end of the reaction (mS/cm) and Ko is the initial conductivity of the 2.3% sodium hydroxide (mS/cm). It was expected that the conversion would decrease with increasing flow rate due to the decrease of residence time, and conversely, the conversion would increase with decreasing flow rate due to the increase of residence time. The conversions of the reactants were also expected to increase with the increase in temperature of water. (GUNT, 2000) 2. Methods Temperature controller Speed pump 1 Pump 2 Switch box Pump 1 Heater switch Master switch Stirrer switch Reaction vessel Beakers Figure 1: The general view of the CE310 CSTR The CE310 Continuous Stirred Tank Reactor was the main apparatus. The switch box contains switches for the pumps, heater, stirrer and a combined conductivity and temperature measuring unit. It also has two different controllers which are used to adjust the water temperature in the heating circuit and to adjust the volumetric flow rate of each pump individually. The main power switch was turned on. The heater and pump 1 were switched on after the temperature of water tank was set to 30°C. 2 liters of NaOH (0.2M) and ethyl acetate (0.2M) were poured into the separate labelled beakers that form part of the CSTR. Both beakers were checked regularly to ensure there was sufficient reagents throughout the experiment. Pump 2 was turned on to start filling the reagents into the reaction vessel. The pump dial speed was also set to 10 1/min. When the mixture reached the overflow limit, the stirrer was turned on. The GUNT-CE310 software in the computer was used to record the conductivity and temperature of the reaction solution. The conductivity measured within the reaction vessel was observed to determine if the steady state has been reached. When a steady value has been achieved, the stirrer and pump 2 Downloaded by Abdulqadir Aliyu (aliyuabdulqadir@gmail.com) lOMoARcPSD|2224226 2 were turned off. The GUNT-CE310 software was paused to stop unnecessary recording. The data was then exported. The volume of the reaction mixture was measured by syringing it out into a measuring cylinder. These steps were repeated with a different flow rates of 20 1/min and 30 1/min. The temperature was increased to 40°C. Each step was repeated again with three different flow rates as before. After the experiment, the remaining reagents were emptied back into the bottles while the reaction mixture and the overflow mixture were poured down the sink. Each reagent beaker was added with 1L of deionized water to wash through the reactor and tubing at a high flow rate. The main power supply was turned off after switching off all the pumps and stirring. 3. Results and Calculations The average steady state conductivity was recorded in Table 1 and Table 2 (Appendix A). The pump speed, steady state conductivity and volume of reaction mixture were recorded in Table 3. Table 3: Conversion of reactant calculated with different pump speeds and temperatures Pump Volume of Pump reaction Reactant speed, Speed, mixture, V Residence Average steady state conversion, Temperature x 𝑣̇ X (%) (°C) time, 𝜏 (s) conductivity (mS/cm) (1/min) (ml/min) (ml) 30 10 42.68 290 407.70 12.40 71.89 30 20 81.46 280 206.24 14.26 67.30 30 30 120.24 260 129.74 15.14 65.13 40 10 42.68 280 393.65 13.09 70.18 40 20 81.46 290 213.61 14.25 67.32 40 30 120.24 260 129.74 14.79 65.99 In Equation 4, the conversion of units of pump speed from 1/min to ml/min was shown. 𝑣̇ = 2 ∙ (1.939𝑥 + 1.949) 𝑬𝒒(𝟒) Where 𝑣̇ is the pump speed (ml/min) and x is the pump speed (1/min) The calculation of residence time was shown in Equation 5. 𝜏= 60 𝑣̇ (𝑉 ) 𝑬𝒒(𝟓) Where 𝜏 is the residence time and V is the volume of the reaction mixture. The conversion of reactant was determined according to Equation 3 as mentioned in Introduction. 𝑋 = (1 − 𝐾 − 𝐾𝑒 ) ∙ 100 𝐾𝑂 − 𝐾𝑒 𝑬𝒒(𝟑) 3 Downloaded by Abdulqadir Aliyu (aliyuabdulqadir@gmail.com) lOMoARcPSD|2224226 Where X is the percentage conversion of the reactants, K is the actual measured value for conductivity, Ke is the conductivity at the end of the reaction and Ko is the initial conductivity of the 2.3% sodium hydroxide. Reactant Conversion (%) From Table 1, Figure 1 was plotted with the calculated conversion of reactant and residence time. 74.00 72.00 30°C 70.00 40°C 68.00 Linear (30°C) 66.00 Linear (40°C) 64.00 62.00 60.00 0.00 50.00 100.00 150.00 200.00 250.00 300.00 350.00 400.00 450.00 Residence Time (s) Figure 1: Graph of reactant conversion against residence time A rearrangement of the Equation 6 to Equation 7 in the form of a straight-line equation (y = mx + 𝑋𝐴 versus 𝜏 where the gradient (m) is kCA0 as shown c) was done to plot a graph of (1−𝑋 )(𝑀−𝑋 ) 𝐴 in Figure 2. 𝑋𝐴 (1−𝑋 𝐴0 𝐴 )(𝑀−𝑋𝐴 ) 𝑋𝐴 (1−𝑋𝐴 )(𝑀−𝑋𝐴 ) 𝑬𝒒(𝟔) 𝜏 = 𝑘𝐶 𝐴 = (𝜏)𝑘𝐶𝐴0 𝑬𝒒(𝟕) Where XA is the conversion of reactant, M is the initial molar ratio of reactants and CA0 is the initial concentration of reactant. From Table 2 (Appendix B), the following graph was produced. 10 y = 0.0135x + 3.5575 R² = 0.9993 9 8 𝑋𝐴/(1−𝑋A )(𝑀−𝑋𝐴 ) y = 0.0084x + 4.577 R² = 0.9977 7 6 30°C 5 40°C 4 3 Linear (30°C) 2 Linear (40°C) 1 0 0.00 50.00 100.00 150.00 200.00 250.00 300.00 350.00 400.00 450.00 Residence time (s) Figure 2: Graph of (1−𝑋 𝑋𝐴 𝐴 )(𝑀−𝑋𝐴 ) against residence time 4 Downloaded by Abdulqadir Aliyu (aliyuabdulqadir@gmail.com) lOMoARcPSD|2224226 Since the gradient for 30°𝐶 is 0.0135 and for 40°𝐶 is 0.0084, therefore the rate constant can be calculated as follows with Equation: 𝑘= 𝑔𝑟𝑎𝑑𝑖𝑒𝑛𝑡 𝐶𝐴0 𝐹𝑜𝑟 30 °𝐶, 𝑘 = 0.0135 0.2 𝑬𝒒 (𝟖) = 0.0675 𝑙 𝑚𝑜𝑙 −1 𝑠 −1 𝐹𝑜𝑟 40°𝐶, 𝑘 = 0.0084 0.2 = 0.042 𝑙 𝑚𝑜𝑙 −1 𝑠 −1 To obtain the activation energy, a graph of ln (k) against 1/T was plotted as shown in Figure 3 with values from Table 3 (Appendix B). -2.6 0.00318 -2.7 0.0032 0.00322 0.00324 0.00328 0.0033 0.00332 y = 4504.1x - 17.553 R² = 1 -2.8 ln (k) 0.00326 -2.9 -3 -3.1 -3.2 1/T (K-1) Figure 3: Graph of ln(k) against 1/T Equation 9 showed the Arrhenius equation where k is the rate constant, Ea is the activation energy, R is the gas constant (8.314J/K mol), and T is the temperature expressed in Kelvin. 𝐸 𝑘 = 𝐴𝑒 −𝑅𝑇𝑎 Eq (9) Equation 10 was obtained by taking the natural logarithm of both sides in Equation 9. It was rearranged to plot a straight line graph for ln(k) versus 1/T, where the slope is -Ea/R as shown in Equation 11. 𝐸 𝑙𝑛𝑘 = 𝑙𝑛𝐴 − 𝑎 𝑅𝑇 𝑬𝒒 (𝟏𝟎) 𝐸 1 𝑙𝑛𝑘 = 𝑙𝑛𝐴 − 𝑎 ( ) 𝑅 𝑇 From Equation 12, the activation energy was calculated. 𝐸𝑎 = 𝑔𝑟𝑎𝑑𝑖𝑒𝑛𝑡 ∙ 𝑅 𝑬𝒒(𝟏𝟐) 𝑬𝒒 (𝟏𝟏) 𝐸𝑎 = −4501.1 × 8.314 = −37447.1 J/mol 4.Discussion Based on Figure 1, the reactant conversion increased with an increasing residence time as expected. For example, at 40 °𝐶, the conversion was 65.99% at the residence time of 129.74s and the conversion was 70.18% at the residence time of 393.65s. This clearly showed an increase of 4.19%. Residence time refers to the time spent by the fluid elements within the 5 Downloaded by Abdulqadir Aliyu (aliyuabdulqadir@gmail.com) lOMoARcPSD|2224226 reactor. Thus, an increased residence time means more contact time for the chemicals in the reactor due to a decreasing pump speed. The reactant conversions should increase with an increased temperature due to the raised of average kinetic energy of reactant molecules. Therefore, a greater proportion of molecules will have sufficient energy for an effective collision, giving a higher conversion of reactant. (Ullah et al., 2015) However, from Figure 1, the graph showed that the conversion of reactant at 30 °𝐶 was higher than the conversion of reactant at 40 °𝐶. The highest reactant conversion in 30 °𝐶 was 71.89% but the highest conversion in 40 °𝐶 was only 70.18%. This error can be explained by the incorrect temperature of water. The actual temperature of water was different from the value set by the temperature controller. According to data saved from the computer software, the temperature recorded in three different flow rates were only 34.1 °𝐶 , 34.6 °𝐶 , 34.7 °𝐶 instead of 40 °𝐶. This was because it takes more time for the CSTR to heat up to that specific temperature. More time should have been given to achieve the temperature of 40 °𝐶 before the conductivity was measured. A lower conductivity would have been obtained in higher temperature, giving a higher conversion of reactant. With the pump speed of 20 1/min, the difference between the reactant conversion at 30 °𝐶 and 40 °𝐶 was only by 0.02%. This small percentage was insignificant to justify the theory. Therefore, a larger temperature range should have been used to plot a more reliable graph. The rate constant at 30 °𝐶 was 0.0675 𝑙 𝑚𝑜𝑙 −1 𝑠 −1 while the rate constant at 40 °𝐶 was 0.042 𝑙 𝑚𝑜𝑙 −1 𝑠 −1. This result was unacceptable as a higher temperature should have given a higher rate constant. This could be due to the same error as mentioned earlier. By using Arrhenius’s equation, the activation energy obtained was -37447.1 J/mol. In this experiment, results could have been improved by reducing parallax error while taking the measurement such as the volume of the reaction mixture. The position of eye must be perpendicular to the reading scale of measuring cylinder. The experiment should have been carried out with more different flow rates to obtain a more accurate result. 5. Conclusion The Continuous Stirred Tank Reactor was used to determine the effect of residence time and temperature on the conversion of reactant based on the saponification of ethyl acetate with sodium hydroxide. The progress of the reaction was determined by the change in the hydroxide concentration. From Figure 1, it was clear that the conversion of reactant increases as residence time increases. From 10 1/min to 30 1/min, the reactant conversion increased by 6.76% at 30 °𝐶 while the reactant conversion increased by 4.19% at 40 °𝐶. An increase in temperature will increase the percentage of reactant conversion as well. However, the results had shown otherwise. This was caused by the inaccurate temperature as mentioned earlier. The results could be improved by measuring the conductivity only when the temperature reaches 40 °𝐶.To increase the accuracy of this experiment, it is recommended that a larger difference in temperature should be used. To plot a more reliable graph, the experiment should have been carried out with more different flow rates. Overall, the experiment was successful. 6 Downloaded by Abdulqadir Aliyu (aliyuabdulqadir@gmail.com) lOMoARcPSD|2224226 References 1) Awdry, S. (2019). University of Bath Single Sign-on. [online] Moodle.bath.ac.uk. Available at: https://moodle.bath.ac.uk/pluginfile.php/1119404/mod_resource/content/5/BOOKLET%20OF%2 0CHEMICAL%20REACTION%20ENGINEERING_Forstudents.pdf [Accessed 8 Feb. 2019]. 2) Mazzotti, M. (2015). Introduction to Chemical Engineering: Chemical Reaction Engineering. [online] Ethz.ch. Available at: https://www.ethz.ch/content/dam/ethz/specialinterest/mavt/process-engineering/separation-processes-laboratorydam/documents/education/bce%20notes/script_7.pdf [Accessed 8 Feb. 2019]. 3) G.U.N.T. (2000) Experiment Instructions: CE 310 Chemical Reactors Trainer. 4) University of Bath, 2018 CE10185 Chemical Engineering Skills and Practice 1, Student Lab Book 2018-19, pp32-38 5) Mazzotti, M. (2015). Introduction to Chemical Engineering: Chemical Reaction Engineering. [online] Ethz.ch. Available at: https://www.ethz.ch/content/dam/ethz/specialinterest/mavt/process-engineering/separation-processes-laboratorydam/documents/education/bce%20notes/script_7.pdf [Accessed 8 Feb. 2019]. 6) Ullah, I., Ahmad, M.I., Younas, M., 2015. Optimization of Saponification Reaction in a Continuous Stirred Tank Reactor (CSTR) using Design of Experiments, Pak. J. Engg. & Appl. Sci. 16, pp. 84-92 7 Downloaded by Abdulqadir Aliyu (aliyuabdulqadir@gmail.com) lOMoARcPSD|2224226 Appendix Appendix A: Average steady state conductivity measured in different temperatures Table 1: Average steady state conductivity at 30°C Steady state conductivity with Temperature Data pump speed of 10 (°C) number 1/min (mS/cm) Steady state conductivity with pump speed of 20 1/min (mS/cm) Steady state conductivity with pump speed of 30 1/min (mS/cm) 30 1 12.4 14.26 15.14 30 2 12.4 14.26 15.14 30 3 12.4 14.26 15.14 30 4 12.4 14.26 15.14 30 5 12.4 14.26 15.14 30 5 12.4 14.26 15.14 30 6 12.4 14.26 15.14 30 7 12.4 14.26 15.14 30 8 12.4 14.26 15.14 30 9 12.4 14.26 15.14 30 10 Average steady state conductivity 12.4 14.26 15.09 12.4 14.26 15.14 Table 2: Average steady state conductivity at 40°C Temperature Data (°C) number 40 1 40 2 40 3 40 4 40 5 40 5 40 6 40 7 40 8 40 9 40 10 Average steady state conductivity Steady state conductivity with pump speed of 10 1/min (mS/cm) 13.09 13.09 13.09 13.09 13.09 13.09 13.09 13.09 13.09 13.09 13.09 Steady state conductivity with pump speed of 20 1/min (mS/cm) 14.26 14.26 14.26 14.26 14.26 14.26 14.26 14.26 14.26 14.21 14.21 Steady state conductivity with pump speed of 30 1/min (mS/cm) 14.79 14.79 14.79 14.79 14.79 14.79 14.79 14.79 14.79 14.79 14.79 13.09 14.25 14.79 8 Downloaded by Abdulqadir Aliyu (aliyuabdulqadir@gmail.com) lOMoARcPSD|2224226 Appendix B: Reactant conversion and rate constant calculated at different temperatures Table 2: Reactant conversion at different temperatures Temperature, T (°C) 30 30 30 40 40 40 Residence Time, 𝜏 Reactant Conversion, XA (s) (-) 407.70 0.719 206.24 0.673 129.74 0.651 393.65 0.702 213.61 0.673 129.74 0.660 𝑋𝐴 (1−𝑋𝐴 )(𝑀−𝑋𝐴 ) (l mol- 1 ) 9.095356 6.293719 5.356245 7.895382 6.305532 5.706219 Table 3: Rate constant at different temperatures Rate constant, k (l Temperature, T mol-1 s-1) Temperature, T (°C) (°C) 1/T (K-1) ln (k) 30 303.15 0.003299 0.0675 -2.69563 40 313.15 0.003193 0.042 -3.17009 9 Downloaded by Abdulqadir Aliyu (aliyuabdulqadir@gmail.com)